Hey there! Are you curious about what the spindle does on a lathe? Well, you’ve come to the right place! In this article, we’ll explore the fascinating role of the spindle and how it contributes to the operation of a lathe. So, let’s dive in and uncover the intriguing world of lathes and spindles!

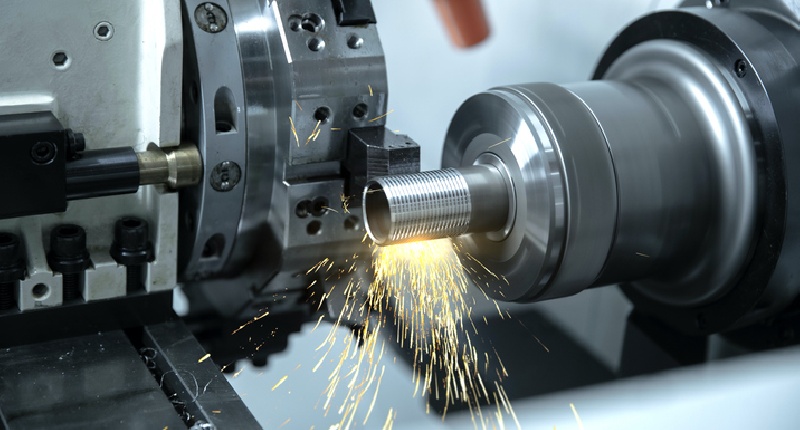

Picture this: you have a block of wood or a metal rod that you want to shape into something amazing. That’s where a lathe comes in. It’s a machine used to rotate a workpiece while cutting, shaping, or drilling it with various tools. And at the heart of this remarkable machine lies the spindle.

Now, you might be wondering, what exactly does the spindle do? Well, simply put, the spindle is like the powerhouse of the lathe. It’s a rotating shaft that holds the workpiece securely and spins it at a controlled speed. This rotational motion is crucial because it allows you to work on the workpiece from different angles and create precise shapes and cuts. So, in essence, the spindle sets the stage for all the magic that happens on a lathe!

What Does the Spindle Do on a Lathe?

Welcome to the world of lathes! If you’re new to this realm of machining, you may find yourself asking, “What does the spindle do on a lathe?” Well, wonder no more. In this article, we’ll delve into the intricacies of the lathe spindle and its crucial role in the turning process. Buckle up and prepare to discover the power behind the lathe’s heart.

Understanding the Spindle: The Heart of the Lathe

The spindle is the central part of the lathe that holds the workpiece and rotates it during the turning process. It is house inside the headstock, which is mounted on the lathe bed. The spindle is driven by either a belt or gear system connected to the lathe’s motor. It provides the power required to rotate the workpiece, allowing for precision cuts and shaping.

The spindle typically features a chuck or a collet, which securely holds the workpiece in place. The chuck is like a clamp, tightly gripping the workpiece and ensuring it doesn’t move or wobble during rotation. This stability is crucial for achieving accurate and symmetrical results. Depending on the lathe’s design, the spindle may have multiple chuck positions to accommodate different workpieces and enhance versatility.

Furthermore, the spindle often incorporates a threaded section called the spindle nose, which allows for the attachment of additional accessories and tooling. These accessories, such as faceplates or specialized chuck jaws, provide further support and grip for specific turning applications. Now that we understand the fundamental role of the spindle, let’s explore its functionalities in more detail.

Rotation and Speed Control for Optimal Turning

The primary function of the lathe spindle is to rotate the workpiece at a controlled speed. This rotation is essential for the cutting tools, such as turning tools or parting tools, to engage with the workpiece effectively. The spindle speed determines the rate at which the workpiece rotates, and it plays a vital role in achieving desired finishes and preventing tool wear.

Most lathes offer variable speed options, allowing users to adjust the spindle speed based on the material being turned, the diameter of the workpiece, and the desired outcome. Higher speeds are generally used for smaller workpieces or materials that require a finer finish. On the other hand, lower speeds are suitable for larger workpieces or tougher materials that require more cutting force. Finding the right spindle speed for each turning project is crucial for achieving optimal results.

In addition to controlling the speed, the spindle also allows for reversing the direction of rotation. This is particularly useful when creating intricate designs or when specific cuts require a different approach. Reversing the spindle direction can help with achieving smoother finishes, reducing vibration, and enhancing the overall quality of the turned piece.

Thread Cutting: An Extra Level of Versatility

Aside from the fundamental functions of rotation and speed control, the spindle on a lathe can also be equipped with a mechanism for thread cutting. This capability allows for the creation of precise screw threads on the workpiece. Thread cutting on a lathe typically involves engaging a threading tool, which moves along the workpiece’s rotating surface, gradually cutting the thread profile into the material.

The ability to cut threads opens up a whole new world of possibilities for turning projects. Whether it’s creating custom bolts, achieving perfect fits for mating components, or adding intricate designs to a turned piece, the thread cutting feature of the lathe spindle is invaluable. With proper technique and a steady hand, you can produce threads of various pitch sizes and profiles.

However, it’s important to note that thread cutting on a lathe requires knowledge and practice. It involves understanding thread pitch, depth, and the correct tool angles. It’s advisable to reference detailed guides or seek expert advice before attempting thread cutting to ensure the best results and avoid damaging the workpiece or the lathe itself.

Maintaining the Spindle: Tips for Optimal Performance

Now that we’ve explored the spindle’s functions on a lathe, let’s talk about maintenance. Keeping your lathe spindle in good working condition is crucial for its overall performance and longevity. Here are a few tips to help you maintain your spindle:

- Regularly clean and lubricate the spindle to prevent dust accumulation and ensure smooth rotation.

- Inspect the chuck or collet regularly to ensure it’s properly aligned and tightened securely.

- Check the spindle bearings for any signs of wear or excessive play. Replace them if necessary to avoid issues with rotation or accuracy.

- When changing workpieces, ensure the chuck or collet is cleaned thoroughly to prevent any debris from affecting the spindle’s performance.

- Avoid overloading the spindle by exceeding the recommended weight or torque limits. This can result in damage to the spindle or other components of the lathe.

By following these maintenance tips, you can keep your lathe spindle in excellent condition and ensure optimal performance for all your turning projects.

Exploring the Capabilities Beyond the Spindle: Lathe Attachments and Accessory Options

Now that we have covered the fundamental role of the spindle on a lathe, let’s dive into the versatile world of lathe attachments and accessory options. These add-ons allow you to expand the capabilities of your lathe and tackle a wide range of turning projects. Here are three essential accessories worth exploring:

1. Faceplate:

A faceplate is a large, flat metal disk that attaches to the lathe spindle. It provides a broad surface area for securing irregularly shaped workpieces or those without a perfectly cylindrical shape. The faceplate typically has multiple mounting holes, allowing for flexible positioning and ensuring a secure grip on the workpiece.

This accessory is particularly useful when turning bowls, platters, or other decorative items. With a faceplate, you can securely hold the workpiece without the need for a chuck, providing ample freedom to shape and carve unique designs on the surface.

2. Steady Rest:

A steady rest is a supportive device that helps stabilize long and slender workpieces during the turning process. It consists of a metal frame with adjustable supports that can be positioned in strategic locations along the workpiece. The supports prevent flexing or vibrating, allowing for precise and smooth turning operations.

Steady rests are invaluable when working with long spindles, thin dowels, or delicate items that require extra support. They ensure optimal results by minimizing flexing and reducing the risk of accidents caused by workpiece movement. When utilizing a steady rest, it’s essential to align it carefully with the spindle and adjust the supports to fit snugly against the workpiece.

3. Live Center:

A live center, also known as a driving center or revolving center, is a tool designed to support the opposite end of the workpiece from the lathe chuck. It consists of a tapered point that rotates with the workpiece, allowing for accurate centering and preventing excessive friction or stress on the workpiece during rotation.

The live center is especially beneficial when working on spindle-like projects that extend beyond the reach of the chuck. It provides additional support, reducing the risk of bending or deflection, and ensuring precise turning results. The live center is typically adjustable, allowing for different point angles or interchangeable points to match the requirements of the workpiece.

By exploring these accessories and other options specific to your lathe model, you can unlock new creative possibilities, enhance precision, and take your turning projects to the next level.

Taking Safety Precautions: Ensuring a Safe Turning Experience

Now that we’ve ventured into the world of lathes and discussed the role of the spindle and its various functionalities, it’s essential to address safety precautions. Working with a lathe involves rotating machinery and sharp cutting tools, so taking proper safety measures is crucial. Here are some essential safety guidelines to follow:

1. Wear Personal Protective Equipment (PPE):

Always wear appropriate PPE, including safety glasses or goggles, to protect your eyes from debris or flying particles. Additionally, wear hearing protection to reduce noise levels and protective gloves to shield your hands from any potential hazards.

2. Familiarize Yourself with the Emergency Stop:

Be aware of the lathe’s emergency stop button and ensure it’s easily accessible. In case of an emergency, quickly locate and press the button to stop the rotation of the spindle and cutting tools.

3. Maintain a Clear Workspace:

Keep your work area clean and organized to minimize the risk of accidents or injuries. Remove any unnecessary tools, debris, or obstacles that may hinder your movements or interfere with the lathe’s operation.

4. Secure the Workpiece Properly:

Always ensure the workpiece is securely fastened to the lathe’s chuck or collet. A loose workpiece can cause severe accidents and damage to the lathe or other equipment. Double-check the tightness of the chuck before starting the spindle.

5. Approach Cutting Tools with Caution:

When changing cutting tools, handling them with care is essential. Blades and other sharp tools can cause serious injuries if mishandled. Use proper tool holders or protective guards to minimize the risk of accidental contact with the cutting edges.

6. Practice Safe Speed Control:

When adjusting the spindle speed, do so gradually to avoid sudden changes that may affect the stability of the lathe or the workpiece. Always wait for the spindle to come to a complete stop before making any adjustments.

Adhering to these safety precautions ensures a safe and enjoyable turning experience. Remember, safety should always be the top priority when working with any machinery or tools.

Conclusion:

The spindle on a lathe is the powerhouse behind the turning process. Its ability to rotate the workpiece, control speed, and facilitate thread cutting adds immense versatility and precision to turning projects. Understanding the role of the lathe spindle and its functionalities allows for enhanced creativity and opens doors to a world of possibilities.

Remember to follow proper maintenance procedures to keep your spindle in optimal condition and explore additional lathe attachments and accessory options to expand your turning capabilities. And above all, prioritize safety by adopting essential precautions and wearing appropriate protective gear.

Whether you’re a beginner or a seasoned turner, embracing the art of the lathe and harnessing the power of the spindle will undoubtedly lead to fruitful and rewarding turning projects.

Key Takeaways:

- The spindle on a lathe is an important part that holds and rotates the workpiece.

- It is responsible for providing the necessary power and precision to shape the workpiece.

- By rotating the workpiece, it allows various cutting tools, like chisels or drills, to shape and remove material.

- The speed of the spindle can be adjusted to control the cutting action and achieve different results.

- The spindle is a vital component that enables the lathe to perform a wide range of shaping and machining operations.

Frequently Asked Questions

Have you ever wondered about the functions of the spindle on a lathe? Look no further! Below, we’ve answered some common questions to help you understand what the spindle does and its importance in lathe operations.

1. How does the spindle on a lathe contribute to its functionality?

The spindle on a lathe plays a crucial role in the machine’s overall functionality. It is responsible for holding and rotating the workpiece securely in place while the lathe tools shape and cut it. By rotating the workpiece, the spindle allows for precise and accurate machining, ensuring uniformity in the finished product.

In addition to rotating the workpiece, the spindle also provides a mounting point for various types of lathe chucks, faceplates, and other workholding devices. This versatility allows for different machining techniques and enables the lathe to accommodate a wide range of workpiece sizes and shapes.

2. Can you explain how the spindle speed affects lathe operations?

The spindle speed has a significant impact on lathe operations. By controlling the rotational speed of the spindle, machinists can optimize the cutting process for different materials and cutting tools. Higher spindle speeds are typically used for smaller workpieces or when precision and fine finishing are required. Lower spindle speeds, on the other hand, are suitable for larger workpieces or when heavy cutting is needed.

Adjusting the spindle speed also helps minimize vibrations and ensure smooth cutting. With the right speed selection, machinists can achieve the desired surface finish, prevent tool chatter, and increase tool life, leading to better overall machining results.

3. Is the spindle on a lathe compatible with different tooling systems?

Yes, the spindle on a lathe is designed to be compatible with various tooling systems. Most lathes have a standardized spindle that allows for the use of collets, three-jaw or four-jaw chucks, faceplates, and other workholding devices. The spindle usually features a threaded end or a taper to accommodate these different tooling systems.

This compatibility enhances the versatility of the lathe, enabling machinists to switch between different types of tooling quickly and efficiently. It also facilitates the secure clamping of workpieces, ensuring stability during the machining process.

4. Can the spindle on a lathe be reversed?

Yes, many lathes have a reversible spindle feature. This means that the rotation of the spindle can be changed to either clockwise or counterclockwise direction. The ability to reverse the spindle offers added flexibility in lathe operations.

By reversing the spindle, machinists can perform tasks such as thread cutting, facing, or parting off in the opposite direction. This can be particularly useful when working on symmetrical parts or when specific cutting techniques require a reverse rotation.

5. Does the spindle on a lathe require maintenance?

Yes, like any other mechanical component, the spindle on a lathe requires regular maintenance to ensure its optimal performance. It is important to keep the spindle clean and free from dirt, debris, and excessive lubrication. Regular lubrication, as per the manufacturer’s guidelines, is essential to prevent wear and promote smooth rotation.

Inspecting the spindle for any signs of damage, such as cracks or excessive runout, is also crucial. If any abnormalities are detected, it is recommended to have the spindle inspected or serviced by a qualified technician to avoid any potential issues during lathe operations.

Summary

So, what does the spindle do on a lathe? Well, the spindle is like the heart of the lathe. It holds the workpiece securely in place and spins it around so that you can shape it with tools. Without the spindle, the lathe wouldn’t be able to do its job!

Whether it’s making furniture legs or bowls, the spindle is essential for turning wood or metal. You can think of it as the engine that powers the lathe. So next time you see a lathe, remember the important role of the spindle in making those cool and useful objects we see every day!