When it comes to machining, there are numerous tools and machines that are used to shape and transform raw materials into finished products. One such machine is a center lathe. So, what does a center lathe do? Let’s dive in and find out!

A center lathe is a versatile machine that is commonly used for turning cylindrical or conical shapes. This machine uses a rotating cutting tool to remove material from the workpiece to create the desired shape. Whether it’s metal, wood, or even plastic, a center lathe can handle a wide variety of materials.

With its spinning chuck and precision control, a center lathe allows skilled operators to perform various operations like facing, grooving, threading, and drilling. It’s like a sculptor’s chisel, but for metal and other materials. So, whether you need to create the perfect bolt or fashion a custom piece, a center lathe is the go-to machine for many machinists.

So, the next time you see a center lathe in action, remember that it’s a powerful tool that transforms raw materials into intricate shapes and brings your designs to life. Now that we have a basic understanding of what a center lathe does, let’s explore its inner workings and discover more about this fascinating machine!

What Does a Center Lathe Do?

A center lathe is a versatile and essential tool in the world of machining. It is used to shape and cut metal, wood, and other materials with precision and accuracy. From turning cylinders and creating threads to drilling and boring holes, a center lathe is a powerhouse of productivity in manufacturing and fabrication processes. In this article, we will explore the various functions and capabilities of a center lathe, as well as its benefits and tips for efficient use.

Turning Cylinders and Shafts

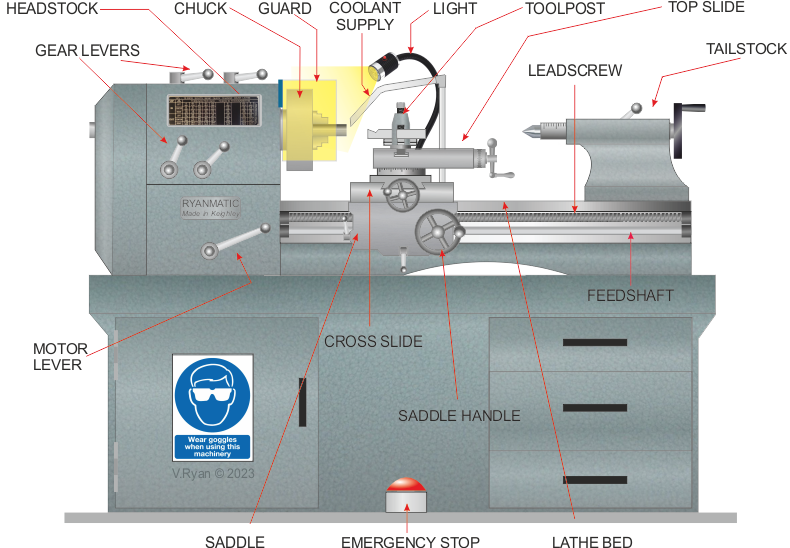

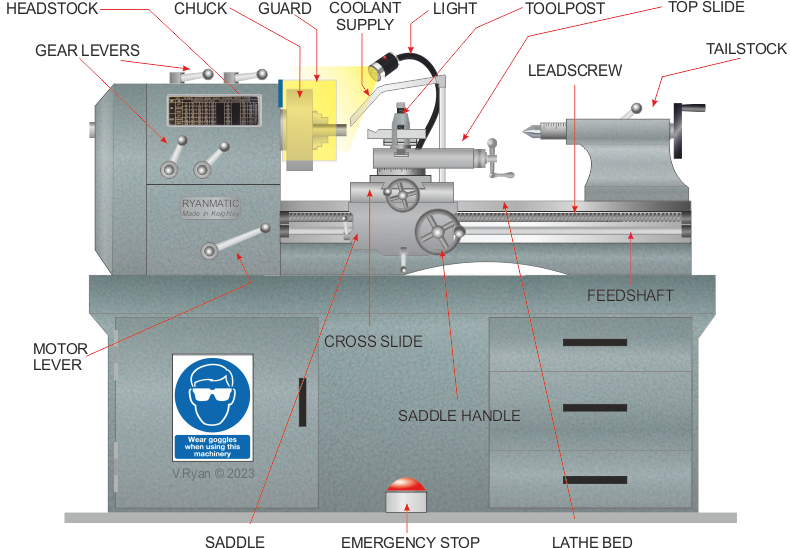

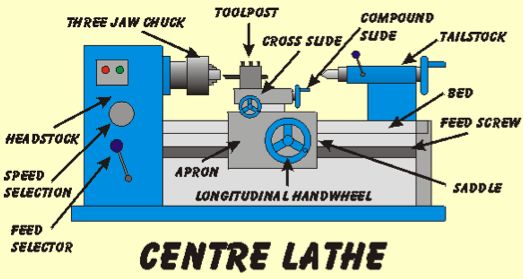

One of the primary functions of a center lathe is to turn cylinders and shafts. The workpiece is clamped between two centers, with one center supporting the material at the headstock end and the other center at the tailstock end. As the workpiece rotates, a cutting tool held in a tool holder is fed into the material, removing layers of material and shaping it into a desired diameter and length. This process is commonly used for creating cylindrical components such as pins, shafts, and rods.

Center lathes come in different sizes and capacities, allowing for the machining of small and large workpieces. The tool movement is controlled by manually adjusting the tool holder or by using automatic feed mechanisms, depending on the lathe model and application. The precision and accuracy of a center lathe enable the production of smooth and perfectly round cylinders and shafts, meeting the required specifications and tolerances.

Center lathes are often equipped with additional attachments such as steady rests and followers, which provide support and stability when working with long or thin workpieces. These attachments help to minimize vibrations and maintain dimensional accuracy during the turning process.

Creating Threads

In addition to turning cylinders and shafts, a center lathe is also used for creating threads. Threads are essential in many applications, providing the ability to fasten components together securely. The process of thread cutting involves feeding a cutting tool into the workpiece in a helical path, removing material and forming threads with precise pitch, depth, and profile.

Center lathes are equipped with a thread-cutting mechanism that enables the user to cut various types of threads, including external threads (screws) and internal threads (nuts). The lathe can be set to different thread pitches by changing the gear ratios and using different combinations of gears. This allows for flexibility in thread cutting, accommodating a wide variety of thread sizes and specifications.

Thread cutting on a center lathe requires skill and knowledge of the threading process. The operator must set the lathe to the correct speed, engage the half-nut mechanism, and accurately synchronize the tool movement with the rotating workpiece. With practice and experience, precise and high-quality threads can be produced consistently.

Drilling and Boring Holes

Another important function of a center lathe is drilling and boring holes. Center lathes can be equipped with a drilling attachment or a live center in the tailstock, allowing for the drilling of accurate and concentric holes. The workpiece is clamped and rotated, while a drill bit is fed into the material, removing material and creating holes with desired diameters and depths.

Boring, on the other hand, involves enlarging existing holes or creating internal cylindrical surfaces. Boring bars with replaceable cutting inserts are used to remove material from the inside of the workpiece, creating holes with high precision and smooth surfaces. Center lathes can bore holes of various diameters, making them suitable for a wide range of applications.

Drilling and boring on a center lathe require attention to detail and proper tool selection. The operator must ensure the workpiece is securely clamped and aligned, and that the cutting tools are sharp and properly adjusted. With accurate measurements and careful operations, center lathes can produce holes and bores that meet tight tolerances and specifications.

Benefits of Using a Center Lathe

Using a center lathe offers numerous benefits in manufacturing and fabrication processes:

- Precision: Center lathes are known for their high precision, enabling the production of components with tight tolerances and exact measurements.

- Versatility: Center lathes can perform a wide range of functions, including turning, threading, drilling, and boring, making them a versatile tool in various industries.

- Efficiency: Center lathes are designed for efficient material removal, allowing for quick and accurate machining processes.

- Durability: Center lathes are built to withstand rigorous use and provide long-lasting performance, ensuring reliability and productivity.

- Customization: Center lathes can be equipped with various attachments and accessories, allowing for customization based on specific machining requirements.

These benefits make center lathes indispensable tools in industries such as automotive, aerospace, construction, and more.

Tips for Efficiently Using a Center Lathe

To maximize the efficiency and productivity of a center lathe, consider the following tips:

- Proper Tool Selection: Use the appropriate cutting tools and tool holders for the specific machining operation.

- Regular Maintenance: Keep the center lathe clean and well-lubricated to ensure smooth operations and prevent tool wear.

- Workpiece Preparation: Prepare the workpiece by ensuring it is properly centered and securely clamped in the lathe.

- Safety First: Follow all safety guidelines and procedures, including wearing appropriate protective equipment and using machine guards.

- Continuous Learning: Stay updated with the latest advancements in machining techniques and technologies to improve your skills and knowledge.

Conclusion

A center lathe is a versatile machine that offers a wide range of functions in machining and fabrication. From turning to threading, drilling to boring, a center lathe plays a crucial role in shaping and cutting various materials with precision and accuracy. By understanding its capabilities and following best practices, you can make the most of this essential tool, achieving excellent results in your machining projects.

Key Takeaways: What Does a Centre Lathe Do?

- A centre lathe is a machine tool used for shaping and machining cylindrical workpieces.

- It rotates the workpiece while a cutting tool moves in a linear motion to remove material and create the desired shape.

- Centre lathes can be used for various operations, including turning, facing, threading, and drilling.

- They are commonly used in manufacturing industries to produce precision components.

- Centre lathes require skilled operators who can set up the machine, choose the correct cutting tools, and monitor the machining process.

Frequently Asked Questions

Welcome to our FAQ section where we answer commonly asked questions about centre lathes. If you’ve ever wondered what a centre lathe does and how it functions, you’ve come to the right place. Discover more about this versatile machine tool and its applications below.

1. What are the main functions of a centre lathe?

A centre lathe is a type of machining tool that is primarily used for shaping and turning cylindrical workpieces. Its main functions include turning, facing, drilling, boring, threading, and tapering operations. With the help of various cutting tools, a centre lathe can create precise and smooth surfaces on the workpiece.

Additionally, a centre lathe can be used for a range of materials, including metal, wood, and plastics, making it a versatile tool in many industries such as manufacturing, construction, and engineering.

2. How does a centre lathe work?

A centre lathe operates by securing the workpiece between two centers, which are mounted on the lathe bed. The rotational movement of the workpiece is controlled by a motor, while the cutting tool, mounted on a tool post, moves along the workpiece to shape it.

The operator can adjust the speed and position of the cutting tool to achieve the desired shape and surface finish. The movement of the cutting tool is controlled manually by the operator or automatically using computer numerical control (CNC) systems in more advanced centre lathes.

3. What are the advantages of using a centre lathe?

Using a centre lathe offers several advantages in machining operations. Firstly, it allows for high precision and accuracy in shaping cylindrical workpieces. The cutting tools can be adjusted to create intricate details and achieve tight tolerances.

Secondly, a centre lathe provides versatility in manufacturing processes. It can handle various materials, workpiece sizes, and shapes, making it suitable for a wide range of applications. Additionally, it is relatively easy to set up and operate, making it accessible to both beginners and experienced machinists.

4. What are some common applications of a centre lathe?

A centre lathe is used in numerous industries and applications. It is frequently employed in metalworking processes, such as the fabrication of shafts, rods, and valves. Woodworking industries use centre lathes to create decorative items like bowls and table legs.

Furthermore, a centre lathe is essential for repairing and maintaining machinery parts. It allows for precise machining of worn-out or damaged components, extending their lifespan. In summary, wherever there is a need for shaping cylindrical workpieces, a centre lathe proves invaluable.

5. Are there different types of centre lathes?

Yes, there are various types of centre lathes available, each designed for specific applications. Some common types include bench lathes, engine lathes, and toolroom lathes. Bench lathes are compact and suitable for small-scale projects, while engine lathes are larger and capable of handling heavier workpieces.

Toolroom lathes, on the other hand, are versatile machines used in tool and die making, prototyping, and maintenance operations. Each type of centre lathe comes with its own set of features and capabilities, allowing users to choose the most suitable one for their specific needs.

Summary

A centre lathe is a useful machine that helps shape metal objects. It rotates the material and uses various tools to cut, shape, and smooth the metal. The operator carefully controls the lathe to create precise and intricate designs.

By adjusting the cutting speed, feed rate, and tool position, the lathe can create different shapes and sizes. It can make cylindrical objects like pipes and shafts, as well as intricate details like threads and grooves. The centre lathe is a versatile tool used in industries like manufacturing and engineering to create various metal components.