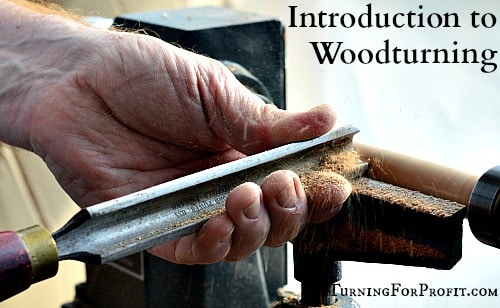

Are you curious about wood turning and wondering what you need to get started? Well, you’re in the right place! Wood turning is a fascinating craft that allows you to transform a piece of wood into beautiful and functional objects.

So, what exactly do you need for wood turning? Don’t worry, it’s not as complicated as it may seem. To begin your wood turning journey, you’ll need a few essential tools and materials. Whether you’re a beginner or an experienced woodworker, having the right equipment is crucial for successful and enjoyable wood turning projects.

In this article, we’ll walk you through the key items you need for wood turning, from the lathe itself to the various cutting tools and safety equipment. So grab your curiosity and let’s dive into the exciting world of wood turning!

If you’re interested in wood turning, here are some essential tools and materials you’ll need to get started:

- A lathe: This machine spins the wood and allows you to shape it.

- Chisels and gouges: These cutting tools help you shape the wood on the lathe.

- Safety gear: Don’t forget eye protection, a face shield, and dust mask to stay safe.

- Wood: Choose a softwood or hardwood depending on your preference and project.

- Sanding materials: Sandpaper or sanding pads will help you achieve a smooth finish.

With these basics, you’ll be ready to start your wood turning journey!

The Essentials for Woodturning: What Do You Need to Get Started?

Woodturning is a captivating craft that allows you to transform blocks of wood into beautiful and functional objects. Whether you’re a beginner or a seasoned woodturner, having the right tools and equipment is crucial for successful and enjoyable projects. In this article, we will explore the essential items you need to get started with woodturning and delve into the details of their importance and functionality.

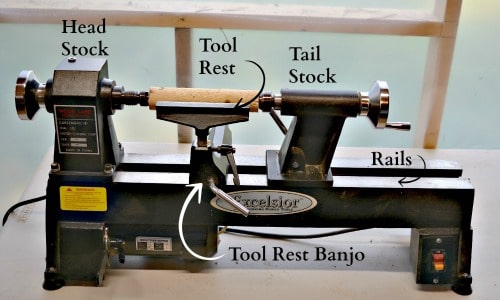

1. Lathe: The Foundation of Woodturning

An indispensable tool for woodturning, a lathe is the centerpiece of any woodturner’s workshop. A lathe is a machine that holds the wood and rotates it at various speeds, allowing you to shape and sculpt it into desired forms. When choosing a lathe, consider factors such as motor power, swing capacity (the maximum diameter of the wood you can work with), and the type of lathe (such as benchtop or freestanding).

Additionally, make sure to invest in reliable accessories like a faceplate, chuck, and steady rest. A faceplate helps secure the wood on the lathe, while a chuck provides a secure grip on the wood during turning. The steady rest supports long and thin pieces, reducing the risk of vibration and instability. These accessories maximize the versatility of your lathe and simplify the woodturning process.

Remember, safety should always be a priority when working with a lathe. Use proper eye protection, avoid loose clothing and jewelry, and secure the workpiece firmly before starting the lathe to prevent accidents or injuries.

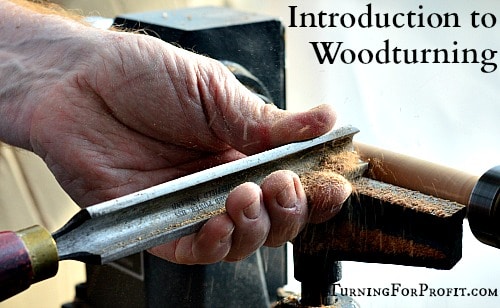

2. Turning Tools: Shaping Wood with Precision

A set of high-quality turning tools is paramount for achieving precision and finesse in your woodturned projects. The most common types of turning tools include gouges, skews, parting tools, and scrapers.

Gouges are versatile tools that are used for hollowing out and shaping the wood’s surface. Skews are excellent for creating smooth and accurate cuts with clean edges. Parting tools help separate the wood into smaller pieces, while scrapers are handy for finishing and refining the wood’s surface.

Investing in high-quality, sharp turning tools is essential. Dull tools can make woodturning difficult and result in rough surfaces and inaccurate cuts. Regularly sharpen your tools using a sharpening system and keep them honed to ensure optimal performance and clean cuts.

3. Safety Equipment: Protecting Yourself and Your Workshop

Woodturning is a hands-on craft that requires careful attention to safety. Alongside the lathe and turning tools, equipping yourself with appropriate safety equipment is crucial for a risk-free woodturning experience.

Eye protection, such as safety goggles or a face shield, is essential to shield your eyes from flying wood chips, dust, and other potential hazards. Additionally, dust collection systems or air filtration units help remove airborne particles, minimizing health risks associated with wood dust inhalation.

Another critical safety measure is the use of a faceplate or chuck that securely holds the wood on the lathe. This minimizes the risk of the wood dislodging during turning and causing injuries.

4. Workbench and Supporting Tools: Creating a Solid Foundation

A sturdy workbench is crucial for stability and support while woodturning. It should be of an appropriate height to ensure a comfortable working position, offering enough space to maneuver the tools and wood effectively. Additionally, having a tool rest extension provides further support, especially for larger turning projects.

Investing in supporting tools such as calipers, dividers, and measuring tools enables accurate measurements and precise shaping. These tools help you achieve consistency in your woodturning projects and ensure an aesthetically pleasing outcome.

Consider incorporating a sharpening station into your woodworking space. Properly maintained and sharp turning tools are essential for achieving clean cuts and preventing accidents. A sharpening station with sharpening stones or a sharpening system makes the honing process more efficient and convenient.

5. Wood and Finishing Supplies: Enhancing the Beauty of Your Projects

A wide variety of wood species can be used for woodturning, each offering unique grain patterns, colors, and characteristics. Choose woods suitable for turning, such as hardwoods (like maple or oak) or more exotic options (like rosewood or ebony), based on your project requirements.

Finishing supplies, such as sandpaper, sealers, and wood finishes, are essential for delivering a polished and smooth final product. Sandpaper of various grits helps create a refined surface, while sealers and finishes protect the wood and enhance its natural beauty.

Research different finishing techniques and experiment with various products to find the best combination for achieving the desired results. Always follow proper safety precautions when working with finishing supplies, such as proper ventilation and using appropriate protective gear.

Choosing the Right Woodturning Tools and Accessories

Now that we have covered the essentials needed for woodturning, let’s dive deeper into some additional tools and accessories that can elevate your woodturning experience and broaden your creative possibilities.

1. Hollowing Tools: Unleashing Creativity in Hollow Forms

Hollowing tools allow woodturners to create intricate hollow forms like bowls, vases, and goblets. These specialized tools come in various shapes and sizes. Some popular options include spindle gouges with long flutes, scrapers, or specialized hollowing tools with curved plunging tips.

When working with hollowing tools, it is essential to maintain stability and control throughout the hollowing process. Take your time to understand the tool’s functionality and practice on smaller projects before attempting larger-scale hollow forms.

Remember to wear appropriate eye protection and ensure that the lathe speed and tool handling techniques are suitable for hollowing. Safety should always be a priority when working with hollowing tools, as the process involves removing a significant amount of material from the center of the wood.

2. Chucks and Jaws: Versatile Holding and Expanding Options

A chuck is a must-have accessory for woodturning, as it provides a secure grip on the wood while allowing for easy and convenient changes between projects. Chucks consist of removable jaws that can be adjusted to hold different sizes and shapes of wood securely. This versatility eliminates the need for faceplates and simplifies the woodturning process.

Various types of jaws are available, offering different gripping mechanisms like standard jaws, dovetail jaws, or specialized jaws for holding bowls, pen blanks, and other specific projects. Investing in different sets of jaws greatly enhances your options and capabilities as a woodturner, allowing you to tackle a wide range of projects with ease.

When selecting chucks and jaws, ensure compatibility with your lathe and consider factors such as jaw size range, gripping strength, and ease of installation. Research the available options and consult experienced woodturners for recommendations based on your specific needs.

3. Dust Collection Systems: Keeping Your Workshop Clean

Woodturning produces a significant amount of wood chips and fine dust particles. A dust collection system helps keep your workshop clean and maintains a healthy work environment. There are various types of dust collection systems available, ranging from portable units to centralized systems.

Depending on the size of your workshop and the volume of woodturning you undertake, choose a dust collection system that suits your needs. These systems typically consist of a high-powered vacuum or dust extractor, ducting, and collection bags or containers. Ensure that the system is properly installed and that you follow maintenance protocols to keep it running efficiently.

Having a dust collection system not only keeps your workshop tidy but also reduces health risks associated with wood dust inhalation. Ensure that you position the system strategically to capture the dust and chips generated during woodturning effectively.

4. Specialty Turning Tools: Expanding Possibilities

As you progress in your woodturning journey, you may want to explore niche techniques and project types. Specialty turning tools cater to specific requirements and open up new creative possibilities.

Some examples of specialty turning tools include texturing tools for creating unique surface patterns, captive ring tools for constructing decorative rings on spindle projects, and thread chasing tools for generating delicate threads on boxes or lids.

When venturing into specialty turning tools, take the time to understand their proper usage and practice on scrap wood before attempting more complex projects or working on valuable pieces. Specialty tools often require additional skills and attention to detail, but the results can be truly stunning.

Safety First: Tips for a Safe Woodturning Experience

Woodturning is an exciting and fulfilling hobby, but it requires caution and adherence to safety guidelines. Here are a few tips to keep in mind for a safe woodturning experience:

1. Always wear appropriate safety gear, including eye protection, ear protection, and respiratory protection to prevent injuries and health hazards.

Safety goggles or a face shield protect your eyes from flying debris, while ear protection guards against the loud noise generated by the lathe. A properly fitted dust mask or respirator helps filter out dust particles.

2. Familiarize yourself with the safety features of your lathe and ensure they are in proper working condition.

Be aware of emergency stop buttons, spindle lock mechanisms, and other safety features provided by the manufacturer. Regularly inspect and maintain your lathe to ensure optimal performance and safety.

3. Keep your work area clean and well-lit.

Clear away wood chips, debris, and clutter from your work area to minimize the risk of slips, trips, and falls. Adequate lighting enhances visibility and reduces the chances of mistakes or accidents due to poor visibility.

4. Practice proper tool handling techniques and maintain sharp tools.

Always hold the tools firmly and position your body in a stable and balanced stance. Keep your turning tools sharp to ensure clean cuts and avoid forcing the tool, which can lead to slips or accidents.

5. Take breaks and avoid rushing.

Woodturning can be an absorbing and time-consuming activity. Remember to take regular breaks to rest and refocus. Avoid rushing through your projects, as haste can compromise safety and the quality of your work.

By following these safety tips and using your tools and equipment responsibly, you can enjoy the art of woodturning while keeping yourself and others safe.

In conclusion, woodturning is an enriching craft that offers immense creative possibilities. By understanding the essential tools and equipment required for woodturning, you can embark on your woodturning journey with confidence and excitement. Remember to prioritize safety, invest in high-quality tools, and continuously refine your skills. Happy woodturning!

Key Takeaways: What Do You Need for Wood Turning?

- Wood lathe: The main tool for wood turning.

- Lathe tools: Chisels and gouges to shape the wood.

- Face mask and goggles: To protect against dust and debris.

- Wood blanks: Blocks of wood for turning projects.

- Sanding materials: Sandpaper and sanding pads for finishing.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section on wood turning! Here, we’ll address common queries regarding the tools and supplies needed for this craft. Whether you’re a beginner or exploring new techniques, we’ve got you covered. Keep reading to learn more!

1. What are the essential tools for wood turning?

Wood turning requires a few key tools to get started. One essential tool is the lathe, which is used to hold and rotate the wood while you shape it. You’ll also need a set of turning chisels, which come in various shapes and sizes for different cutting tasks. Some commonly used chisels include gouges, scrapers, and parting tools. Additionally, a sharpening system is crucial to keep your tools in top condition.

To ensure accuracy and safety, it’s recommended to have a face shield and a set of woodturning calipers. A sturdy workbench or stand is also important for stability. While these are just the basics, you can always expand your tool collection as you gain experience and tackle more advanced projects.

2. What kind of wood is best for wood turning?

When it comes to wood turning, the ideal wood depends on the project at hand. Some popular choices for turning projects include hardwoods like maple, cherry, and oak. These woods are known for their durability and ability to hold intricate details. Softwoods like pine and cedar can also be used, but they tend to be more prone to dents and scratches.

Seasoned wood is preferred for turning, as it has a lower moisture content and is less likely to warp or crack during the drying process. It’s important to note that green, or freshly cut, wood can be used for certain projects but requires different techniques and considerations. Ultimately, the best wood for your project will depend on your desired outcome, budget, and availability.

3. Do I need a special workspace for wood turning?

While it’s not absolutely necessary to have a dedicated workspace for wood turning, having a designated area can greatly enhance your experience. A spacious and well-ventilated workshop or garage is ideal, as it provides a safe and controlled environment. It’s important to have sufficient lighting and ventilation to ensure comfort and visibility while you work.

A sturdy workbench or lathe stand is essential to provide stability and support. To keep your workspace organized, consider investing in storage solutions for your tools, wood blanks, and other supplies. It’s also recommended to have a dust collection system or a shop vac to keep the area clean and free of wood chips and debris.

4. What safety precautions should I take when wood turning?

Wood turning involves sharp tools and fast-spinning wood, so safety precautions are crucial. Always wear proper personal protective equipment, including safety glasses or a full-face shield, to protect your eyes from flying debris. A dust mask or respirator is also recommended to prevent inhalation of fine wood particles and dust.

When working on the lathe, ensure that your clothing, hair, and jewelry are secured and out of the way to prevent entanglement. Take the time to familiarize yourself with the proper techniques for using each tool and always work at a comfortable speed. It’s also important to keep your tools properly sharpened to reduce the risk of accidents. Lastly, be mindful of proper handling and disposal of wood shavings and sawdust to prevent fire hazards.

5. How can I improve my wood turning skills?

Improving your wood turning skills takes practice and dedication. One way to enhance your skills is by attending workshops or joining a local woodturning club. These opportunities allow you to learn from experienced turners and gain valuable insights and tips.

Experimenting with different types of wood and trying new techniques can also help you grow as a woodturner. Take on challenging projects to expand your skillset and push your creativity. Don’t forget to document your progress and learn from any mistakes you make along the way. Above all, be patient with yourself and enjoy the process of learning and creating beautiful turned pieces.

The Wood Turning Lathe A to Z for Beginners, a Roger Webb easy learning tutorial

Summary

Ready to start your wood turning journey? You’ll need a few key things. First, a lathe – a machine that spins the wood. Next, some tools – like gouges and scrapers – to shape and smooth the wood. Safety gear is a must too, such as goggles and a face shield. And don’t forget the sandpaper and finish to give your project that final polish. With these essentials, you’ll be well on your way to creating beautiful turned wood pieces!

But remember, safety comes first. Always follow proper procedures and use protective gear when turning wood. And don’t forget to have fun and be creative. Happy turning!