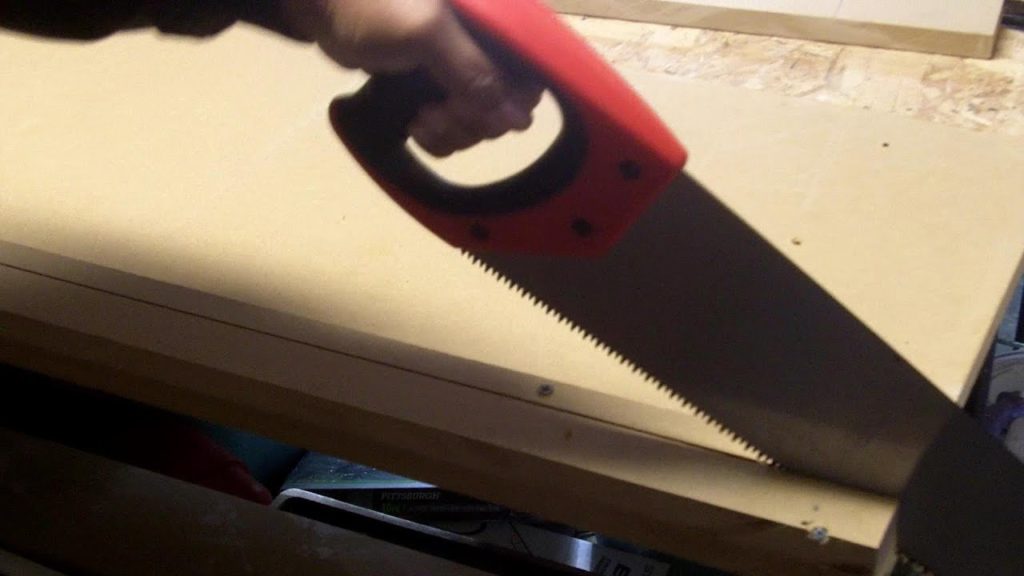

Are you wondering what hand saw you should use to cut MDF? Well, you’ve come to the right place! Cutting Medium Density Fiberboard (MDF) can be a bit tricky, but with the right saw, it becomes a breeze. Let’s dive in and discover the perfect tool for the job.

When it comes to cutting MDF, you want a hand saw that can handle the dense nature of the material. One excellent choice is a crosscut saw. With its sharp, angled teeth, a crosscut saw is specifically designed to make clean, precise cuts across the grain of the wood.

Another great option is a fine-toothed backsaw. This type of saw has smaller teeth that cut more slowly, but with greater accuracy. If you’re working on intricate projects or need to make detailed cuts, a backsaw is an excellent choice.

So, whether you opt for a crosscut saw or a fine-toothed backsaw, both will make the task of cutting MDF a breeze. Armed with the right tool, you’ll be able to tackle your woodworking projects with confidence and precision. Let’s get sawing!

How to Cut MDF with a Hand Saw:

1. Measure and mark the MDF sheet.

2. Use a straight edge to guide your saw.

3. Start the cut with a light score.

4. Apply downward pressure while sawing back and forth.

5. Take your time and maintain a steady pace.

6. Sand the edges for a smooth finish.

Remember to wear safety goggles and work in a well-ventilated area. Happy cutting!

What Hand Saw to Cut MDF?

When it comes to cutting Medium Density Fiberboard (MDF), choosing the right hand saw is crucial. MDF is a popular building material due to its affordability, durability, and versatility. However, its dense and uniform composition may present challenges when using traditional hand saws. In this article, we will explore the types of hand saws that are suitable for cutting MDF, tips for achieving clean cuts, and the benefits of using the appropriate saw.

The Benefits of Using a Jigsaw for Cutting MDF

One of the most efficient and precise hand saws for cutting MDF is the jigsaw. This versatile power tool features a narrow blade with fine teeth, allowing for smooth and accurate cuts through MDF. The jigsaw’s reciprocating action eliminates the need for excessive force, reducing the risk of splintering or damaging the material. Additionally, jigsaws often come with adjustable speed settings, allowing users to customize their cutting speed according to the thickness of the MDF and the desired finish.

Using a jigsaw also offers the advantage of maneuverability. The slim, lightweight design of the tool allows for intricate cuts and curved shapes, making it ideal for projects that require precision and versatility. Whether you’re cutting straight lines or intricate patterns, a jigsaw can provide the necessary control and accuracy.

Furthermore, jigsaws can easily accommodate different types of blades, including ones specifically designed for cutting MDF. These specialized blades have increased tooth count and carbide tips, ensuring cleaner and more efficient cuts. When using a jigsaw to cut MDF, it is recommended to use a fine-toothed blade and set the saw to a slower speed, as this will minimize tear-out and produce smoother edges.

The Versatility of a Circular Saw for MDF Cutting

If you’re looking for a hand saw that excels at making straight cuts in MDF, the circular saw is a top choice. This power tool features a round blade with sharp teeth, allowing for fast and precise cuts. Circular saws are popular among DIY enthusiasts and professional woodworkers due to their versatility and efficiency.

When using a circular saw to cut MDF, it is important to select a blade with fine teeth in order to minimize splintering and tear-out. Carbide-tipped blades are recommended for their longevity and cutting performance. It is also crucial to adjust the cutting depth of the blade to match the thickness of the MDF. This will prevent the blade from cutting too deep and damaging the material, while also minimizing the risk of kickback.

One of the advantages of using a circular saw for MDF cutting is its ability to make rip cuts with ease. The straight fence guide provided with most circular saws ensures straight and accurate cuts, making it suitable for projects that require long, straight edges. Furthermore, circular saws can be equipped with dust collection systems, reducing the amount of airborne dust and debris during cutting.

The Handiness of a Dovetail Saw for Precise MDF Joinery

When it comes to precise joinery work involving MDF, a dovetail saw is an invaluable tool. Dovetail saws are characterized by their thin, narrow blades and fine teeth, making them perfect for intricate cuts and creating tight-fitting joints. While the main purpose of dovetail saws is to cut dovetail joints, they can also be utilized for other joinery techniques.

When using a dovetail saw for MDF joinery, it is important to go slow and steady, allowing the thin blade to make accurate cuts without excessive force. The fine teeth on the blade ensure smooth and clean cuts, which are essential for achieving tight-fitting joints. It is recommended to use a miter box or a precision cutting guide in conjunction with the dovetail saw to ensure precise angles and accurate cuts.

The compact size and lightweight nature of dovetail saws make them portable and easy to maneuver. Whether you’re working on furniture projects or intricate woodworking designs, a dovetail saw can provide the precision and control needed for outstanding results.

Choosing the Right Blade for MDF Cutting

When selecting a blade for cutting MDF with a hand saw, it is crucial to consider the tooth count and quality. The higher the tooth count, the smoother the cut will be. For MDF cutting, blades with fine teeth are recommended, as they reduce tear-out and produce cleaner edges.

Another important factor to consider is the material of the blade. Carbide-tipped blades are highly recommended for their durability and cutting performance. The carbide tips allow the blade to withstand the high-density nature of MDF, ensuring longevity and efficient cutting.

Additionally, some blades are specifically designed for cutting MDF and other engineered woods. These blades often feature an anti-stick coating that reduces friction, preventing the blade from overheating and getting clogged with resin or adhesive. Choosing a specialized blade can greatly enhance the cutting experience and prolong the life of your hand saw.

Tips for Achieving Clean Cuts in MDF

While selecting the right hand saw and blade is essential, there are additional tips that can help you achieve clean cuts in MDF:

- Measure and mark the cutting lines accurately before starting.

- Secure the MDF firmly to prevent any movement during cutting.

- Use a straight edge or a cutting guide to ensure straight cuts.

- Apply masking tape to the cutting line to reduce splintering.

- Allow the blade to do the work and avoid excessive force.

- Make sure your hand saw is sharp and in good condition for optimal cutting performance.

- Consider using a dust collection system or working in a well-ventilated area to minimize exposure to airborne dust and debris.

Comparing Hand Saws for MDF Cutting

| Hand Saw | Advantages | Disadvantages |

|---|---|---|

| Jigsaw |

|

|

| Circular Saw |

|

|

| Dovetail Saw |

|

|

Additional Considerations for Cutting MDF

Aside from selecting the right hand saw and blade for cutting MDF, there are a few additional factors to keep in mind:

Maintenance and Safety

Regularly maintaining your hand saw is crucial for optimal cutting performance and safety. Keep the blades sharp and clean to ensure smooth cuts and reduce the risk of accidents. Follow the manufacturer’s guidelines for maintenance and safety precautions, such as wearing appropriate protective gear like goggles and gloves.

Workshop Setup

Creating a well-organized and efficient workshop setup can greatly enhance your cutting experience. Ensure proper lighting to accurately see the cutting lines, and have a sturdy workbench or table to secure the MDF during cutting. Utilize dust collection systems or work in a well-ventilated area to minimize the inhalation of airborne particles.

Experimentation and Practice

Don’t be afraid to experiment with different hand saws and blades to find the combination that works best for your specific cutting needs. Practice on scrap MDF pieces to refine your techniques and gain confidence in handling the tools. With time and experience, you’ll become proficient in cutting MDF with precision and ease.

Remember, the key to successful MDF cutting lies not only in choosing the right hand saw but also in implementing proper cutting techniques, maintaining the tools, and ensuring a safe and organized working environment. By following these guidelines and investing in the right equipment, you’ll be able to achieve clean, precise cuts in MDF for your woodworking and DIY projects.

Key Takeaways: What Hand Saw to Cut MDF?

- Choose a crosscut hand saw with fine teeth for clean and smooth cuts in MDF.

- Ensure the saw has a sharp blade to avoid splintering or chipping the MDF edges.

- Consider using a backsaw or a Japanese pull saw for more precise cuts in MDF.

- Use painter’s tape along the cut line to minimize tear-out and protect the surface of the MDF.

- Always wear appropriate safety gear, such as goggles and a dust mask, when cutting MDF.

Frequently Asked Questions

Are you wondering about the best hand saw to use for cutting MDF? Look no further! We’ve got you covered with the answers to your burning questions. Read on to find out all you need to know about cutting MDF with a hand saw.

Q: What are the essential features to look for in a hand saw for cutting MDF?

A: When selecting a hand saw for cutting MDF, there are a few key features to consider. Firstly, ensure that the saw has fine, sharp teeth, preferably with a high tooth count. This will help you achieve clean and smooth cuts on the MDF material. Secondly, look for a saw with a rigid blade to prevent bending or flexing during the cutting process. Lastly, opt for a saw with a comfortable grip to ensure ease of use and control while cutting.

Remember, choosing the right hand saw with these essential features will greatly enhance your cutting experience with MDF.

Q: Can I use any type of hand saw to cut MDF?

A: While you can technically use various types of hand saws to cut MDF, some are better suited for the job than others. It is recommended to use either a fine-toothed crosscut hand saw or a backsaw specifically designed for cutting plywood or MDF. These saws have finer teeth, which allow for smoother cuts and reduce the chances of the MDF material splintering. It’s important to note that using a saw with larger teeth, such as a rip saw or a general-purpose hand saw, may result in rougher edges and increased chances of splintering on the MDF.

Therefore, for the cleanest and most precise cuts on MDF, it’s best to choose a hand saw specifically designed for crosscutting or for cutting plywood and MDF materials.

Q: How should I prepare the MDF board before cutting with a hand saw?

A: Before you start cutting the MDF board with a hand saw, it’s essential to prepare the material properly. Begin by measuring and marking the cut line accurately using a ruler or a straightedge. Next, apply masking tape along the marked line. The tape helps prevent the MDF from splintering or chipping during the cutting process. Additionally, it can help reduce friction between the saw blade and the MDF, resulting in smoother cuts.

Remember to ensure the tape is securely adhered to the MDF surface before you start cutting to achieve the best results with your hand saw.

Q: How do I achieve clean and splinter-free cuts when using a hand saw on MDF?

A: To achieve clean and splinter-free cuts when using a hand saw on MDF, a few techniques can prove helpful. Firstly, ensure you have a sharp and properly maintained saw blade. A dull blade can lead to more tear-out and splintering. Additionally, using a backer board, such as a scrap piece of MDF, underneath the piece you’re cutting can prevent splintering on the side that would typically be facing down. Finally, take your time and apply consistent, gentle pressure while cutting to have better control over the saw and minimize the chances of splintering.

By employing these techniques, you can achieve cleaner, smoother, and splinter-free cuts when using a hand saw on MDF.

Q: Are there any safety precautions I should follow when cutting MDF with a hand saw?

A: Absolutely! Safety should be a top priority when cutting any material, including MDF. Here are some essential safety precautions to follow when using a hand saw on MDF. Firstly, always wear protective goggles to shield your eyes from dust, debris, and potential splinters. Secondly, ensure a stable work surface and secure the MDF board firmly in place before cutting to prevent it from moving or slipping. Additionally, maintain a secure grip on the saw handle, and position your body and hands away from the blade’s path to avoid accidental injuries.

Remember to take your time, work in a well-ventilated area, and follow all safety guidelines and instructions provided with the hand saw to ensure a safe cutting experience with MDF.

How To Make A Long Straight Cut With A Handsaw

Summary

When choosing a hand saw to cut MDF, it is important to consider the type of cut you need. For general cuts, a cross-cut saw with fine teeth is a good option. If you need more precise and smoother cuts, a panel saw with a higher number of teeth per inch is recommended. It’s also important to use a saw with a sharp blade and to take your time to ensure accuracy. Remember to always wear safety goggles and gloves when operating a hand saw.

In addition to selecting the right saw, it’s important to use proper cutting techniques. Start by marking your cut line clearly and use a guide to keep your cuts straight. Apply even pressure while cutting and make sure to support the MDF to avoid splintering. With the right saw and technique, you’ll be able to make clean and accurate cuts in MDF for your projects.