Are you curious about what an engine lathe is? Well, let me break it down for you in a fun and engaging way!

So, what do you mean by engine lathe? An engine lathe is a super cool machine used for shaping metal. It’s like a sculptor’s tool, but instead of clay or stone, it works with materials like steel and aluminum.

Now, you might be wondering, “Why is it called an engine lathe?” Well, that’s because it was originally powered by an engine. Imagine a machine with a motor that spins the metal piece while you shape it with various tools. How awesome is that?

In a nutshell, an engine lathe is a powerful and versatile machine that allows you to craft intricate metal creations. It’s like a metal artist’s dream come true! Stick around to learn more about how an engine lathe works and the amazing things you can create with it. Let’s dive in!

Understanding the Engine Lathe: A Comprehensive Guide

Welcome to our in-depth guide on engine lathes. In this article, we will explore the ins and outs of engine lathes, from their definition and components to their applications and benefits. Whether you’re a seasoned machinist or simply curious about the world of metalworking, this guide will provide you with all the essential information you need to know about engine lathes.

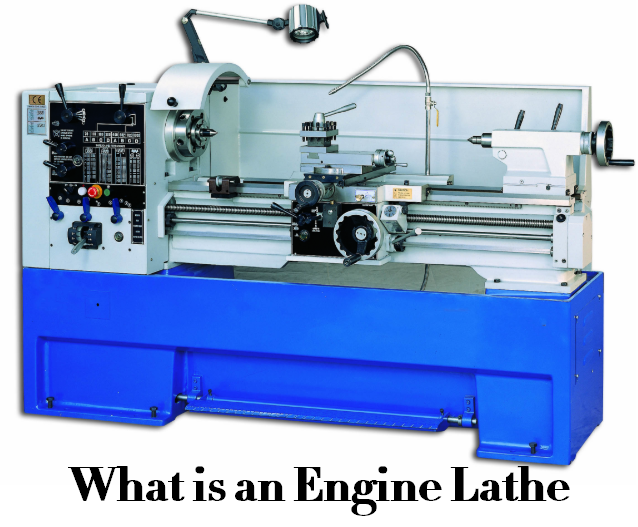

What is an Engine Lathe?

At its core, an engine lathe refers to a type of lathe machine that is commonly used in metalworking and woodworking industries. It is a versatile tool designed for turning, facing, and threading operations on various workpieces. Engine lathes are known for their precision and power, making them a crucial component in manufacturing processes.

Engine lathes consist of several key components, including the bed, headstock, tailstock, carriage, and tool post. The bed is the horizontal base of the lathe, providing stability and support. The headstock houses the main spindle, which rotates the workpiece. The tailstock serves as a support for longer workpieces and provides additional rigidity. The carriage moves along the length of the bed and holds the cutting tools, while the tool post holds the cutting tools securely in place.

Benefits of Engine Lathes

Engine lathes offer a wide range of benefits in the manufacturing industry. Firstly, they allow for precise and accurate machining, making it possible to create intricate and complex workpieces. The ability to control the speed and feed rate of the lathe ensures optimal results.

Secondly, engine lathes are versatile machines, capable of handling different types of materials and workpieces. From turning small components to larger cylinders and shafts, engine lathes can accommodate various sizes and shapes, making them suitable for a diverse range of applications.

Additionally, engine lathes are relatively easy to operate and maintain. With proper training and knowledge, operators can quickly become proficient in using the machine, resulting in increased productivity and efficiency. Moreover, engine lathes are known for their durability and longevity, making them a wise investment for manufacturing businesses.

Applications of Engine Lathes

Engine lathes find applications in numerous industries, including automotive, aerospace, and general machining. Some common uses of engine lathes include:

- Turning and facing operations: Engine lathes are often used to shape and smooth workpiece surfaces, creating precision cylindrical shapes.

- Threading: The lathe’s power and precision make it ideal for creating threaded components such as bolts and screws.

- Boring: Engine lathes can bore holes accurately, ensuring proper fit and alignment of parts.

- Tapering: The lathe’s ability to create tapered workpieces is crucial in industries that require precise fittings, such as plumbing and hydraulic systems.

Engine lathes are also utilized in tool and die making, prototype development, and repair work. Their versatility and accuracy make them indispensable tools in a wide range of manufacturing processes.

Choosing the Right Engine Lathe for Your Needs

When selecting an engine lathe, there are several factors to consider. These include the size of the workpiece, the desired level of precision, the materials to be machined, and the specific operations required. It is crucial to assess your needs and requirements to ensure the lathe you choose can meet your expectations.

Size and Capacity

The size and capacity of the lathe refer to its swing over bed and distance between centers. The swing over bed determines the maximum diameter of the workpiece that can be accommodated, while the distance between centers determines the maximum length of the workpiece. Consider the size and dimensions of the workpieces you plan to machine to select a lathe with suitable capacity.

Motor Power

The motor power of the lathe determines its ability to handle different materials and cutting operations. Higher horsepower allows for machining harder materials and performing more demanding operations. Consider the types of materials and operations you will be working with to select a lathe with an appropriate motor power.

Features and Accessories

Additional features and accessories can enhance the versatility and functionality of the lathe. Consider features such as variable speed control, thread cutting capabilities, and digital readouts for increased precision and convenience. Pay attention to the availability of accessories such as chucks, tool holders, and steady rests, which can expand the lathe’s capabilities.

Proper Maintenance and Safety Precautions

To ensure the longevity of your engine lathe and the safety of operators, proper maintenance and adherence to safety precautions are essential. Regular cleaning, lubrication, and inspection of the lathe’s components are necessary to prevent wear and damage. Operators should receive adequate training on the safe operation of the lathe, including proper tool handling, tool selection, and understanding of the lathe’s safety features.

Conclusion

Engine lathes are invaluable tools in the manufacturing industry, allowing for precise machining and versatility. With their ability to handle various materials and perform a wide range of operations, engine lathes play a vital role in creating intricate and functional workpieces. By understanding the components, applications, and benefits of engine lathes, you can make informed decisions when it comes to selecting and operating these essential machines.

Key Takeaways:

- An engine lathe is a type of lathe machine used to shape and cut metal materials.

- It uses a rotating spindle to hold and rotate the workpiece while cutting tools remove material.

- Engine lathes are commonly used in metalworking industries for various operations like turning, facing, knurling, and drilling.

- These lathes are versatile and can be used for both small and large-scale projects.

- Engine lathes are essential tools for manufacturing and repairing metal parts.

Frequently Asked Questions

Engine lathe, also known as a center lathe, is a type of lathe machine commonly used in metalworking and woodworking industries. It is designed to perform various operations like turning, facing, and threading on cylindrical workpieces. Engine lathes are versatile and can be manually operated or automated. Here are some frequently asked questions about engine lathes:

1. How does an engine lathe work?

An engine lathe works by rotating a workpiece on its axis while a cutting tool is applied to shape or remove material. The workpiece is held tightly in a chuck or collet, and the cutting tool is manually or automatically fed against the rotating workpiece. This process allows for precision machining and the creation of cylindrical shapes.

The operator adjusts the speed of the engine lathe depending on the material being worked on and the desired outcome. They can control the depth and width of the cuts using handwheels, levers, or even computer numerical control (CNC) systems for automated lathes.

2. What are the different types of operations possible with an engine lathe?

An engine lathe can perform a wide range of operations such as turning, facing, chamfering, grooving, knurling, threading, drilling, and boring. Turning involves the removal of material from the outer surface of a workpiece to create a cylindrical shape. Facing is the process of creating a flat surface at the end of a workpiece. Chamfering involves creating beveled edges, while grooving provides space for a retaining ring or groove. Knurling is a process that creates a textured pattern on the surface of a workpiece, mainly for enhanced grip or aesthetic purposes. Threading is done to create screw threads, and drilling and boring involve creating holes of different sizes and depths.

These operations can be performed manually or using computer-controlled machines, offering precision and accuracy in metal and woodwork projects.

3. What are the benefits of using an engine lathe?

Using an engine lathe offers several benefits in metalworking and woodworking industries. First, it provides high precision and accuracy in creating cylindrical shapes and threaded surfaces, ensuring a perfect fit and finish. Engine lathes are versatile and can handle a variety of materials, such as metal, wood, and plastic. They allow for customization and the creation of complex shapes and designs.

Furthermore, engine lathes are relatively easy to set up and operate, making them suitable for both beginners and experienced machinists. They are cost-effective compared to more advanced CNC machines and can be manually operated, offering flexibility and control throughout the machining process.

4. What safety precautions should be taken when operating an engine lathe?

When operating an engine lathe, it is important to prioritize safety. Here are some precautions to follow:

– Always wear appropriate personal protective equipment, including safety glasses or goggles, hearing protection, and gloves.

– Ensure the workpiece is securely held in the chuck or collet and that it is properly aligned before starting the machine.

– Keep the work area clean and organized to prevent tripping hazards.

– Use cutting tools with care, ensuring they are in good condition and properly secured in the tool holder.

– Avoid loose clothing, jewelry, or long hair that could get caught in the lathe’s moving parts.

– Follow safe operating procedures and consult the manufacturer’s manual for specific guidelines.

5. What are the main differences between an engine lathe and a CNC lathe?

The main difference between an engine lathe and a CNC lathe lies in the level of automation and control. An engine lathe is manually operated, requiring the operator to control the cutting tools, speed, and feed manually. On the other hand, a CNC lathe is controlled by a computer program, allowing for automated machining processes.

CNC lathes offer higher precision, repeatability, and speed compared to engine lathes. They can perform complex operations with minimal human intervention, making them ideal for large-scale production. However, engine lathes are more affordable and versatile, offering flexibility and customization options for smaller-scale projects or when manual control is preferred.

Summary

An engine lathe is a really cool machine used to shape and cut metal. It has some important parts like the bed, headstock, and tailstock. The bed is a big flat surface that holds the workpiece. The headstock holds the motor that spins the workpiece. And the tailstock supports the other end of the workpiece. With an engine lathe, you can make all kinds of cool metal things like screws and gears. It’s super handy for machining and shaping metal parts.

So, the engine lathe is like a powerful builder tool for making metal stuff!