Are you wondering what causes bandsaw drift? Well, you’re in the right place! When it comes to using a bandsaw, one frustrating issue that woodworkers often encounter is bandsaw drift. But fear not, because in this article, we’ll delve into the causes of this phenomenon and provide you with some helpful tips to overcome it. So, let’s jump right in and demystify bandsaw drift together!

You might be thinking, “What exactly is bandsaw drift?” Bandsaw drift refers to the frustrating tendency of a bandsaw blade to veer off course, resulting in cuts that are not perfectly straight. It can be quite frustrating, especially when you’re trying to achieve precise and accurate cuts. But don’t worry, because understanding the causes of bandsaw drift is the first step towards solving this problem like a pro.

Now, you may be wondering, “What causes bandsaw drift?” Well, there are several factors at play. One of the main culprits is blade tension. If the blades on your bandsaw are not properly tensioned, they can become loose or twisted, causing the blade to wander off track. Another common cause is improper blade alignment. If your blade is not properly aligned with the guides and wheels, it can lead to drift during the cutting process. But don’t worry, we’ve got some tricks up our sleeve to help you overcome these issues and get back to making precise cuts in no time!

What Causes Bandsaw Drift: Unveiling the Culprits Behind the Frustration

Are you an avid woodworker who has experienced frustration with bandsaw drift? Do you find yourself pulling your hair out trying to achieve straight cuts, only to be thwarted by the seemingly uncontrollable movement of the blade? If so, you’re not alone. Bandsaw drift is a common challenge that woodworkers face, but fear not, for in this article, we will explore the various factors that cause bandsaw drift and provide you with the insights and techniques needed to overcome this vexing issue.

The Anatomy of Bandsaw Drift: Understanding the Basics

Before delving into the causes of bandsaw drift, it’s important to understand the anatomy of a bandsaw and how it operates. A bandsaw consists of a continuous loop of blade that runs on two or more wheels. The blade’s teeth are responsible for making the cuts, and it travels at high speeds to ensure smooth and efficient operations.

However, despite its impressive mechanics, bandsaw drift can occur due to various factors. From blade tension and tracking to improper blade selection and even human error, there are multiple culprits behind the frustrating phenomenon. Let’s explore these causes in more detail.

1. Blade Tension: Maintaining the Goldilocks Zone

Blade tension plays a crucial role in preventing bandsaw drift. When a blade is under-tensioned, it can deflect during the cutting process, leading to uneven and wandering cuts. On the other hand, over-tensioning the blade places excess stress on the machine, which can cause premature wear and tear.

To achieve optimal tension, start by referring to the manufacturer’s guidelines for your specific bandsaw model. Typically, you want to tighten the blade to the point where it produces a clear ringing sound when plucked. Ensuring the blade is neither too loose nor too tight will help minimize drift and deliver accurate and clean cuts.

Additionally, it’s important to periodically check and readjust the tension as the blade can naturally lose tension over time due to usage and exposure to humidity and temperature fluctuations.

2. Blade Tracking: Following the Correct Path

Proper blade tracking is another critical factor in preventing bandsaw drift. The blade must stay centered on the wheels for smooth and straight cuts. Misalignment of the blade, known as off-tracking, can cause the blade to veer off course, resulting in unwanted drift.

Start by examining the position of the blade on the wheels. It should be running in the center of the tire, neither too close to the front edge nor too close to the back edge. Use the tracking adjustment knob or lever on your bandsaw to make the necessary adjustments to align the blade properly.

Keep in mind that blades can occasionally shift during use, so periodic checks and adjustments to ensure proper tracking are vital for maintaining drift-free operation.

3. Blade Selection: Choosing the Right Blade for the Job

The type and quality of the blade you choose can significantly impact drift. A blade with a high tooth count and a narrow width tends to be more prone to wandering. On the other hand, blades with a lower tooth count and wider width have a greater tendency to cut straighter.

The material you plan to cut is also a determining factor. For instance, resawing thick stock requires a different blade compared to cutting curves in thin veneer. Understanding the various blade options available and selecting the appropriate one for your specific task can help reduce bandsaw drift and improve the overall cutting performance.

Before making any blade changes, remember to power off the machine and follow the manufacturer’s instructions for blade replacement.

4. Blade Condition: Keep It Sharp and in Shape

A dull or damaged blade can exacerbate bandsaw drift. A dull blade will struggle to make clean cuts, adding extra strain on the saw and increasing the likelihood of drift. It’s crucial to regularly inspect your blade for signs of wear or damage, such as missing or broken teeth, and replace it as necessary to ensure optimal performance.

Additionally, maintaining a sharp blade is essential for minimizing drift. You can sharpen your blade using various methods like a file, a dedicated sharpsaw, or even sending it to a professional sharpening service. Remember to follow the manufacturer’s guidelines and safety precautions when sharpening or replacing blades.

5. Feed Rate and Technique: Mastering the Art of Control

The way you feed your workpiece into the bandsaw can also contribute to drift. Pushing the wood too aggressively can cause the blade to deflect and wander off course. On the other hand, feeding the wood too slowly can cause the blade to bind and potentially lead to drift as well.

Mastering the art of feed rate and technique is essential for achieving straight cuts with minimal drift. As a general rule of thumb, maintain a steady, controlled feed rate and let the blade do the cutting. Avoid applying excessive force and let the saw’s natural cutting action guide the wood through the process.

Experiment with different feed rates and techniques to find the sweet spot that minimizes drift and delivers the desired results. Practice and experience will help develop the necessary finesse for achieving precision cuts.

6. Machine Setup: Fine-Tuning for Success

The overall setup of your bandsaw can affect its performance and potential for drift. Factors such as blade alignment, guide adjustment, and wheel condition play crucial roles in achieving accurate and drift-free cuts.

Regularly inspect and maintain your bandsaw to ensure it is in optimal working condition. Check for any loose or worn-out components and tighten or replace them as necessary. Pay attention to the alignment of the guides, wheels, and other critical parts, making the necessary adjustments to ensure everything is in proper alignment.

Consult your bandsaw’s user manual for specific instructions on setup and maintenance, and never hesitate to reach out to a professional or experienced woodworker for guidance if needed.

7. Material Characteristics: Understand the Wood’s Behavior

Lastly, it’s important to consider the characteristics of the wood you’re cutting. Different species of wood have varying densities, grain patterns, and levels of moisture content, all of which can influence how the blade interacts with the material.

Some types of wood, such as burls or highly figured pieces, may have irregular grain patterns that can contribute to bandsaw drift. Additionally, wood with high moisture content can cause the blade to wander due to its tendency to bind or compress the kerf.

Take the time to understand the specific properties of the wood you’re working with and make any necessary adjustments to your technique or blade selection to minimize drift.

Mastering Bandsaw Drift: Techniques and Tips

Now that we’ve explored the various causes of bandsaw drift, let’s dive into some techniques and tips to help you overcome this challenge:

1. Blade Maintenance:

– Regularly check and replace blades, keeping them sharp and in good condition.

– Follow the manufacturer’s guidelines for blade tension and tracking adjustments.

– Resaw blades and skip-tooth blades are often recommended for minimizing drift.

2. Woodworking Techniques:

– Experiment with different feed rates and cutting techniques to find what works best for you.

– Take your time to understand the unique characteristics of the wood you’re working with.

– Use appropriate techniques, such as relief cuts, to help reduce tension and minimize drift.

3. Machine Setup:

– Regularly inspect and maintain your bandsaw, ensuring proper alignment of all components.

– Ensure the blade is correctly tensioned and aligned with the center of the tires.

– Adjust the guides and bearings to minimize friction and reduce the chances of drift.

4. Patience and Practice:

– Don’t get discouraged! Bandsaw drift can be challenging, but with practice, you can master it.

– Take your time, start with smaller projects, and gradually work your way up.

– Seek guidance from experienced woodworkers or join a community to gain insights and advice.

By implementing these techniques and tips, you’ll be well on your way to conquering bandsaw drift and achieving precise, professional-quality cuts.

Key Takeaways: What Causes Bandsaw Drift?

- Bandsaw drift is when the blade doesn’t cut straight and veers off to the side.

- Tension in the blade can cause bandsaw drift.

- Blade alignment issues can also lead to bandsaw drift.

- Inadequate blade tracking can be a cause of bandsaw drift.

- Using dull or incorrectly set blades can contribute to bandsaw drift.

Frequently Asked Questions

Bandsaw drift can be a frustrating problem for woodworkers. It refers to the tendency of a bandsaw blade to veer off course during a cut, resulting in uneven cuts and wasted material. Understanding the causes of bandsaw drift is essential for overcoming this issue and achieving accurate cuts.

1. What are the common causes of bandsaw drift?

Bandsaw drift can be caused by a variety of factors such as misaligned blade guides, improper tensioning of the blade, dull or poorly set teeth on the blade, or even a warped or twisted blade. The type of wood being cut can also contribute to bandsaw drift, as certain species may have irregular grain patterns that can affect the blade’s path.

To eliminate bandsaw drift, it is crucial to ensure proper blade alignment, tension, and sharpness. Regular maintenance and adjustment of the bandsaw, as well as using the appropriate blade for the type of wood being cut, can help minimize or eliminate this issue.

2. How can I determine if my bandsaw blade is misaligned?

An easy way to check if your bandsaw blade is misaligned is to make a straight cut on a scrap piece of wood. If the blade veers off course and produces an angled cut, it is a clear indication of misalignment. You can also visually inspect the blade while it is spinning to see if it runs true or if it wobbles or flexes excessively.

If misalignment is suspected, it is important to consult the bandsaw’s user manual for instructions on how to properly align the blade. This typically involves adjusting the position of the blade guides and ensuring that they are parallel to the blade. By correcting any misalignment, you can significantly reduce bandsaw drift.

3. Are there any techniques I can use to minimize bandsaw drift?

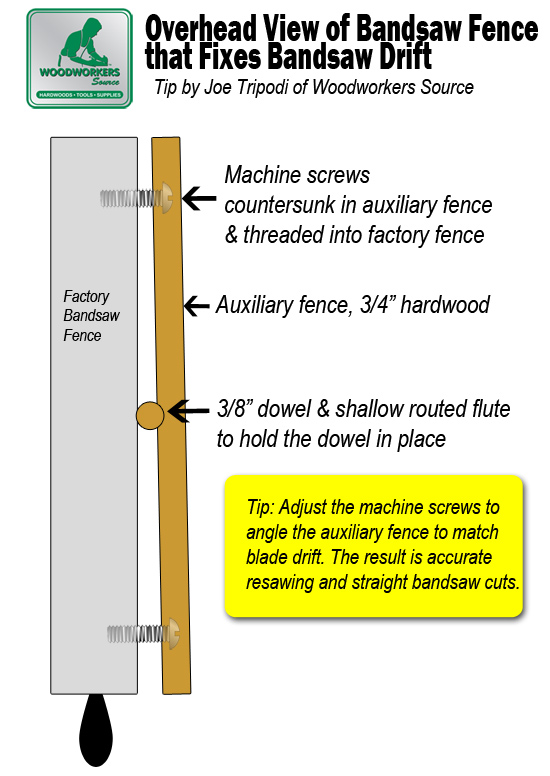

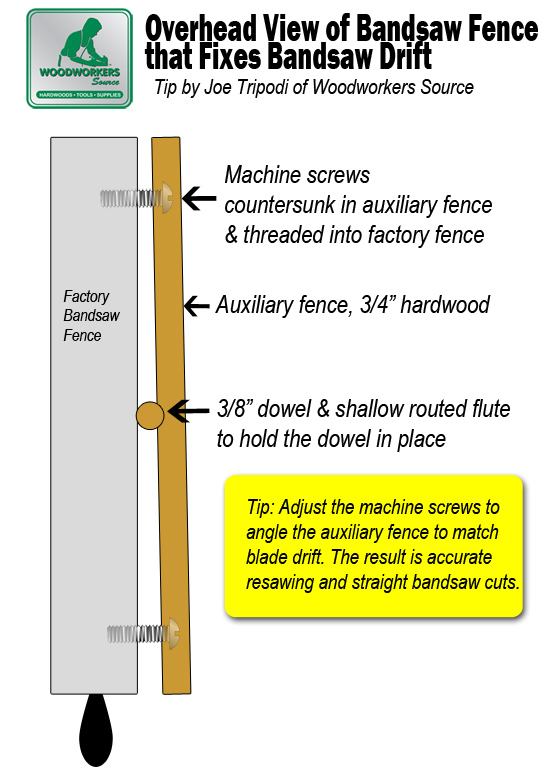

Yes, there are techniques that can help reduce bandsaw drift. One effective technique is using a fence or guide to keep the workpiece firmly against it as it is being fed into the blade. This helps maintain a consistent cutting line and minimizes the chances of the blade veering off course.

You can also try using a smaller blade width, as narrower blades tend to have less tendency to drift. Additionally, applying a lubricant, like paste wax, to the blade can reduce friction and make the cuts smoother, reducing the likelihood of drift.

4. Can the type of blade affect bandsaw drift?

Yes, the type of blade you use can affect bandsaw drift. Different blades have different characteristics and are designed for various cutting tasks. The tooth configuration, blade width, and blade tension all play a role in how well the blade cuts and how prone it is to drift.

For example, a blade with fewer teeth per inch (TPI) is more aggressive and may be more prone to drift. Conversely, a blade with more TPI will provide a smoother cut but may require slower feed rates. Choosing the right blade for the specific task at hand, as well as ensuring it is properly set and tensioned, can help minimize bandsaw drift.

5. How often should I maintain and adjust my bandsaw to prevent drift?

Maintaining and adjusting your bandsaw regularly is essential for preventing bandsaw drift. It is recommended to clean the bandsaw after each use, removing any sawdust or debris that can affect its performance. Lubricating the moving parts and checking the blade tension is also important.

Additionally, it is a good practice to check for blade sharpness and teeth set regularly. Dull or improperly set teeth can contribute to bandsaw drift. By incorporating these maintenance tasks into your woodworking routine, you can keep your bandsaw in optimal condition and minimize the chances of drift.

How to Adjust for Bandsaw Drift

Summary

A bandsaw is a handy tool, but sometimes it doesn’t cut straight. This is called drift. Drift happens because of a few different things. First, the blade itself might be the problem. If the blade is dull or not installed properly, it can cause the cut to go off track. Second, the tension of the blade is important. If the tension is too loose or too tight, it can lead to drift. Finally, the way you feed the material into the saw can also affect drift. By going too fast or not keeping a steady pace, you can make the blade wander. So, to avoid drift, make sure your blade is sharp and installed correctly, adjust the tension properly, and feed the material carefully and consistently.