Have you ever wondered, “What does TPI mean on a bandsaw blade?” Well, you’re in luck because I’m here to demystify it for you! TPI stands for “teeth per inch,” and it’s a vital measurement when it comes to bandsaw blades.

So, what exactly does TPI entail? It refers to the number of teeth present on a one-inch portion of the bandsaw blade. The TPI value determines the blade’s cutting speed, the type of material it can handle, and the finish it produces. Understanding TPI is essential for achieving precise and efficient cuts with your bandsaw.

Now, you might be wondering, “How do I choose the right TPI for my bandsaw blade?” Well, fear not! In the upcoming sections, we’ll explore different TPI options and their suitable applications. So, let’s dive in and unravel the mystery of TPI on bandsaw blades together!

Have you ever wondered what TPI means on a bandsaw blade? The term “TPI” stands for “teeth per inch.” It refers to the number of teeth on the blade that are spaced evenly along one inch of the blade’s length. The TPI value determines the blade’s cutting capacity and the type of material it is best suited for. A higher TPI provides a smoother cut on thin materials, while a lower TPI offers faster cutting speed on thicker materials.

What Does TPI Mean on a Bandsaw Blade?

Welcome to our guide on understanding what TPI means on a bandsaw blade. If you’re new to woodworking or just starting to explore the world of bandsaw blades, you may have come across the term TPI. TPI stands for Teeth Per Inch, and it refers to the number of teeth that are present on one inch of the bandsaw blade. In this article, we will delve into the significance of TPI, the impact it has on cutting performance, and how to choose the right TPI for your bandsaw blade needs.

Understanding TPI and Its Importance

When it comes to the performance of your bandsaw blade, TPI plays a crucial role. The number of teeth on a bandsaw blade affects the speed, smoothness, and accuracy of the cuts you make. A higher TPI means more teeth per inch, which translates to a smoother cut with finer detail. On the other hand, a lower TPI provides a coarser cut and is better suited for faster, rougher cuts. It’s essential to understand the relationship between TPI and the materials you intend to cut as it can significantly impact your overall woodworking experience.

For instance, cutting thicker materials such as hardwoods or metal may require a lower TPI to provide the necessary cutting power. On the contrary, when cutting thinner materials like plywood or softwoods, a higher TPI will deliver cleaner results. Therefore, determining the right TPI for your bandsaw blade depends on various factors, including the material you’re working with, the type of cut desired, and your personal preferences.

The Influence of TPI on Cutting Performance

Now that we’ve covered the basics, let’s explore how TPI affects cutting performance in more detail.

1. Fine Cuts with Higher TPI

A higher TPI on a bandsaw blade allows for more teeth, resulting in finer cuts. This is ideal for delicate projects that require smooth and precise detailing. Higher TPI bandsaw blades also produce less sawdust, reducing the need for cleanup and leaving a cleaner work area. However, keep in mind that higher TPI blades may have a slower cutting speed and might dull more quickly when used on tougher materials.

2. Coarser Cuts with Lower TPI

If you’re working on projects that prioritize speed over precision, a lower TPI bandsaw blade can be the right choice. These blades have fewer teeth per inch, making them ideal for rough cuts and faster material removal. They work efficiently when cutting through thicker materials or when you need to remove a significant amount of waste quickly. However, due to the larger space between teeth, the resulting cut may not be as smooth as that achieved with a higher TPI blade.

3. Versatility with Variable TPI

In some cases, you may require a bandsaw blade that offers versatility across different materials and cutting tasks. Variable TPI blades feature different sections with varying tooth counts along the length of the blade. This design allows for a combination of fine and coarse teeth, enabling you to switch between different cutting applications without changing blades. Variable TPI blades are a popular choice for woodworkers who work on a variety of projects and materials.

4. Selecting the Right TPI for Your Bandsaw Blade

Choosing the right TPI for your bandsaw blade involves understanding the material, thickness, and desired cut. Here are some general guidelines to help you make a selection:

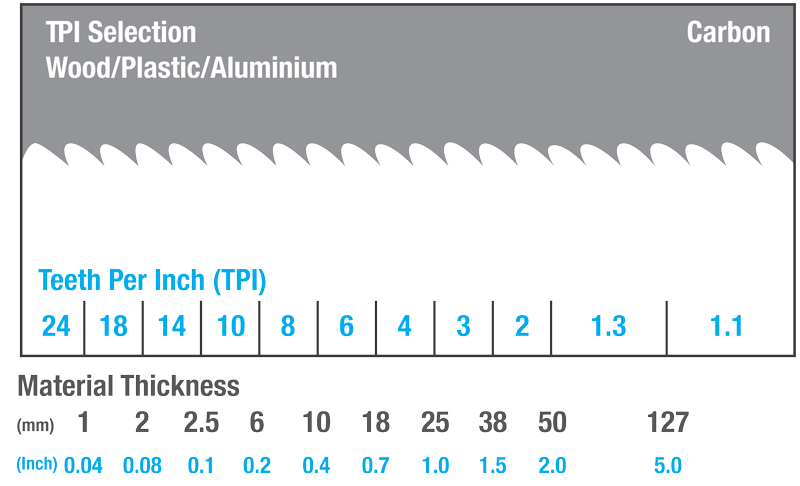

- Higher TPI (10-24): Ideal for intricate cuts and fine details in thin materials like veneer, plywood, or softwoods.

- Medium TPI (6-10): Suitable for general-purpose cutting in a variety of materials and thicknesses.

- Lower TPI (2-6): Recommended for cutting thicker materials such as hardwoods or metals where power and speed are essential.

Ultimately, finding the right TPI for your bandsaw blade may involve some trial and error and experimentation to achieve the desired results. It’s always a good idea to have a selection of blades with different TPIs on hand to ensure you have the right tool for the job.

Additional Considerations when Using TPI on Bandsaw Blades

While TPI is a critical factor in determining the performance of your bandsaw blade, there are a few more aspects to consider:

1. Blade Thickness

The thickness of the bandsaw blade itself also plays a role in its cutting performance. Thicker blades tend to be more durable and can handle heavier materials, but they may require more power to operate. Thinner blades, on the other hand, are better suited for intricate cuts but may be more prone to twisting or breaking under heavy loads.

2. Feed Rate

The feed rate, or the speed at which you guide the material through the bandsaw blade, also affects the cutting performance. Adjusting the feed rate can help compensate for the TPI of the blade and optimize the quality of the cut. Experimenting with different feed rates while using blades with different TPIs can help you find the right combination for the best results.

3. Blade Tension

Proper blade tension is crucial for achieving accurate and clean cuts. A loosely tensioned blade can result in wandering cuts or blade slippage, while an overly tight blade can cause unnecessary stress on the blade and the bandsaw itself. Refer to your bandsaw’s manual for guidelines on correctly tensioning the blade for optimal performance.

In summary, TPI is a critical factor to consider when choosing a bandsaw blade for your woodworking projects. By understanding the relationship between TPI, material, and desired cut, you can ensure the best cutting performance and achieve the results you desire. Remember to experiment with different TPIs, blade thicknesses, feed rates, and blade tension to find the perfect combination for your specific woodworking needs.

Key Takeaways: What Does TPI Mean on a Bandsaw Blade?

- 1. TPI stands for “teeth per inch.”

- 2. It refers to the number of teeth on a bandsaw blade within one inch.

- 3. A higher TPI means more teeth and a finer, smoother cut.

- 4. A lower TPI means fewer teeth and a faster, rougher cut.

- 5. Choosing the right TPI depends on the thickness and type of material being cut.

Frequently Asked Questions

Welcome to our FAQ section, where we’ll answer some common questions about bandsaw blades and what TPI means. If you’ve ever wondered about the meaning of TPI on a bandsaw blade, you’re in the right place. Let’s dive in!

1. How does TPI affect a bandsaw blade’s cutting performance?

TPI stands for Teeth Per Inch, and it refers to the number of teeth on a bandsaw blade within one inch. The TPI of a blade significantly impacts its cutting performance. Blades with a high TPI (e.g., 14 or more) have more teeth, resulting in a finer cut. These are ideal for cutting thinner materials like sheet metal or veneer, providing smoother finishes. On the other hand, blades with a low TPI (e.g., 4 or less) have fewer teeth, but they cut faster. These blades are suitable for thicker materials like lumber or plastic.

Understanding the TPI range for different applications is crucial for achieving desired results and optimizing cutting efficiency. So, whether you’re working on a delicate project or need to power through thicker material, selecting the right TPI for your bandsaw blade is essential.

2. How do I choose the appropriate TPI for my bandsaw blade?

Choosing the right TPI for your bandsaw blade depends on the type and thickness of the material you’ll be cutting. For materials like metal or hard plastic, a higher TPI (10-24) is recommended to ensure a smooth and precise cut. For softer materials such as wood, a lower TPI (2-6) is usually suitable for faster cuts. It’s also important to consider the thickness of the material—thicker materials generally require blades with fewer teeth (lower TPI).

Keep in mind that different TPI ranges are available for different bandsaw blade widths, and manufacturers often provide guidelines and recommendations specific to their blades. Refer to these guidelines and consider the particular characteristics of your material to select the appropriate TPI for your bandsaw blade.

3. Can I use a bandsaw blade with a different TPI than recommended?

While it’s generally recommended to use a bandsaw blade with the appropriate TPI for the material and cut you’re making, there can be some flexibility. For instance, if you don’t have a blade with the exact TPI recommended, you can make adjustments based on the general principles we discussed earlier. Just keep in mind that utilizing a significantly different TPI may affect the quality of your cuts. A blade with too high of a TPI for a specific material may cause the blade to clog or overheat, while a blade with too low of a TPI might result in a rougher finish and slower cutting speed.

If you often work with a particular range of materials, investing in blades with different TPIs could be beneficial. This way, you can have the appropriate blade on hand for any situation and achieve optimal cutting results.

4. How can I maintain the performance of my bandsaw blade with the right TPI?

To maintain the performance of a bandsaw blade with the right TPI, proper maintenance is key. Regularly inspect the blade for any signs of wear, such as dull teeth or damage. If needed, replace the blade promptly to avoid poor cutting results or potential hazards. Additionally, make sure to clean the blade after use to remove any debris that might affect its cutting efficiency.

When storing the bandsaw blade, coil it properly to prevent kinks or damage that could cause premature wear. Lubricating the blade with a suitable cutting fluid can also help prolong its life and optimize performance.

5. Are there any safety precautions to consider when using a bandsaw blade with a specific TPI?

Safety should always be a priority when using any type of bandsaw blade, regardless of the TPI. However, blades with higher TPI are generally more prone to clogging, so take extra precautions to avoid accidental blade slippage or kickback. Keep your hands and fingers a safe distance away from the blade and always wear appropriate safety gear, including goggles and gloves.

Furthermore, always follow the manufacturer’s guidelines and recommendations for operating the bandsaw, including the proper tension for the blade and the correct speed setting. By adhering to these safety measures, you can enjoy a smooth cutting experience with your bandsaw blade.

Summary

So, what does TPI mean on a bandsaw blade? TPI stands for “teeth per inch.” It tells you how many teeth are on the blade in one inch. A higher TPI means a smoother cut, while a lower TPI means a faster cut.

To choose the right TPI for your bandsaw, consider the material you’re cutting. For thick materials like metal, a lower TPI is better. For thinner materials like wood, a higher TPI is preferred. Remember to check the manufacturer’s recommendations for the best results. Now you know how to pick the right bandsaw blade for your needs!