Have you ever wondered what effect changing the belt position has on a drill press? Well, you’re in luck! In this article, we’ll explore the impact of adjusting the belt position on the functionality of a drill press. Whether you’re a curious student or an enthusiastic DIYer, understanding this concept will enhance your woodworking or metalworking skills. So, let’s dive in and discover the fascinating world of drill press belt positions!

When it comes to using a drill press, changing the belt position plays a crucial role in its performance. You might be wondering, what exactly happens when we shift belts on a drill press? Does it affect the speed, power, or drilling capabilities? These are the questions we’ll tackle throughout this article. By the end, you’ll have a clear understanding of how adjusting the belt position impacts the functionality and efficiency of this versatile tool.

If you’re ready to unlock the secrets of the drill press, strap on your toolbelt (pun intended!) and join us in exploring the world of belt positions. From the basics of belt adjustments to the potential benefits and limitations, we’ll cover it all. By the time you finish reading, you’ll be equipped with the knowledge to make informed decisions about changing the belt position on your own drill press. Let’s get started, shall we?

Changing the belt position on a drill press can have a significant effect on its performance. By adjusting the belt, you can vary the speed at which the drill bit rotates, allowing you to match the speed to the material or task at hand. Lower speeds are ideal for drilling through metal, while higher speeds are better for wood or plastic. Experimenting with different belt positions can enhance drilling precision and prevent damage to your workpiece.

Effects of Changing Belt Position on the Drill Press

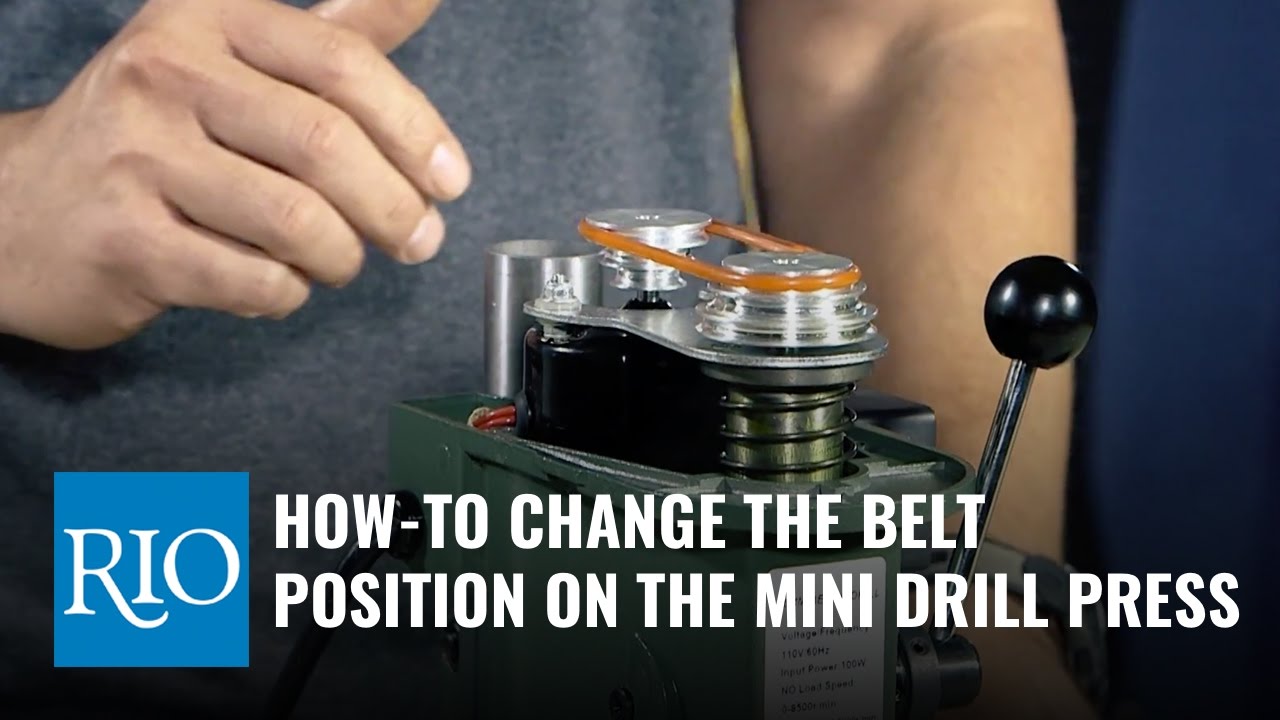

Welcome to our in-depth article on the effects of changing the belt position on a drill press. Many drill presses offer the option to change the belt position, which can have a significant impact on the performance and versatility of the machine. In this article, we will explore the various effects that changing the belt position can have, including speed adjustments, torque variations, and the ability to work with different materials and drill bit sizes. Whether you’re a professional woodworker, metalworker, or simply a DIY enthusiast, understanding the effects of changing the belt position on a drill press can greatly enhance your projects and improve the efficiency of your work.

1. Speed Adjustments for Different Materials

One of the key effects of changing the belt position on a drill press is the ability to adjust the speed of the spindle. Different materials require different drilling speeds to achieve the best results. For example, drilling through soft materials like wood may require higher speeds, while drilling through harder materials like metal or concrete may require lower speeds. By changing the belt position on the drill press, you can easily adjust the speed to match the specific material you’re working with, ensuring clean and precise holes without damaging the workpiece or the drill bit.

Furthermore, some drill presses offer variable speed options, allowing you to adjust the speed continuously within a specific range by changing the belt position. This feature provides even more versatility and control, especially when working with delicate materials or when using specialized drill bits, such as those used for drilling through glass or ceramic.

2. Torque Variations for Different Applications

In addition to speed adjustments, changing the belt position on a drill press can also affect the torque produced by the machine. Torque refers to the rotational force applied by the drill press, which determines its ability to drill through tough materials or drive screws and fasteners into various surfaces. Different applications may require different levels of torque to achieve the desired results.

By changing the belt position, you can optimize the torque output of the drill press for specific tasks. For example, if you’re drilling through a dense material that requires more torque, you can adjust the belt position to increase the torque and ensure efficient drilling. On the other hand, for applications that require less torque, such as driving screws into softwood, you can adjust the belt position to reduce the torque and prevent the screws from being overdriven.

3. Versatility in Drill Bit Size Compatibility

Changing the belt position on a drill press also affects the compatibility of different drill bit sizes. Drill presses are designed to accommodate a wide range of drill bit sizes, from tiny drill bits used for fine woodworking to large drill bits used for heavy-duty applications. However, the speed and torque requirements of each drill bit size can vary significantly.

By changing the belt position, you can ensure that the drill press operates at the optimal speed and torque for the specific drill bit size you’re using. This not only improves the performance and efficiency of the drill press but also extends the lifespan of the drill bits by preventing overheating or excessive wear.

Additional Considerations and Tips

Now that we’ve explored the effects of changing the belt position on a drill press, here are some additional considerations and tips to keep in mind:

1. Safety Precautions

- Always follow the manufacturer’s instructions and safety guidelines when changing the belt position on your drill press.

- Ensure that the drill press is turned off and unplugged before making any adjustments to the belt position.

- Keep your hands and fingers away from the moving parts of the drill press to avoid any injuries.

2. Experiment and Practice

Changing the belt position on a drill press may require some trial and error to find the optimal settings for your specific tasks. Experiment with different belt positions, speeds, and torque settings to achieve the best results. Practice on scrap materials before working on your actual projects to gain confidence and familiarity with the drill press.

3. Maintenance and Lubrication

Regularly clean and lubricate the pulley system and belt of your drill press to ensure smooth operation. This will prevent the belt from slipping or becoming stiff, improving the overall performance of the drill press.

Keep these considerations in mind, and you’ll be well-equipped to harness the full potential of your drill press by understanding and utilizing the effects of changing the belt position. Whether you’re a professional or an avid DIYer, this knowledge will undoubtedly enhance your drilling experience and improve the quality of your finished projects.

Key Takeaways: What Effect Does Changing the Belt Position Have on the Drill Press?

- Changing the belt position on the drill press affects the speed at which the drill bit rotates.

- By adjusting the belt position, you can switch between high and low speed settings on the drill press.

- Using a higher speed setting allows for faster drilling but may result in less torque.

- Lower speed settings provide more torque, making it easier to drill through harder materials.

- Experimenting with different belt positions allows you to optimize the drill press for various drilling tasks.

Frequently Asked Questions

Here are some commonly asked questions about the effects of changing the belt position on a drill press:

1. How does changing the belt position on a drill press affect its speed?

When you change the belt position on a drill press, you adjust the speed at which the spindle rotates. Depending on the configuration, moving the belt to a different set of pulleys can either increase or decrease the speed. This is crucial because different materials and drill bit sizes require different drilling speeds to achieve optimal results. By changing the belt position, you can ensure that the drill press operates at the right speed for the task at hand.

2. What impact does changing the belt position have on the torque of a drill press?

The belt position on a drill press directly affects its torque, which is the turning force generated by the motor. By changing the belt position to a pulley with a larger diameter, you can increase the torque. Conversely, moving the belt to a smaller pulley decreases the torque. This is important because higher torque allows the drill press to handle tougher materials and perform heavy-duty tasks. By adjusting the belt position, you can tailor the torque output to match the requirements of your drilling project.

3. Does changing the belt position affect the precision of a drill press?

Yes, changing the belt position on a drill press can impact its precision. When you move the belt to a higher-speed setting, the drill press spins faster, which can lead to increased vibrations and potential inaccuracies in drilling. On the other hand, using a lower-speed setting reduces vibrations and provides better control, resulting in more precise drilling. It is essential to select the appropriate belt position that balances speed and precision depending on the specific drilling task at hand.

4. Can changing the belt position on a drill press affect its power consumption?

Changing the belt position on a drill press does not directly affect its power consumption. However, it indirectly influences the motor’s load, which can impact power usage. When you adjust the belt position to a higher-speed setting with a smaller pulley, the motor has to work harder to generate the increased torque required for drilling. In turn, this higher load on the motor may result in slightly higher power consumption compared to a lower-speed setting. It’s important to be aware of this potential energy usage difference when selecting the appropriate belt position for your drilling needs.

5. Are there any safety considerations when changing the belt position on a drill press?

Yes, safety is paramount when changing the belt position on a drill press. Always ensure that the drill press is powered off and unplugged before making any adjustments to the belt position. Take care to follow the manufacturer’s instructions and use the appropriate tools to change the belt. Additionally, it’s essential to wear proper personal protective equipment, such as safety goggles, when operating the drill press. By adhering to these safety guidelines, you can minimize the risk of accidents and ensure safe operation while changing the belt position on a drill press.

Summary

Changing the belt position on a drill press can have different effects on its speed. When the belt moves to a smaller pulley, the drill press will spin faster. This is useful for drilling through harder materials. On the other hand, when the belt moves to a larger pulley, the drill press will spin slower. This is better for drilling through softer materials or when precision and control are needed. It’s important to adjust the belt position according to the specific task at hand to achieve the desired drilling speed.