Picture this: you’ve got a brilliant DIY project in mind, and you’re ready to make it happen. Wood glue? Check. Tools? Check. But wait, you start wondering, “What does wood glue not stick to?” It’s a valid question because not all surfaces are created equal when it comes to bonding with this adhesive wonder. Well, my curious friend, you’ve come to the right place. In this article, I’ll uncover the surprising answers and reveal the materials that wood glue just can’t adhere to. So, let’s dive in and explore the fascinating world of wood glue’s limitations together!

When it comes to working with wood glue, understanding its limitations is crucial. Sure, wood glue can stick wood pieces together like magic, creating sturdy bonds. But, my young DIY enthusiast, you need to know what it won’t stick to. Whether you’re working on a repair, an art project, or a fabulous creation, knowing which materials won’t bond with wood glue will save you time, frustration, and sticky messes. So, let’s unravel the mysteries behind this versatile adhesive and find out what you should avoid using it on.

Now, imagine you’re in the middle of your project, and you reach for the wood glue, only to realize it won’t work on the material you’re trying to bond. Don’t worry! I’m here to help you avoid such sticky situations. By the end of this article, you’ll be armed with knowledge about what wood glue doesn’t stick to, and you’ll have the confidence to tackle any DIY project with ease. So, grab your favorite hammer, put on your safety goggles, and let’s explore the exciting world of wood glue!

What Does Wood Glue Not Stick To? Exploring the Limitations of Wood Glue

Welcome to this in-depth exploration of what wood glue does not stick to. Wood glue is an essential adhesive for woodworking projects, but it’s important to understand its limitations. While wood glue can provide a strong bond on most surfaces, there are certain materials and conditions where it may not be as effective. In this article, we will dive into the factors that can affect the bonding ability of wood glue, providing you with valuable insights for your woodworking projects.

The Limitations of Wood Glue on Metal Surfaces

Wood glue is specifically designed for bonding wood to wood, and its effectiveness on other materials such as metal can be limited. The smooth surface and non-porous nature of metal make it challenging for wood glue to adhere properly. Additionally, metals often have oils or coatings that can interfere with the bonding process.

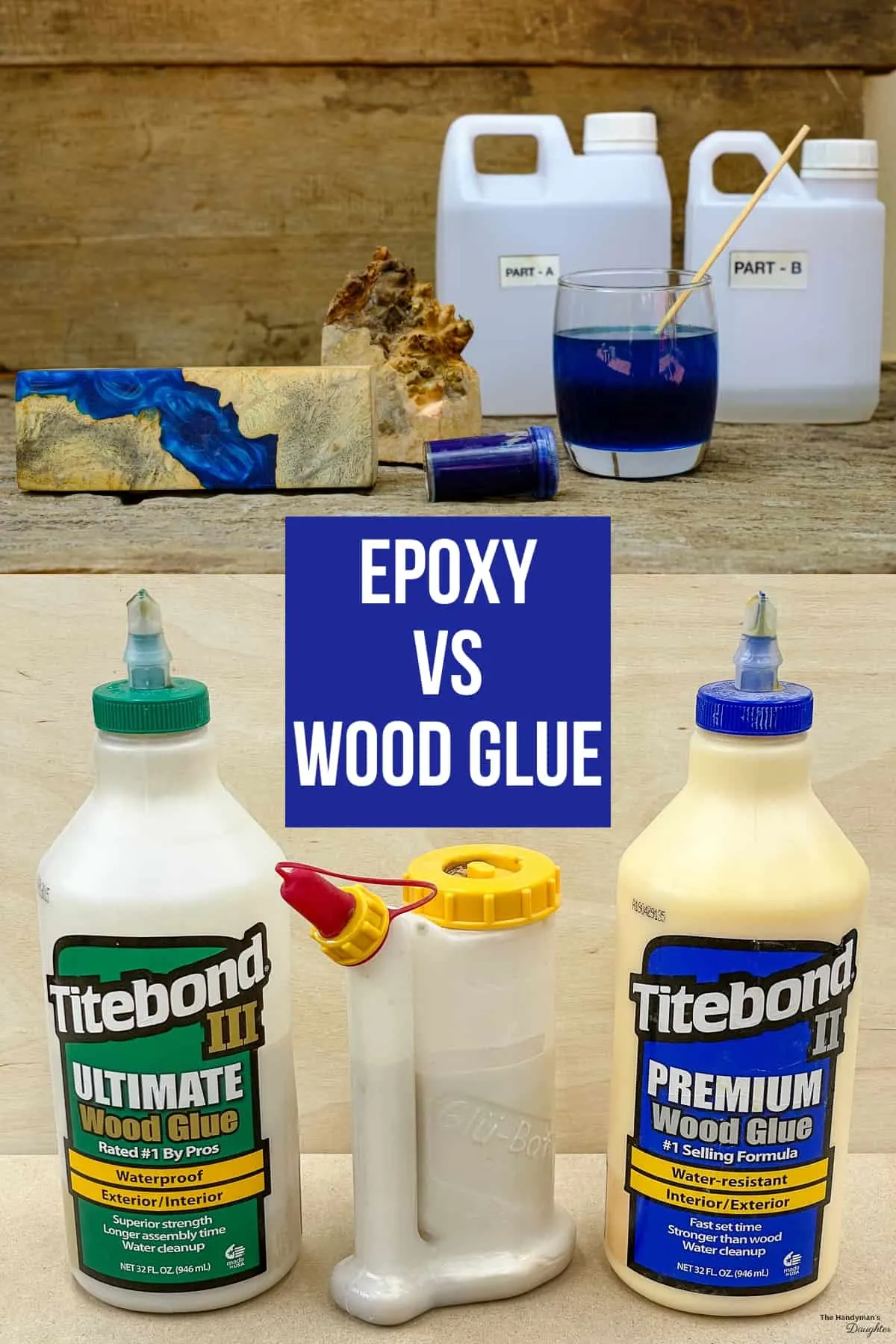

However, there are certain types of wood glue that are formulated to bond wood to metal, such as epoxy-based glues or polyurethane glues. These glues have additional additives that enhance their bonding capabilities on metal surfaces. If you need to bond wood to metal, it is recommended to use these specialized glues for better results.

Furthermore, preparing the metal surface before applying wood glue can significantly improve the bond. You can roughen the surface with sandpaper or use a degreaser to remove any oils or coatings. This will create a better surface for the wood glue to adhere to.

The Challenges of Bonding Wood Glue to Plastic

Bonding wood glue to plastic surfaces can also be problematic due to the differences in the materials’ properties. Most wood glues are not designed to bond effectively with plastics, especially those with smooth and non-porous surfaces. Additionally, plastics often have flexibility and expansion properties that can cause the bond to weaken over time.

If you need to bond wood to plastic, it is recommended to use specialized adhesive products that are formulated for this purpose. These products are designed to create a strong and durable bond between wood and plastic surfaces.

Furthermore, it is crucial to properly prepare the plastic surface before applying any adhesive. You can roughen the surface with sandpaper or use a plastic primer to improve the adhesion. Taking these additional steps will increase the chances of a successful bond between wood and plastic.

The Influence of Moisture on Wood Glue Bonding

Moisture can significantly impact the bonding ability of wood glue. Wood glue relies on the moisture in the wood to cure and form a strong bond. However, excess moisture or extremely dry conditions can compromise the bond.

If the wood surface is overly wet or has high moisture content, the excess water can dilute the wood glue and weaken the bond. On the other hand, if the wood surface is too dry, the glue may not be able to penetrate the wood fibers properly, resulting in a weak bond.

It is important to ensure that the wood surface is at an optimal moisture level before applying wood glue. This can be achieved by allowing the wood to acclimate to the environment where it will be used. Additionally, if you are working with highly moisture-prone woods, such as green or freshly cut wood, it is recommended to allow the wood to dry adequately before applying the glue.

Wood Glue and Oily or Waxy Surfaces

Oily or waxy surfaces can be challenging for wood glue to adhere to. The presence of oils or waxes creates a barrier between the wood glue and the wood surface, preventing a proper bond from forming.

To overcome this issue, it is essential to remove any oils or waxes from the wood surface before applying the glue. This can be done by using a degreaser or sanding the surface to remove the oily or waxy layer. By creating a clean and porous surface, the wood glue will have a better chance of forming a strong bond.

Additionally, it is worth noting that certain types of wood, such as teak or rosewood, naturally contain oils or waxes that can affect the bonding ability of wood glue. In these cases, it is recommended to use epoxy-based glues or polyurethane glues that are designed to bond well with oily or waxy surfaces.

Wood Glue and High-Temperature Environments

High-temperature environments can pose challenges for wood glue bonding. Heat can weaken the bond created by the glue, causing it to lose its strength over time. This is especially true for traditional PVA (Polyvinyl Acetate) wood glues.

When working in high-temperature environments, it is advisable to consider using specialized heat-resistant wood glues or adhesives that can withstand the elevated temperatures. These glues are formulated to maintain their strength and integrity even under extreme heat conditions.

Furthermore, it is crucial to ensure proper curing and drying of the wood glue in high-temperature environments. Higher temperatures can accelerate the drying process, so it is important to follow the manufacturer’s instructions and allow sufficient time for the glue to cure.

Factors That Can Help Improve Wood Glue Bonding

While wood glue may have limitations, there are several factors that can help improve its bonding ability:

- Clean Surfaces: Ensure that the surfaces to be bonded are clean and free from any debris or contaminants.

- Tight Joints: Make sure that the joints are well-fitted and tightly secured before applying the glue.

- Even Distribution: Apply an even and sufficient amount of glue to ensure proper coverage and bonding.

- Clamping: Use clamps or other means of pressure to hold the glued pieces together firmly while the glue cures.

- Curing Time: Allow sufficient time for the glue to cure and fully bond before subjecting the project to stress or load.

By taking these factors into consideration and understanding the limitations of wood glue, you can achieve strong and durable bonds in your woodworking projects.

Choosing the Right Wood Glue for Your Project

When it comes to woodworking projects, selecting the right wood glue is essential for achieving strong and long-lasting bonds. Various types of wood glues are available, each with their own strengths and characteristics. Here are three common types of wood glues:

1. PVA (Polyvinyl Acetate) Wood Glue

PVA wood glue is a popular choice for woodworking projects due to its affordability, ease of use, and versatility. It is available in different formulations, including white glue and yellow glue.

White glue is suitable for general woodworking and can be used for bonding porous materials such as wood, paper, and fabric. Yellow glue, also known as carpenter’s glue, is designed for stronger bonds and can withstand higher stress and humidity levels. It is ideal for structural woodworking projects.

PVA wood glue is water-based, making it easy to clean up with water while still wet. It has a relatively fast drying time and forms a strong bond within hours.

2. Epoxy Wood Glue

Epoxy wood glue is a two-part adhesive that consists of a resin and a hardener. When these components are mixed together, a chemical reaction occurs, resulting in a durable and waterproof bond. Epoxy glue is known for its excellent bonding strength and resistance to heat and moisture.

This type of glue is often used for bonding wood to non-porous materials such as metal, plastic, or glass. It is also suitable for applications that require gap-filling due to its thick consistency.

Epoxy wood glue has a longer curing time compared to PVA glues, typically ranging from a few hours to a full day. It is important to follow the manufacturer’s instructions regarding mixing ratios and curing times for optimal results.

3. Polyurethane Wood Glue

Polyurethane wood glue is a versatile adhesive that forms a strong bond on both porous and non-porous materials. It is known for its ability to expand, filling gaps and creating a strong bond in hard-to-reach areas.

This type of glue is waterproof and can withstand extreme temperatures, making it suitable for both indoor and outdoor woodworking projects. It is often used for laminating, veneering, and other applications that require a strong and durable bond.

Polyurethane wood glue has a longer curing time compared to PVA glues, typically ranging from a few hours to a full day. It is essential to clamp the glued pieces together during the curing process to ensure a tight and secure bond.

Essential Tips for Effective Wood Glue Application

Applying wood glue may seem straightforward, but certain techniques and practices can enhance its effectiveness. Here are some essential tips for achieving optimal results:

1. Prepare the Surfaces:

Before applying the glue, make sure that the surfaces to be bonded are clean, dry, and free from any debris, oils, or finishes. Sanding the surfaces lightly can also improve the bonding surface.

2. Apply the Right Amount of Glue:

Apply an even and sufficient amount of glue to both surfaces. Avoid using too much glue as it can result in excess squeeze-out and weaken the bond. Conversely, too little glue may not create a strong enough bond.

3. Spread the Glue Evenly:

Use a brush, roller, or a spreader to evenly distribute the glue on the surfaces. This helps ensure full coverage and better bonding.

4. Join the Surfaces:

Once the glue is applied, join the surfaces together and apply even pressure. Clamps, weights, or other methods can be used to hold the pieces firmly in place while the glue cures.

5. Clean Up Excess Glue:

Remove any excess glue immediately using a damp cloth or sponge. Wood glue is water-based, so it can be cleaned up easily while still wet.

6. Allow Sufficient Curing Time:

Follow the manufacturer’s instructions regarding curing time. Avoid subjecting the project to stress or load until the glue has fully cured.

By following these tips and techniques, you can ensure that your wood glue bonds are strong, reliable, and long-lasting.

Conclusion

Wood glue is a versatile adhesive that can create strong and durable bonds in woodworking projects. While it has its limitations on certain surfaces such as metal and plastic, understanding these limitations and using specialized glues when necessary can help overcome these challenges. By properly preparing the surfaces, choosing the right glue for the project, and following the recommended techniques, you can achieve optimal bonding results. Remember to always follow the manufacturer’s instructions for the specific glue you are using. With proper application and knowledge, wood glue can be a valuable tool in your woodworking arsenal.

Key Takeaways: What Does Wood Glue Not Stick To?

- Wood glue does not stick well to oily or waxy surfaces.

- It does not bond effectively with plastics or metals.

- Waterproof or silicone-treated surfaces may also prevent wood glue from sticking.

- Surfaces with a lot of moisture or humidity may interfere with the adhesive properties of wood glue.

- Wood glue does not work well on surfaces coated with polyurethane or other sealants.

Frequently Asked Questions

When working with wood glue, it’s essential to understand what surfaces it will not adhere to. Here are answers to common questions related to what wood glue does not stick to.

1. Can wood glue be used on plastic surfaces?

No, wood glue is not suitable for bonding plastic surfaces. Wood glue is specifically formulated to bond porous materials, such as wood, plywood, and other natural fibers. Plastic surfaces, on the other hand, are non-porous and require specialized adhesives designed for plastics.

If you need to bond plastic materials, it is best to use an adhesive specifically formulated for plastic bonding. These adhesives have properties that allow them to create a strong bond on plastic surfaces, ensuring a durable and reliable connection.

2. Does wood glue adhere to metal?

Wood glue does not adhere well to metal surfaces. Metal is a non-porous material, which means that wood glue cannot penetrate its surface and form a strong bond. In addition, the different physical properties of wood and metal can cause issues with the bond’s strength and durability.

If you need to glue wood to metal, it is recommended to use an adhesive specifically designed for metal bonding, such as epoxy or a construction adhesive. These adhesives are formulated to create a strong bond between different materials, including metal and wood.

3. Can I use wood glue on painted surfaces?

Wood glue typically does not adhere well to painted surfaces. The paint creates a barrier between the glue and the underlying material, reducing the bond strength. Additionally, the smooth and non-porous nature of paint can prevent proper penetration of the glue, resulting in a weak bond.

If you need to bond wood to a painted surface, it is best to remove the paint before applying the wood glue. Sanding or using a paint stripper can help remove the paint and create a porous surface that the wood glue can bond with. Alternatively, consider using a construction adhesive that is specifically formulated for bonding painted surfaces.

4. Does wood glue work on wet or moist wood?

Using wood glue on wet or moist wood is generally not recommended. Moisture can interfere with the adhesive properties of the glue, preventing it from forming a strong bond. The water or moisture present in the wood can dilute the glue, affecting its ability to cure properly.

For optimal results, it is advisable to work with dry wood when using wood glue. If you are working with wet or moist wood, allow it to dry thoroughly before applying the glue. This will ensure a stronger bond and better overall performance of the glue.

5. Can wood glue be used on oily or greasy surfaces?

No, wood glue cannot effectively bond to oily or greasy surfaces. Oils and greases create a barrier between the wood glue and the surface, preventing proper adhesion. These substances reduce the contact area between the glue and the material, compromising the bond’s strength.

Prior to applying wood glue, it is important to thoroughly clean the surface and remove any oils or greases. This can be done using a degreaser or a suitable cleaning solution. By removing these contaminants, you will ensure better adhesion and a stronger bond.

Summary

Wood glue is great for sticking wood together, but it doesn’t work well on everything.

For example, it doesn’t stick well to metal, plastic, or glass. So if you’re working on a project and need to glue wood to these materials, you’ll need a different type of adhesive.

Also, wood glue is not waterproof, so it won’t hold up well in wet or damp conditions. If you want your project to be water-resistant, look for a waterproof glue instead.

In conclusion, wood glue is fantastic for woodworking but won’t work on everything and isn’t waterproof.