Looking for the best circular saw blade to cut plywood? Well, you’re in luck! Whether you’re a DIY enthusiast or just getting started with woodworking, choosing the right blade is crucial for clean and precise cuts. In this guide, we’ll explore which circular saw blade is best for cutting plywood and why. So, let’s dive in and discover the perfect blade for your plywood projects!

When it comes to cutting plywood with a circular saw, not all blades are created equal. You need a blade specifically designed for this task. The best blade for cutting plywood is typically a fine-toothed blade with a high tooth count. These blades have more teeth per inch, which means they can make smoother, splinter-free cuts in plywood. So, say goodbye to those unsightly splinters and hello to cleaner, professional-looking cuts!

Now, you might be wondering why a high tooth count is important for cutting plywood. Well, the more teeth a blade has, the smaller and finer they are. This allows the blade to slice through the delicate layers of plywood without tearing or chipping the surface. So, if you want precise, clean cuts in plywood, a high tooth count blade is the way to go! Get ready to tackle your plywood projects like a pro with the perfect circular saw blade.

If you’re looking to cut plywood with a circular saw, the best blade to use is a carbide-tipped blade with a high tooth count. These blades are designed to make smooth and clean cuts in plywood without splintering or chipping. The carbide tips ensure durability and longevity, while the high tooth count helps to achieve precise cuts. With the right blade, you’ll be able to tackle plywood projects with ease and get professional-looking results.

The Best Circular Saw Blade for Cutting Plywood: A Comprehensive Guide

When it comes to cutting plywood, using the right circular saw blade is essential for achieving clean and precise cuts. But with so many options available in the market, it can be challenging to determine which blade is best suited for your needs. In this comprehensive guide, we will delve into the world of circular saw blades and explore the features and factors to consider when selecting the best blade for cutting plywood. Whether you’re a professional carpenter or a DIY enthusiast, this article will equip you with the knowledge to make an informed decision.

Understanding Circular Saw Blades

Smooth and accurate plywood cuts demand the right blade. Let’s start by understanding the anatomy of a circular saw blade.

1. Blade Diameter and Arbor Size

The blade’s diameter and arbor size are crucial considerations when choosing a circular saw blade for cutting plywood. Most circular saws have an arbor size of 5/8 inches, but some models may have smaller or larger arbor sizes. Ensure that the blade you select matches your saw’s arbor size to ensure compatibility and prevent accidents or damage to your equipment.

Furthermore, the blade diameter influences the cutting capacity. For plywood cuts, a blade with a diameter between 7-1/4 inches and 8-1/4 inches is typically sufficient. This range strikes the right balance between versatility and cutting efficiency.

2. Blade Material

The material from which the blade is made is a crucial factor that determines its performance. For plywood cutting, carbide-tipped blades are highly recommended. These blades are made from a combination of tough steel and tungsten carbide, ensuring durability and extended blade life. The carbide tips are designed to withstand the abrasive nature of plywood, providing clean and precise cuts without wearing down quickly.

Carbide-tipped blades come in different variations, such as ATB (Alternate Top Bevel), TCG (Triple Chip Grind), and Hi-ATB. Each variation has its unique tooth configuration, which affects the cutting performance. Consider the specific requirements of your plywood cutting project and choose a blade with the appropriate tooth configuration for optimal results.

3. Tooth Count

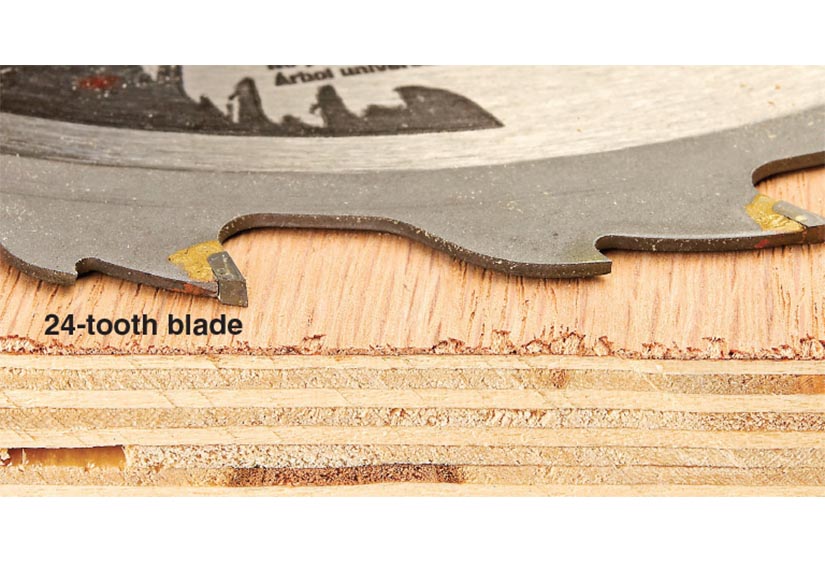

The tooth count refers to the number of teeth on a circular saw blade. When it comes to cutting plywood, a blade with a higher tooth count is generally preferred. A higher tooth count provides more teeth engaging with the material, resulting in smoother cuts with minimal splintering. Blades with 40 to 60 teeth are commonly recommended for plywood cutting, but you can choose a different tooth count depending on the thickness and quality of your plywood.

4. Hook Angle

The hook angle of a circular saw blade refers to the angle of the teeth in relation to the blade’s centerline. It plays a significant role in determining the cutting speed and aggressiveness of the blade. For plywood cutting, a blade with a low or neutral hook angle is recommended. A low hook angle (around 10 degrees) provides more control and minimizes the risk of kickbacks, ensuring safer and more precise cuts.

In contrast, a blade with a higher hook angle (around 20 degrees) is more suitable for ripping through thick lumber. Choosing a blade with the appropriate hook angle for your plywood cutting needs will optimize performance and safety.

5. Blade Coating

Blade coatings can enhance the performance and durability of a circular saw blade. While not essential for cutting plywood, a blade with a non-stick coating can reduce friction and minimize resin build-up on the blade surface. This feature can be particularly beneficial when cutting plywood with adhesive backing or when working with wet or green wood.

Opting for a blade with a non-stick coating can make your cutting experience smoother and more efficient while prolonging the blade’s lifespan.

6. Anti-Vibration Features

Vibrations during cutting can result in less accurate and rougher cuts. Some circular saw blades come with anti-vibration features designed to reduce blade wobble and enhance stability during cutting. These features help minimize the chances of blade deflection, allowing for cleaner and more precise cuts. When working with plywood, where precision is paramount, investing in a blade with anti-vibration technology can significantly improve the overall quality of your cuts.

7. Specialty Blades for Plywood

While standard carbide-tipped blades are suitable for cutting plywood, there are specialized blades available that offer unique advantages. For instance, plywood blades with anti-splinter or anti-chip features are designed specifically to reduce tear-out and splintering, resulting in cleaner cuts. These blades often have additional teeth or specialized tooth geometry to minimize tear-out along the edges of the plywood.

Additionally, there are blades designed for cutting double-sided laminates or veneered plywood. These blades feature a higher tooth count and special tooth geometry to prevent chipping or tearing of the delicate veneer surfaces.

Choosing the Right Circular Saw Blade

Now that we have explored the key features and factors to consider when selecting a circular saw blade for cutting plywood, let’s summarize the main points to help you make an informed decision. Remember, finding the right blade for your specific needs is crucial for achieving clean and precise plywood cuts. Here are some tips to guide you:

1. Consider the Blade Diameter and Arbor Size

Make sure the diameter and arbor size of the blade are compatible with your circular saw to ensure proper fitting and functionality.

2. Opt for Carbide-Tipped Blades

Choose a blade made from tough steel with carbide tips for durability and longevity. Carbide-tipped blades are specifically designed to withstand the abrasive nature of plywood cutting.

3. Take Into Account the Tooth Count

For clean and smooth cuts on plywood, blades with a higher tooth count (around 40 to 60) are recommended. However, adjust the tooth count based on the thickness and quality of your plywood.

4. Consider the Hook Angle

A blade with a low or neutral hook angle offers more control and minimizes the risk of kickbacks. Opt for a low hook angle blade (around 10 degrees) for safer and more precise cuts on plywood.

5. Explore Specialty Blade Options

If you have specific plywood cutting requirements, such as reducing splintering or cutting laminates, consider specialized blades that offer unique advantages for these applications.

6. Anti-Vibration Features

If precision is vital for your project, invest in a blade with anti-vibration features. These blades minimize vibrations, resulting in cleaner and more accurate cuts.

7. Maintenance and Care

Regularly clean your circular saw blades to remove built-up resin and debris. Proper maintenance helps extend the lifespan and performance of your blades.

By considering these factors and aligning them with your specific cutting needs, you can confidently select the best circular saw blade for cutting plywood. Remember to prioritize safety by using appropriate protective gear and following safe cutting practices. Happy cutting!

Key Takeaways: Best Circular Saw Blade for Cutting Plywood

- Choose a blade with a high tooth count, preferably 40 to 80 teeth, for smoother cuts on plywood.

- Opt for a blade with a thin kerf, around 0.1 to 0.125 inches, to minimize tear-out and maximize efficiency.

- Consider using a blade with carbide-tipped teeth for enhanced durability and longevity.

- Look for a blade with an ATB (Alternate Top Bevel) or ATBR (Alternate Top Bevel with Raker) tooth configuration to achieve clean cuts on plywood surfaces.

- Ensure the blade has the right diameter and arbor size to fit your circular saw.

Frequently Asked Questions

Looking to cut plywood with a circular saw? Find out which saw blade is best suited for the job!

1. What type of circular saw blade should I use for cutting plywood?

For cutting plywood, it is recommended to use a blade specifically designed for fine cuts, such as a plywood cutting blade. These blades usually have more teeth than standard blades, allowing for smoother and cleaner cuts.

Plywood cutting blades typically have a high tooth count, ranging from 80 to 100, which helps reduce splintering and tear-out. They also have a narrow kerf, which means they remove less material, resulting in less waste.

2. Can I use a general-purpose blade for cutting plywood?

While it is possible to use a general-purpose blade for cutting plywood, it may not provide the best results. General-purpose blades are typically designed to handle a variety of materials and may have a lower tooth count. This can result in rough cuts, splintering, and tear-out when cutting plywood.

If you plan on cutting a significant amount of plywood, it is advisable to invest in a plywood-specific blade. This will ensure cleaner cuts, minimize waste, and make the cutting process much smoother and easier.

3. What should I consider when choosing a circular saw blade for plywood?

When choosing a circular saw blade for plywood, consider the tooth count, tooth geometry, and blade diameter. Higher tooth count blades are generally better for plywood as they create cleaner cuts and reduce splintering.

Opt for blades with a negative hook angle, which helps prevent the blade from grabbing the material and causing kickback. Additionally, ensure that the blade diameter matches the requirements of your circular saw to ensure compatibility and safety.

4. Are there any safety precautions I should take when using a circular saw with a plywood blade?

Yes, several safety precautions should be taken when using a circular saw with a plywood blade. Always wear safety goggles to protect your eyes from debris and use a dust mask to avoid inhaling sawdust. Ensure the blade is properly installed and tightened, and check for any damage or signs of wear before use.

Make sure the material you are cutting is securely clamped to prevent it from moving during the cut. Lastly, keep a firm grip on the saw with both hands and maintain a stable stance to ensure control and stability while cutting.

5. How often should I replace a circular saw blade used for cutting plywood?

The lifespan of a circular saw blade used for cutting plywood will depend on various factors such as usage, the type of plywood being cut, and the condition of the blade. As a general rule, it is recommended to replace the blade when it becomes dull or damaged.

Signs of a dull blade include rough cuts, splintering, increased cutting effort, and excessive heat during operation. Regularly inspect the blade for any signs of wear or damage and replace it as needed to ensure optimal cutting performance and safety.

Summary

So, when it comes to cutting plywood with a circular saw, it’s important to choose the right blade. A fine-tooth blade with high tooth count is best for clean, splinter-free cuts. Additionally, a blade specifically designed for plywood with anti-kickback features can make the job safer. Remember to select the correct size blade to match your saw and always prioritize safety by wearing protective equipment and following proper handling techniques.

To recap, a fine-tooth, high tooth count blade designed for plywood will give you the best results. Happy cutting!