Have you ever wondered what direction a lathe should turn? Well, you’re in luck! In this article, we’ll dive into the fascinating world of lathes and uncover the answer to this intriguing question. So, if you’re ready to learn something new and exciting, let’s get started!

Imagine a machine that can shape and carve materials with precision and finesse. That’s exactly what a lathe does. But here’s the twist: a lathe can spin in different directions depending on the task at hand. Curious to know how? Keep reading!

Whether you’re a woodworking enthusiast or just have a curious mind, understanding the direction a lathe should turn is essential. Join us as we explore this topic and unravel the mysteries of lathe rotation. So, buckle up and get ready for an exciting journey into the world of lathes!

When operating a lathe machine, it is crucial to know the correct direction for turning. To determine the direction, you can refer to the spindle rotation. Most lathes have reversible spindles that can rotate clockwise or counterclockwise. The direction depends on the specific task and the type of cutting tool being used. Always consult the lathe’s manual or seek guidance from an experienced operator to ensure proper direction for safe and efficient operation.

The Direction of Turn for a Lathe: Understanding the Basics

A lathe is a versatile and powerful machine used in various industries, from woodworking to metalworking. One common question that often comes up is, “What direction should a lathe turn?” Understanding the correct direction of turn is crucial for safety, precision, and achieving the desired results. In this article, we will delve into the topic and provide you with a comprehensive guide on the direction of turn for a lathe.

Importance of Understanding the Direction of Turn for a Lathe

Before we dive into the specifics of lathe direction, it’s essential to understand why it matters. The direction of turn affects various factors, such as the cutting mechanism, chip formation, and finish quality. By knowing the correct direction, you can prevent accidents, ensure optimal tool performance, and produce accurate and smooth surfaces. Now, let’s explore the different aspects and considerations related to the direction of turn for a lathe.

The Two Standard Directions: Clockwise (CW) and Counterclockwise (CCW)

When it comes to the direction of turn for a lathe, there are two standard options: clockwise (CW) and counterclockwise (CCW). The choice of direction depends on several factors, including the type of lathe, the workpiece, and the specific operation being performed.

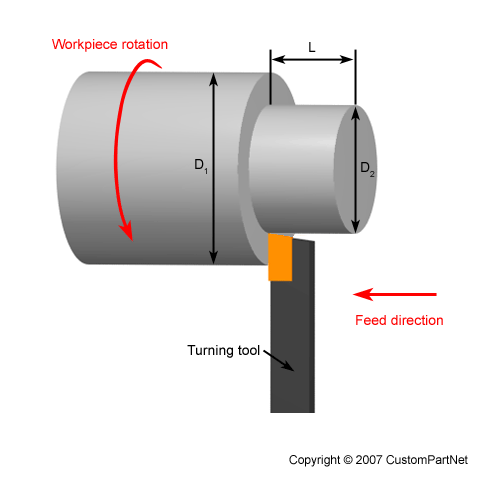

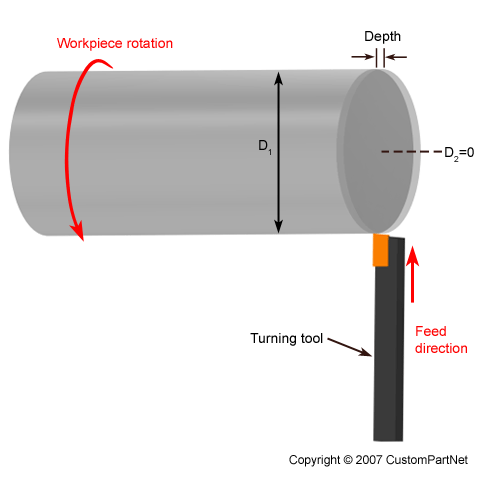

In general, most lathes are designed to rotate the workpiece in a clockwise direction (CW). This is referred to as the “normal rotation” or “right-handed rotation.” Clockwise rotation is commonly used for operations like facing, turning, and boring. It is the default direction that produces consistent results for most cutting processes.

However, there are instances where counterclockwise (CCW) rotation is necessary. This is particularly true for certain applications, such as thread cutting or left-hand turning. In these cases, a lathe with the capability to rotate in reverse is required. It’s important to note that not all lathes have a reverse function, so it’s crucial to determine the specific needs of your project before starting.

The Role of Lathe Chucks in Determining the Direction of Turn

Lathe chucks play a significant role in determining the direction of turn. A chuck is a device used to hold the workpiece securely in place while it rotates. Depending on the chuck’s design and mounting position, the direction of turn can vary.

The most commonly used chuck is the scroll chuck, which is self-centering and designed for clockwise rotation (CW). When using a scroll chuck, the workpiece will rotate in the normal direction when mounted securely.

However, there are also specialized chucks, such as Jacob chucks or independent chucks, which allow for counterclockwise rotation (CCW). These chucks are typically used for specific applications, such as cutting left-hand threads or creating left-handed profiles on the workpiece.

Considerations for Specific Operations and Workpiece Materials

While the default direction of turn for most operations is clockwise (CW), there are certain instances where the choice of direction may vary based on the specific operation or workpiece material.

For example, when performing certain types of machining operations on brittle materials like cast iron or ceramic, counterclockwise (CCW) rotation may be preferred. This is because CCW rotation can help reduce the risk of chipping or fracturing the material.

Similarly, when cutting threads, the direction of turn is determined by the thread type and pitch. Right-hand threads are cut using clockwise (CW) rotation, while left-hand threads require counterclockwise (CCW) rotation. It’s crucial to consult the appropriate threading charts or guidelines to ensure the correct direction is used.

Tips for Determining the Direction of Turn

If you’re unsure about the direction of turn for a specific lathe operation, here are a few tips to help you determine the appropriate direction:

- Consult the lathe manufacturer’s guidelines or user manual. They often provide specific instructions regarding the direction of turn.

- Refer to industry standards and best practices for the specific operation or workpiece material.

- Consider seeking advice from experienced machinists or professionals who have expertise in lathe operations.

- Perform test cuts or trials on a scrap piece of material to determine the optimal direction for achieving the desired results.

Understanding Safety Precautions and Best Practices

Operating a lathe safely is of utmost importance. Here are some key safety precautions and best practices to keep in mind:

- Always wear appropriate personal protective equipment, such as safety glasses, gloves, and protective clothing.

- Ensure the workpiece is securely mounted in the lathe chuck or collet.

- Regularly inspect and maintain the lathe, including checking for loose or damaged components.

- Familiarize yourself with emergency stop procedures and the location of safety devices, such as emergency stop buttons or foot pedals.

- Never reach into the rotating workpiece or attempt to adjust cutting tools while the lathe is in operation.

Choosing the Right Direction for Your Lathe Operations: Summary

The direction of turn for a lathe depends on various factors, including the type of lathe, the specific operation, and the workpiece material. Clockwise (CW) rotation is the default direction for most operations, while counterclockwise (CCW) rotation is used for specific applications like left-hand threading. Understanding how to determine the correct direction and following safety precautions will ensure safe and precise lathe operations. Always consult the lathe manufacturer’s guidelines and industry best practices to make an informed decision before starting any lathe operation.

Key Takeaways: What Direction Should a Lathe Turn?

- A lathe should always turn in the opposite direction of the cutting tool.

- In most cases, lathes turn clockwise when facing the machine.

- Some lathes have the option to change the direction of rotation for specific tasks.

- Always consult the lathe’s manual for the recommended direction of rotation.

- Turning the lathe in the wrong direction can lead to tool breakage and a poor quality finish.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section! Here, we answer some common queries about the direction a lathe should turn. Read on to learn more!

1. Which direction should a lathe turn for normal cutting operations?

For normal cutting operations on a lathe, the spindle should rotate in a clockwise direction when viewed from the headstock end. This means that the workpiece will rotate in a counterclockwise direction. This rotation creates a shearing action between the cutting tool and the workpiece, allowing for smooth and efficient material removal.

It’s important to remember that this direction is considered standard, but some lathes might have the option to reverse the rotation. Always consult your lathe’s manual or manufacturer’s instructions to ensure you have the correct rotational direction for your specific lathe model.

2. Is there a specific reason why a lathe should turn in this direction?

Yes, there is a specific reason why a lathe should turn in the designated direction. The clockwise rotation of the lathe spindle allows for efficient chip removal during cutting operations. The cutting tool moves from right to left, which, when combined with the counterclockwise rotation of the workpiece, ensures that the chips are directed away from the cutting zone.

This prevents the chips from interfering with the cutting process and getting stuck between the tool and the workpiece. It also helps in maintaining a clean and smooth cutting surface. The consistent direction of rotation also promotes consistent cutting forces, reducing the chances of vibrations and improving overall machining quality.

3. Can a lathe’s direction of rotation be reversed?

In some cases, a lathe’s direction of rotation can be reversed. Some lathe models offer this feature for specific applications, such as thread cutting or left-handed turning. However, it’s important to note that not all lathes have this capability.

If you need to reverse the rotation of your lathe, consult the manual or contact the manufacturer to determine if it is possible and how to safely accomplish it. Reversing the rotation might involve adjusting certain settings or switching the motor wiring, so it’s crucial to follow the instructions provided by the lathe’s manufacturer.

4. What are the consequences of turning a lathe in the wrong direction?

Turning a lathe in the wrong direction can lead to various issues. Firstly, it will result in improperly cut surfaces, affecting the overall quality of the workpiece. Additionally, cutting tools are often designed to work optimally in a specific direction, so using them in the wrong direction can cause premature wear and dulling.

Moreover, incorrect lathe rotation can potentially create safety hazards. It may result in the workpiece getting caught, causing it to jam or dislodge, posing a risk to the operator and others nearby. To avoid these consequences, always ensure you’re using the correct direction of rotation for your lathe and specific cutting operation.

5. How can I determine the rotation direction of my lathe?

To determine the rotation direction of your lathe, you can start by referring to the manual or documentation provided by the manufacturer. It typically specifies the correct rotational direction for your lathe model. The manual may also provide information on reversing the direction, if applicable.

If you don’t have access to the manual, you can visually inspect your lathe. Stand at the headstock end and observe the rotation of the spindle when the lathe is turned on. The spindle should rotate in a clockwise direction for normal cutting operations, as mentioned earlier. Take note of any labels or markings on the lathe that indicate the proper rotational direction.

Summary:

When using a lathe, the direction it should turn depends on the type of material you’re working with. For most materials, like wood and plastic, the lathe should turn in a clockwise direction. This gives a smoother finish and reduces the risk of accidents. However, for certain materials, like metal, the lathe should turn in a counterclockwise direction. This helps prevent the cutting tool from digging into the material and causing damage. So, always consider the material you’re working with to determine the direction the lathe should turn.

In addition to the material, the lathe’s manual or the instructions provided will give you specific guidance on which direction to turn the lathe. It’s important to follow these instructions carefully to ensure safe and effective operation. Remember to always wear appropriate safety gear and keep your hands away from the turning tool. By understanding the correct direction for your lathe, you can produce high-quality workpieces while maintaining safety.