Are you curious about what spindle travel means on a drill press? Well, buckle up, because we’re about to embark on an exciting journey into the world of power tools!

Picture this: you’ve got a drill press in front of you, ready to unleash its drilling prowess. But wait, what exactly does “spindle travel” mean?

In simple terms, spindle travel refers to the distance that the drill bit can move up and down within the drill press. It’s like the elevator ride for your drill bit, taking it to different depths in your workpiece.

Now that we’ve got a basic understanding, let’s dive deeper into the ins and outs of spindle travel on a drill press. Get ready to become a drilling expert in no time!

Understanding Spindle Travel on a Drill Press: A Comprehensive Guide

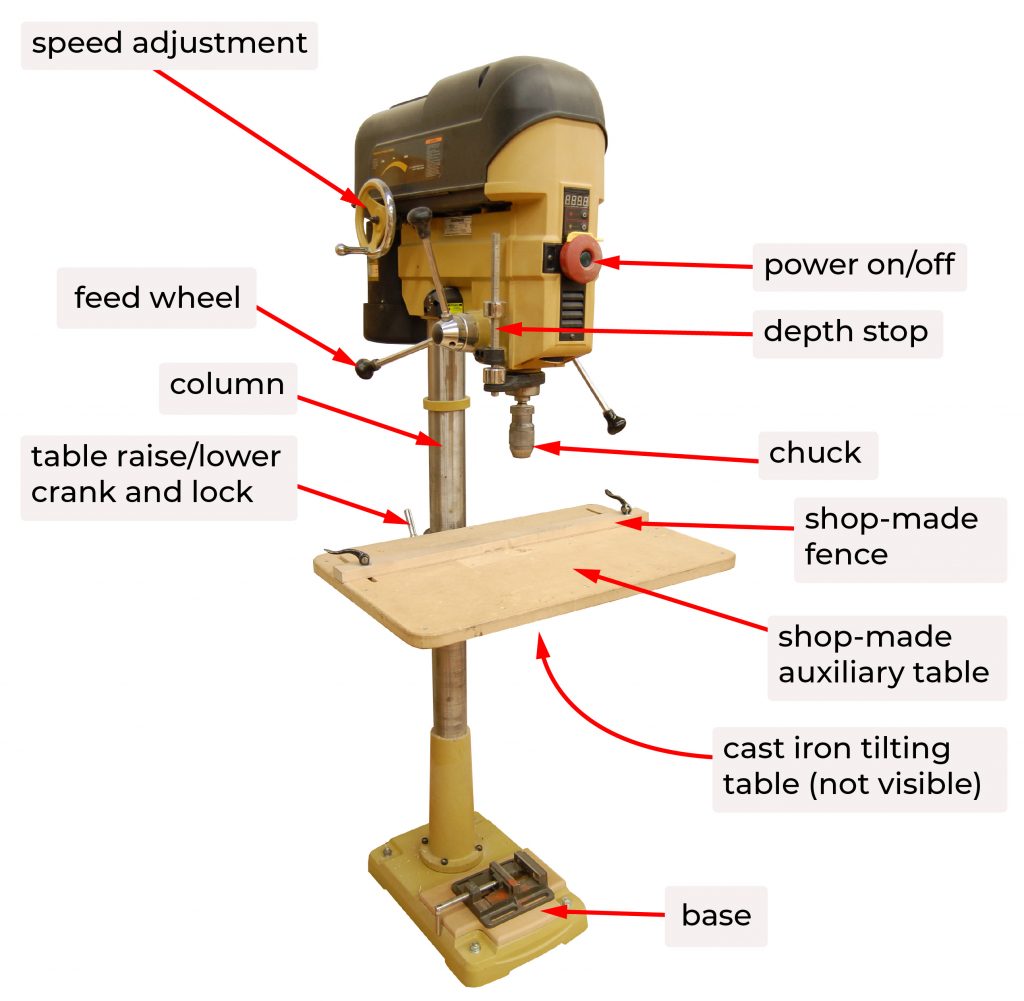

Drill presses are essential tools in woodworking, metalworking, and various other industries. One crucial specification to consider when purchasing a drill press is its spindle travel. But what exactly does spindle travel mean on a drill press? In this article, we’ll delve into the details of spindle travel, its importance, and how it affects the functionality of a drill press.

What is Spindle Travel?

Spindle travel refers to the maximum distance the spindle, or chuck, of a drill press can move vertically. In simpler terms, it measures how far you can lower the drill bit into your workpiece. This vertical movement is crucial for accommodating different material thicknesses and achieving the desired depth of cut.

Usually, the spindle travel is measured in inches, and it can range anywhere from 2 to 6 inches, depending on the drill press model and brand. The spindle travel is determined by the design and construction of the drill press, specifically the length of the quill, which is the part that holds the chuck and can move up and down.

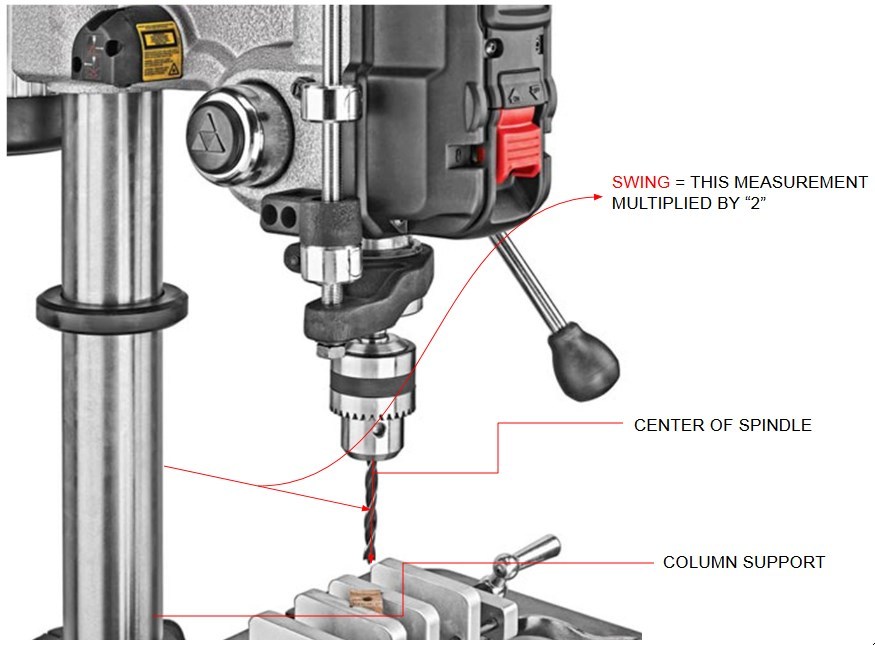

It’s important to note that the spindle travel is different from the throat depth, which refers to the distance between the center of the spindle and the support column of the drill press. While both specifications are significant, they serve different purposes and should be considered separately when choosing a drill press.

Importance of Spindle Travel

The spindle travel is a critical specification to consider because it directly affects the versatility and functionality of a drill press. Having a sufficient spindle travel allows you to tackle a wide range of projects, as you can drill holes at varying depths in different materials.

Without enough spindle travel, you may be limited in the types of projects you can undertake. For example, if you’re working on thick stock or need to drill holes deep into your workpiece, insufficient spindle travel would restrict your options and force you to find alternative methods.

On the other hand, having a drill press with ample spindle travel offers greater flexibility and convenience. Regardless of the material thickness or depth of cut required, you can adjust the spindle travel accordingly and achieve precise and accurate results.

Factors to Consider When Choosing Spindle Travel

When selecting a drill press, it’s essential to consider your specific needs and the types of projects you’ll be working on. Here are a few factors to keep in mind regarding spindle travel:

- Material thickness: Determine the maximum material thickness you will commonly work with and ensure the spindle travel can accommodate it.

- Project requirements: Consider the depth of cut you need for your projects. If you frequently work on projects that require drilling deep holes, opt for a drill press with a larger spindle travel.

- Versatility: If you envision working on a wide range of projects with varying material thicknesses, it’s advisable to choose a drill press with a generous spindle travel to ensure flexibility.

Benefits of Ample Spindle Travel

Having a drill press with ample spindle travel can offer several advantages:

- Enhanced versatility: With greater spindle travel, you can adapt to different project requirements and work with various material thicknesses.

- Precision and accuracy: Ample spindle travel allows you to drill holes at the desired depth, resulting in precise and accurate results.

- Convenience and ease of use: A drill press with sufficient spindle travel eliminates the need for additional tools or workarounds, making your projects more efficient and streamlined.

Choosing the Right Drill Press for Your Needs

When selecting a drill press, it’s crucial to consider various factors, including spindle travel. Evaluate your specific needs, the types of projects you plan to work on, and the desired depth of cut. Additionally, pay attention to the overall build quality, motor power, and additional features that enhance the functionality and usability of the drill press.

By understanding the importance of spindle travel and factoring it into your decision-making process, you can confidently choose a drill press that meets your requirements and enables you to tackle a wide variety of projects with ease and precision.

Top 3 Drill Presses with Ample Spindle Travel

After understanding the significance of spindle travel on a drill press, let’s take a look at three top-rated drill presses that offer ample spindle travel:

Drill Press vs. Other Power Tools: Which is Right for You?

While drill presses are indispensable tools in many workshops, there are instances where other power tools may be a more suitable choice for certain projects. Let’s compare a drill press with some popular alternatives to determine which tool is best suited for different applications:

Common Tips for Using a Drill Press with Optimal Spindle Travel

Now that you’re aware of the importance of spindle travel and how it affects your drill press’s functionality, here are a few tips to ensure you make the most of your drill press:

Key Takeaways: What Does Spindle Travel Mean on a Drill Press?

- Spindle travel refers to the distance the drill bit can travel up and down on a drill press.

- It determines the maximum depth of holes that can be drilled.

- The spindle travel is usually measured in inches or millimeters.

- Drill presses with larger spindle travel allow for drilling deeper holes.

- When choosing a drill press, consider the spindle travel to ensure it meets your drilling needs.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we will answer some common queries about drill press spindle travel. Read on to find out more!

1. How does spindle travel affect the functionality of a drill press?

The spindle travel on a drill press refers to the distance the spindle can move vertically. It determines the maximum depth you can drill into a material. The greater the spindle travel, the deeper holes you can create. This feature is crucial, especially when working with materials of different thicknesses, as it allows you to adjust the drill bit’s depth accordingly.

Having sufficient spindle travel ensures versatility in your drilling tasks. With deeper spindle travel, you can work on a wider range of projects, from simple tasks like creating holes for screws to more complex projects that require drilling deep into the material.

2. Is spindle travel the same as stroke length?

While both spindle travel and stroke length refer to vertical movement, they are not the same. Spindle travel specifically applies to drill presses, while stroke length is a term commonly used in relation to tools like jigsaws or reciprocating saws. The primary difference lies in their functionalities and the tools they are associated with.

In the context of a drill press, the spindle travel determines the depth of the hole you can drill, whereas stroke length in other tools refers to the distance the blade or cutting element moves back and forth. So, while they share a similar concept of vertical movement, their applications and specific functions are distinct.

3. Can I adjust the spindle travel on a drill press?

Unfortunately, the spindle travel on a drill press is a fixed measurement and cannot be directly adjusted. It is determined by the design and construction of the drill press. Different drill press models offer varying spindle travel distances, so it’s essential to choose a drill press with the spindle travel that suits your specific needs.

However, you can still achieve different depth levels by adjusting the depth stop. The depth stop is a feature that limits the drill bit’s travel, allowing you to drill holes to a consistent depth. By setting the depth stop, you can control the depth of the holes you want to drill, even though it doesn’t directly modify spindle travel.

4. What is the typical range of spindle travel on drill presses?

The range of spindle travel on drill presses can vary depending on the specific model and manufacturer. However, the typical range of spindle travel for most drill presses falls between 3 to 6 inches. This range is usually sufficient for most woodworking or metalworking projects.

If you require a drill press with greater spindle travel for your specific projects, you may need to consider purchasing a specialized drill press model that offers extended spindle travel options. These models are designed for heavy-duty applications and can provide spindle travel beyond the typical range.

5. Is spindle travel the only factor to consider when choosing a drill press?

No, spindle travel is just one of several factors to consider when selecting a drill press. Other crucial factors include the drill press’s motor power, speed range, table size, and overall build quality. It’s vital to ensure that the drill press you choose aligns with your specific project requirements and provides the necessary features for your intended applications.

Consider evaluating your project needs, the materials you’ll be working with, and how frequently you’ll be using the drill press. By taking all these factors into account, you can make an informed decision and choose a drill press that meets your needs and delivers the performance you desire.

Summary

Here’s a quick recap of what we’ve learned about spindle travel on a drill press:

When we talk about spindle travel, we’re talking about how deep the drill bit can go. It’s like the drill press’s superpower! The spindle is the part that holds the drill bit, and the travel is how far it can move up and down. The more travel, the deeper you can drill.

In order to choose the right drill press for our projects, we need to consider the spindle travel. If we want to drill big holes or go really deep, we’ll need a drill press with more travel. But if we only need to drill shallow holes, then a drill press with less travel will do the job just fine. So, remember, more travel means more drilling power!