If you’re a DIY enthusiast or a budding woodworker, you may find yourself pondering, “what circular saw blade is best?” Well, my friend, you’ve come to the right place! Whether you’re slicing through hardwood or tackling a delicate trim job, choosing the right circular saw blade is crucial for achieving clean cuts and optimal results. So, let’s dive in and discover the secrets of finding the perfect blade for your cutting needs.

When it comes to circular saw blades, one size definitely doesn’t fit all. There’s a whole world of options out there, each designed to excel in specific cutting applications. From ripping blades that plow through thick lumber to crosscut blades that create precise mitered joints, the key is to select a blade that’s tailored to your project. So, let’s unravel the mysteries of blade types, tooth configurations, and materials, and uncover which one is the best fit for your next woodworking adventure.

Now, I know what you may be thinking: “How do I even begin to navigate this dizzying array of choices?” Don’t worry; I’ve got your back! In this guide, I’ll demystify the world of circular saw blades, providing you with the essential knowledge and insider tips to make an informed decision. So, grab your safety goggles and let’s embark on this blade-tastic journey together!

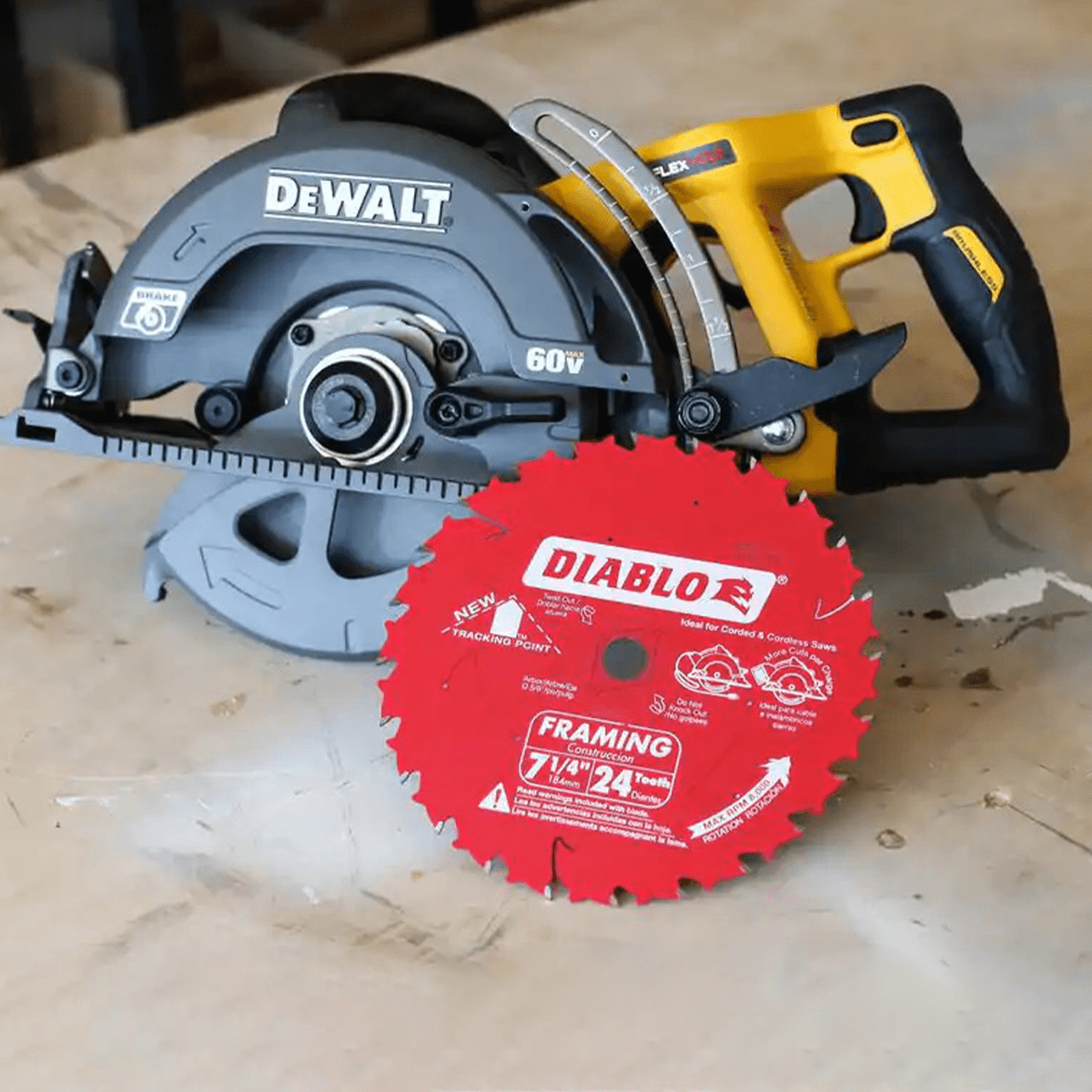

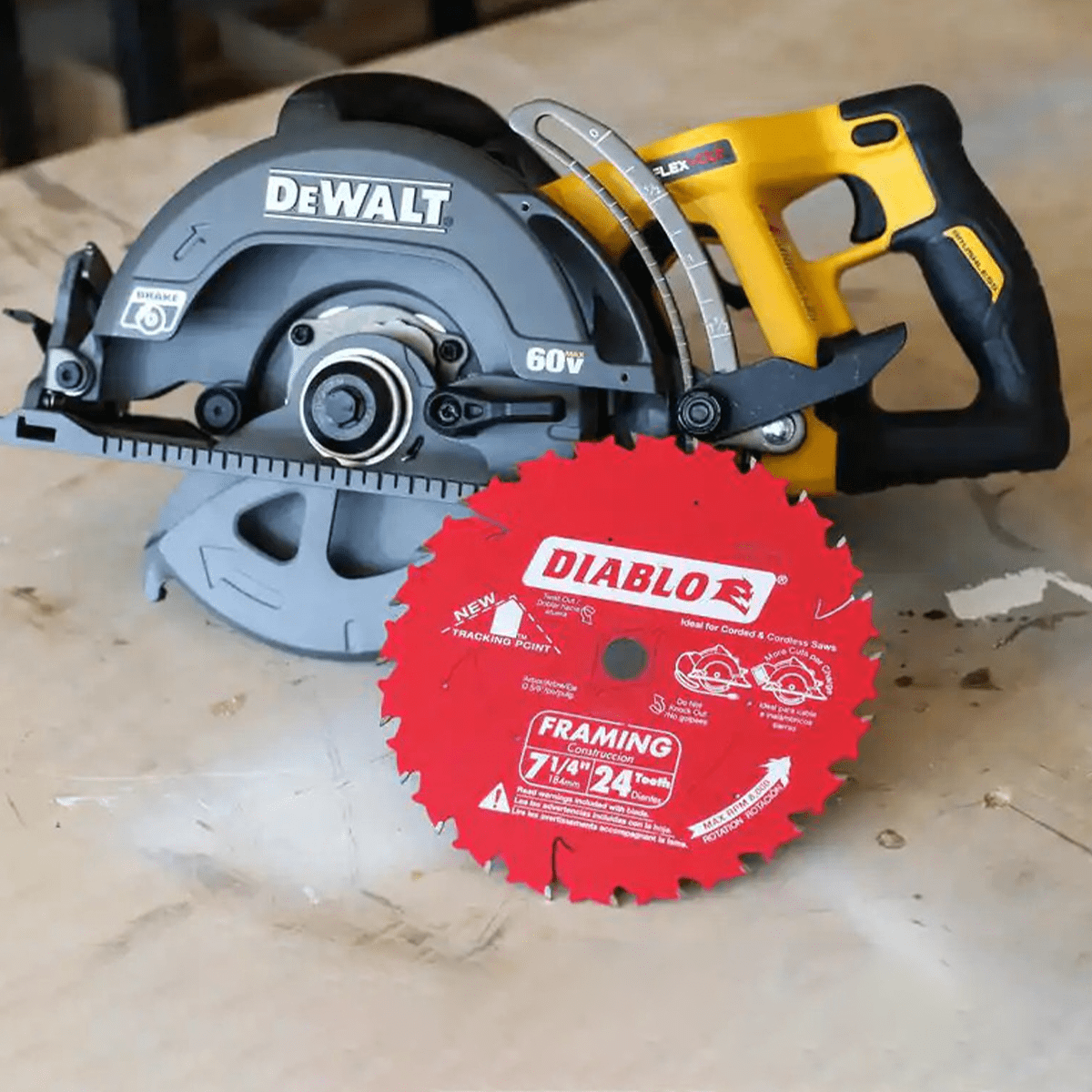

Choosing the right circular saw blade is crucial for achieving clean and precise cuts. Consider the material you’ll be cutting, such as wood, metal, or plastic, as different blades are designed for specific tasks. Look for blades with a higher tooth count for smoother cuts and blades with carbide tips for durability. Additionally, consider the blade diameter and arbor size to ensure compatibility with your circular saw. By selecting the appropriate blade for your needs, you can ensure optimal performance and results.

Choosing the Best Circular Saw Blade for Your Needs

When it comes to using a circular saw, having the right blade is crucial for achieving clean and precise cuts. With the wide variety of circular saw blades available in the market, it can be overwhelming to determine which one is the best for your specific needs. This article will guide you through the process of choosing the best circular saw blade, taking into consideration factors such as material, tooth count, diameter, and more. Whether you’re a professional carpenter or a DIY enthusiast, this comprehensive guide will help you make an informed decision.

Factors to Consider when Choosing a Circular Saw Blade

1. Material of the Blade

The material of the circular saw blade plays a significant role in determining its cutting performance and longevity. There are various blade materials available, including high-speed steel (HSS), carbide-tipped, and diamond-tipped blades. HSS blades are suitable for cutting softwoods and non-abrasive materials, while carbide-tipped blades offer better durability and are ideal for cutting hardwoods and abrasive materials. Diamond-tipped blades are specifically designed for cutting through hard materials like concrete and tile.

When selecting a circular saw blade, consider the type of material you will primarily be cutting and choose a blade that is specifically designed for that material. This will ensure optimal performance and prolong the life of the blade.

Tip: If you frequently work with different types of materials, consider investing in a multipurpose blade that can handle a variety of cutting tasks.

2. Tooth Count

The tooth count of a circular saw blade refers to the number of teeth on the blade. Blades with a higher tooth count provide smoother and cleaner cuts, making them ideal for crosscutting and finer woodworking tasks. On the other hand, blades with a lower tooth count are better suited for ripping and cutting through thicker materials.

When choosing a circular saw blade, consider the type of cuts you will be making most frequently. If you require clean and precise cuts, opt for a blade with a higher tooth count. However, if speed and efficiency are more important to you, a blade with a lower tooth count may be a better choice.

Tip: If you often work on a variety of projects, consider having multiple blades with different tooth counts to accommodate different cutting tasks.

3. Blade Diameter

The blade diameter is an essential factor to consider when choosing a circular saw blade. Most circular saws have a specific blade diameter that they are designed to accommodate. Using a blade with a diameter that is too large or too small for your saw can result in improper fitment and compromise the safety and performance of the tool.

Before purchasing a circular saw blade, check the diameter specifications of your saw and ensure that the blade you choose is compatible. It’s also worth noting that larger blade diameters provide deeper cuts, while smaller blades are more maneuverable and suitable for cutting in tight spaces.

Tip: If you frequently work with different saws, consider investing in multiple blades with different diameters to ensure compatibility with all your tools.

4. Blade Grind

The blade grind refers to the shape of the blade’s cutting edge. There are three main types of blade grinds: flat top grind (FTG), alternate top bevel (ATB), and triple-chip grind (TCG).

FTG blades have flat teeth that are ideal for ripping through thick materials. ATB blades have alternating bevels on the teeth, making them versatile for both crosscutting and ripping tasks. TCG blades have a combination of flat and beveled teeth and are best suited for cutting hard and abrasive materials.

Consider the type of cuts you will be making and choose a blade with the appropriate grind. If you frequently work with a variety of materials, an ATB blade offers a good balance between crosscuts and rips.

5. Blade Coating

Blade coatings can enhance the performance and lifespan of a circular saw blade. Coatings such as carbide tipped, titanium nitride, and non-stick coatings can reduce friction, dissipate heat, and prevent corrosion.

When choosing a circular saw blade, consider the type of coating that will best suit your needs. Carbide tipped blades offer excellent durability and are resistant to wear, while titanium nitride-coated blades provide enhanced cutting performance. Non-stick coatings can reduce pitch and resin build-up, making the blade easier to clean and maintain.

Tip: If you work with materials that tend to produce a lot of heat or sticky residues, choosing a blade with a suitable coating can help improve cutting efficiency and extend the blade’s lifespan.

6. Blade Kerf

The blade kerf refers to the width of the cut made by the circular saw blade. A wider kerf may result in more material waste but can provide greater stability and durability. Conversely, a thinner kerf produces less waste but may be less stable and more prone to deflection.

Consider the type of project you will be working on and choose a blade with the appropriate kerf. If precision and accuracy are crucial, a blade with a narrower kerf may be the best option. However, if speed and durability are more important, a wider kerf can provide better performance.

7. Blade Maintenance and Lifespan

Proper maintenance is essential to prolonging the lifespan of your circular saw blade and ensuring optimal cutting performance. Regular cleaning, sharpening, and proper storage can help prevent build-up of pitch, resin, and other debris that can affect the blade’s performance.

When choosing a circular saw blade, consider the ease of maintenance and the availability of replacement parts. Some blades may require specialized tools or professional sharpening, while others can be easily maintained with basic cleaning and sharpening techniques.

Tip: Investing in a high-quality blade and practicing proper maintenance can significantly extend its lifespan and provide long-term cost savings.

Additional Tips for Choosing the Best Circular Saw Blade

While the factors mentioned above are key considerations when choosing a circular saw blade, here are a few additional tips to help you make the best decision:

1. Consider the type of projects you will be working on most frequently. Different projects may require specific blade characteristics, such as fine cuts for woodworking or aggressive cuts for construction materials.

2. Research customer reviews and ratings for different blade brands and models. This can provide valuable insights into the performance and durability of the blades.

3. Consult with experienced professionals or experts in the field for their recommendations and insights. They can offer valuable advice based on their firsthand experience and knowledge.

4. Don’t compromise on quality. Investing in a high-quality circular saw blade may initially cost more, but it will provide better performance, longevity, and ultimately save you money in the long run.

5. Take safety precautions seriously. Always follow the manufacturer’s guidelines and safety instructions when using a circular saw blade. Proper safety measures can prevent accidents and ensure a successful and enjoyable woodworking experience.

By considering these factors and tips, you can choose the best circular saw blade for your specific needs and achieve professional-quality results in your woodworking or construction projects. Remember to prioritize safety and proper maintenance to ensure the longevity and performance of your chosen blade. Happy cutting!

Key Takeaways: What Circular Saw Blade is Best?

- Choose a blade with the right size for your saw to ensure compatibility.

- Consider the material you’ll be cutting and select a blade designed for that specific material.

- Opt for carbide-tipped blades, as they offer durability and can handle various cutting tasks.

- Check the number of teeth on the blade – more teeth provide smoother cuts on softer materials.

- For precision cuts, go for a thin-kerf blade, while a thicker blade is better for heavy-duty cutting.

Frequently Asked Questions

When using a circular saw, choosing the right blade is crucial for achieving the best results. Here are answers to some commonly asked questions about finding the best circular saw blade for your needs.

1. What factors should I consider when choosing a circular saw blade?

When selecting a circular saw blade, there are a few key factors to consider:

First, determine the type of material you will be cutting most frequently. Different blades are designed for wood, metal, or masonry, and using the wrong blade can result in poor performance or even damage to the blade or saw.

Second, consider the tooth count on the blade. Blades with more teeth provide a smoother finish, while blades with fewer teeth are better suited for fast and rough cuts. For general-purpose cutting, a blade with around 24-40 teeth is a good choice.

2. What is the importance of the blade diameter?

The blade diameter plays a crucial role in determining the cutting capacity of a circular saw. Blades with larger diameters can cut through thicker materials, while smaller diameter blades are better for thinner materials.

It’s important to note that your circular saw should be compatible with the blade diameter you choose. Most circular saws have a maximum blade size they can accommodate, so be sure to check your saw’s specifications before purchasing a blade.

3. Do I need a specialized blade for cutting different types of wood?

While it is not always necessary, using a specialized blade for cutting different types of wood can improve the quality of your cuts. Hardwood blades with carbide-tipped teeth are ideal for cutting hardwoods, while a general-purpose crosscut blade can work well for softer woods.

If you frequently work with plywood or melamine, a blade with a high tooth count and a negative hook angle will reduce the risk of chipping and produce cleaner cuts.

4. How often should I replace my circular saw blade?

The lifespan of a circular saw blade depends on various factors, such as the type of material being cut, the frequency of use, and the user’s cutting technique. However, as a general guideline, it’s recommended to replace the blade when it becomes dull or shows signs of damage.

A dull blade can cause the saw to work harder, resulting in slower cuts, rough finishes, and potentially increased safety hazards. Regularly inspect your blade for any signs of wear, such as missing or damaged teeth or excessive chipping.

5. Can I use a circular saw blade designed for metal to cut other materials?

While it may seem tempting to use a metal-cutting blade for other materials, it’s important to remember that each blade is specifically designed for a particular material. Metal-cutting blades have different tooth geometries and tooth materials compared to blades designed for wood or masonry.

Using a metal-cutting blade on other materials can result in poor performance, increased risks, and potential damage to the blade or saw. To ensure optimal results, always use the appropriate blade for the material you are cutting.

Summary

Picking the right circular saw blade is important for getting the best performance out of your saw. There are different types of blades for cutting different materials, so make sure you choose the right one. If you’re cutting wood, a general-purpose blade with 24 teeth is a good option. For cutting metal, look for a blade specifically designed for metal cutting. Remember to always use a blade guard and wear safety goggles to protect yourself.

It’s also crucial to consider the size and shape of the blade. The diameter of the blade affects the depth of the cut, so choose accordingly. Additionally, pay attention to the number of teeth on the blade. More teeth provide a smoother cut, while fewer teeth are better for faster cutting. Lastly, remember to check if the blade is compatible with your saw’s arbor size. By choosing the right circular saw blade, you’ll be able to cut through your materials with ease and precision.