Are you wondering what circular saw blade to use when cutting MDF? Well, you’ve come to the right place! Cutting Medium Density Fiberboard (MDF) requires a specific type of saw blade that ensures clean and precise cuts. But don’t worry, I’ll break it down for you in this article.

Cutting MDF can be a breeze if you have the proper circular saw blade. So, what exactly should you look for? Firstly, you’ll want to choose a blade with a high tooth count. This helps minimize splintering and produces smooth edges. Plus, a blade with carbide-tipped teeth will last longer, making it a worthwhile investment.

When it comes to the size of the blade, a standard 10-inch blade should work perfectly for most MDF cutting tasks. Just remember to adjust the saw’s setting for the desired depth of cut. And don’t forget to wear safety goggles and take the necessary precautions when operating power tools!

In summary, finding the right circular saw blade for cutting MDF is essential for achieving clean and precise cuts. Choose a blade with a high tooth count and carbide-tipped teeth for optimal results. With the right blade and a steady hand, you’ll be tackling MDF cutting projects like a pro in no time!

What Circular Saw Blade to Cut MDF?

Introduction:

When it comes to cutting MDF (medium-density fiberboard), choosing the right circular saw blade is crucial to achieve clean and precise cuts. MDF is a popular choice for woodworking projects due to its affordability and versatility, but it can be challenging to work with if you don’t have the appropriate tools. In this article, we will explore the different types of circular saw blades available for cutting MDF and provide tips to help you make the best choice for your project.

1. Types of Circular Saw Blades for Cutting MDF

When selecting a circular saw blade for cutting MDF, there are a few important factors to consider. The most crucial aspect is the type of blade you choose. Below are three common types of saw blades that are recommended for cutting MDF:

- Carbide-tipped Blades: Carbide-tipped blades are the most commonly used blades for cutting MDF. These blades are designed to withstand the abrasiveness of MDF and provide clean cuts with minimal tear-out. They feature sharp carbide teeth that stay sharp for longer, reducing the need for frequent blade changes.

- High-Tooth Count Blades: Blades with a high tooth count, such as 80 to 100 teeth, are ideal for cutting MDF. These blades create finer, smoother cuts and minimize chip-out. The high number of teeth helps distribute the cutting force evenly, resulting in cleaner edges.

- Triple-Chip Grind Blades: Triple-chip grind blades have a unique tooth configuration that consists of a flat-topped tooth followed by a chamfered tooth. This design reduces the risk of chipping or splintering when cutting MDF. These blades are highly recommended for cutting laminated MDF or MDF with veneer.

It’s important to remember that MDF can be hard on saw blades, so it’s best to choose high-quality blades that are specifically designed for cutting this material. Investing in a good blade will ensure cleaner cuts and longevity of your cutting tool.

2. Blade Size for Cutting MDF

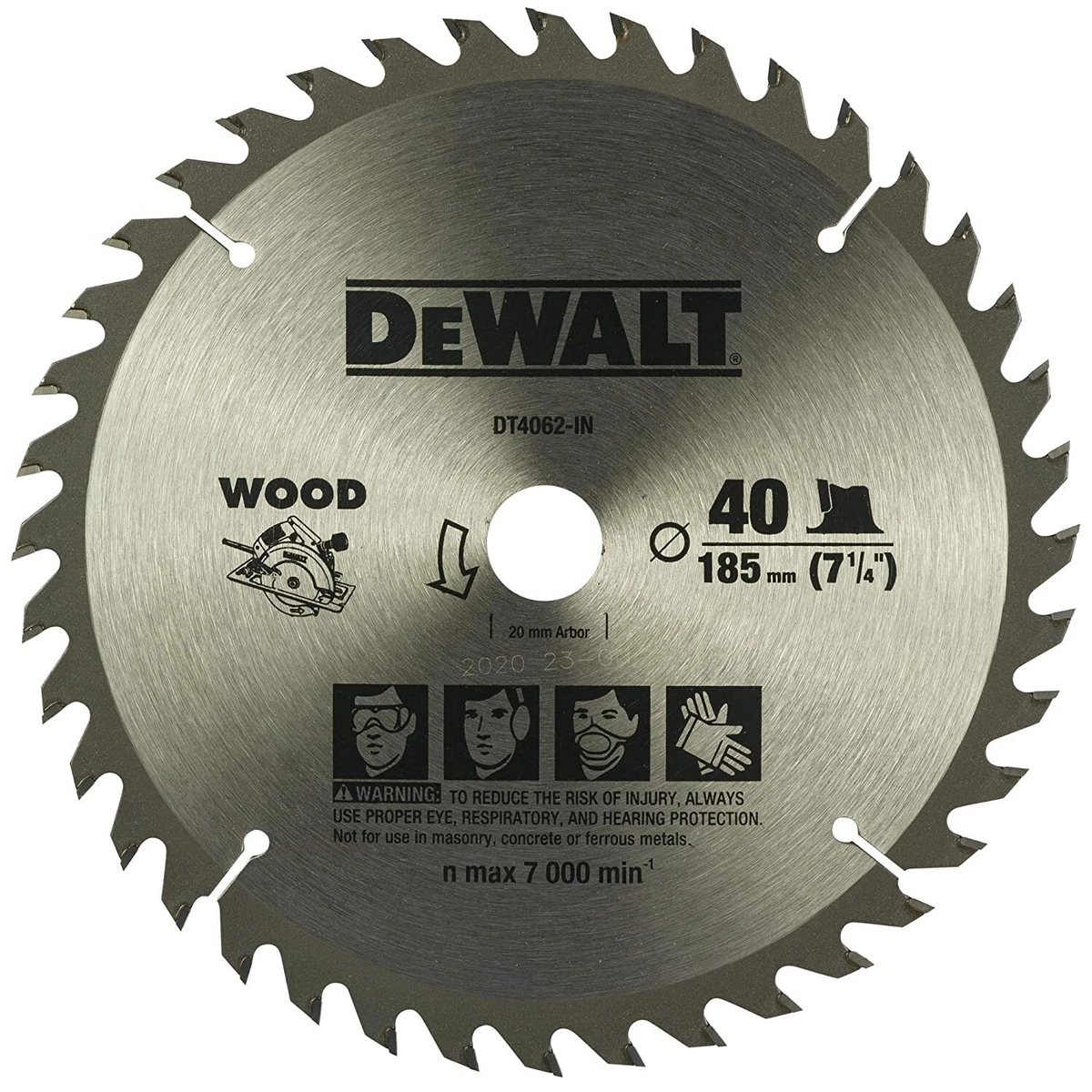

Another factor to consider when choosing a circular saw blade for cutting MDF is the size of the blade. The most common blade size for circular saws is 7 ¼ inches (184mm). This size is suitable for most standard MDF sheets that are typically up to ¾ inch thick.

However, if you frequently work with thicker or larger MDF sheets, you may opt for a larger blade size, such as 10 inches (254mm). Larger blades can provide deeper cuts and faster cutting speeds, which can be advantageous for larger-scale projects or thicker MDF materials.

When selecting a blade size, ensure that it is compatible with your circular saw. Check the manufacturer’s recommendations or consult the user manual to determine the maximum blade size your saw can accommodate.

3. Tips for Cutting MDF with a Circular Saw Blade

Now that you know the types of circular saw blades and the ideal blade size for cutting MDF, let’s explore some useful tips to achieve the best results:

- Mark Your Cut Line: Before starting the cutting process, mark the precise line where you want to cut the MDF. This will help guide your saw, ensuring accuracy and minimizing errors.

- Use a Clamped Straight Edge: To ensure straight cuts, use a straightedge or a guide rail clamped firmly onto the MDF. This will serve as a guide for your circular saw, enhancing accuracy and reducing the risk of the saw wandering off course.

- Go Slow and Steady: When cutting MDF, it’s best to use a slower cutting speed. This will help prevent overheating of the blade and reduce the likelihood of chipping or tear-out. Apply even pressure to the saw throughout the cutting process for smooth and clean cuts.

- Wear Safety Gear: Always prioritize safety when using power tools. Wear protective eyewear, gloves, and a dust mask to prevent any potential injuries or health hazards during the cutting process.

- Allow the Blade to Cool: MDF can generate heat during the cutting process, which can dull the blade faster. To prevent this, pause periodically to allow the blade to cool down. This will help prolong the life of your blade and ensure better cutting performance.

By following these tips and using the right circular saw blade, you can achieve clean and precise cuts on MDF, making your woodworking projects look more professional and refined.

The Benefits of Using the Right Circular Saw Blade for MDF

Using the correct circular saw blade for cutting MDF offers several benefits:

1. Clean and Precise Cuts:

The right circular saw blade reduces tear-out, chipping, and splintering, resulting in cleaner and more precise cuts. This ensures that your MDF projects have smooth edges and a professional finish.

2. Improved Efficiency:

A high-quality saw blade designed for MDF cuts through the material effortlessly, reducing the time and effort required for the cutting process. This enhances overall efficiency, allowing you to complete your projects more quickly.

3. Longevity of the Blade:

Investing in a durable and purpose-built circular saw blade ensures its longevity. These blades are designed to withstand the abrasiveness of MDF, resulting in fewer blade changes and reducing the need for frequent replacements.

4. Versatility:

Choosing the right circular saw blade for MDF expands the versatility of your tool. With the right blade, you can confidently tackle a wide range of MDF projects, from small crafts to larger woodworking endeavors.

The Right Circular Saw Blade for MDF vs. Other Materials

1. Plywood

When cutting plywood, it is best to use a blade specifically designed for this material. Plywood blades have a high tooth count and a low TPI (teeth per inch), which helps reduce tear-out and produces clean cuts. These blades typically have a thin kerf to minimize material waste and are an excellent investment for woodworking projects involving plywood.

2. Particle Board

For particle board, a specialized blade is also recommended. Particle board blades have a higher tooth count to ensure smooth cuts and minimize chip-out. Additionally, these blades feature a design that helps dissipate heat generated during the cutting process, preventing blade dulling and extending its lifespan.

3. Hardboard

Hardboard, also known as high-density fiberboard (HDF), requires a blade specifically designed for hard materials. These blades have a high tooth count and hardened carbide tips to withstand the hardness of the material. With the right blade, you can achieve clean and precise cuts on hardboard without damaging or dulling the blade.

In Summary

When it comes to cutting MDF, choosing the right circular saw blade is essential. Carbide-tipped blades, high-tooth count blades, and triple-chip grind blades are all suitable options for achieving clean and precise cuts. Consider the blade size based on the thickness and size of your MDF sheets, and ensure compatibility with your circular saw. By following the tips provided and using the correct blade, you can achieve professional-looking results in your MDF woodworking projects.

Key Takeaways: What Circular Saw Blade to Cut MDF?

- Choose a carbide-tipped blade for cutting MDF as it is durable and can handle the dense material.

- Look for a blade with a high number of teeth (around 80) for smoother cuts on MDF.

- A thin-kerf blade reduces the chance of chipping or splintering while cutting MDF.

- Consider using a blade with anti-kickback features to ensure safety and prevent accidents.

- Make sure to use the appropriate speed and feed settings recommended for cutting MDF with a circular saw.

Frequently Asked Questions

Here are some commonly asked questions about choosing the right circular saw blade for cutting MDF:

1. Can I use any circular saw blade to cut MDF?

While you can technically use any circular saw blade to cut MDF, it’s important to choose one specifically designed for this material. Opting for a blade with a high tooth count and carbide tips will ensure cleaner cuts and prevent chipping or splintering. This type of blade is commonly known as an MDF blade or a laminate blade.

These blades have a special design that helps reduce friction and heat buildup, resulting in smoother cuts and a longer blade life. So, while you may be tempted to use a general-purpose blade, investing in a blade specially made for cutting MDF will give you much better results.

2. How many teeth does the blade need to have to cut MDF effectively?

When it comes to cutting MDF, it is recommended to use a blade with a high tooth count. The higher the tooth count, the smoother the cut will be. For MDF, a blade with at least 80 teeth is generally recommended for finer cuts.

The high tooth count helps reduce chipping, splintering, and tear-out while cutting, resulting in cleaner edges. So, choosing a blade with a high tooth count will produce better quality cuts and minimize the need for additional finishing work.

3. What should I consider when choosing a circular saw blade for cutting MDF?

When selecting a circular saw blade for cutting MDF, there are a few important factors to consider. Firstly, consider the tooth count. As mentioned earlier, a blade with a higher tooth count will give you cleaner cuts.

Additionally, consider the blade diameter and arbor size to ensure compatibility with your circular saw. Finally, check if the blade has carbide tips, as carbide is known for its durability and ability to withstand the demands of cutting dense materials like MDF.

4. Can I use a blade designed for plywood to cut MDF?

While a blade designed for plywood may work for cutting MDF, it’s not the ideal choice. MDF is denser and harder than plywood, so using a blade specifically designed for MDF will give you smoother cuts and better overall performance.

Blades designed for MDF often have a lower tooth count to prevent overheating and reduce the risk of burning the material. They also feature a special coating or design that helps reduce friction and minimize chip-out.

5. Do I need a special type of blade for cutting curved shapes in MDF?

If you plan to cut curved shapes in MDF, it’s recommended to use a blade specifically designed for these types of cuts. These specialized blades, often called scroll-cutting or jigsaw blades, have narrow widths and fine teeth that allow for precise and smooth cuts in curved or intricate patterns.

Using the right blade for curved cuts will help you achieve cleaner edges and prevent the wood from splintering or chipping along the curved lines.

Summary

So, if you’re cutting MDF with a circular saw, here are the key things to remember:

First, use a carbide-tipped blade because it’s durable and can handle the dense MDF material. Second, choose a blade with a high tooth count, preferably around 80 to 100 teeth. This will give you smoother cuts with minimal chipping.

Additionally, make sure your blade is sharp and clean before starting to cut. Set the blade depth properly to avoid cutting too deep or too shallow. Finally, take your time and use a steady hand to guide the saw along the cut line for the best results.

By following these tips, you’ll be able to make precise and clean cuts in MDF with your circular saw. Practice makes perfect, so don’t be afraid to give it a try!