So you’ve got yourself a bandsaw and you’re ready to unleash its cutting power, but there’s one question on your mind: what determines the maximum thickness that can be cut on a bandsaw? Well, my curious friend, you’re in the right place! In this article, we’ll dive into the fascinating world of bandsaw cutting depths and explore the factors that influence how thick your cut can be.

When it comes to bandsaws, the maximum thickness that can be cut depends on a variety of factors. First and foremost is the size of the bandsaw itself. Bigger bandsaws usually have larger throat capacities, allowing you to cut thicker materials. Additionally, the power of the bandsaw’s motor plays a role in determining the maximum depth of cut.

But that’s not all! The type and condition of the blade you’re using also come into play. A sharp blade with the appropriate tooth configuration can make cleaner and deeper cuts compared to a dull or incorrect blade. So, choosing the right blade for your cutting needs is key to achieving maximum cutting thickness on a bandsaw. Let’s explore these factors further and unlock the secrets of bandsaw cutting depths together!

What Determines the Maximum Thickness That Can Be Cut on a Bandsaw?

When it comes to woodworking, a bandsaw is a versatile and indispensable tool. It allows you to make smooth and precise cuts on a variety of materials, including wood, metal, and plastic. However, every bandsaw has limitations, and one of the most important factors to consider is the maximum thickness that can be cut. Understanding what determines this maximum thickness is crucial for achieving accurate and efficient cuts. In this article, we will explore the key factors that determine the maximum thickness that can be cut on a bandsaw, providing you with valuable insights to enhance your woodworking skills.

The Power of the Motor

One of the primary determinants of the maximum thickness that can be cut on a bandsaw is the power of its motor. The motor is responsible for driving the blade and providing the necessary force to cut through the material. Bandsaws come in a range of motor sizes, typically measured in horsepower (HP). The greater the horsepower, the more powerful the motor, and the thicker the material it can handle. However, it’s important to note that the power of the motor alone is not the only factor to consider. The design and quality of the bandsaw, as well as the type and condition of the blade, also play a role in determining the maximum thickness that can be effectively cut.

When choosing a bandsaw, it’s essential to consider the type of projects you will be working on and the materials you plan to cut. If you frequently work with thick and dense materials, such as hardwoods or metals, a bandsaw with a higher horsepower motor would be more suitable. On the other hand, if you primarily work with thinner materials, such as plywood or plastic, a bandsaw with a lower horsepower motor may be sufficient.

The Size and Configuration of the Blade

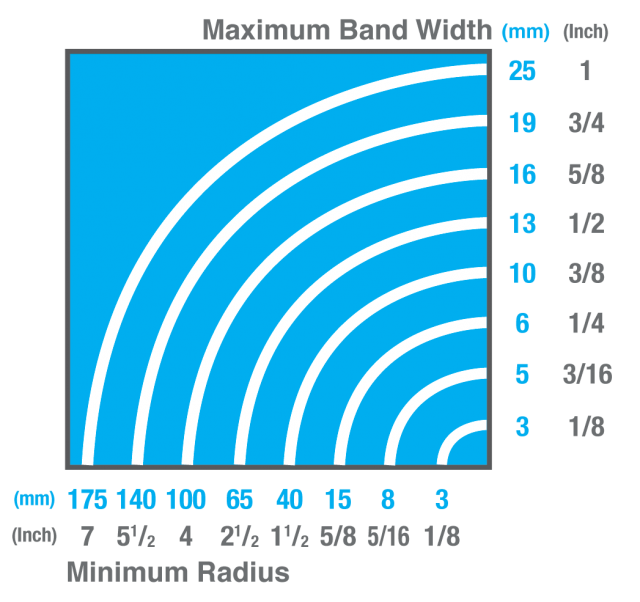

The size and configuration of the blade are other crucial factors that determine the maximum thickness that can be cut on a bandsaw. Bandsaw blades come in various widths, lengths, and tooth configurations, each suitable for specific cutting applications. The width of the blade, in particular, plays a significant role in the maximum thickness that can be cut. Wider blades have more strength and rigidity, allowing them to handle thicker materials with ease. Consequently, a bandsaw with a wider blade will have a higher maximum cutting capacity.

In addition to the width, the tooth configuration of the blade also influences the cutting capacity. Bandsaw blades can have different tooth patterns, such as regular, skip, or hook. The tooth configuration affects the speed, smoothness, and precision of the cut. Blades with a regular tooth pattern are generally suitable for general-purpose cutting, while blades with a skip or hook tooth pattern are better suited for faster, rougher cuts on thicker materials. Depending on the material and the desired cut quality, choosing the right tooth configuration is crucial for achieving optimum results.

Another important consideration is the condition of the blade. A dull or damaged blade can significantly reduce the maximum thickness that can be cut. It is essential to regularly inspect and maintain the blade, ensuring it is sharp, free from defects, and correctly tensioned. Investing in high-quality blades and replacing them when necessary will help to maximize the cutting capacity of your bandsaw.

The Throat Size and Cutting Capacity

The throat size and cutting capacity are physical attributes of a bandsaw that directly influence the maximum thickness that can be cut. The throat size refers to the distance between the blade and the vertical frame of the bandsaw. A larger throat size allows for the cutting of wider stock, which in turn increases the maximum thickness that can be accommodated. Therefore, when selecting a bandsaw, consider your intended projects and the typical width of the materials you plan to cut.

Additionally, the bandsaw’s cutting capacity is an important specification to consider. The cutting capacity is usually measured as the maximum distance from the table to the upper guide assembly. This measurement determines the height or thickness of the material that can be cut while maintaining accuracy and safety. It is crucial to choose a bandsaw with a cutting capacity that suits your needs. If you frequently work with thick stock, opting for a bandsaw with a higher cutting capacity will ensure you can tackle a wider range of projects.

Blade Tension and Tracking

Proper blade tension and tracking are critical for achieving accurate and efficient cuts on a bandsaw. Blade tension refers to the amount of tension applied to the blade to keep it straight and stable during cutting. Insufficient tension can cause the blade to wander or drift, resulting in imprecise cuts. On the other hand, excessive tension can put unnecessary stress on the blade and eventually lead to premature wear or breakage. Finding the right balance of tension is essential for optimizing the cutting performance of your bandsaw.

Blade tracking refers to the alignment of the blade with the wheels and guides of the bandsaw. When the blade is correctly tracked, it runs smoothly and accurately through the material. Misaligned or poorly tracked blades can lead to wavy cuts or even blade damage. Regularly monitoring and adjusting the blade tracking is necessary to ensure the bandsaw operates at its optimal performance and maximizes its cutting capacity. Following the manufacturer’s guidelines and performing routine maintenance will help maintain proper blade tension and tracking.

Bandsaw Type and Features

Alongside the factors mentioned above, the type of bandsaw and its additional features can also affect the maximum thickness that can be cut. There are several types of bandsaws available on the market, including benchtop, floor-standing, and portable models. Each type has its unique design, size, and capacity. Benchtop bandsaws are typically smaller and more suitable for lighter-duty tasks, while floor-standing bandsaws are larger, more powerful, and capable of handling thicker stock.

Furthermore, bandsaws may come equipped with features like blade guides, quick tension release mechanisms, and fence systems. These features can improve the accuracy, ease, and safety of the cutting process. Choosing a bandsaw with the appropriate type and features for your specific needs and projects will contribute to achieving optimal cutting results.

Proper Setup and Technique

Lastly, the proper setup and technique employed while using a bandsaw can significantly impact the maximum thickness that can be cut. Ensuring the bandsaw is set up correctly, including aligning the blade, adjusting the guides and fence, and securing the workpiece, is crucial for achieving precise cuts and preventing accidents. Additionally, using the appropriate cutting techniques, such as using a slow and steady feed rate and applying consistent and even pressure, will contribute to the overall performance and cutting capacity of the bandsaw.

Regularly inspecting and maintaining the bandsaw, including lubricating the moving parts, checking for proper blade tension, and replacing worn-out components, will help to optimize its cutting capacity and extend its lifespan. It is also important to follow safety protocols and wear protective equipment when operating a bandsaw to prevent injuries.

Different Blade Types and Their Cutting Capacities

Now that we have explored the factors that determine the maximum thickness that can be cut on a bandsaw, let’s delve into the different types of blades and their cutting capacities. Choosing the right blade for your specific cutting needs will ensure the best possible results and help you maximize the capabilities of your bandsaw.

Regular Tooth Blade

A regular tooth blade is the most commonly used type of bandsaw blade. It features a uniform tooth pattern with evenly spaced teeth. Regular tooth blades are versatile and suitable for a wide range of materials and cutting applications. They offer a balance between cutting speed and finish quality, making them ideal for general-purpose cutting, such as cutting curves, crosscuts, and rip cuts on various thicknesses of wood. Regular tooth blades can effectively cut materials up to a certain thickness, depending on their width and the power of the bandsaw motor.

For thinner materials, regular tooth blades can deliver smooth and precise cuts. However, when used on thicker stock, the cutting speed may decrease, and the finish quality may be slightly rougher. It is important to ensure the bandsaw’s motor can handle the thickness of the material being cut to prevent strain on the blade and the motor itself.

When using a regular tooth blade, it is advisable to feed the material slowly and steadily, allowing the blade to cut smoothly through the workpiece. Adjusting the blade tension and tracking as necessary will help maintain optimal cutting performance.

Hook Tooth Blade

A hook tooth blade features deep gullets and large, widely spaced teeth that have a hook-shaped profile. This tooth configuration is designed to remove material quickly, making the hook tooth blade ideal for rough, fast cuts on thick stock. Hook tooth blades are commonly used for resawing, which involves cutting large boards into thinner pieces, and for cutting thick lumber or dense materials like hardwoods.

The large gullets of the hook tooth blade allow for efficient chip removal, preventing the blade from becoming bogged down or overheated. This tooth configuration also enables the blade to make aggressive cuts at higher speeds, significantly reducing cutting time. However, the trade-off is a rougher finish and a wider kerf, which may require additional sanding or further processing to achieve the desired final dimension and smoothness.

It is important to ensure that the bandsaw has the necessary power and cutting capacity to handle the thickness of the material when using a hook tooth blade. Adjusting the blade tension and tracking to suit the tooth configuration is crucial for achieving optimal cutting results.

Skip Tooth Blade

The skip tooth blade features a tooth pattern with widely spaced teeth and a large gullet followed by a smaller gullet. This tooth configuration allows for efficient chip removal while reducing the amount of heat and friction generated during the cutting process. Skip tooth blades are commonly used for cutting materials that produce a significant amount of chips or sawdust, such as softwoods, plastics, and non-ferrous metals.

Due to their tooth pattern, skip tooth blades have a coarser finish compared to regular tooth or hook tooth blades. They are typically used for cutting thicker stock where a smooth finish is not a priority. The wider kerf of the skip tooth blade also allows for a faster cutting speed. However, it is essential to ensure that the bandsaw is powerful enough to handle the thickness of the material being cut.

When using a skip tooth blade, adjusting the blade tension and tracking becomes crucial for achieving optimal cutting performance. Slow and steady feeding is recommended to prevent the blade from becoming overloaded and to ensure a clean and accurate cut.

Tips for Maximizing the Cutting Capacity of Your Bandsaw

Now that you have a deeper understanding of what determines the maximum thickness that can be cut on a bandsaw, here are some essential tips to help you maximize the cutting capacity and performance of your bandsaw:

- Choose the appropriate bandsaw type and size for your specific needs and projects.

- Consider the horsepower of the motor to ensure it can handle the intended cutting tasks.

- Invest in high-quality blades and regularly inspect and maintain them.

- Opt for wider blades for increased strength and rigidity when cutting thicker materials.

- Select the right tooth configuration for the desired cut quality and material.

- Adjust the blade tension and tracking to maintain optimal cutting performance.

- Ensure the bandsaw is set up properly, including aligning the blade and adjusting the guides.

- Use proper cutting techniques, such as a slow and steady feed rate and consistent pressure.

- Follow safety protocols and wear protective equipment when operating the bandsaw.

By following these tips, you can optimize your bandsaw’s cutting capacity and achieve accurate and efficient cuts on a wide range of materials.

Improve Your Woodworking Skills with a Bandsaw

A bandsaw is a valuable tool that can enhance your woodworking skills and open up a world of possibilities in your projects. By understanding what determines the maximum thickness that can be cut on a bandsaw, you can make informed decisions when selecting a bandsaw and choosing the appropriate blades. Remember to consider factors such as motor power, blade size and configuration, throat size, and cutting capacity. Additionally, paying attention to proper blade tension, tracking, and setup, as well as employing correct cutting techniques, will further optimize your bandsaw’s performance.

Take the time to familiarize yourself with your bandsaw’s capabilities and limitations. Experiment with different materials, thicknesses, and cuts to expand your knowledge and skills. With practice and patience, you will become proficient in using the bandsaw to its fullest potential, achieving precise and impressive results in your woodworking projects.

What Determines the Maximum Thickness that can be Cut on a Bandsaw?

When it comes to determining the maximum thickness that can be cut on a bandsaw, several factors come into play. Here are the key takeaways:

- The power and strength of the bandsaw’s motor play a significant role in determining the maximum thickness that can be cut. A more powerful motor can handle thicker materials with ease.

- The size and capacity of the bandsaw’s blade also affect the maximum thickness that can be cut. A wider and thicker blade is capable of cutting through thicker materials.

- The tension applied to the blade is crucial. Proper tension ensures that the blade stays aligned and cuts smoothly, allowing for thicker materials to be cut effectively.

- The type of material being cut determines the maximum thickness. Harder materials may require a more powerful bandsaw or a different blade to handle increased thickness.

- The operator’s skill and technique play a role in determining the maximum thickness that can be cut. Proper feed rate, blade position, and control contribute to successful cuts through thicker materials.

Frequently Asked Questions

In this section, we’ll answer some commonly asked questions about what determines the maximum thickness that can be cut on a bandsaw. Whether you’re a beginner or an experienced woodworker, understanding the factors that impact the maximum thickness on a bandsaw is essential for achieving accurate and safe cuts.

1. How does the power of the bandsaw affect the maximum thickness that can be cut?

The power of the bandsaw motor plays a crucial role in determining the maximum thickness that can be cut. A more powerful motor generates greater cutting force, allowing the bandsaw to handle thicker and denser materials with ease. Higher horsepower bandsaws are typically capable of slicing through thicker stock without getting bogged down or strained.

If you frequently work with thicker pieces of wood or tougher materials, it’s advisable to invest in a bandsaw with a more powerful motor. This will ensure that your machine can handle the load efficiently, reducing the risk of motor strain or burning out.

2. Can the size of the bandsaw blade affect the maximum thickness that can be cut?

Yes, the size and type of bandsaw blade do have an impact on the maximum thickness that can be cut. Blades with wider widths tend to have greater stability and rigidity, making them better suited for cutting thicker materials. Thicker blades are less likely to deflect or wander off course, resulting in cleaner cuts.

However, it’s important to note that the capabilities of your bandsaw are limited by its design. If your machine is not built to accommodate wider or thicker blades, using them may cause damage or pose safety hazards. Always refer to the manufacturer’s guidelines to determine the maximum blade width recommended for your bandsaw.

3. What role does the tension of the bandsaw blade play in cutting thicker materials?

The tension of the bandsaw blade is critical when it comes to cutting thicker materials. Proper blade tension ensures that the blade remains straight and doesn’t twist or buckle during the cutting process. When cutting thicker stock, a higher tension is usually required to prevent blade deflection and maintain accuracy.

Inspecting and adjusting the tension of your bandsaw blade regularly is essential for achieving good results. Consult your bandsaw’s manual or follow the manufacturer’s recommendations for proper blade tensioning techniques. Remember that inadequate tension can lead to poor cuts and potential risks, while excessive tension may cause premature blade wear and strain on the machine.

4. Does the type of material being cut affect the maximum thickness on a bandsaw?

Yes, the type of material being cut does impact the maximum thickness that can be successfully handled by a bandsaw. Softer woods, such as pine or cedar, are generally easier to cut through compared to denser hardwoods like oak or maple. Thicker pieces of softwood can typically be cut with less strain on the bandsaw compared to the same thickness of hardwood.

Additionally, the moisture content of the material can also affect the cutting performance. Wood with a higher moisture content may be more prone to burning or causing the blade to dull quickly. Therefore, it’s important to consider the type and moisture level of the material when determining the maximum thickness that can be cut on a bandsaw.

5. Are there any safety considerations when cutting thicker stock on a bandsaw?

When cutting thicker stock on a bandsaw, it’s crucial to prioritize safety. The increased thickness of the material can put greater strain on the machine and potentially cause kickback if not handled correctly. Always wear appropriate personal protective equipment (PPE), including safety glasses and hearing protection.

Take your time, use proper cutting techniques, and ensure your material is securely held in place with a suitable fence or guide. It’s also essential to be mindful of the bandsaw’s capacity and not exceed the recommended maximum cutting thickness. Following these safety measures will help prevent accidents and ensure a smooth and successful cutting process.

Summary

Cutting thickness on a bandsaw depends on the size of the saw’s wheels and the blade’s tension. Smaller wheels limit the thickness, while larger ones increase it. Tighter blade tension allows for thicker cuts, whereas looser tension limits the thickness.

The maximum cut on a bandsaw is also affected by the horsepower of the motor. A higher horsepower can handle thicker materials, but lower ones cannot. Ultimately, the maximum thickness that can be cut on a bandsaw varies depending on these factors and the specific model of the bandsaw.