What does a line boring machine do? Well, let me tell you! Have you ever wondered how engineers fix those big, metal cylinders in heavy machinery when they get damaged or worn out? That’s where line boring machines come to the rescue!

Line boring machines are incredible tools used to repair and accurately align holes in large metal parts. These machines work like skilled surgeons, restoring the precise dimensions of the original holes. They can fix bores in engine blocks, crankshafts, bearings, and even construction equipment like excavators and bulldozers.

Imagine a car that needs an engine repair, or a massive ship with a damaged propeller shaft. Without line boring machines, it would be a real headache for mechanics and engineers to fix these issues. But with these powerful machines, they can save the day by restoring the integrity and functionality of crucial components.

So, in a nutshell, line boring machines are like superheroes for heavy machinery. They ensure that everything fits together perfectly and keeps the world running smoothly. Pretty cool, huh? Now let’s dive deeper into this fascinating world and explore the workings of these mechanical marvels in more detail.

What Does a Line Boring Machine Do?

A line boring machine is a valuable tool in the field of machining and engineering. It plays a crucial role in precision work and allows for the accurate machining of holes that need to be perfectly aligned. Whether it’s repairing heavy equipment or manufacturing new parts, a line boring machine ensures the proper functioning and longevity of mechanical assemblies. In this article, we will explore the various applications, benefits, and tips related to line boring machines.

The Functions of a Line Boring Machine

A line boring machine is primarily used to enlarge and refine existing holes or create new holes with precise dimensions. It is often employed in industries such as construction, oil and gas, mining, and marine engineering. One of the machine’s key functions is to repair worn out or damaged bores in engines, gearboxes, and other types of equipment. By removing minimal amounts of material, the machine restores the original dimensions of the bore, ensuring the proper fit of the components.

Additionally, line boring machines are used to create accurate bores in new parts. Whether it’s for mounting bearings, shafts, or other rotating components, line boring ensures the alignment and proper functioning of the mechanical assembly. This process is essential for maintaining the integrity and reliability of a variety of machinery, including large industrial equipment and engines.

The versatility of line boring machines allows for the machining of horizontal, vertical, and inclined bores, making them suitable for a wide range of applications. From repair and maintenance work to precision manufacturing, these machines provide reliable and efficient solutions.

The Benefits of Using a Line Boring Machine

There are several advantages to using a line boring machine in machining and engineering processes. Firstly, it ensures the accuracy and precision required for aligning bores and creating perfectly matched parts. This accuracy translates into increased efficiency and reduced downtime, as the machine eliminates the need for manual measurements and adjustments.

Secondly, line boring machines offer cost-effective solutions. They allow for the repair and reconditioning of worn-out bores, which can extend the lifespan of equipment and reduce the need for expensive replacements. This means that businesses can save money by maintaining and repairing their existing machinery instead of purchasing new ones.

Finally, line boring machines contribute to overall productivity by streamlining and expediting machining processes. Their automated features, such as automated feed and cutting speeds, eliminate the need for manual labor and reduce the risk of human error. This results in improved efficiency and consistent quality in the final product.

Applications of Line Boring Machines

Line boring machines find applications in various industries and sectors. One prominent application is in the repair and maintenance of engines and other powertrain components. By accurately aligning cylinder bores and crankshaft journals, line boring machines optimize engine performance and minimize vibration, ensuring smooth and reliable operation.

Another common application is in the manufacturing of heavy machinery, such as construction equipment and mining machinery. Line boring machines create precise bores for mounting pivotal components, ensuring the durability and proper functionality of these machines in demanding work environments.

Line boring machines also play a significant role in the marine and offshore industry. They are used in the repair and maintenance of large-scale ship engines and propeller shafts, ensuring the smooth operation of vessels and preventing costly breakdowns.

Tips for Using a Line Boring Machine

To achieve the best results with a line boring machine, it is essential to follow some key tips and guidelines. Firstly, it is crucial to choose the right cutting tools and techniques according to the material being machined. Different materials require specific cutting inserts and approaches to achieve optimal results.

Secondly, proper setup and alignment of the machine are critical. Taking the time to accurately position the workpiece and align the machine will ensure precise and consistent results. This includes checking and adjusting the spindle runout, aligning the boring bar, and securing the workpiece securely in place.

Lastly, regular maintenance and care of the line boring machine are necessary to ensure its longevity and performance. This includes cleaning and lubricating the machine, checking and replacing worn-out parts, and following the manufacturer’s recommended maintenance schedule.

Additional Information

The Advancements in Line Boring Machine Technology

In recent years, line boring machine technology has seen significant advancements. Manufacturers have introduced precision computer numerical control (CNC) capabilities, which have revolutionized the machining process. CNC line boring machines offer increased automation, accuracy, and flexibility, making them an essential tool for modern machining operations.

The Future of Line Boring Machines

As the demand for precision machining continues to grow, line boring machines will play an increasingly important role in various industries. With advancements in technology, these machines will become more efficient, accurate, and user-friendly. The future of line boring machines looks bright as they continue to provide precise solutions for various machining and engineering needs.

Key Takeaways – What Does a Line Boring Machine Do?

- A line boring machine is a tool used to create precise holes in metal surfaces.

- It is commonly used in industries such as automotive, construction, and manufacturing.

- The machine helps in repairing or enlarging existing holes with accuracy.

- Line boring machines are equipped with cutting tools that remove material to create the desired hole size.

- These machines are essential for achieving proper alignment and fit for mechanical parts.

Frequently Asked Questions

Line boring machines are essential tools used in various industries to repair or modify existing holes. By utilizing this device, precise and accurate holes can be created or resized in materials like metal, wood, or plastic. Here are some commonly asked questions about line boring machines:

1. How does a line boring machine work?

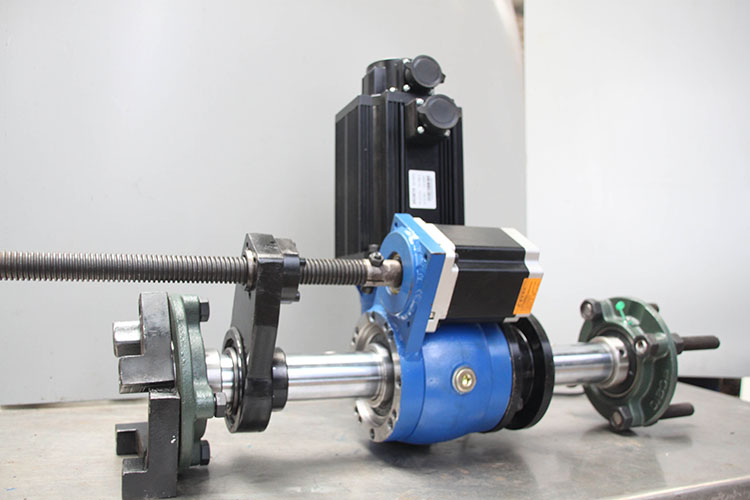

A line boring machine works by mounting a cutting tool called a boring bar onto a rotating base. The machine is then placed over the workpiece, and the boring bar is inserted into the existing hole. As the machine rotates, the cutting tool removes material, gradually enlarging or modifying the hole as needed. Some line boring machines may have additional features like a feed mechanism to automatically advance the cutting tool.

Overall, the machine’s purpose is to ensure precision and accuracy in creating or resizing holes, making it easier to align and assemble parts that rely on these holes.

2. What are the applications of a line boring machine?

Line boring machines have a wide range of applications across various industries. These include:

– Repairing or resizing worn-out or damaged bearing bores

– Modifying existing holes to accommodate larger or different types of hardware

– Creating new holes in materials like metal, wood, or plastic

– Aligning parts by creating precise and accurate holes for assembly

In industries such as construction, automotive, aerospace, and manufacturing, line boring machines play a crucial role in maintaining and improving the integrity of parts and structures.

3. What are the advantages of using a line boring machine?

Using a line boring machine offers several advantages:

– Precision: Line boring machines ensure accurate and precise hole dimensions, allowing for proper alignment and assembly of parts.

– Efficiency: These machines can quickly and efficiently create or resize holes, reducing manual labor and saving time.

– Cost-effectiveness: By repairing or modifying existing holes instead of fabricating new parts, line boring machines help save costs on materials and manufacturing processes.

– Versatility: Line boring machines can be used on various materials, making them suitable for different industries and applications.

– Enhanced durability: Properly aligned and accurately sized holes ensure the longevity and reliability of assembled parts and structures.

4. What safety precautions should be taken when using a line boring machine?

When operating a line boring machine, it is essential to follow proper safety precautions to prevent accidents or injuries:

– Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection.

– Ensure the work area is well-ventilated and free of obstructions or debris that could cause accidents.

– Familiarize yourself with the machine’s manual and instructions, and follow them carefully.

– Maintain a safe distance from the rotating parts to avoid getting caught or injured.

– Regularly inspect the machine for any signs of damage or malfunction, and address them before use.

By prioritizing safety and taking necessary precautions, users can maximize the benefits of a line boring machine while minimizing risks.

5. What factors should be considered when choosing a line boring machine?

When selecting a line boring machine, several factors should be taken into account:

– Size and capacity: Consider the maximum dimensions of the workpieces you will be dealing with to ensure compatibility with the machine’s specifications.

– Power source: Determine whether you need a machine powered by electricity, hydraulics, or other energy sources based on your specific requirements.

– Versatility: Depending on your needs, choose a machine that can handle different materials, hole sizes, and configurations.

– Budget: Set a budget and look for a line boring machine that offers the best value for money without compromising on quality and features.

– User-friendliness: Consider ease of operation, maintenance requirements, and availability of technical support or training for optimal usage.

By evaluating these factors, you can select a line boring machine that aligns with your specific needs and provides efficient and reliable performance.

Line boring and Bore welding Caterpillar D10 Dozer push arm | Sir Meccanica WS2

Summary

A line boring machine is a handy tool that helps fix holes in large metal objects. It works by creating precise, straight holes so that new parts can fit correctly. The machine is operated by a skilled person who guides the machine to cut through the metal with precision. This process is important for repairing things like engine blocks or construction equipment. Line boring machines are used in various industries and can save lots of time and money by fixing damaged parts instead of replacing them. So next time you come across a big hole in a heavy metal object, remember that there’s a line boring machine ready to get it back in shape!

In conclusion, a line boring machine is a valuable tool that fixes holes in large metal objects. It creates straight holes for new parts and is used in different industries to save time and money.