So, you’ve heard about bandsaw motors and you’re wondering, “What does a bandsaw motor do?” Well, my curious friend, you’ve come to the right place! In this little introduction, I’m going to clue you in on the secret powers of a bandsaw motor. Brace yourself for some awesome knowledge ahead!

Picture this: you’re in a woodworking shop, ready to make some magic happen with your trusty bandsaw. But wait, what really makes that bandsaw come to life? It’s the bandsaw motor! Think of it as the engine that powers the whole operation. This nifty contraption is responsible for the cutting action of the bandsaw. Pretty cool, right?

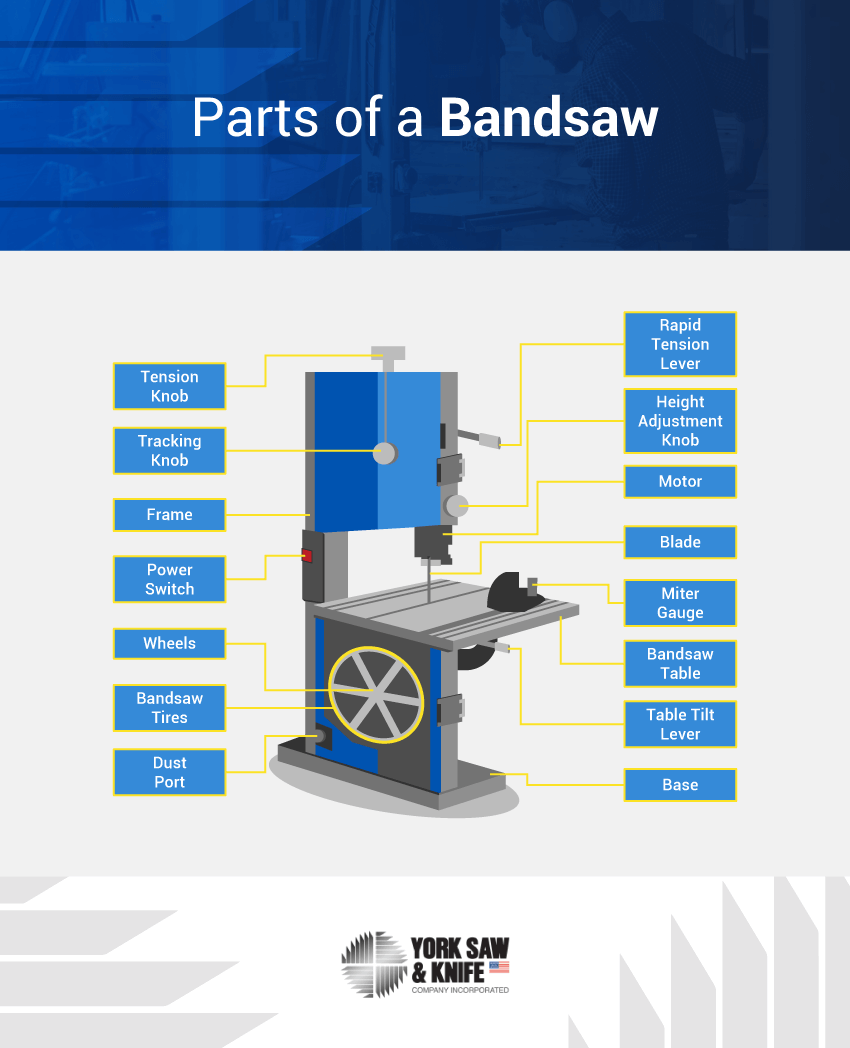

Now, let me break it down for you in simpler terms. The bandsaw motor is like the muscles in your body. It provides the power needed to turn the wheels and move the blade in a continuous loop. This motion allows you to effortlessly cut through all sorts of materials, from wood to metal. Without a bandsaw motor, your bandsaw would be as useful as a flat tire on a bicycle!

So, my young woodworking enthusiast, next time you fire up your bandsaw and see that motor humming away, remember its vital role in making your cutting dreams come true. The bandsaw motor is the unsung hero of the woodworking shop, quietly doing its job and helping you create beautiful creations. Now that you know what a bandsaw motor does, it’s time to put that knowledge to good use and start cutting with confidence! Let’s get sawing!

What Does a Bandsaw Motor Do?

Have you ever wondered what makes a bandsaw work? One key component is the bandsaw motor. It is the powerhouse behind the smooth and precise cutting action of the bandsaw. In this article, we will take an in-depth look at the role of a bandsaw motor, its components, and how it contributes to the overall functionality of the machine.

Understanding the Basics of a Bandsaw Motor

A bandsaw motor is responsible for driving the blade and providing the necessary power for cutting through various materials, such as wood, metal, or plastic. It converts electrical energy into mechanical energy to drive the bandsaw’s blade, ensuring smooth and accurate cuts. The motor’s power output is measured in horsepower (HP) or watts, and it typically depends on the size and capacity of the bandsaw.

Most bandsaw motors are electric motors that run on alternating current (AC). They are designed to generate enough torque to rotate the bandsaw’s pulley system, which in turn drives the blade. The motor is connected to the bandsaw’s drive belt or gear mechanism, which transfers the rotational power to the blade at the desired speed. The speed of the blade can often be adjusted using the bandsaw’s controls, allowing for precise cuts on different materials.

Components of a Bandsaw Motor

A bandsaw motor is composed of several key components that work together to ensure optimal performance. These components include:

- Stator: The stator is a stationary part of the motor that contains the windings and generates a rotating magnetic field when an electric current flows through it. The magnetic field interacts with the rotor to produce torque and rotate the motor.

- Rotor: The rotor is the rotating part of the motor and is usually located inside the stator. It consists of a shaft and a series of conductive bars or coils that are connected to the power source. When the magnetic field created by the stator interacts with the rotor, it causes the rotor to rotate.

- Bearings: Bearings are used to support the rotating shaft of the motor and reduce friction. They are typically located at both ends of the motor and ensure smooth rotation.

- Cooling System: Bandsaw motors often feature a cooling system to prevent overheating during prolonged use. This can include a fan or ventilation slots to dissipate heat and maintain optimal operating temperatures.

These components work seamlessly together to provide the necessary power and drive for the bandsaw, resulting in efficient and precise cutting performance.

Maintenance and Care Tips for Bandsaw Motors

To ensure the longevity and optimal performance of a bandsaw motor, proper maintenance and care are essential. Here are some tips to keep in mind:

- Regularly inspect the motor for any signs of damage, such as frayed wires or loose connections. If any issues are found, have them repaired or replaced by a qualified technician.

- Keep the motor and its surrounding area clean and free from dust or debris. This helps prevent clogging or build-up that can affect the motor’s efficiency.

- Check the cooling system regularly and clean or replace the cooling components as needed. Adequate cooling is crucial for preventing motor overheating.

- Refer to the manufacturer’s guidelines for lubrication and ensure that the motor’s bearings are properly lubricated. This helps reduce friction and prolongs the lifespan of the motor.

- Avoid overloading the bandsaw motor by attempting to cut materials beyond its capacity. Consult the bandsaw’s manual for recommended usage guidelines.

By following these maintenance tips, you can ensure that your bandsaw motor remains in excellent condition and continues to deliver reliable cutting performance for years to come.

Choosing the Right Bandsaw Motor for Your Needs

When selecting a bandsaw motor, there are several factors to consider to ensure it meets your specific requirements. Here are a few key considerations:

Power Output

The power output of the bandsaw motor is one of the most critical factors to consider. Higher horsepower motors provide more cutting power, making them suitable for heavy-duty applications or cutting thick and challenging materials. However, if you primarily work with thinner materials or require a more compact and portable bandsaw, a lower horsepower motor may be sufficient.

Speed Control

Some bandsaw motors come with built-in speed control options, allowing you to adjust the blade speed to match the specific material being cut. This feature is particularly useful when working with different types of materials that require varying speeds for optimal results.

Motor Mounting

Consider the mounting options available for the bandsaw motor and ensure compatibility with your bandsaw model. Motors can be mounted in various locations, either inside the bandsaw cabinet or externally, depending on the design of the machine.

Efficiency and Noise Level

Efficiency and noise levels can vary among different bandsaw motors. Opt for a motor that is energy-efficient to reduce power consumption and minimize heat generation. Additionally, motors with lower noise levels can provide a more comfortable working environment.

Cost and Brand Reputation

Finally, consider your budget and the reputation of the motor’s brand. While cost is an important consideration, it is equally essential to choose a reliable and reputable brand known for producing high-quality motors.

By evaluating these factors and considering your specific needs, you can make an informed decision and choose the right bandsaw motor that will optimize your cutting experience.

Common Issues and Troubleshooting Tips for Bandsaw Motors

Despite regular maintenance and care, bandsaw motors can sometimes encounter issues. Here are some common problems and troubleshooting tips:

Motor Not Starting

If the motor fails to start, ensure that it is receiving power from a functional electrical outlet. Check the power cord for any damage or loose connections. If these factors are not the cause, there may be an issue with the motor’s internal components. In such cases, it is best to consult a professional technician for diagnosis and repairs.

Overheating

If a bandsaw motor is overheating, it may be due to inadequate cooling or excessive use. Check the cooling components and ensure they are clean and functioning correctly. Consider reducing the load on the motor or allowing it to cool down between prolonged cutting sessions.

Unusual Noise or Vibration

If the motor produces unusual noises or excessive vibrations, it may indicate an issue with the bearings or other internal components. Inspect the motor for any loose parts or damaged bearings. Replace any worn-out or faulty components to restore smooth operation.

Inconsistent Speed

If the motor’s speed varies or fluctuates during operation, it may be due to issues with the electrical supply or controls. Check the bandsaw’s electrical connections and ensure they are secure. If the issue persists, consult a professional for further diagnosis and repairs.

By familiarizing yourself with these common issues and troubleshooting tips, you can address potential motor problems promptly and keep your bandsaw running smoothly.

Tips for Maximizing the Performance of Your Bandsaw Motor

To get the most out of your bandsaw motor and enhance its overall performance, consider the following tips:

Use the Right Blade

The type and quality of the blade used in a bandsaw can significantly impact the motor’s performance. Choose a blade that is suitable for the material being cut and ensure it is properly tensioned to minimize strain on the motor.

Proper Blade Alignment

Ensure that the blade is aligned correctly with the bandsaw’s guides and wheels. Proper alignment reduces friction and prevents premature wear on both the blade and the motor.

Regular Maintenance

Stick to a regular maintenance routine, including cleaning, lubricating, and inspecting the motor. This helps prevent issues and extends the lifespan of the motor.

Follow Safety Guidelines

Always follow the safety guidelines provided by the bandsaw manufacturer. Proper safety measures not only protect you but also minimize the risk of damage to the motor and other components.

By implementing these tips, you can ensure that your bandsaw motor performs at its best and delivers exceptional cutting results.

Conclusion

In conclusion, a bandsaw motor is a vital component that drives the cutting action of a bandsaw. Understanding its role, components, and maintenance requirements can help you make informed decisions when choosing, using, and maintaining your bandsaw motor. By following proper care and maintenance practices, troubleshooting any issues, and maximizing the motor’s performance, you can enjoy the benefits of a reliable and efficient bandsaw for years to come.

Key Takeaways: What Does a Bandsaw Motor Do?

- A bandsaw motor powers the blade of a bandsaw, enabling it to cut through various materials.

- It provides the necessary speed and torque to ensure efficient cutting.

- Electric bandsaw motors are commonly used and require a power source to operate.

- They come in different sizes and horsepower ratings, allowing users to choose according to their cutting needs.

- The motor’s power is transferred to the blade through a series of pulleys and belts.

Frequently Asked Questions

Welcome to our FAQ section where we answer some common questions about bandsaw motors and their functions. If you’re curious about what a bandsaw motor does, you’ve come to the right place. Read on to discover more!

1. How does a bandsaw motor work?

At its core, a bandsaw motor is responsible for generating the power needed to run the bandsaw. When you turn on the switch, electricity flows into the motor, which converts it into mechanical energy. This energy is then transferred to the saw blade, causing it to rotate and cut through various materials with precision.

The bandsaw motor consists of several components, including the armature, coils, and brushes. The armature acts as the spinning part, while the coils create a magnetic field that interacts with the armature, causing it to rotate. The brushes, which are in contact with the armature, deliver electrical current to the coils, powering their magnetic field generation. This continuous cycle of electrical current and magnetic forces keeps the bandsaw motor running smoothly.

2. Can bandsaw motors be adjusted to different speeds?

Yes, bandsaw motors can be adjusted to different speeds. This feature is known as variable speed control. Many modern bandsaw models come equipped with this functionality, allowing users to alter the speed of the motor according to their specific cutting needs.

By adjusting the speed of the bandsaw motor, you can optimize cutting performance for different materials and thicknesses. Slower speeds are typically used for harder materials like metal, while faster speeds are suitable for softer materials like wood. Variable speed control gives you more flexibility and control over the cutting process, ensuring cleaner cuts and reducing the risk of damage to the material being worked on.

3. What are the key factors to consider when choosing a bandsaw motor?

When selecting a bandsaw motor, there are several factors to consider. Here are a few key ones:

– Power: The horsepower of the motor determines its cutting capacity. Higher horsepower motors can handle thicker and denser materials.

– Speed: Variable speed control allows you to adjust the motor’s speed to match the material you’re cutting.

– Voltage: Make sure the motor’s voltage is compatible with your power supply to ensure proper functionality.

– Efficiency: Look for motors with efficient power consumption to save energy and reduce operating costs.

– Durability: Choose a motor made from sturdy materials, capable of withstanding the demands of repeated use.

By considering these factors, you can choose a bandsaw motor that meets your specific cutting requirements and provides long-lasting performance.

4. Can bandsaw motors be repaired if they break down?

Yes, bandsaw motors can be repaired if they break down. However, the feasibility and cost-effectiveness of repairs depend on the extent of the damage and the availability of replacement parts. In some cases, it may be more practical to replace the motor.

If your bandsaw motor breaks down, it is recommended to consult a professional technician or an authorized service center for an assessment. They can determine whether the motor can be repaired or if it needs to be replaced. Regular maintenance and proper usage can help prolong the lifespan of your bandsaw motor and minimize the chances of a breakdown.

5. Can bandsaw motors be used for other applications besides woodworking?

While bandsaw motors are commonly associated with woodworking, they can be used for other applications as well. Bandsaws equipped with the appropriate motor can cut through various materials, including metal, plastic, and even food products.

For metal cutting, bandsaw motors with higher horsepower and lower blade speeds are typically used. They are capable of providing the necessary torque and cutting force required to work with metal. Food-grade bandsaw motors are designed with hygiene and sanitation in mind, making them suitable for cutting meats, fish, and other edible products. With the right motor and blade setup, bandsaws have versatile applications beyond woodworking.

Summary

The bandsaw motor is an important part of a bandsaw machine. It powers the blade, allowing it to cut through various materials. The motor’s speed can be adjusted to cut different thicknesses, making it versatile for different projects. It’s important to choose the right motor size to ensure it can handle the workload. Maintaining the motor by keeping it clean and lubricated will help it last longer and work efficiently. Overall, the bandsaw motor plays a key role in making accurate and smooth cuts in woodworking and other projects.