What does a boring machine do? If you’ve ever wondered about the inner workings of construction and engineering, you’re in the right place. Boring machines may sound dull, but trust me, their job is anything but! In this article, we’ll dive into the fascinating world of boring machines, exploring how they work and the important role they play in digging tunnels and creating underground passages. So, strap on your hard hat, and let’s get drilling!

Ever wanted to know how those massive tunnels under the ground are built? Well, that’s where boring machines come in. Picture this: a huge, powerful machine that can dig through soil, rock, and other materials, creating tunnels that connect different places. It’s like a superhero with a drill for a hand, carving its way through the earth. Boring machines are used in various industries, from transportation to mining, helping us reach places we couldn’t access otherwise.

But how do these machines work their magic underground? It’s simple, really. Boring machines have a rotating cutting head with sharp teeth that chew through the ground as they move forward. As they dig, they also use a conveyor system to remove the excavated material from the tunnel. This process continues until the machine reaches its destination, creating a tunnel that opens up a whole new world of possibilities. So, the next time you walk through an underground passage, remember the incredible work of those boring machines that made it all possible!

Now that we’ve scratched the surface of what boring machines do, get ready to dig deeper. In the following sections, we’ll explore the different types of boring machines, the projects they’re used for, and some jaw-dropping facts that will leave you in awe. So, put on your explorer’s hat, and let’s embark on a journey to uncover the secrets of these fascinating underground diggers!

What Does a Boring Machine Do? Unveiling the Depths of This Remarkable Machine

In the world of construction and manufacturing, there are countless machines that play crucial roles in building and shaping the world around us. One such machine that often goes unnoticed but is an indispensable tool in various industries is the boring machine. The name might not be the most captivating, but the capabilities of this machine are nothing short of remarkable. From creating tunnels to drilling precise holes, a boring machine is a powerful workhorse that takes on the most challenging tasks with ease. In this article, we will delve into the world of boring machines, exploring their functions, applications, and the impact they have in various industries.

How Does a Boring Machine Work? Unraveling the Inner Workings of Precision Engineering

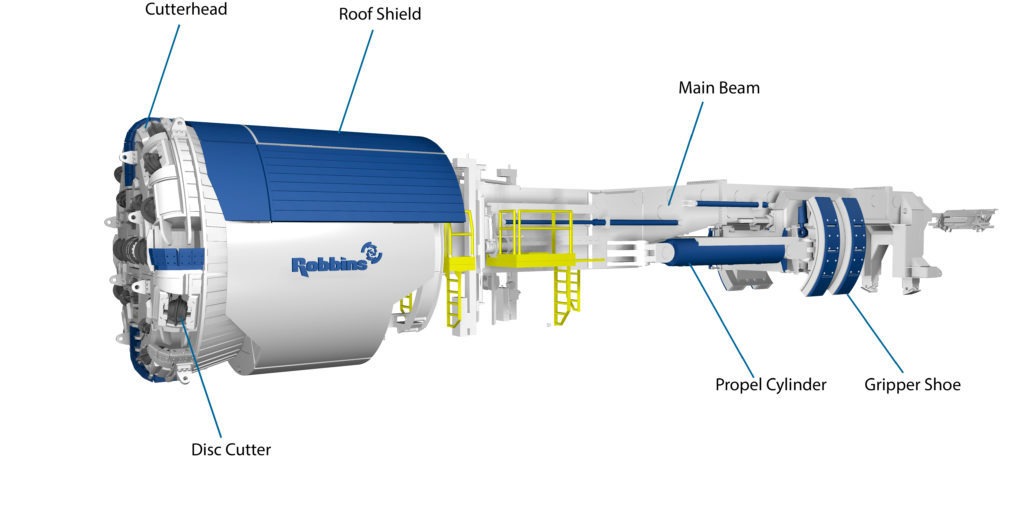

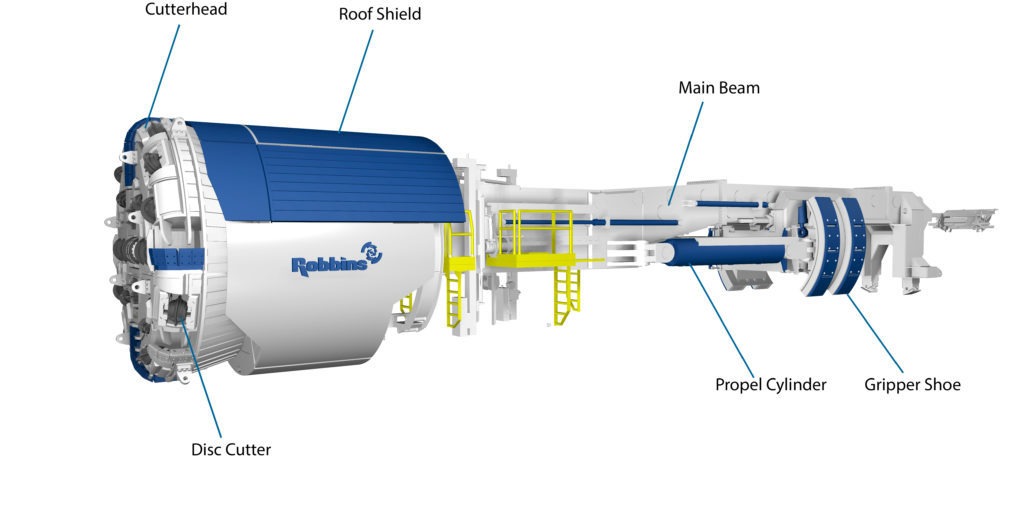

When it comes to understanding what a boring machine does, it’s crucial to familiarize yourself with how it works. Boring machines are designed to create openings with exceptional precision and accuracy. Whether it’s drilling straight holes or excavating tunnels, these machines utilize a variety of mechanisms and cutting tools to get the job done efficiently. The four primary components that make up a typical boring machine are the drive mechanism, the cutting head, the table, and the support column.

The Drive Mechanism: Harnessing Power for Operation

The drive mechanism of a boring machine is responsible for the machine’s movement and power transmission. It consists of a motor, gears, and various mechanisms that allow the machine to move and rotate the cutting head. Some boring machines are driven by hydraulic systems, while others may have electric or pneumatic drive mechanisms. The drive mechanism brings life to the machine, enabling it to tackle the toughest tasks with precision and power.

The Cutting Head: Carving Paths with Precision

The cutting head is arguably the most critical part of a boring machine. It is the section that holds the cutting tools and performs the actual drilling or cutting. There are different types of cutting heads depending on the specific task at hand. For instance, a rotary boring machine utilizes a rotating cutting head with multiple cutting tools, allowing it to create round holes with precision. On the other hand, a line boring machine features a fixed cutting head that can be adjusted horizontally and vertically to create long, linear excavations such as tunnels.

The Table: Providing Stability and Control

The table of a boring machine provides the necessary stability and control during operation. It acts as a surface where the workpiece or material being bored is secured. The table can be adjusted vertically, horizontally, and sometimes even inclined to ensure precise positioning of the workpiece. Some boring machines have a rotary table that allows for 360-degree movement, enabling the machine to tackle complex shapes and contours effortlessly.

The Support Column: The Backbone of Stability

The support column is the backbone of a boring machine, providing stability and support to the entire structure. It houses the drive mechanism, the cutting head, and the table, ensuring that everything is securely held in place during operation. The support column is typically made of heavy-duty materials like cast iron or steel to withstand the loads and vibrations generated while boring holes or excavating tunnels.

Applications of Boring Machines: From Tunnels to Precision Drilling

Now that we’ve explored the inner workings of a boring machine, let’s dive into the vast array of applications where these machines excel. Boring machines are used in various industries, each with its unique requirements and challenges. Here are some of the key applications where boring machines play a significant role:

In Construction: Creating Tunnels and Underground Passages

One of the most well-known applications of boring machines is in the field of construction, specifically tunneling. Boring machines have revolutionized the process of creating tunnels, making it faster, more efficient, and safer. Tunnel boring machines (TBMs) are massive machines equipped with a rotating cutting head that excavates soil, rock, or other materials, allowing for the construction of tunnels for transportation, utilities, and even mining operations. These machines can create tunnels of varying sizes and shapes, from small utility tunnels to large subway tunnels that span several kilometers.

In Manufacturing: Precision Drilling and Boring

Boring machines are also widely used in manufacturing industries that require precise and accurate drilling or boring of holes. Whether it’s creating holes for bolts, dowels, or intricate patterns for specialized components, boring machines offer unparalleled precision and repeatability. From the production of automobile engine blocks to furniture manufacturing, boring machines are the go-to equipment for achieving high-quality results with minimal errors.

In Mining: Extracting Resources from the Earth

In the mining industry, boring machines are utilized to extract valuable resources from the earth’s crust. The cutting heads of mining boring machines are specifically designed to handle the arduous task of excavating rocks and minerals. These machines can bore into the ground, creating openings for mining operations and allowing access to valuable resources such as coal, iron ore, and precious metals.

In Geotechnical Engineering: Investigating Soil and Rock Layers

Boring machines also find their applications in geotechnical engineering, where they are used to investigate and analyze soil and rock layers. By drilling into the ground and extracting samples, geotechnical engineers can examine the composition, stability, and suitability of the ground for construction projects. Boring machines equipped with specialized drilling tools and sensors provide valuable data that helps engineers make informed decisions and ensure the safety and longevity of structures.

In Oil and Gas Exploration: Paving the Way for Energy

Boring machines play a crucial role in the oil and gas industry, aiding in the exploration and extraction of fossil fuels. These machines are used to create holes called boreholes, which provide access to oil and gas reservoirs deep beneath the earth’s surface. Through the use of advanced drilling techniques, boring machines can reach significant depths, allowing for the extraction of valuable energy resources.

In Infrastructure Development: Building Bridges and Piles

Infrastructure development projects such as building bridges, piers, and foundations rely on boring machines to create sturdy and reliable structures. Boring machines are used to create holes for the installation of bridge foundations, caissons, and piles. By utilizing precise drilling methods, these machines ensure that the foundations are strong and stable, capable of withstanding the loads and forces imposed on them.

The Advantages of Using Boring Machines: Efficiency, Accuracy, and Safety

Boring machines offer several advantages that make them indispensable in various industries. Here are some of the key benefits:

Efficiency and Speed

Boring machines are incredibly efficient, allowing for rapid excavation and drilling. They can complete tasks much faster compared to manual methods, saving valuable time and increasing productivity. With their ability to handle large-scale projects, boring machines contribute to the timely completion of construction and manufacturing projects.

Precision and Accuracy

When it comes to drilling or excavating with precision, boring machines are unmatched. They can create holes and tunnels with exceptional accuracy, ensuring that the desired specifications are met. This level of precision is crucial in industries where even the slightest deviation can result in costly errors or compromised safety.

Safety and Reliability

Boring machines are designed with safety in mind. They eliminate the need for manual labor in potentially hazardous environments, reducing the risk of accidents and injuries. The advanced technology and robust construction of these machines ensure their reliability, allowing for consistent and safe operation.

Versatility and Adaptability

Whether you need to drill through solid rock, excavate soft soil, or create complex shapes and contours, boring machines offer versatility and adaptability. With the ability to switch out cutting heads, adjust tables, and utilize various drilling techniques, these machines can tackle a wide range of tasks and adapt to different project requirements.

Investing in the Right Boring Machine: Factors to Consider

Choosing the right boring machine for a specific application requires careful consideration of various factors. Here are some key factors to keep in mind:

Project Requirements

Identify the specific requirements of your project, such as the size and type of holes needed, the material being drilled, and any unique challenges that need to be addressed. This will help you determine the type of boring machine and cutting heads that are most suitable.

Size and Portability

The size and portability of a boring machine can have a significant impact on its usability and versatility. Consider the available space at your work site and whether you require a machine that can be easily moved or transported between different locations.

Power and Speed

Depending on the scale and complexity of your project, you need to ensure that the chosen boring machine has sufficient power and speed to handle the task at hand. Consider factors such as motor horsepower, RPM (Rotations Per Minute), torque, and feed rate.

Accuracy and Precision

For projects that demand high levels of accuracy and precision, it is crucial to select a boring machine that can consistently deliver precise results. Look for a machine that incorporates advanced features such as digital readouts, automatic depth control, and adjustable cutting heads.

Work Environment

The work environment plays a significant role in determining the suitability of a boring machine. Consider factors such as noise levels, dust and debris management, safety features, and the availability of power sources in your work area.

Enhancing Efficiency: Tips for Operating a Boring Machine

To make the most out of a boring machine and ensure optimal performance, consider the following tips:

Regular Maintenance

Implement a regular maintenance schedule to keep your boring machine in excellent working condition. This includes cleaning, lubricating, and inspecting the machine for any signs of wear or damage. Follow the manufacturer’s guidelines for maintenance procedures and intervals.

Proper Tool Selection

Choose the right cutting tools for the material being drilled or bored. Different materials require specific cutting tool designs and materials to achieve the best results. Consult with experts or refer to the machine’s manual to determine the most suitable tools.

Operator Training

Ensure that the operator of the boring machine receives proper training on machine operation, safety protocols, and troubleshooting techniques. Investing in operator training leads to safer operations, better performance, and reduced downtime due to operator error.

Utilize Automation Features

If your boring machine includes automation features such as digital controls or automatic depth control, take full advantage of them. Automation can significantly improve accuracy, productivity, and ease of operation.

Maintain a Clean and Organized Work Area

A clean and organized work area promotes safety and efficiency. Remove any obstacles, debris, or loose tools from the workspace to minimize the risk of accidents and to ensure smooth operation of the machine.

Choosing the Right Boring Machine for Your Needs

When it comes to selecting the right boring machine for your specific needs, it’s essential to consider factors such as the scope of your project, the materials being drilled, and the level of precision required. Consulting with experts and conducting thorough research on available options will help you make an informed decision. Remember to prioritize efficiency, accuracy, and safety when choosing a boring machine, as this will ultimately determine the success of your project.

As we’ve explored the depths of what a boring machine can do, it becomes evident that these machines are more than just their name suggests. From constructing tunnels to drilling precise holes, boring machines have established themselves as vital assets in various industries. Their power, precision, and versatility make them indispensable tools for achieving remarkable feats in construction, manufacturing, geotechnical engineering, and more. By understanding their inner workings, applications, and advantages, we recognize the incredible impact these machines have on shaping the world we live in.

The Future of Boring Machines: Innovations and Advancements

The world of boring machines is not stagnant. With advancements in technology and increasing demand for more efficient and environmentally friendly solutions, the future of boring machines looks bright. Here are three key areas where we can expect to see innovations and advancements:

Automation and Robotics

As automation continues to revolutionize various industries, we can expect to see more advanced and sophisticated automation features integrated into boring machines. Robotics may play a significant role in enhancing the precision, speed, and safety of these machines. By reducing human involvement and incorporating intelligent algorithms, boring machines can become even more efficient and productive.

Sustainability and Environmental Considerations

Environmental consciousness is becoming increasingly important in today’s world. Boring machine manufacturers are investing in developing greener technologies that reduce emissions, improve energy efficiency, and minimize environmental impact. We can expect to see more eco-friendly features, such as electric-powered drilling systems and reduced noise and vibration levels, in future generations of boring machines.

Integration of Artificial Intelligence

Artificial intelligence (AI) has the potential to revolutionize the capabilities of boring machines. AI algorithms can analyze and interpret vast amounts of data generated during drilling operations, providing real-time feedback and optimizing drilling parameters for the best results. With AI integration, boring machines can become highly adaptive, learning from each project and continuously improving their performance.

The future of boring machines holds incredible promise, and we can anticipate even more efficiency, precision, and sustainability in the years to come. As technology continues to evolve, these machines will continue to shape the landscape of construction, manufacturing, and engineering industries.

Key Takeaways: What Does a Boring Machine Do?

- A boring machine is a powerful tool used to create holes and tunnels in various materials.

- It is commonly used in construction to dig tunnels for pipes, cables, and utilities.

- Boring machines can also be used to create holes in wood, metal, and other materials.

- They are typically operated by professionals who are trained in using the machine safely and effectively.

- With the help of different attachments, boring machines can perform various tasks like drilling, reaming, and enlarging existing holes.

Frequently Asked Questions

Curious about what a boring machine does? We’ve got the answers to your burning questions.

1. How does a boring machine work?

A boring machine is a powerful tool used to create precise holes or tunnels in various materials, such as wood or metal. It operates by rotating a cutting tool, known as a boring head, which gradually removes material to create the desired hole or tunnel. The machine is guided by a system of levers and controls that allow for precise positioning and movement.

Some boring machines are operated manually, with the user controlling the movement and speed of the cutting tool. Others are computer-controlled, where the operator inputs the desired dimensions and the machine carries out the boring process automatically. Either way, the boring machine ensures accurate and efficient hole creation.

2. What are the applications of a boring machine?

Boring machines have a wide range of applications across various industries. In construction, they are commonly used for creating tunnels, such as those needed for underground utility lines or transportation systems. They are also widely used in woodworking for creating dowel holes, mortises, or openings for hinges.

In manufacturing, boring machines play a vital role in creating holes for precise fittings, such as bearings or shafts. Additionally, they are employed in mining operations for extracting minerals or drilling holes for exploration purposes. The versatility of boring machines makes them a valuable tool in numerous industries.

3. Are there different types of boring machines?

Yes, there are several types of boring machines, each designed for specific purposes. Horizontal boring machines, for example, are commonly used for creating tunnels or holes in a horizontal direction, while vertical boring machines are ideal for holes that need to be created vertically, such as in standing wooden beams.

Additionally, there are portable boring machines that can be easily transported to different job sites, allowing for greater flexibility. CNC boring machines, on the other hand, are equipped with computer controls, enabling precise and automated hole creation. The type of boring machine chosen depends on the specific needs and requirements of the project.

4. What safety precautions should be taken when using a boring machine?

When working with a boring machine, it is essential to prioritize safety. Always wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself from potential flying debris or sharp edges. Ensure that the work area is well-lit and free from any obstructions.

It is crucial to familiarize yourself with the machine’s operating manual and follow all recommended guidelines. Never bypass safety features or modify the machine without proper authorization. Regularly inspect and maintain the machine to ensure optimal safety and performance. Remember, safety should always be the top priority when using any type of power tool.

5. Can a boring machine be used for repair work?

Absolutely! Boring machines are not only used for creating new holes; they can also be employed for repairing existing ones. For example, if a pipe needs to be replaced in a building, a boring machine can create a tunnel under the foundation to access the damaged pipe without causing extensive disruption or excavation.

Similarly, in woodworking, a boring machine can be used to repair furniture by creating holes for dowels or screws to reinforce weakened joints. The versatility and precision of boring machines make them a valuable tool for repair and restoration work in various industries.

What is a tunnel boring machine (TBM)?

Summary

Boring machines help make holes in the ground or remove soil and rocks easily. They are big machines that dig tunnels or underground passages. Boring machines are used to create subway tunnels, underground pipelines, and even mines. They save time and effort compared to doing it by hand!

So, next time you see a boring machine at work, remember its important job of making holes and tunnels and how it helps make our lives easier.