What does lathe work mean? If you’ve ever been curious about this fascinating craft, then you’re in the right place! Lathe work is a traditional method of shaping and cutting materials like wood or metal with the help of a lathe machine. It’s like having a super-powered tool that can transform raw materials into beautiful and functional objects. So, let’s dive in and explore the exciting world of lathe work!

You might be wondering, how does a lathe machine work its magic? Well, imagine a spinning wheel that holds the material being worked on. As the wheel turns, sharp tools are used to shape and cut away excess material, revealing the desired form. It’s like sculpting with precision and control, allowing craftsmen to create intricate designs and smooth finishes. From crafting wooden furniture to fabricating metal parts, lathe work has endless possibilities!

Whether you’re a budding craftsmen or simply curious about the art of lathe work, this article will take you on a journey through its history, techniques, and incredible creations. Get ready to be amazed by the skill, creativity, and craftsmanship that goes into turning simple materials into works of art. So, let’s dive in and unravel the secrets of lathe work together!

Curious about lathe work? Let’s dive in! Lathe work refers to the process of shaping or cutting materials using a lathe machine. This versatile tool spins the workpiece while various tools are used to shape and cut it into the desired form. From woodworking to metalworking, lathe work is used in a wide range of industries and projects. Discover the endless possibilities of lathe work and unleash your creativity!

Understanding Lathe Work: Exploring the Basics

Lathe work is a fundamental aspect of machining and metalworking that involves the use of a lathe machine. This article aims to provide a comprehensive overview of what lathe work entails, its applications, and the key components involved. Whether you’re a novice or a seasoned professional, understanding the principles of lathe work is essential to harnessing the full potential of this versatile tool.

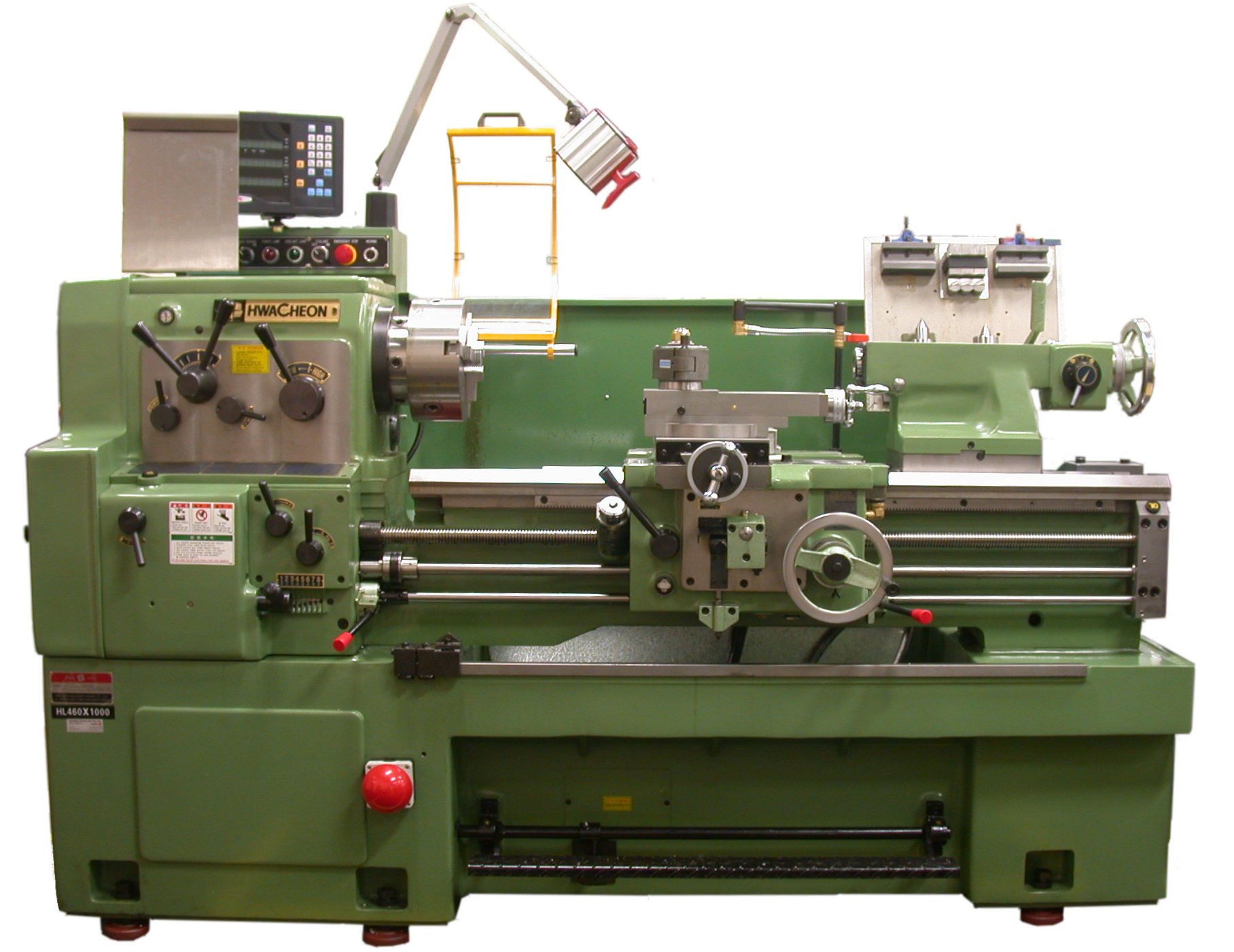

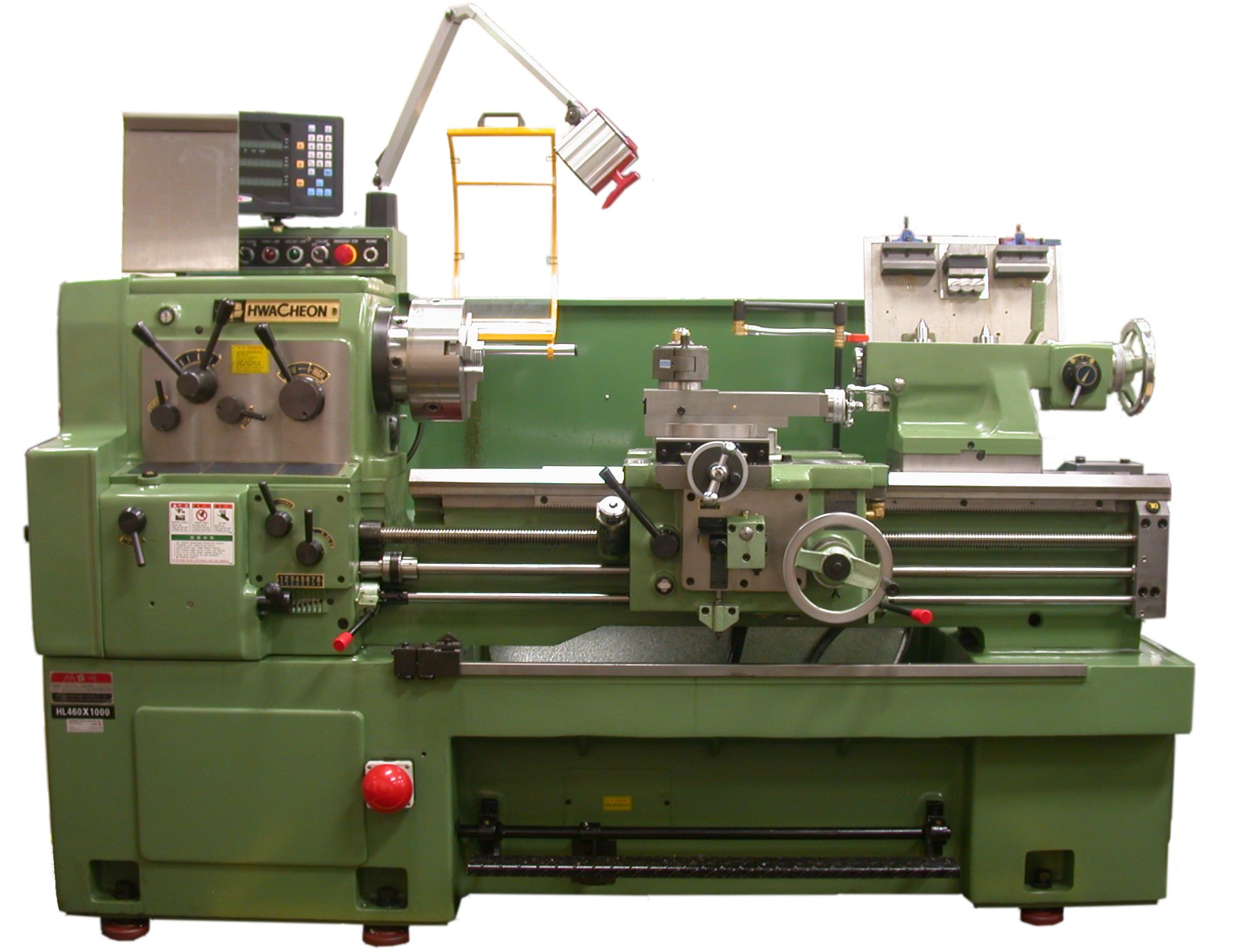

The Lathe Machine: A Closer Look

Before delving into the intricacies of lathe work, let’s take a closer look at the lathe machine itself. The lathe machine is a power-driven tool that rotates a workpiece against a cutting tool to shape, cut, drill, or sand it to the desired form. It consists of several key components, including the bed, headstock, tailstock, and carriage. These components work together to provide the necessary stability, precision, and control required for efficient lathe work.

The Bed: The Foundation of the Lathe Machine

The bed is the horizontal base of the lathe machine that provides support to all other components. Typically made of cast iron, it ensures stability and rigidity during operations. The bed also houses the headstock and tailstock, which are crucial for holding and rotating the workpiece.

On top of the bed, there are precision-machined ways or guides that allow the carriage to move smoothly and accurately. The ways are often equipped with V-shaped or dovetail-shaped surfaces to ensure optimal alignment and precision. Additionally, the bed may have features like T-slots to accommodate other tooling accessories or attachments.

Overall, the construction and quality of the bed play a vital role in determining the accuracy and performance capabilities of the lathe machine.

The Headstock: Powering the Rotation

The headstock is located at the left end of the lathe machine’s bed. It houses the main spindle, which provides the rotational movement to the workpiece. The spindle is driven by an electric motor and is equipped with various speed settings to accommodate different materials, cutting tools, and machining operations.

The headstock also contains a mechanism for controlling the spindle speed, such as a gearbox or a variable speed control. This allows the operator to adjust the rotational speed according to the specific requirements of the workpiece and the desired outcome. Additionally, the headstock may have features like a chuck or a collet closer for securely holding the workpiece in place.

In summary, the headstock is responsible for driving the rotation of the workpiece, providing the foundation for various lathe operations.

The Tailstock: Enabling Stability and Support

Situated at the right end of the lathe machine’s bed, the tailstock complements the headstock by providing stability and support to the workpiece. It consists of a quill, which can be extended or retracted to accommodate different workpiece lengths.

The tailstock can be locked in position along the bed to ensure precise alignment with the headstock. It also features a center or a center-point, which aligns with the center hole of the workpiece to maintain accuracy during rotational operations. In some cases, the tailstock may also be equipped with a chuck or a drill chuck for holding and drilling the workpiece.

Overall, the tailstock plays a crucial role in providing stability and support, enabling precise machining and minimizing workpiece deflection or vibration.

The Carriage: Enhancing Precision and Control

The carriage is responsible for controlling the tool movement and position during lathe work. It slides along the ways of the lathe bed and consists of several important components, including the saddle, cross-slide, and compound rest.

The saddle is mounted on the ways and allows for lateral movement along the bed. It carries the cross-slide, which enables the tool to move perpendicular to the workpiece axis. The compound rest, situated on top of the cross-slide, provides an additional degree of movement and control, allowing for angled cuts and taper turning.

The carriage is typically equipped with handwheels or power feed mechanisms to facilitate smooth and precise tool movement. It also houses the tool post, which securely holds the cutting tool at the desired position and angle. With the help of the carriage, operators can achieve accurate cuts, threads, and other intricate lathe operations.

Common Lathe Work Operations and Techniques

Now that we have a solid understanding of the key components of a lathe machine, let’s explore some of the most common lathe work operations and techniques used in various industries. From turning and facing to drilling and boring, there are numerous ways to utilize a lathe machine effectively.

The Versatility of Lathe Work: Applications in Different Industries

Lathe work finds its applications in a wide range of industries, including automotive, aerospace, manufacturing, and woodworking. The ability to shape and transform raw materials into functional components makes lathe work indispensable in these sectors. From creating intricate metal parts for machinery to crafting wooden furniture with precision, the versatility of lathe work is undeniable.

Tips for Getting Started with Lathe Work

For those interested in exploring the world of lathe work, here are some useful tips to get you started:

- Invest in quality tools: A lathe machine is only as good as the tools used with it. Choose high-quality cutting tools, chucks, and tool holders for superior results.

- Master the basics: Start with simple turning operations and gradually progress to more complex techniques. Focus on mastering tool control, speed settings, and workpiece setup.

- Practice safety precautions: Lathe work involves high speeds and sharp tools, so always wear protective gear, follow safety guidelines, and keep a clean working environment.

- Seek guidance and resources: Join online communities, take classes, and refer to comprehensive guides and tutorials to enhance your lathe work skills.

- Experiment and innovate: Don’t be afraid to try new techniques, explore different materials, and push the boundaries of lathe work. Innovation often stems from experimentation and thinking outside the box.

Conclusion

Lathe work encompasses a vast array of operations and techniques that play a crucial role in various industries. With a solid understanding of the key components of a lathe machine and the versatility of lathe work, individuals can tap into the immense potential of this machining process. Whether you’re a hobbyist or a professional, embracing lathe work opens up a world of possibilities for creating precision-crafted components and realizing your creative vision.

Key Takeaways: What Does Lathe Work Mean?

- Lathe work refers to the process of shaping materials using a lathe machine.

- A lathe machine spins the material while a cutting tool shapes it into the desired form.

- Lathe work is commonly used in woodworking, metalworking, and machining industries.

- It allows for precision shaping of materials, creating smooth and precise finishes.

- Lathe work can be performed on various materials such as wood, metal, and plastics.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer some common queries about lathe work. Whether you’re new to machining or just curious about the intricacies of lathe work, we’ve got you covered. Read on to find out more!

1. How does a lathe work?

A lathe is a machine tool that rotates a workpiece on its axis while various cutting tools are applied to shape the material into the desired form. The workpiece is usually held firmly in place by clamps or chucks. As the workpiece turns, the cutting tool, which is stationary, removes material by shaving, cutting, or drilling. This process allows for precise shaping, smoothing, and sizing of the workpiece.

A lathe typically consists of a bed, headstock, tailstock, carriage, and tool post. The bed provides stability and supports the other components. The headstock holds the spindle, which rotates the workpiece. The tailstock can be moved along the bed to support longer workpieces. The carriage holds the cutting tools and can be manually or automatically moved along the bed. The tool post securely holds the cutting tools in place.

2. What materials can be worked on a lathe?

A lathe can be used to work on a wide range of materials, including metal, wood, plastic, and even glass. When it comes to metal, lathes are commonly used to work with materials such as steel, aluminum, brass, and copper. Wood lathes are specifically designed for woodworking and are ideal for shaping and turning wooden objects, such as furniture legs or decorative items.

Plastic lathes are used in industries like manufacturing and prototyping to shape plastic materials like acrylic or nylon. Glass lathes, on the other hand, are used by specialized glassblowers to shape molten glass into various forms. The versatility of lathe work makes it a valuable tool in many different industries.

3. What are some common lathe operations?

There are several common lathe operations that can be performed on a lathe machine. Turning is one of the most basic and fundamental operations, which involves removing material from the outside or inside of a cylindrical workpiece to achieve a desired shape or diameter. Facing is another operation used to smooth the end of a workpiece to create a flat surface. Drilling, parting, and threading are other common operations performed on a lathe.

Drilling involves creating holes in the workpiece, while parting is the process of cutting off a section of the workpiece to separate it from the rest. Threading is used to create screw threads on the surface of the workpiece. Each operation requires different cutting tools, techniques, and setups, but they all contribute to the versatility of lathe work.

4. What are the advantages of lathe work?

Lathe work offers several advantages that make it a preferred method for machining. One of the main advantages is its versatility, as it can be used to work on various materials and perform different operations. The ability to create highly precise shapes and dimensions is another benefit of lathe work. It allows for intricate details and smooth finishes, making it popular in industries like aerospace, automotive, and engineering.

Lathe work is also efficient and cost-effective. It can rapidly produce multiple identical parts with consistent accuracy. The simplicity of the process and the availability of numerous cutting tools make lathe work accessible to both professionals and hobbyists. Whether it’s for mass production or creating one-of-a-kind pieces, lathe work provides a reliable and efficient solution.

5. Can lathe work be done manually or with CNC?

Lathe work can be done manually or with the help of computer numerical control (CNC). Manual lathe work involves the operator manually controlling the movements of the cutting tools, adjusting the speed and feed rate, and monitoring the operation. It requires skill and experience to produce precise results.

On the other hand, CNC lathes are automated machines that follow pre-programmed instructions to perform the desired operations. The operator sets up the machine, inputs the specifications, and the CNC lathe takes care of the rest. CNC lathes offer increased precision, repeatability, and the ability to handle complex designs. They are commonly used in industrial settings for high-volume production.

Summary

Lathe work is about shaping and cutting materials like metal or wood using a lathe machine. It’s a way to create different shapes and designs by rotating the object and using cutting tools.

Lathe machines have been around for a long time and are used in various industries, such as manufacturing and woodworking. They are versatile and can make things like bowls, furniture legs, or even metal parts for machines.

Learning lathe work takes practice and patience, but it can be a fun and rewarding skill to have. With a lathe machine, you can turn ordinary objects into beautiful, functional pieces. So, if you’re interested in making things and being creative, lathe work might be something to explore!