Picture this: you’re tinkering away in your workshop, wondering about the mysterious term “lathe swing.” What does it mean? Well, my curious friend, you’re in luck! Today, we’re diving into the exciting world of lathes and uncovering the secrets behind the intriguing concept of lathe swing.

So, what exactly does lathe swing mean? It’s like a superpower of lathes that determines their capacity to handle workpieces. But don’t worry, we’ll break it down into simple language that even a 13-year-old can understand. Strap on your safety goggles and get ready to embark on this thrilling journey of discovery.

In this article, we’ll explore what lathe swing is, how it’s measured, and why it’s essential for your woodworking or metalworking endeavors. By the end, you’ll have a solid grasp on the concept and be ready to unleash your creative potential with this newfound knowledge. Let’s swing into action!

Have you ever wondered what “lathe swing” means? In the world of machining, lathe swing refers to the maximum diameter of a workpiece that a lathe can accommodate. It determines the size of the material that can be turned on the lathe. Think of it like the “clearance” or “headroom” for your workpiece. Understanding lathe swing is important when choosing the right lathe for your projects.

What Does Lathe Swing Mean? Understanding the Concept

When it comes to lathes, the term “swing” is a crucial measurement that determines the size and capacity of a lathe. It plays a significant role in determining the workpiece size that a lathe can handle. In this article, we will dive deep into what lathe swing means and why it is important in the world of machining. So, if you have been curious about this term and its implications, read on to get a better understanding of lathe swing.

The Definition of Lathe Swing

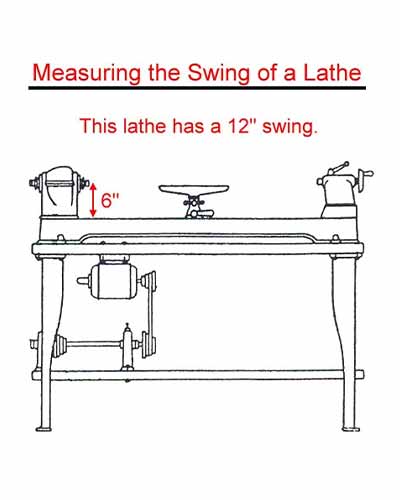

Lathe swing is the maximum diameter of a workpiece that a lathe can accommodate. It is measured as the distance from the centerline of the lathe spindle to the bed of the lathe, multiplied by two. In simple terms, it is the largest diameter of a workpiece that can be rotated on the lathe without any interference. Understanding the lathe swing is crucial because it determines the size limit of the workpieces you can handle with a particular lathe.

The swing capacity of a lathe is typically advertised as a numerical value, such as 12 inches or 20 inches. This measurement can vary depending on the type and model of the lathe. It is important to note that the swing capacity does not refer to the length of the workpiece that a lathe can handle. Instead, it focuses solely on the diameter.

The Importance of Lathe Swing

Knowing the swing capacity of a lathe is essential for several reasons. First and foremost, it helps you determine if a lathe is suitable for your specific machining needs. If you primarily work with smaller diameter workpieces, a lathe with a smaller swing may be sufficient. However, if you frequently work with larger workpieces, you will need a lathe with a larger swing capacity.

Additionally, understanding the lathe swing allows you to plan your projects and choose the appropriate lathe for the job. If you attempt to work with a workpiece that exceeds the lathe’s swing capacity, you risk damaging the lathe or compromising the quality of your work. By selecting a lathe with a swing capacity that matches your workpiece requirements, you can ensure optimal performance and achieve accurate results.

Furthermore, the lathe swing capacity also affects the available workspace around the lathe. The larger the swing capacity, the more space you will need to accommodate the lathe and the workpiece. This is an important consideration if you have limited space in your workshop or manufacturing facility.

Factors Affecting Lathe Swing

Several factors can affect the swing capacity of a lathe. The most obvious factor is the design and size of the lathe itself. A larger lathe with a longer bed generally has a larger swing capacity compared to a smaller lathe. The distance between the lathe spindle and the bed, as well as the overall construction of the lathe, influence the swing capacity.

Additionally, the type of tooling and attachments used on the lathe can affect the swing capacity. Certain tooling arrangements may require more clearance, reducing the effective swing capacity of the lathe. It is important to consider the specific tooling and attachments you plan to use when determining the swing capacity you require.

Lastly, it is worth noting that the swing capacity of a lathe is a maximum limit. It is always recommended to work within the specified range to ensure safety and optimal performance. Attempting to push the limits of the swing capacity can result in instability, poor precision, and potential damage to the lathe and workpiece.

Tips for Choosing the Right Lathe Swing

When selecting a lathe, it is crucial to consider the swing capacity that aligns with your workpiece requirements. Here are a few tips to help you choose the right lathe swing:

- Measure your workpieces: Determine the largest diameter of the workpieces you regularly work with to ensure the lathe you choose can accommodate them.

- Anticipate future needs: If you foresee working on larger projects in the future, it may be wise to choose a lathe with a slightly larger swing capacity to allow room for growth.

- Consider workspace limitations: Evaluate the available space in your workshop or manufacturing facility to ensure the lathe you select fits comfortably without hindering other operations.

- Research lathe models: Compare the swing capacities of different lathe models to find the best match for your specific needs and budget.

Conclusion

Understanding the concept of lathe swing is essential for anyone working with lathes in the machining industry. By knowing the swing capacity of a lathe, you can make informed decisions when selecting a lathe for your projects. Whether you are a hobbyist or a professional machinist, taking the time to research and understand lathe swing will contribute to your success and the quality of your work.

Key Takeaways: What Does Lathe Swing Mean?

- The term “lathe swing” refers to the maximum diameter of a workpiece that can be rotated on a lathe.

- It is determined by the distance between the center line of the lathe and the bed, and is usually twice that distance.

- Knowing the lathe swing is important for determining the size of work a lathe can handle.

- A larger lathe swing allows for turning larger diameter workpieces.

- Swing-over bed and swing-over carriage are two common measurements used to determine the lathe swing.

Frequently Asked Questions

In the world of machining, the term “lathe swing” refers to a key measurement that determines the maximum diameter of a workpiece the lathe can accommodate. It is an important factor in determining the size and capabilities of a lathe machine. Let’s dive into some commonly asked questions about lathe swing:

1. How is lathe swing measured?

Lathe swing is typically measured by finding the distance between the lathe’s bed and the centerline of the spindle. It is essentially the maximum diameter of a workpiece that can be accommodated by the lathe without any obstructions. This measurement is crucial for determining the size and capacity of a lathe.

For example, if you have a lathe with a swing capacity of 12 inches, it means that the lathe can accommodate workpieces up to 12 inches in diameter. This measurement is taken as a radial distance, which means it is the measurement from the centerline of the spindle to the lathe bed.

2. How does lathe swing affect the workpiece size?

The lathe swing directly impacts the maximum size of the workpiece that can be machined on a lathe. If a workpiece exceeds the swing capacity of a lathe, it will not fit properly and could potentially damage the machine. It is important to consider the lathe swing when selecting a lathe for a specific project.

For instance, if you need to work on a 15-inch diameter workpiece, you would need a lathe with a swing capacity greater than 15 inches. If the lathe’s swing capacity is smaller than the workpiece diameter, it might be impossible or unsafe to use that specific lathe for the desired task.

3. What are the advantages of a larger lathe swing?

A larger lathe swing provides several advantages. Firstly, it allows for the machining of larger workpieces, providing flexibility and versatility in various projects. With a larger swing, you can handle a wider range of diameters and undertake more significant turning operations.

Moreover, a larger lathe swing allows for more stability and rigidity when working on larger workpieces, minimizing vibrations and errors. This results in improved accuracy and precision in the machining process. Additionally, a larger swing enhances the accessibility to the workpiece, making it easier to handle and maneuver during machining operations.

4. Can the lathe swing be increased?

The lathe swing is determined by the design and construction of the lathe, so it cannot be easily increased once the lathe is built. The swing capacity is a fundamental characteristic of a lathe, and altering it would require significant modifications that may not be feasible.

To accommodate larger workpieces, one option is to acquire a lathe with a larger swing capacity. Another alternative could be finding creative ways to reposition the workpiece or using additional cutting tools to achieve the desired dimensions within the lathe’s existing swing capacity.

5. How does lathe swing differ from distance between centers?

The lathe swing and the distance between centers are two separate measurements that determine different aspects of a lathe’s capabilities. While the swing refers to the maximum diameter of a workpiece, the distance between centers measures the length of a workpiece that can be accommodated by the lathe without any obstructions.

The distance between centers is determined by measuring the length between the lathe’s headstock and tailstock. It indicates the maximum length of a workpiece that can be turned or machined on the lathe. So, while the swing determines the maximum diameter, the distance between centers determines the maximum length of the workpiece that can be worked on a lathe.

Introduction to Lathe Machine,Working principle,Operations and specifications of lathe

Summary

A lathe is a machine used to shape wood or metal by rotating it against a cutting tool. The “swing” of a lathe is the maximum diameter of the workpiece that can be accommodated by the machine. It is measured by doubling the distance from the center of the lathe spindle to the bed.

Knowing the swing of a lathe is essential because it determines the size of the objects you can work on. If your workpiece is larger than the lathe’s swing, it won’t fit and you won’t be able to use the machine. So, it’s important to understand the swing and choose a lathe that can handle your project size.