Are you wondering what to put under plywood when cutting? Look no further for the answer! When it comes to cutting plywood, it’s important to have the proper support in place. But what exactly should you use?

Well, fear not, young DIY enthusiast! In this article, we’ll explore the options for what to put under plywood when cutting. Whether you’re a budding carpenter or just tackling a small DIY project, we’ve got you covered with all the information you need.

So, fasten your tool belt and get ready to learn about the best practices for supporting plywood while cutting. Let’s dive in and discover the secrets to smooth and accurate plywood cuts!

What Do You Put Under Plywood When Cutting?

1. Importance of Using a Cutting Surface

When it comes to cutting plywood, having a proper cutting surface is essential to ensure accuracy, protect your tools, and prevent damage to your workpiece. Without a suitable surface underneath, you risk splintering the plywood, damaging the saw blade, or causing uneven cuts. Therefore, it is crucial to understand what you should put under plywood when cutting.

The primary function of the cutting surface is to provide support and stability while allowing the saw blade to penetrate the wood without any hindrances. It helps to minimize tear-out and splintering, resulting in cleaner and smoother cuts. Additionally, using a proper cutting surface also extends the life of your saw blade by reducing wear and tear.

There are various options available for a cutting surface, depending on your workspace and the tools you have. Let’s explore some of the most common choices.

2. Using a Sawhorse and Plywood

A sawhorse is a popular choice for creating a sturdy and elevated platform for cutting plywood. It consists of two or more stands with horizontal beams, providing a stable foundation for your workpiece. To create a suitable cutting surface using a sawhorse, you can place a sheet of plywood on top of the stands and secure it with clamps or screws.

Using a sawhorse and plywood combination offers several benefits. Firstly, it elevates the plywood, allowing you to make cuts comfortably without having to bend over. This ergonomic advantage reduces strain on your back, making the cutting process more comfortable. Additionally, a sawhorse provides excellent stability, preventing the plywood from moving or vibrating during cutting, resulting in cleaner and more precise cuts.

Furthermore, by using a sacrificial piece of plywood on top, you can protect the surface of your workbench or the sawhorse itself. This sacrificial layer takes the brunt of the saw cuts, preventing any damage to the underlying structure.

3. Portable Workbench with Clamps

If you don’t have access to a dedicated sawhorse or require more flexibility in your workspace, a portable workbench with clamps can serve as an excellent cutting surface for plywood. These workbenches often come with built-in clamping systems, allowing you to secure the plywood firmly in place.

A portable workbench provides the advantage of mobility, as it can be easily moved around your workshop or even taken to job sites. It offers a stable and level surface for cutting plywood, ensuring accuracy and clean cuts. With the added benefit of clamps, you can securely hold the plywood in position, minimizing any chances of movement during cutting.

Additionally, portable workbenches often feature built-in storage compartments or tool holders, providing convenience and organization for your cutting tools.

4. Using Foam Board Insulation

For those looking for a budget-friendly option, foam board insulation can also serve as a suitable cutting surface for plywood. Made from rigid foam panels, foam board insulation is lightweight, easy to handle, and provides a smooth and flat surface for cutting.

To use foam board insulation as a cutting surface, you would need to secure it onto a flat and stable base, such as a workbench or table. By attaching the foam boards together using adhesive or clamps, you can create a large enough surface area to accommodate the size of your plywood sheets.

The foam boards offer good support and cushioning, reducing the risk of splintering or tear-out. However, it is important to note that foam board insulation may not be as durable as other options and may require occasional replacement or reinforcement.

5. Clamping a Plywood Sheet to a Workbench

If you have a sturdy workbench with a flat surface, clamping a plywood sheet directly to the workbench can be a simple and effective method for creating a cutting surface. This option is particularly convenient if you have limited space or resources.

To clamp the plywood sheet securely, you can use adjustable woodworking clamps or even large C-clamps. Make sure to position the clamps along the edges of the plywood, applying adequate pressure to prevent any movement during cutting.

While clamping a plywood sheet to a workbench provides stability, it is important to protect the workbench surface from any potential damage. Using sacrificial pieces, such as scrap plywood or cardboard, between the workbench and the plywood sheet can help to prevent scratches or gouges.

6. Layering Scraps of Plywood

If you are in a pinch and don’t have access to dedicated cutting surfaces like sawhorses or workbenches, you can utilize scraps of plywood to create a makeshift cutting surface. By layering and aligning the scraps, you can build up a stable platform that provides support for cutting plywood.

Although this method may not offer the same level of stability as dedicated cutting surfaces, it can still be effective for smaller projects or when precise cuts are not a top priority. Make sure to align the scraps flush with each other and secure them using clamps or screws to minimize any movement.

While using scraps of plywood can be a temporary solution, it is important to note that it may not provide the same level of protection for your tools or ensure consistent accuracy in cutting.

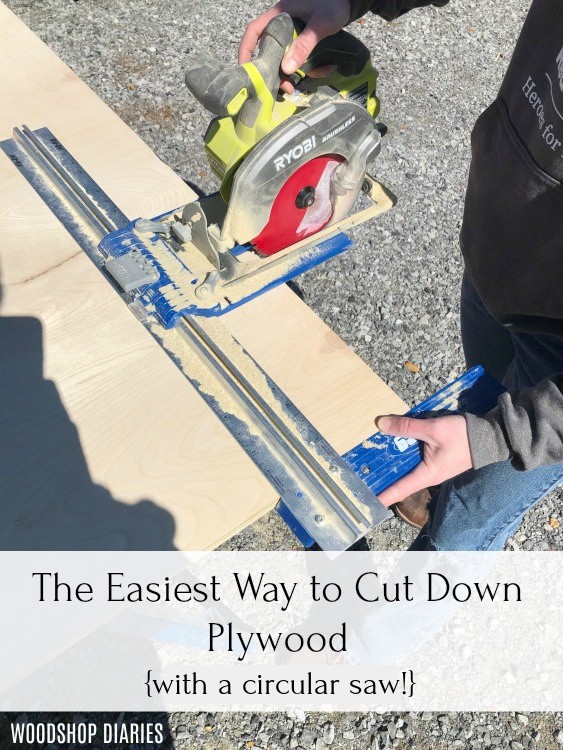

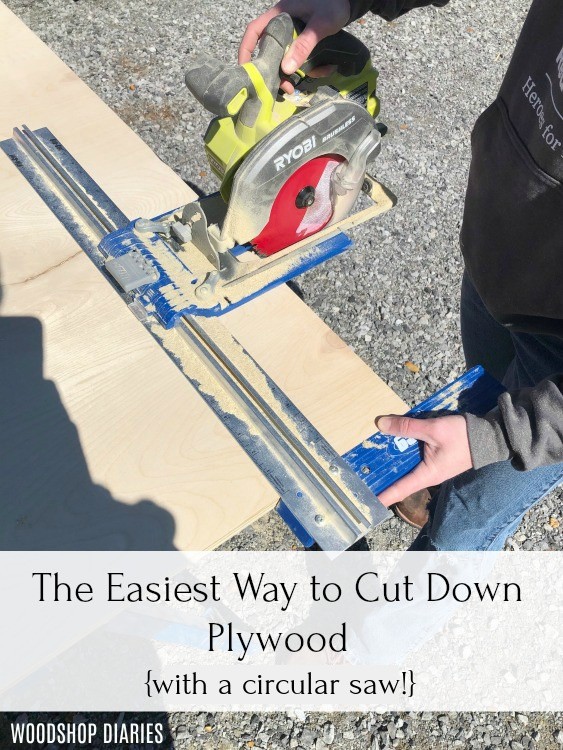

7. Using a Track Saw or Circular Saw with a Guide System

If you frequently work with plywood or other sheet materials, investing in a track saw or circular saw with a guide system can revolutionize your cutting experience. These tools come with an integrated guide rail or track that ensures precise and straight cuts.

The guide system allows you to make long and accurate cuts without the need for additional cutting surfaces. You can simply align the track with your cut line and let the saw follow the path, resulting in clean and splinter-free cuts.

Using a track saw or circular saw with a guide system offers the advantage of portability and versatility. You can easily transport these tools to job sites or use them in different areas of your workshop. Additionally, they provide excellent control and maneuverability, allowing you to make intricate and complex cuts with ease.

Additional Considerations for Cutting Plywood

When cutting plywood, it is important to consider a few additional factors to ensure optimal results:

1. Blade Selection

Choosing the right blade for your saw is crucial for achieving clean and precise cuts in plywood. Look for blades specifically designed for plywood and sheet materials, as they often feature fine teeth and a high tooth count. These blades are designed to minimize tear-out and splintering, resulting in smoother cuts.

1.1 Blade Maintenance and Replacement

Maintaining a sharp and clean blade is essential for optimal cutting performance. Regularly inspect your blade for any signs of dullness or damage, such as chipped or missing teeth. If necessary, replace the blade to ensure consistent and high-quality cuts.

1.2 Blade Depth and Speed

Adjusting the depth of the blade and the speed of the saw can also impact the quality of your cuts. Ensure that the blade depth is set slightly deeper than the thickness of the plywood to prevent any incomplete cuts or splintering. Additionally, adjust the speed of the saw to a suitable level for the type of plywood you are cutting.

2. Safety Precautions

When working with power tools and sharp blades, safety should always be a top priority. Wear appropriate safety gear, such as safety glasses, ear protection, and a dust mask, to protect yourself from potential hazards. Additionally, ensure that your work area is well-lit and free from any clutter or obstructions.

3. Proper Support for Larger Sheets

If you are working with larger sheets of plywood, it is important to provide adequate support throughout the cutting process. Improper support can lead to uneven cuts or even accidents. Consider using additional sawhorses or supports to distribute the weight of the plywood and prevent any sagging.

4. Clamping and Aligning the Plywood

Before making any cuts, ensure that the plywood is securely clamped and aligned along the cut line. This helps to prevent any shifting or movement during cutting, resulting in cleaner and more accurate cuts.

5. Clean Cuts and Finishing

After cutting the plywood, it is important to clean off any sawdust or debris to assess the quality of your cuts. Depending on your project, you may also need to finish the edges or surfaces of the plywood to achieve the desired look or functionality.

6. Proper Disposal of Scraps

Dispose of any leftover plywood scraps responsibly. Consider recycling or repurposing them for future projects if possible.

Conclusion

When cutting plywood, having a suitable cutting surface is crucial for achieving clean, accurate, and splinter-free cuts. Whether you choose to use a sawhorse with plywood, a portable workbench with clamps, foam board insulation, or other improvised methods, the key is to ensure stability and support for the plywood while allowing the saw to move smoothly. Additionally, consider factors such as blade selection, safety precautions, and proper support for larger sheets to optimize your cutting experience. By following these guidelines and incorporating best practices, you can achieve professional results in your plywood cutting projects.

Key Takeaways: What Do You Put Under Plywood When Cutting?

2. A sacrificial piece of plywood or foam board can be placed under the plywood as a backing.

3. Using a sawhorse or workbench with clamps can provide stability and support during cutting.

4. Adding painter’s tape along the cut line can help reduce splintering.

5. It’s important to use a sharp, fine-toothed blade for clean and smooth cuts.

Frequently Asked Questions

When it comes to cutting plywood, there are a few things you can use for support underneath. Here are some common questions and answers to guide you:

Q: What should I put under plywood when cutting?

A: It’s a good idea to use something like sawhorses or a stable workbench to support the plywood when cutting. This will help prevent damage to the plywood and ensure a cleaner, more accurate cut. Alternatively, you can use a sacrificial piece of plywood or a foam insulation board as a base layer. These will provide support and help reduce splintering on the underside of the plywood.

Whichever method you choose, make sure the surface underneath is level and sturdy to prevent any wobbling or movement while you cut.

Q: Can I just cut plywood on the ground or a table without any additional support?

A: While it’s possible to cut plywood on the ground or a table without additional support, it’s not recommended. Without proper support, your cuts may be less accurate, and you run the risk of damaging the surface underneath. Additionally, cutting plywood without support can cause splintering, which may affect the quality of your project.

To ensure clean and precise cuts, it’s best to use some form of support like sawhorses or a workbench to elevate the plywood and provide a stable cutting surface.

Q: Are there any specific sawhorses or workbenches recommended for cutting plywood?

A: When choosing sawhorses or a workbench for cutting plywood, look for sturdy options that can handle the weight and size of the plywood sheets you’ll be working with. Adjustable sawhorses with a wide stance and rubberized feet offer stability and versatility. Workbenches with a sturdy frame and a strong, level surface are also suitable for cutting plywood.

Consider the maximum weight capacity, height adjustability, and overall durability when selecting sawhorses or a workbench for your cutting needs.

Q: What is a sacrificial piece of plywood and how does it help with cutting plywood?

A: A sacrificial piece of plywood is an additional piece of plywood that you can place underneath the plywood you’re cutting. Its purpose is to provide support and prevent tear-out or splintering on the underside of the plywood. By cutting through both the workpiece and the sacrificial piece, you can ensure cleaner cuts and minimize damage to the plywood you’re actually using for your project.

Remember to replace the sacrificial piece when it becomes too damaged to provide proper support for future cuts.

Q: Can I use a foam insulation board instead of plywood for cutting support?

A: Yes, a foam insulation board can be used as an alternative to plywood for cutting support. These boards are lightweight, easy to work with, and provide a stable surface for cutting plywood. They also help prevent splintering on the underside of the plywood. When using a foam insulation board, make sure it is thick enough to support the weight of the plywood and won’t compress under pressure.

Keep in mind that foam insulation boards may not be as durable as plywood, so they may need to be replaced more frequently if they become damaged from repeated cutting.

HOW TO RIP PLYWOOD – 3 ways to rip plywood with a circular saw

Summary

When cutting plywood, it’s important to have a smooth and stable surface underneath. You can use materials like foam insulation, sawhorses, or plywood scraps to support the plywood and prevent damage. Avoid cutting directly on concrete or uneven surfaces.

Additionally, it’s crucial to use the right tools like a circular saw or table saw and take safety precautions such as wearing protective gear and using clamps to secure the plywood. Remember to measure accurately, mark your cut line, and go slow and steady to ensure a clean and precise cut. Happy cutting!

Remember to use a smooth and stable surface like foam insulation or sawhorses underneath plywood when cutting, avoid uneven surfaces, and use the right tools and safety precautions for a clean and precise cut.