Are you wondering what circular saw blade to use when cutting cement board? Well, you’ve come to the right place! Whether you’re a DIY enthusiast or a professional contractor, choosing the correct blade is crucial for achieving clean and precise cuts. In this article, we’ll explore the best circular saw blades for cutting cement board and provide you with some helpful tips along the way.

Cutting cement board requires a blade that is specifically designed for the job. While regular wood-cutting blades might get the job done, they can quickly wear out or produce rough edges. That’s why it’s important to invest in a diamond-tipped or carbide-tipped blade. These blades are designed to withstand the tough nature of cement board and deliver smooth, accurate cuts with minimal effort.

So, which type of blade should you choose? Diamond-tipped blades are known for their exceptional durability and ability to cut through even the toughest materials. On the other hand, carbide-tipped blades are more affordable and still provide excellent cutting performance. Ultimately, it’s a matter of personal preference and the specific needs of your project.

Now that you know the importance of using the right circular saw blade for cutting cement board, let’s dive deeper into the different types of blades and their features. By the end of this article, you’ll have all the knowledge you need to make an informed decision and tackle your cement board cutting tasks like a pro! So, let’s get started!

What Circular Saw Blade to Cut Cement Board: A Comprehensive Guide

Are you looking to cut cement board for your next DIY project? Choosing the right circular saw blade for the job is crucial to ensure precision and efficiency. In this guide, we will explore the different types of circular saw blades available and provide useful tips to help you make an informed decision. Whether you’re a professional contractor or a passionate DIYer, this article will equip you with the knowledge you need to select the best circular saw blade for cutting cement board.

The Importance of the Right Circular Saw Blade

Before diving into the specifics of circular saw blades for cutting cement board, it’s important to understand why choosing the right blade is crucial. Cement board is a dense material that requires a blade specifically designed to cut through it. Using the wrong blade can lead to inefficiency, damage to the blade, and even safety hazards. By using the appropriate blade, you can achieve clean and precise cuts, reducing the risk of splintering or cracking the cement board.

1. Types of Circular Saw Blades for Cutting Cement Board

There are several types of circular saw blades available for cutting cement board. Let’s explore some of the most popular options:

Diamond-Tipped Blades

Diamond-tipped blades are the most common choice for cutting cement board. These blades feature synthetic diamonds embedded in the rim, providing excellent cutting performance and durability. They can effortlessly cut through cement board, leaving clean edges without chipping or cracking. Diamond-tipped blades are available in various sizes and with different tooth configurations to suit different cutting needs.

Carbide-Tipped Blades

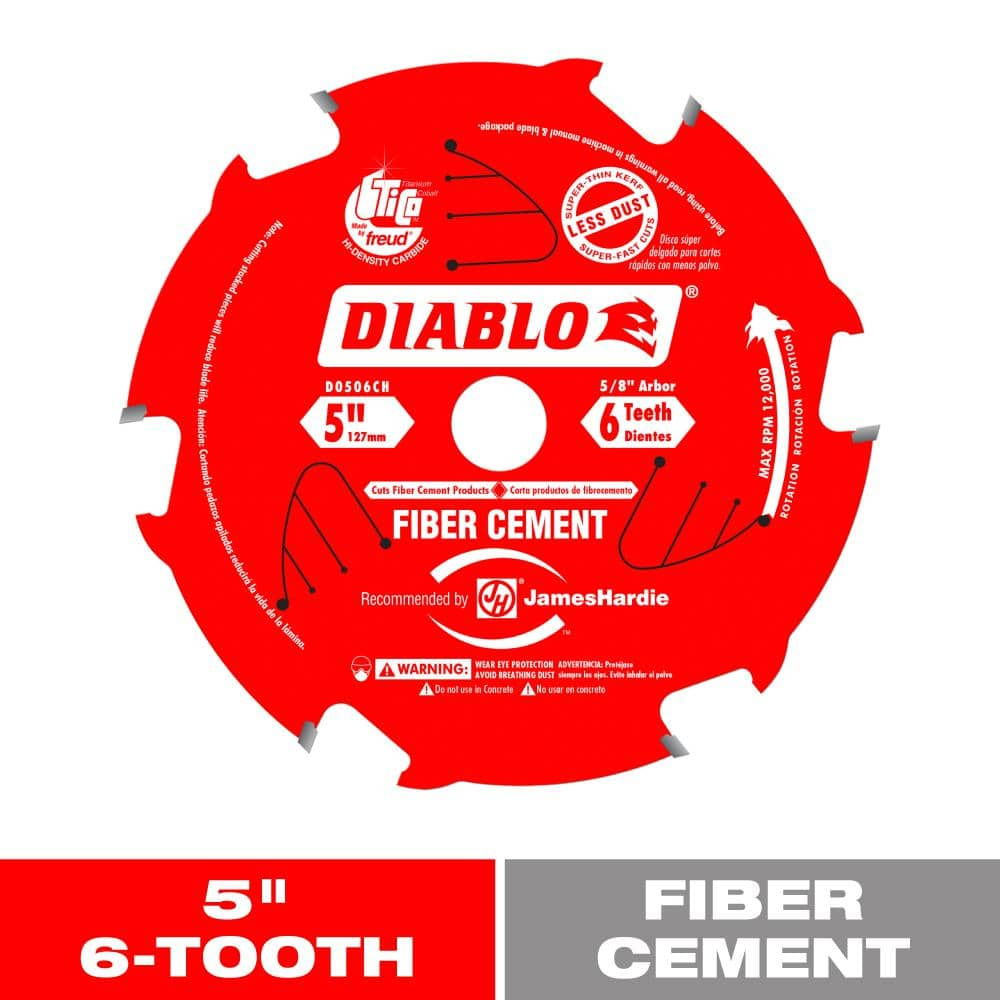

Carbide-tipped blades are another popular option for cutting cement board. These blades have teeth made of carbide, a very hard and durable material. While not as effective as diamond-tipped blades, carbide-tipped blades can still provide satisfactory results when cutting cement board. They are available in different tooth configurations and are generally more affordable than diamond-tipped blades.

Abrasive Blades

Abrasive blades, also known as masonry blades, are made from abrasive materials such as silicon carbide. They are an economical choice but are generally less durable than diamond or carbide-tipped blades. Abrasive blades can effectively cut through cement board, but they may wear down more quickly and may not deliver the same level of precision as the other options.

2. Factors to Consider When Choosing a Circular Saw Blade for Cutting Cement Board

When selecting a circular saw blade for cutting cement board, there are several factors to consider. Let’s take a closer look at these factors to help you make an informed decision:

Blade Diameter

The blade diameter determines the size of the cut you can make. It’s important to choose a blade with a diameter that matches your project requirements. Most circular saw blades for cutting cement board range from 7-1/4 inches to 10 inches in diameter.

Number of Teeth

The number of teeth on the blade affects the cutting speed and the smoothness of the cut. Blades with more teeth typically result in cleaner and smoother cuts, but they may cut more slowly. Consider the specific requirements of your project to determine the ideal number of teeth for your circular saw blade.

Tooth Configuration

The tooth configuration refers to the arrangement of teeth on the blade. Different tooth configurations are designed for different cutting tasks. For cutting cement board, blades with alternating top bevel (ATB) or triple-chip grind (TCG) tooth configurations are commonly recommended.

Arbor Size

The arbor size of the blade should match the arbor size of your circular saw. Make sure to check the specifications of both the blade and the saw to ensure compatibility.

Blade Material

The material used to construct the blade can affect its durability and performance. Diamond-tipped blades and carbide-tipped blades are known for their durability and cutting efficiency, while abrasive blades are more affordable but may not last as long.

Safety Precautions

When working with circular saw blades, safety should always be a top priority. Make sure to wear appropriate safety gear, such as safety goggles and gloves, to protect yourself from any potential hazards. Follow the manufacturer’s instructions for blade installation and use, and always handle the saw and blade with caution.

Choosing the Right Circular Saw Blade: Tips and Tricks

Now that we’ve explored the different types of circular saw blades for cutting cement board and the factors to consider, here are some additional tips and tricks to help you make the right choice:

3. Consider the Thickness of the Cement Board

The thickness of the cement board should be taken into account when selecting a circular saw blade. Thicker boards may require blades with larger diameters and more teeth to achieve clean cuts.

4. Opt for Quality Blades

Investing in high-quality circular saw blades can make a significant difference in the quality of your cuts and the longevity of the blade. Look for reputable brands known for their durability and cutting performance.

5. Read User Reviews

Before purchasing a circular saw blade, take the time to read user reviews online. It can give you insights into the experiences of other users and help you determine the suitability of a particular blade for your needs.

6. Test the Blade on a Scrap Piece of Cement Board

If you’re unsure about the performance of a specific blade, consider testing it on a scrap piece of cement board before starting your project. This will allow you to assess the cutting quality and make any necessary adjustments.

By following these tips and considering the factors mentioned earlier, you will be well-equipped to choose the right circular saw blade for cutting cement board. Remember to prioritize safety, and always use the appropriate safety gear when operating power tools. With the right blade in hand, you’ll be able to tackle your cement board cutting projects with confidence and precision.

Key Takeaways: What Circular Saw Blade to Cut Cement Board?

- Choose a diamond-tipped circular saw blade for cutting cement board.

- Ensure the blade is designed specifically for cutting cement or fiber cement board.

- Use a blade with a continuous rim or segmented rim design for cleaner cuts.

- Opt for a blade with a high number of teeth for smoother and more precise cuts.

- Remember to prioritize safety by wearing protective goggles, gloves, and a dust mask when cutting cement board.

Frequently Asked Questions

Welcome to our FAQs section where we answer commonly asked questions about selecting the right circular saw blade for cutting cement board. Whether you’re a DIY enthusiast or a professional contractor, we’ve got you covered with all the information you need to make an informed choice.

1. What type of circular saw blade is best for cutting cement board?

When it comes to cutting cement board, the best type of circular saw blade to use is a carbide-tipped blade. Carbide blades are known for their durability and ability to cut through tough materials like cement board with ease. The carbide tips on these blades are specifically designed to withstand the abrasiveness of cement board, ensuring clean and precise cuts.

It’s also important to look for a blade with a high tooth count, as this will give you finer cuts and minimize chipping. Aim for a blade with at least 7 or 8 teeth per inch (TPI) for optimal results. Additionally, make sure the blade is compatible with your circular saw model for a secure and efficient cutting experience.

2. Can I use a regular wood-cutting circular saw blade to cut cement board?

While it may be tempting to use a regular wood-cutting circular saw blade to cut cement board, it is not recommended. Wood-cutting blades are designed for softer materials and lack the durability and tooth configuration needed to effectively cut through cement board without causing damage to the blade or the board itself.

Using a wood-cutting blade on cement board can result in chipped edges, rough cuts, and an increased risk of blade damage. To ensure clean and precise cuts on cement board, it’s best to invest in a carbide-tipped blade specifically designed for this purpose.

3. How do I choose the right size circular saw blade for cutting cement board?

When choosing the right size circular saw blade for cutting cement board, it’s important to consider the thickness of the board. Most cement boards used in construction projects are 1/2 inch or 1/4 inch thick. For 1/2 inch thick cement board, a 7 1/4 inch circular saw blade is commonly used, while a 4 1/2 inch blade can work well for 1/4 inch thick cement board.

It’s crucial to match the blade size to the thickness of the cement board to ensure accurate and efficient cutting. Using a blade that is too small may result in incomplete cuts, while a blade that is too large can cause unnecessary friction and decrease cutting performance.

4. Should I use a dry-cutting or wet-cutting circular saw blade for cutting cement board?

When it comes to cutting cement board, the choice between a dry-cutting or wet-cutting circular saw blade depends on your personal preference and the specific requirements of your project. Dry cutting is more commonly used and suitable for smaller DIY projects or when time is limited. A dry-cutting blade creates less mess and allows for faster cuts.

On the other hand, wet cutting is recommended for larger projects or when precision is crucial. Wet-cutting blades utilize water to cool down the blade and suppress dust, resulting in cleaner cuts and increased blade longevity. However, wet cutting requires additional equipment and can be slower compared to dry cutting.

5. How can I ensure safety when using a circular saw to cut cement board?

When using a circular saw to cut cement board, it’s important to prioritize safety. Here are some tips to ensure a safe cutting experience:

1. Secure the workpiece: Use clamps or other securing methods to hold the cement board firmly in place during the cutting process.

2. Wear protective gear: Always wear safety glasses, gloves, and a dust mask to protect yourself from flying debris and dust particles.

3. Follow manufacturer’s instructions: Read the user manual of your circular saw and the blade manufacturer’s recommendations for usage and safety guidelines.

4. Take breaks: If you’re working on a large project, take regular breaks to prevent fatigue and maintain focus.

5. Disconnect the power: Before changing the blade or performing any maintenance on the circular saw, ensure it is disconnected from the power source.

Remember, safety should always be your top priority when operating power tools, including circular saws.

Summary

Cutting cement board with a circular saw requires the right blade and proper precautions. A diamond-tipped blade with medium or fine grit is best for clean and precise cuts. Make sure to wear safety gear like goggles and a face mask to protect yourself from dust. Keep the saw steady and move it slowly for accurate cuts. Remember to measure and mark your cuts beforehand to ensure accuracy.

Before cutting, make sure the cement board is securely in place and supported to prevent any cracking or crumbling. Finally, take your time and be patient when cutting through cement board to avoid any mishaps. With the right blade and precautions, you’ll be able to cut cement board with ease and precision.