Have you ever wondered what “double insulated” means on power tools? Well, you’ve come to the right place! In this article, we’ll dive into this term and unravel its significance. So, let’s get started and demystify the world of power tools!

When it comes to power tools, safety is always a top priority. That’s where the concept of “double insulated” comes in. But what does it actually mean? Fear not, young reader, for we shall delve into the explanation shortly. So, get ready to unlock the secrets behind this intriguing feature!

Now, you might be wondering why understanding “double insulated” matters. Well, my curious friend, it’s all about safety. Knowing what it means can help you make informed decisions when choosing and using power tools. So, let’s embark on this knowledge-packed journey and demystify the concept of double insulation together!

What Does “Double Insulated” Mean on Power Tools?

Introduction: Power tools are essential for many DIYers and professionals alike. They make tasks easier and more efficient. When shopping for power tools, you might have come across the term “double insulated.” But what does it mean, and why is it important? In this article, we will delve into the meaning of double insulation on power tools, its benefits, and how it keeps you safe.

Understanding the Importance of Double Insulation

Power tools are designed to handle high voltage electricity to perform various tasks. However, this also presents a potential risk of electrical shock to the user. To mitigate this risk, power tools are equipped with insulation to prevent direct contact with live parts. Double insulation, also known as “Class II insulation,” offers an additional layer of protection.

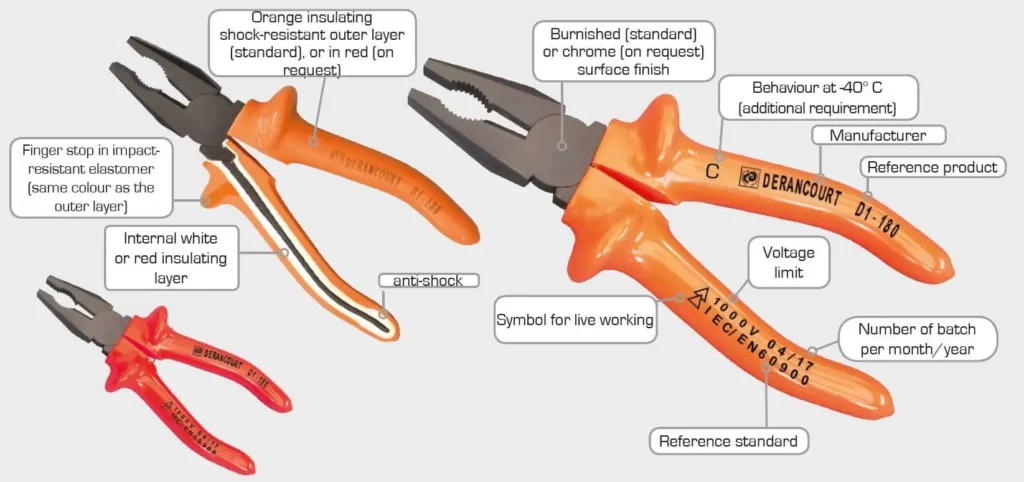

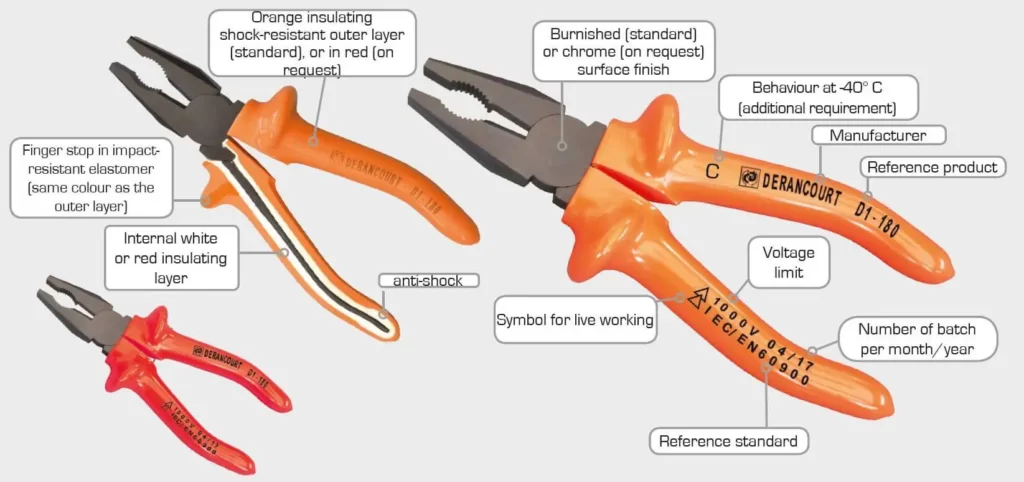

Double insulation is marked by a distinctive symbol, which is usually a square within a square. This symbol indicates that the power tool has been constructed in such a way that it does not rely on the grounding of the electrical system for protection against electrical shock. Instead, it uses two layers of insulating materials or insulation thickness to provide protection.

One of the main advantages of double insulation is that it eliminates the need for a grounding conductor, such as a three-pronged plug. This makes power tools with double insulation more versatile as they can be used with any standard power outlet without requiring a ground connection. Additionally, double insulation reduces the risk of electrical shock from a fault in the electrical system, such as a short circuit.

The Benefits of Double Insulation

While the primary benefit of double insulation is increased safety, there are several other advantages to using power tools with this feature.

1. Enhanced Safety

Double insulation provides an extra layer of protection against electrical shock, ensuring the safety of the user. This is particularly important in situations where power tools are used in wet or damp environments, where the risk of electric shock is higher.

Additionally, double insulation reduces the likelihood of electrical accidents caused by damage to the power tool’s insulation. Even if the outer layer of insulation is compromised, the second layer provides a backup protection, minimizing the risk of electric shock.

2. Increased Flexibility

Power tools with double insulation can be used in various settings without the need for a grounded power source. This flexibility allows for greater mobility and makes it easier to work in different locations without limitations.

Whether you’re working in your garage, on a construction site, or in a remote area, you can confidently use double-insulated tools without worrying about access to a grounded power outlet. This is especially beneficial for professionals who work in different environments.

3. Improved Durability

Double insulation provides an extra layer of protection against physical damage to the internal components of the power tool. The additional layer helps safeguard the electrical components from external impacts, such as drops or bumps, reducing the risk of damage and extending the tool’s lifespan.

Furthermore, double-insulated power tools are often designed to be more robust and sturdy. They are built to withstand harsh conditions and heavy-duty use, making them a reliable choice for demanding projects.

4. Compliance with Safety Standards

In many countries, power tools must comply with safety regulations and standards to ensure the protection of users. Double insulation is a requirement in many of these standards, making it a crucial feature of power tools. By choosing a double-insulated tool, you can be confident that it meets the necessary safety requirements and has undergone rigorous testing.

5. Easy Maintenance

Power tools with double insulation often require less maintenance compared to tools with other types of insulation. The two-layered insulation system provides superior protection against electrical faults, reducing the likelihood of internal damage. This means fewer repairs and less frequent maintenance, saving you time and money in the long run.

Double Insulation vs. Grounded Tools

While double insulation has several benefits, it’s important to understand the differences between double-insulated power tools and those that rely on grounding for protection.

Grounded power tools, also known as “Class I tools,” rely on a grounding conductor to direct electrical faults away from the user. These tools typically have a three-pronged plug that connects to a grounded power outlet. While grounded tools provide adequate protection when used correctly, they may not be as versatile as double-insulated tools due to the requirement for a grounded power source.

Double-insulated power tools, on the other hand, provide protection through a combination of insulation layers and do not require grounding. This makes them more flexible and allows for use in a wider range of environments. However, it’s essential to remember that double insulation does not provide the same level of protection against electrical shock caused by direct contact with live wires.

It’s crucial to select the appropriate tool, considering the specific requirements of your project and the safety measures necessary for your work environment.

Tips for Choosing and Using Double-Insulated Power Tools

When selecting and using power tools with double insulation, here are some essential tips to keep in mind:

1. Look for the Double Insulation Symbol

Before purchasing a power tool, ensure that it features the double insulation symbol. This symbol confirms that the tool meets the necessary safety standards and provides enhanced protection.

Subheading Example:

Double insulation symbol:

2. Follow Safety Guidelines

Always follow the manufacturer’s safety guidelines and instructions when using power tools. This includes wearing appropriate protective gear, using tools in the recommended manner, and storing them correctly when not in use.

3. Regularly Inspect for Damage

Inspect your power tools regularly for any signs of damage or wear. Check the power cord, insulation, and overall condition of the tool. If you notice any issues, such as frayed cords or cracked insulation, discontinue use and have the tool repaired or replaced.

4. Keep Tools Dry

Avoid using power tools with double insulation in wet or damp conditions unless they are specifically designed for such environments. Moisture can compromise the insulation and increase the risk of electrical shock.

5. Store Tools Properly

Store your power tools in a dry, secure location. Protect them from dust, debris, and extreme temperatures, which can affect their performance.

Conclusion

Double insulation on power tools is an important safety feature that provides enhanced protection against electrical shock. It eliminates the need for grounding and offers increased flexibility, durability, and compliance with safety standards.

When choosing power tools, consider the specific requirements of your projects and work environment. Always check for the double insulation symbol and follow the manufacturer’s safety guidelines to ensure safe and efficient use.

Key Takeaways: What Does Double Insulated Mean on Power Tools?

- Double insulated power tools have an extra layer of insulation to protect the user.

- This insulation helps prevent electrical shocks by redirecting any potential current leaks.

- Double insulation is indicated by a symbol, such as a square within a square.

- These tools are considered safer to use when working with electricity.

- Double insulation eliminates the need for grounding.

Frequently Asked Questions

When it comes to power tools, understanding what “double insulated” means is important for your safety and durability of the tool. Below, we’ve answered some common questions related to what “double insulated” means on power tools.

What does it mean when a power tool is double insulated?

Double insulation is a safety feature on power tools that provides an extra layer of protection. These tools have an extra layer of insulation internally, separating the electrical parts from the exterior housing. This design helps prevent electrical shock if there’s a fault in the tool or if the user accidentally comes into contact with live wires. Double insulated power tools are identified by a square symbol with two overlapping squares.

What’s great about double insulation is that it eliminates the need for a grounding wire, making these tools safer to use in environments where grounding isn’t possible or convenient. Overall, double insulated power tools offer an additional level of safety and are a reliable choice for both professionals and DIY enthusiasts.

Is double insulation the same as grounding?

No, double insulation should not be confused with grounding. While both aim to provide safety, they are different concepts. Grounding involves connecting a power tool to the earth’s ground through a grounding wire to redirect the flow of electrical current, while double insulation relies on an extra layer of insulation to prevent shocks. Double insulated tools are designed to eliminate the need for grounding, making them safer in various working conditions.

It’s essential to note that not all power tools are double insulated. Some tools, particularly older models, may not have this feature, relying on grounding instead. When using a power tool, it’s crucial to read the user manual and understand the safety features to ensure proper usage and minimize the risk of electrical shock.

Can I still get an electric shock with a double insulated power tool?

While double insulation provides an added layer of safety, it’s important to remember that no tool can guarantee 100% protection against electric shocks. Double insulated power tools greatly reduce the risk of shocks, especially in cases where the outer casing is damaged or compromised. However, misuse, damaged cords, or exposure to wet conditions can increase the chances of electric shocks, even with a double insulated tool.

To protect yourself, always follow safety guidelines, such as wearing appropriate personal protective equipment, avoiding exposure to water or wet environments, and inspecting tools for any visible damage before each use. Additionally, consult the user manual that comes with the tool to understand the specific safety instructions and recommendations provided by the manufacturer.

Are there any disadvantages to using double insulated power tools?

While double insulated power tools offer enhanced safety, it’s important to be aware of a few potential disadvantages. One key disadvantage is that these tools tend to be bulkier and heavier compared to non-double insulated counterparts. The additional insulation layer adds extra weight and size to the tool, which may affect user comfort, especially during long periods of use.

Furthermore, double insulated tools may be more expensive compared to non-double insulated models. The additional safety features and insulation materials result in a higher manufacturing cost, which can be reflected in the retail price. However, when it comes to protecting your safety and minimizing the risk of electric shocks, the investment in a double insulated power tool is often worth it.

Can I use double insulated power tools in wet conditions?

While double insulated power tools provide an extra safety measure, they are not designed for use in wet conditions. Moisture and water present a significant risk of electric shocks regardless of the tool’s insulation. If you need to work in wet or damp conditions, it’s important to use tools specifically designed for such environments, such as those with a waterproof or water-resistant rating.

Always prioritize your safety and consult the manufacturer’s guidelines and safety recommendations for specific working conditions. Using the right tool for the job and taking precautions can help prevent accidents and ensure a safe working experience.

Summary

When power tools have a double insulated label, it means they have extra protection. Double insulation keeps users safe from electric shocks by using two layers of insulation. This is important because it prevents the electricity from coming into contact with your body. If the power tool has a double insulated label, you can feel confident that it has gone through rigorous safety testing.

Double insulation is indicated by a symbol that looks like a square within a square. You might see this symbol on power tool labels or in the user manual. It’s essential to understand the meaning of this symbol so you can stay safe while using power tools. So, remember, if a power tool is double insulated, it means it has an extra layer of safety to keep you protected.