Welcome, curious minds! Have you ever wondered what direction a bandsaw cuts? Well, you’re in for a treat because today we’re diving into the fascinating world of bandsaws! So, grab your safety goggles and let’s get started!

Now, picture this: you have a piece of wood that needs some precise cutting. You want to make sure your bandsaw is slicing through it like a hot knife through butter. But here’s the thing, bandsaws have a secret trick up their sleeve – they cut in a vertical direction! That means the blade moves up and down as it glides through the material. How cool is that?

But hold on, we’re not done yet. Bandsaws also have another nifty feature. They have a table that you can tilt to make angled cuts. So, whether you’re trimming a straight line or creating a fancy bevel, a bandsaw has got you covered.

So, there you have it! A bandsaw cuts in a vertical direction and is versatile enough to tackle a variety of cuts. Now that you know the secret, it’s time to put your newfound knowledge to the test. Happy sawing, my friends!

Understanding the Direction of a Bandsaw Cut: A Comprehensive Guide

Bandsaws are versatile power tools commonly used in woodworking and metalworking. They offer precision and efficiency when it comes to cutting various materials. However, understanding the direction in which a bandsaw cuts is crucial for achieving accurate and clean results. In this article, we will delve into the intricacies of bandsaw cutting and explore the factors that affect the direction of the cut, along with tips for optimal performance.

The Anatomy of a Bandsaw: Unraveling the Blade’s Path

Before we dive into the direction of a bandsaw cut, let’s first familiarize ourselves with the key components of this remarkable tool. At the heart of a bandsaw lies the blade, which circulates along two or more wheels, known as the upper and lower wheels. The blade is guided by guides, which help maintain its alignment and prevent it from wandering off course during the cutting process.

Factors Affecting the Direction of a Bandsaw Cut

Now that we understand the basic structure of a bandsaw, let’s explore the factors that influence the direction in which it cuts. Firstly, the orientation of the blade teeth plays a crucial role in determining the cut’s direction. The teeth on a bandsaw blade are typically aligned in a downward direction, allowing the cut to be made on the downward stroke. This is known as a “downward cutting” bandsaw.

Another significant factor is the layout of the material being cut. When using a bandsaw, it is essential to position the material correctly to achieve the desired cut. For instance, if you want a straight cut, you should ensure that the material is aligned parallel to the blade. Angling the material or using improper techniques may result in an uneven or skewed cut.

Additionally, the feed rate, blade tension, and blade sharpness affect the direction and quality of the cut. Maintaining the appropriate feed rate ensures a controlled and smooth cut, while proper blade tension prevents blade drift and maintains accuracy. Keeping the blade sharp is crucial for achieving clean cuts and preventing unnecessary strain on the tool.

Tips for Achieving Optimal Bandsaw Cuts

Now that we have a good understanding of the factors influencing bandsaw cuts, let’s explore some tips to help you achieve optimal results.

1. Choose the right blade: Different materials require different blade types. Selecting the appropriate blade for your specific cutting needs will greatly improve the quality of your cuts.

2. Set the blade tension correctly: Improper blade tension can lead to a multitude of issues, including inaccurate cuts and premature wear. Refer to the manufacturer’s guidelines to ensure you have the correct tension for your blade.

3. Maintain a consistent feed rate: Avoid rushing the cut or applying excessive pressure. Instead, maintain a steady pace to ensure a smooth and even cut.

4. Use adequate lubrication: Applying a suitable cutting fluid or lubricant can reduce friction, heat, and blade wear, resulting in cleaner cuts and a longer blade lifespan.

5. Regularly inspect and maintain your bandsaw: Keep your bandsaw in top condition by regularly checking for any loose components, ensuring proper blade alignment, and lubricating moving parts. Regular maintenance will maximize its performance and longevity.

Conclusion

Understanding the direction of a bandsaw cut is essential to achieve precise and clean results. Factors such as blade teeth orientation, material layout, and blade tension play a significant role in determining the cut’s direction and quality. By following the tips provided, you can enhance your bandsaw cutting skills and produce professional-grade results. Remember to choose the appropriate blade, maintain consistent feed rates, and perform regular maintenance to optimize the performance of your bandsaw. Happy cutting!

Key Takeaways: What Direction Does a Bandsaw Cut?

- A bandsaw typically cuts in a downward motion.

- The blade of the bandsaw moves in a continuous loop.

- The direction of the cut can be adjusted by tilting the table or using a fence.

- It is important to feed the material into the bandsaw steadily and smoothly.

- Always follow safety precautions and wear protective gear when using a bandsaw.

Frequently Asked Questions

Welcome to our frequently asked questions section about bandsaw cutting direction. Here, we will address common queries related to the direction in which a bandsaw cuts. Whether you’re a woodworking enthusiast or a beginner with a bandsaw, we’ve got your answers covered!

1. How does a bandsaw cut through materials?

A bandsaw cuts through materials by using a continuous metal blade with teeth that move in a continuous loop. The blade is stretched tightly around two wheels, and as the wheels rotate, the blade moves in a downward direction, coming into contact with the material being cut. The downward force, combined with the movement of the blade, creates a cutting action that allows the bandsaw to make precise cuts through various materials.

The cutting action of a bandsaw is typically achieved by using a table where the material being cut is placed. The operator guides the material along the table as the bandsaw blade cuts through it. This setup allows for greater control and accuracy when cutting different shapes and sizes.

2. In which direction does a bandsaw cut?

A bandsaw typically cuts in a downward direction. This means that the blade moves from the top of the material down towards the table, where it is supported. The downward cutting motion of a bandsaw provides several benefits. First, it increases the stability of the material being cut, as the weight of the material helps to keep it in place during the cutting process. Additionally, cutting in a downward direction allows for better control and visibility, as the operator can see the cutting line more clearly.

It’s worth noting that some bandsaws can also be set up to cut in an upward direction, but this is less common. The downward cutting motion is the standard practice for most bandsaw operations, ensuring efficient and precise cuts.

3. Can a bandsaw cut curves and circles?

Yes, a bandsaw is excellent for cutting curves and circles in various materials. The continuous loop of the blade allows for smooth and accurate curved cuts. The narrow width of the blade also helps to minimize waste and allows for tight turns when cutting intricate shapes.

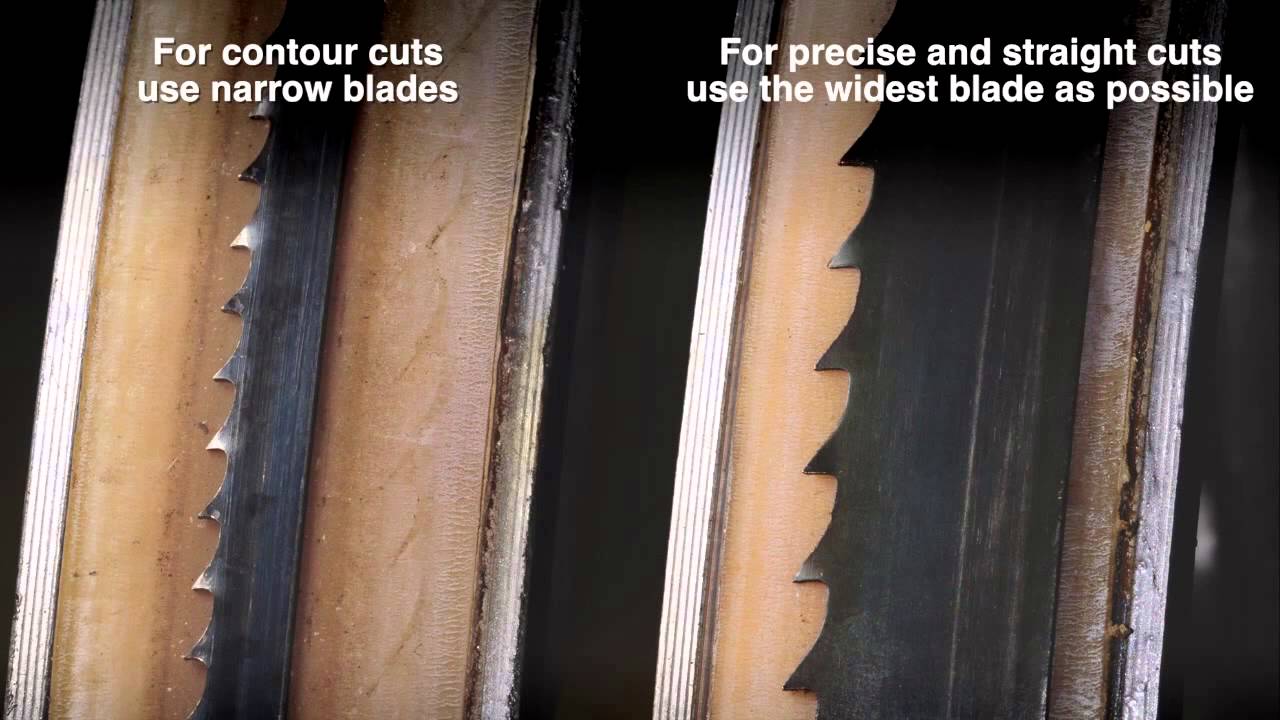

When cutting curves and circles, it’s essential to select the appropriate blade width and tooth configuration. This ensures better control and prevents blade drift, resulting in cleaner and more precise cuts. Additionally, adjusting the speed of the bandsaw can further optimize the cutting process when working on different materials or curves of varying sizes.

4. What safety precautions should I take when using a bandsaw?

When using a bandsaw, safety should always be a top priority. Here are a few key safety precautions to keep in mind:

First, ensure that you are wearing appropriate personal protective equipment, such as safety glasses and hearing protection. Keep your hands away from the blade and use push sticks or guides to maintain a safe distance between your fingers and the cutting area. It’s crucial to keep the workspace clean and free from clutter to prevent accidents.

Additionally, be sure to familiarize yourself with the bandsaw’s manual and follow all safety guidelines provided by the manufacturer. Regularly inspect the blade for any signs of damage or wear and replace it if necessary. Lastly, always unplug the bandsaw when not in use and keep it out of reach of children.

5. Can a bandsaw cut different materials besides wood?

Yes, bandsaws are versatile tools that can cut through various materials, not just wood. They can effectively cut through materials like metal, plastic, and even certain types of ceramics. However, it’s important to use the appropriate blade designed for the specific material you are cutting. Different blades with varying tooth configurations and hardness are available to suit different cutting needs. By selecting the right blade, you can achieve clean and accurate cuts in a variety of materials.

When cutting materials other than wood, it’s essential to adjust the bandsaw’s speed and feed rate accordingly. This helps prevent excessive heat buildup and ensures efficient cutting without damaging the blade or the material being cut. Always refer to the manufacturer’s recommendations and consult experienced users for advice when working with new materials.

Summary

So, here’s what you need to know about which direction a bandsaw cuts. When you’re using a bandsaw, it cuts in a straight line. This means that the blade of the bandsaw will move up and down to make precise cuts in the material you’re working with. Just remember to keep your fingers away from the blade!

In addition, it’s important to mention that the bandsaw can cut both straight lines and curves. The key is to adjust the blade tension and the right speed for the type of cut you want to make. So, whether you’re cutting wood, metal, or plastic, keep these tips in mind to work safely and effectively with a bandsaw. Happy cutting!