Have you ever wondered what lathe dimensions mean? Well, you’re in the right place! Let’s dive into the fascinating world of lathes and decode those mysterious numbers. Whether you’re an aspiring woodworker or just a curious mind, understanding lathe dimensions will give you a deeper appreciation for this versatile tool.

When it comes to lathes, size matters. The dimensions of a lathe refer to its capacity and capabilities. But don’t worry, it’s not rocket science! We’ll break it down for you in simple terms. From swing over bed to distance between centers, we’ll unravel the secrets behind these numbers and help you make sense of it all.

So, if you’re ready to unlock the mysteries of lathe dimensions and discover their significance, let’s embark on this exciting journey together. By the end, you’ll have a solid understanding of what these numbers mean and how they impact your turning projects. Get ready to level up your lathe knowledge!

Understanding Lathe Dimensions: A Comprehensive Guide

Lathe machines are widely used in various industries for cutting, shaping, and machining materials. When it comes to purchasing a lathe, understanding the dimensions is crucial. In this article, we will delve into the details of what lathe dimensions mean, their significance, and how they can impact your machining projects. Whether you are a professional machinist or an aspiring hobbyist, this guide will equip you with the knowledge to make informed decisions when selecting a lathe.

Importance of Lathe Dimensions

The dimensions of a lathe play a vital role in determining its capabilities and compatibility with your specific machining needs. By understanding the various dimensions, you can assess the size, capacity, and performance of the lathe machine. This knowledge ensures that the lathe you choose aligns with your project requirements, avoiding any costly mistakes or limitations.

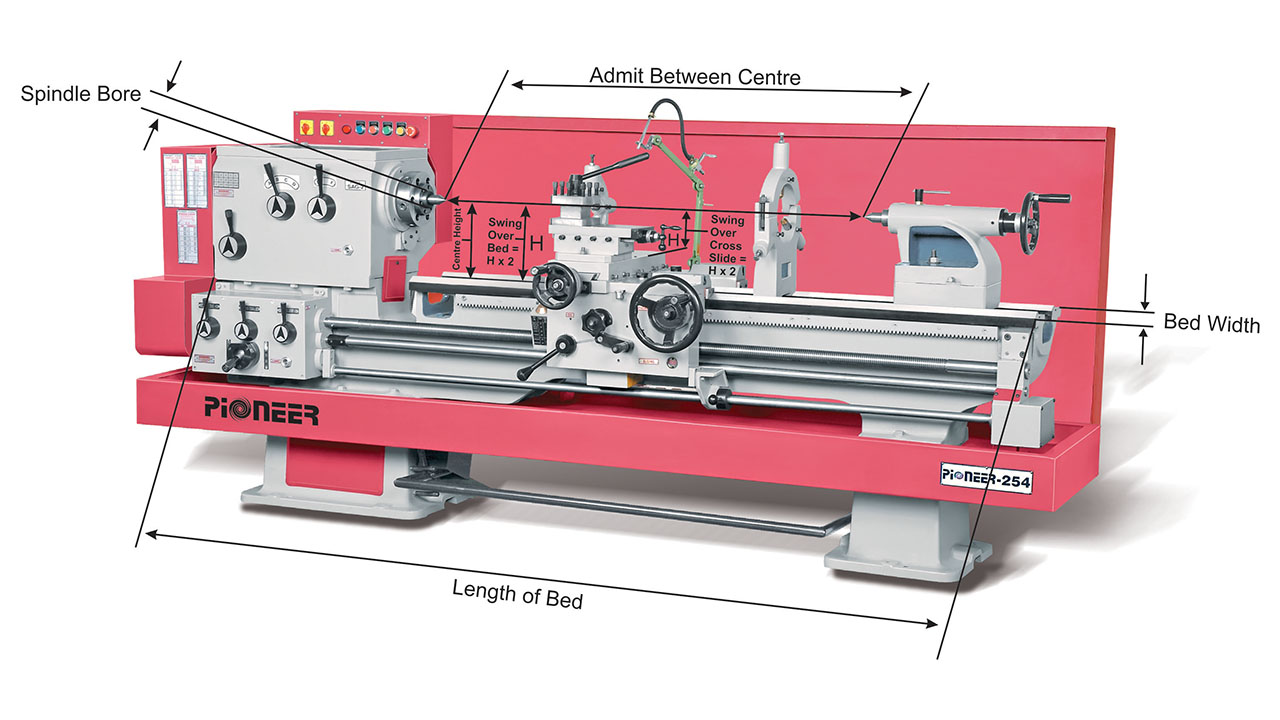

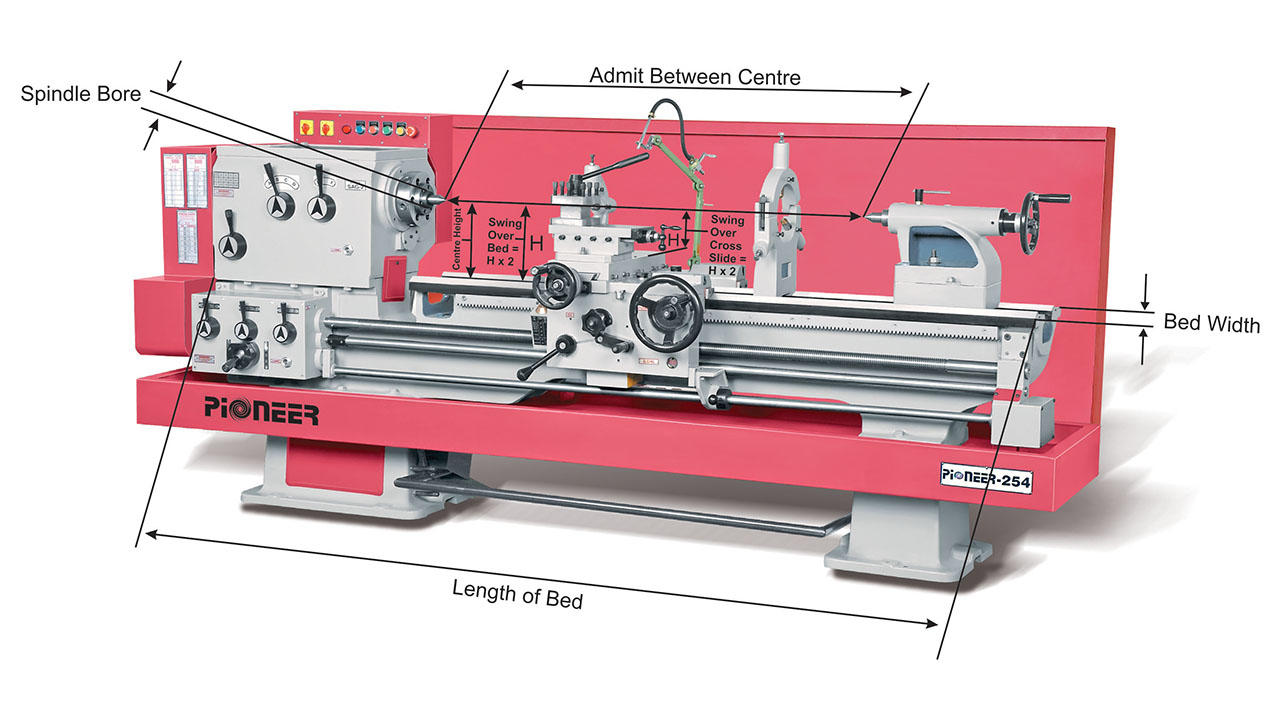

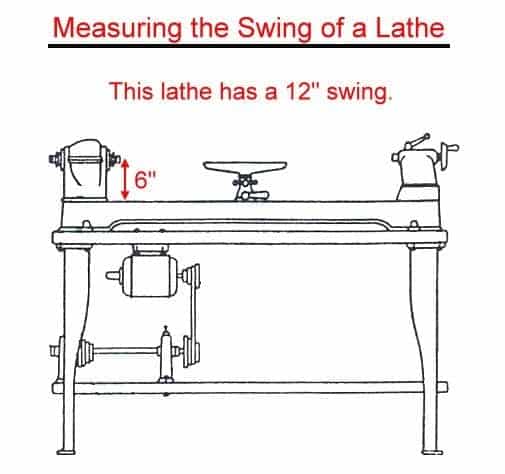

Determining the Swing Over Bed

The term “swing over bed” refers to the maximum diameter of the workpiece that can be accommodated by the lathe. To measure this dimension, you need to determine the distance between the lathe’s bed (the flat horizontal surface) and the centerline of the spindle. Typically, lathe machines are labeled with their swing over bed measurement, indicating the largest workpiece that can be turned on the lathe without any interference. It is crucial to choose a lathe with a swing over bed that allows for the size of workpieces you commonly work on.

Determining the swing over bed involves considering the following aspects:

1. The diameter of the stock: Ensure that the stock you intend to work on will fit comfortably within the swing over bed measurement, allowing for smooth operations.

2. Radius vs. diameter: Remember that when working on a lathe, the radius of the workpiece is halved compared to the diameter. Consider this conversion when assessing the swing over bed.

Understanding the Distance Between Centers

The distance between centers is another critical dimension to consider when selecting a lathe. It refers to the maximum length of the workpiece that can be supported on the lathe between the headstock (the end holding the spindle) and the tailstock (the end with the movable barrel center). This dimension determines the size and length of the workpieces you can successfully turn on the lathe.

A larger distance between centers provides more flexibility in working with longer workpieces. However, it’s essential to consider your specific needs. If you typically work on shorter projects, a lathe with a shorter distance between centers may suffice and save you valuable space.

The Importance of Spindle Bore Diameter

The spindle bore diameter is a crucial dimension for those who engage in projects involving large-diameter workpieces. This dimension refers to the diameter of the hole through the center of the lathe’s spindle. It determines the maximum diameter of the stock that can be inserted through the spindle and worked on.

Choosing a lathe with an appropriate spindle bore diameter is essential to ensure you can accommodate larger workpieces. Insufficient spindle bore diameter will limit the size of stock you can work on and may require additional modifications or workarounds.

Considering Bed Length and Width

The bed dimensions of a lathe are often overlooked but are instrumental in determining the stability, rigidity, and tolerance of the machine. The bed length refers to the distance between the headstock and the tailstock, while the bed width indicates the distance between the lathe’s ways (the flat surfaces on which the carriage slides).

A longer bed provides better support for longer workpieces, reducing the chances of deflection and allowing for consistent and accurate machining. Similarly, a wider bed minimizes vibrations and enhances stability, particularly when working with heavier or bulkier materials. It is advisable to choose a lathe with an adequate bed length and width to ensure optimal stability and precision during machining operations.

Exploring Speed Ranges and Motor Power

In addition to physical dimensions, it is crucial to consider the speed ranges and motor power of a lathe machine. The speed range refers to the variation in spindle speed that a lathe can offer. Different projects require different speed settings to achieve optimal results, so having a lathe with a wide speed range allows for versatility and adaptability.

The motor power determines the overall performance and cutting capabilities of the lathe. Higher motor power enables smoother cutting operations and the ability to work on tougher or denser materials. When considering the motor power, it is essential to evaluate the types of materials and projects you typically work on to ensure your lathe can handle the required workload.

Selecting the Appropriate Lathe Based on Dimensions

Now that we have explored the various dimensions of a lathe and their significance, it’s important to draw connections between the dimensions and your specific needs. Assessing your typical work requirements, such as the size of stock, length of workpieces, and the materials you frequently work with, will guide you in selecting the most suitable lathe machine.

Always bear in mind that investing in a lathe requires careful consideration of all the dimensions and specifications. It is advisable to consult professionals, compare different models, and assess customer reviews before making a final decision. Remember, choosing the right lathe will not only enhance your machining capabilities but also contribute to the overall success of your projects.

The Versatility of Lathe Dimensions

Benefits of a Compact Lathe

A compact lathe often offers flexibility and portability. Its smaller footprint and lighter weight make it suitable for small workshops or hobbyist settings. Additionally, compact lathes are often more affordable compared to larger, industrial-grade lathes. They can handle smaller projects with ease and are ideal for those starting their journey into machining.

Comparing Benchtop and Floor-Standing Lathes

Benchtop lathes and floor-standing lathes offer distinct advantages depending on the scale and type of projects you undertake. Benchtop lathes are smaller, lighter, and more affordable, making them suitable for hobbyists and those with limited space. On the other hand, floor-standing lathes are sturdier, more powerful, and capable of handling larger workpieces. They are commonly found in professional workshops and manufacturing facilities.

Additional Considerations for Lathe Dimensions

Tips for Optimizing Lathe Usage

1. Clearly define your project requirements: Understand the specific dimensions and tolerances you need to achieve before selecting a lathe.

2. Consider future needs: Anticipate potential growth or changes in your projects and select a lathe that can accommodate those needs.

3. Factor in the weight: Consider the weight of the lathe and ensure your workspace can support it adequately.

4. Consult experts: Tap into the knowledge and expertise of professionals or experienced machinists to ensure you make an informed decision.

5. Safety first: Familiarize yourself with the proper safety protocols and ensure the lathe dimensions align with your safety requirements.

Key Features to Look for in a Lathe

1. Digital readout (DRO): A DRO system provides accurate measurements and enhances precision during machining operations.

2. Quick-change tool post: This feature allows for easy and efficient tool changes, saving valuable time during machining.

3. Variable speed control: Opt for lathes with variable speed control to adjust the spindle speed according to your project requirements.

4. Thread-cutting capabilities: If you frequently work on threads, look for lathes with threading functionality to streamline the process.

Investing Wisely in Your Lathe

When it comes to purchasing a lathe, it is essential to invest wisely. Consider your budget, future project requirements, and the reputation of the manufacturer. Opting for a reliable and reputable brand may cost more initially but could save you from facing unexpected repairs or replacements down the line. Research customer reviews, warranties, and after-sales service to ensure a smooth and satisfying experience with your lathe machine.

In conclusion, understanding the dimensions of a lathe is crucial for selecting the right machine to meet your machining needs. By considering swing over bed, distance between centers, spindle bore diameter, bed length and width, speed ranges, and motor power, you can make an informed decision. Additionally, exploring the versatility of lathe dimensions, comparing different types of lathes, and considering additional tips and features will further enhance your lathe usage. Invest wisely in your lathe machine, and it will become an invaluable asset in your machining projects for years to come.

Key Takeaways: What Do Lathe Dimensions Mean?

- Lathe dimensions refer to the size and capacity of a lathe machine.

- Lathe dimensions are typically specified in terms of swing over bed and distance between centers.

- Swing over bed is the maximum diameter of the workpiece that can be accommodated on the lathe.

- Distance between centers is the length of the workpiece that can be supported by the lathe.

- Understanding lathe dimensions is important for choosing the right lathe for your specific needs.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about lathe dimensions. Whether you’re a beginner or an experienced user, understanding lathe dimensions is crucial for proper use and getting accurate results. Read on to learn more!

1. How are lathe dimensions usually measured?

Lathe dimensions are typically measured in terms of swing and center distance. The swing refers to the maximum diameter of workpiece that can be turned on the lathe, while center distance refers to the length between the lathe’s centers. These measurements will determine the size and capacity of the lathe, allowing you to determine its suitability for your specific projects.

The swing is measured by doubling the distance from the center of the lathe to the bed. For example, a lathe with a 16-inch swing would have an 8-inch distance from the center to the bed. Similarly, center distance is measured by the distance between the lathe’s headstock and tailstock centers.

2. What are the implications of lathe dimensions in terms of project size?

The dimensions of a lathe play a crucial role in determining the size of the project you can tackle. A larger swing and center distance will allow you to work on bigger workpieces, while a smaller lathe will have limitations in terms of the maximum diameter and length of the workpiece. It’s important to choose a lathe that matches the size and scope of your projects to ensure smooth and efficient operation.

Additionally, lathe dimensions also affect the stability and rigidity of the machine. A larger lathe with substantial dimensions will offer more stability, minimizing vibrations and allowing for more accurate and precise turning. This is especially important when working on delicate or intricate projects that require high levels of precision.

3. Can lathe dimensions be adjusted or modified?

While the overall dimensions and capacity of a lathe are fixed, there are certain aspects that can be adjusted or modified to some extent. For example, the tool rest and tailstock can be repositioned along the lathe bed, allowing for flexibility in the workpiece placement and support. Additionally, you may have options to attach different size chucks or faceplates to accommodate various workpiece sizes.

However, it’s important to note that these adjustments are limited and within the capabilities of the specific lathe model. Modifying the overall dimensions or increasing the swing and center distance beyond the manufacturer’s specifications is usually not possible without significant modifications or upgrading to a larger lathe.

4. What factors should be considered when choosing a lathe based on its dimensions?

When choosing a lathe, it’s important to consider the specific projects you’ll be working on. First and foremost, assess the size and diameter of the workpieces you’ll be turning. Determine the swing and center distance requirements based on your projects, ensuring that the lathe can accommodate your needs.

Additionally, consider the available workspace in your workshop or garage. Measure the dimensions of the lathe and ensure it fits comfortably in the designated area, allowing for easy maneuverability and proper ventilation. Finally, factor in your own abilities and comfort level with operating larger machines, as bigger lathes may require more experience and skill to handle effectively.

5. Are there any standards or recommended dimensions for lathes?

There are no set standards or universally recommended dimensions for lathes, as the requirements vary depending on the specific projects and applications. The dimensions of a lathe should be chosen based on the workpiece sizes you’ll be handling and the level of precision required.

However, different manufacturers offer a range of lathe models with varying dimensions to cater to different needs. It’s advisable to consult the manufacturer’s specifications and recommendations when choosing a lathe, as they will provide guidance on the ideal dimensions for various types of projects and user levels.

Summary

So, what do lathe dimensions mean? Well, the dimensions of a lathe refer to its size and capacity. The length, swing, and distance between centers are the three main dimensions that determine what you can do with a lathe. The length tells you how long of a piece you can work on. The swing is the maximum diameter that can fit on the lathe. And the distance between centers is the maximum length between the headstock and tailstock. Understanding these dimensions will help you choose the right lathe for your projects.

Additionally, it’s important to know that lathe dimensions can vary between different lathe models. So if you’re looking to buy a lathe, make sure to review the specifications and consult with experts to ensure it meets your requirements. Finally, don’t forget to consider your workspace and any additional features or accessories you may need. With these factors in mind, you’ll be ready to embark on your lathe turning adventures!