Have you ever wondered what a gap bed lathe does? Well, get ready to find out! In this article, we’ll explore the fascinating world of gap bed lathes and discover their purpose. So, buckle up and prepare to be amazed!

Now, you might be scratching your head and asking, “What exactly is a gap bed lathe?” Don’t worry, my friend, I’ve got you covered. A gap bed lathe is a powerful machine that is used to shape and cut various materials like metal, wood, and even plastic. It’s like having your very own superhero for precision engineering!

But what sets a gap bed lathe apart from other types of lathes? The answer lies in its unique design. You see, a gap bed lathe features a removable section in the bed, aptly called the “gap,” which allows for larger workpieces to be attached and turned. It’s all about flexibility and accommodating those extra-long projects!

So, get ready to dive deep into the world of gap bed lathes, where precision meets versatility. Let’s explore how these incredible machines work and the amazing things they can create. Get excited, my friends, because the world of gap bed lathes is about to blow your mind! Let’s go!

What Does a Gap Bed Lathe Do?

Welcome to our in-depth exploration of gap bed lathes! In this article, we will delve into the functions and capabilities of these invaluable machines. Whether you’re a seasoned professional or an aspiring machinist, understanding the purpose and versatility of a gap bed lathe is essential. From the basics to advanced applications, we’ve got you covered. So, let’s get started!

1. Introduction to Gap Bed Lathes

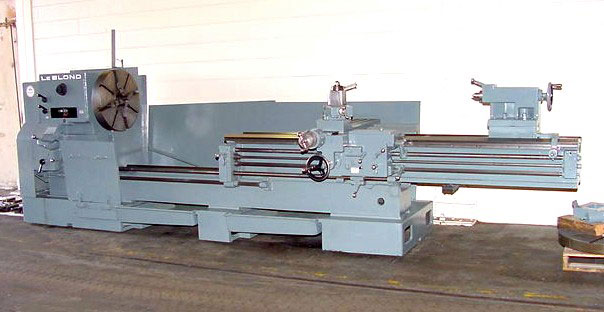

A gap bed lathe is a type of lathe machine commonly used in metalworking industries. It got its name from the inclusion of a removable gap section in the bed of the lathe. The gap allows the user to accommodate larger workpieces that exceed the swing capacity of the lathe. The gap bed lathe is especially useful for projects that involve large-diameter turning, such as pipe threading, turbine rotor machining, or creating long shafts.

One of the key advantages of a gap bed lathe is its versatility. By removing the gap section, the lathe can function as a standard lathe, offering precision turning capabilities for smaller workpieces. This flexibility makes gap bed lathes a popular choice in industries like aerospace, automotive, and general machining.

2. Features and Components of a Gap Bed Lathe

To fully understand what a gap bed lathe does, it’s essential to familiarize ourselves with its features and components. Here are some key elements:

Bed: The bed is the base of the lathe, providing stability and support. In the case of a gap bed lathe, the bed includes a removable gap section for accommodating larger workpieces.

Headstock: Located on one end of the lathe, the headstock houses the main spindle, which rotates the workpiece. It also contains various gears for adjusting the spindle speed.

Tailstock: Positioned on the opposite end of the headstock, the tailstock provides additional support for longer workpieces. It can be adjusted along the bed’s length to accommodate different lengths of workpieces.

Carriage: The carriage is responsible for

translating the cutting tool along the workpiece’s length. It consists of the saddle, cross-slide, and compound rest, which allow for precise positioning and machining.

Tool Post: The tool post holds the cutting tools and allows for their adjustment and interchangeability. It is an essential component for achieving different cutting operations.

3. Applications and Benefits of Gap Bed Lathes

Gap bed lathes find extensive applications in various industries due to their versatility and capabilities. Here are some common uses:

Large-Diameter Turning: As mentioned earlier, the gap bed lathe’s primary function is to accommodate larger workpieces that exceed the swing capacity of a standard lathe. This makes it ideal for projects that involve turning large-diameter parts, such as pipes, shafts, and rotors.

Heavy-Duty Machining: Gap bed lathes are designed to handle heavy workloads and tough materials. They are capable of machining materials like steel, cast iron, and alloys with ease, making them indispensable in industries that require heavy-duty cutting and shaping.

Thread Cutting: With the right tooling and setup, gap bed lathes can perform precise thread cutting operations. This makes them invaluable in industries that require threading for various applications, such as pipe fittings, bolts, and screws.

Multiple Operations in One Setup: Gap bed lathes are designed to handle a wide range of operations, including facing, turning, boring, and taper turning. This eliminates the need for multiple setups, saving time and ensuring better accuracy and alignment.

Improved Rigidity: The design of gap bed lathes offers improved rigidity compared to some other types of lathes, making them more suitable for heavy cutting operations. The stability provided by the sturdy bed and construction ensures better accuracy and surface finish.

In conclusion, gap bed lathes are powerful machines that bring versatility and efficiency to metalworking projects. Whether you’re working on large-scale components or need precision machining, these lathes can handle the task. With their diverse applications and benefits, gap bed lathes continue to be a staple in industries that rely on accurate and efficient turning operations. So, whether you’re a manufacturer, machinist, or hobbyist, consider incorporating a gap bed lathe into your workshop for enhanced productivity and capabilities.

Key Takeaways: What Does a Gap Bed Lathe Do?

- A gap bed lathe is a machine used to shape and cut metal.

- It has a removable gap in the bed that allows for larger workpieces to be placed and turned.

- Gap bed lathes are used in industries such as automotive, aerospace, and manufacturing.

- They can be used to create various shapes, threads, and contours on metal objects.

- These machines are versatile and can be operated manually or with computer control.

Frequently Asked Questions

In this section, we will answer some commonly asked questions about gap bed lathes, their functions, and their applications.

1. How does a gap bed lathe differ from a regular lathe?

A gap bed lathe is similar to a regular lathe but with an additional gap in the bed. This gap allows for the machining of larger workpieces that would not fit on a standard lathe. The gap usually spans the length of the bed, and it can be covered or uncovered based on the needs of the project. Regular lathes do not have this gap and are designed for smaller workpieces.

Gap bed lathes are versatile machines that offer greater flexibility when it comes to handling larger and longer workpieces. They are commonly used in industries such as aerospace, automotive, and construction, where there is a need to turn or shape large cylindrical components.

2. What are the advantages of using a gap bed lathe?

The main advantage of using a gap bed lathe is the increased capacity it offers. With the gap in the bed, you can work on longer or larger diameter workpieces that wouldn’t fit on a regular lathe. This is particularly useful in industries that deal with large parts or long shafts.

Another advantage is the versatility of a gap bed lathe. With the gap covered, you can use it as a regular lathe for smaller projects. When the gap is uncovered, the lathe becomes a powerful tool for handling larger workpieces. This flexibility makes gap bed lathes a valuable asset in any workshop.

3. What are the common applications of a gap bed lathe?

Gap bed lathes find their application in various industries and projects. They are commonly used for machining large shafts, cylinders, and rolls. In the automotive industry, gap bed lathes are used for turning crankshafts, brake drums, and other oversized components. In the construction industry, they are used for machining pillars and columns. Additionally, gap bed lathes are often employed in the manufacturing of equipment such as turbines, propellers, and conveyor rollers.

Overall, any project that requires the machining of long or large-diameter components can benefit from the use of a gap bed lathe.

4. Are gap bed lathes suitable for beginners?

Gap bed lathes can be suitable for beginners, provided they receive proper training and guidance. These machines are more complex and require a good understanding of lathe operations. Beginner machinists should start by familiarizing themselves with regular lathes before moving on to gap bed lathes.

It’s important to note that safety measures should always be followed when operating any lathe, including gap bed lathes. Beginners should receive training on safe operating procedures, tool handling, and proper setup before using a gap bed lathe.

5. What factors should be considered when purchasing a gap bed lathe?

When purchasing a gap bed lathe, several factors need to be considered. First and foremost, the size and weight capacity of the lathe should be suitable for your intended applications. Consider the largest workpieces you will be machining and ensure the lathe can accommodate them.

Secondly, look for features such as variable speed control, digital readouts, and automatic feed systems. These features can enhance the efficiency and accuracy of your machining processes. Finally, consider the reputation and service support of the manufacturer. Choose a reliable brand that offers good customer support and a warranty for peace of mind.

Summary

A gap bed lathe is a type of machine that helps shape and cut materials. It has a gap in the bed, which allows larger pieces to be worked on. With a gap bed lathe, you can create smooth and precise cuts in different materials like metal or wood. It is a handy tool for crafting and engineering projects.

Using a gap bed lathe involves the following steps: secure the material in the lathe, choose the appropriate cutting tools, adjust the speed and feed rate, and start shaping or cutting. Safety precautions, like wearing goggles and following instructions, are crucial when using a gap bed lathe. By understanding its purpose and how to operate it safely, you can unleash your creativity and accomplish amazing projects with this useful machine.