Are you curious about woodturning and the tools involved? Well, let’s dive into the fascinating world of woodturning and explore the question, “What is a bowl gouge woodturning?”

If you’re new to woodturning, a bowl gouge is a specialized tool that helps create beautiful bowls and vessels from blocks of wood. It’s like a chisel but with a curved cutting edge, allowing you to shape the wood smoothly and precisely.

Imagine holding a bowl gouge in your hand, gently guiding it over the spinning wood, and watching the shavings gracefully fall away. With a bowl gouge, you have the power to transform a plain block of wood into a stunning piece of functional art.

So, get ready to explore the world of woodturning and discover the incredible possibilities that await with a bowl gouge in hand! Let’s embark on this exciting journey together and unlock your creativity with woodturning.

What is a Bowl Gouge Woodturning?

Woodturning is a centuries-old craft that involves spinning a piece of wood on a lathe and using cutting tools to shape and sculpt it into various forms. One essential tool in a woodturner’s toolbox is a bowl gouge. A bowl gouge is a specialized type of gouge chisel that is designed specifically for turning bowls and other hollow forms.

Unlike other chisels that have a flat or straight cutting edge, a bowl gouge has a deep U-shaped flute that allows the tool to remove large amounts of material quickly and efficiently. The flute runs along the length of the chisel, and the cutting edge is ground to a bevel angle that provides excellent control and smooth cutting action.

Woodturners use bowl gouges to hollow out the inside of bowls and create smooth, even curves on the outer surface. The sharp cutting edge of the gouge shaves away layers of wood, creating the desired shape and form. With practice and skill, a woodturner can create intricate designs, textured surfaces, and delicate details using a bowl gouge.

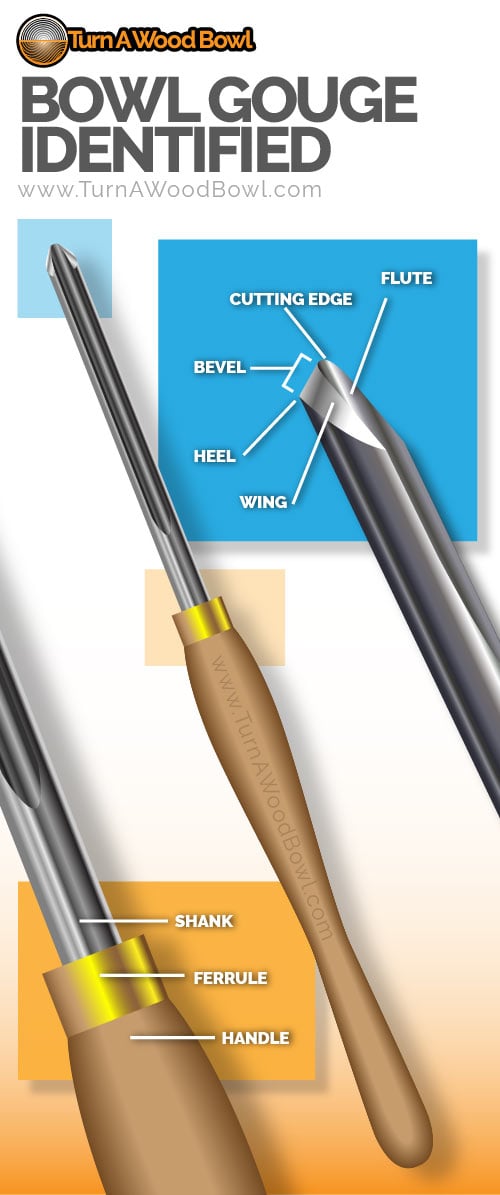

The Anatomy of a Bowl Gouge

A bowl gouge consists of several key components that work together to make it an effective tool for woodturning. These components include:

- Handle: The handle is the part of the gouge that the woodturner grips and controls. It is usually made of wood or metal and is designed to be comfortable to hold and provide good control.

- Shank: The shank is the long, slender part of the gouge that extends from the handle. It is typically made of high-quality tool steel that can withstand the forces and stresses of woodturning.

- Flute: The flute is the U-shaped channel that runs along the length of the gouge. It is the main cutting edge of the tool and is responsible for removing wood chips and creating the desired shape.

- Bevel: The bevel is the ground surface at the tip of the gouge. It is angled to provide the correct cutting action and control. The bevel should be properly sharpened to ensure clean, accurate cuts.

- Grind Shape: Bowl gouges are available in various grind shapes, including traditional grind, fingernail grind, and swept back grind. Each grind shape has its own advantages and is suited to different types of woodturning projects.

Understanding the anatomy of a bowl gouge is essential for woodturners to use the tool effectively and achieve the desired results in their projects.

Benefits of Using a Bowl Gouge

Using a bowl gouge in woodturning offers several benefits for both experienced woodturners and beginners:

- Versatility: A bowl gouge can be used for a wide range of projects, from turning small bowls and boxes to larger hollow forms like vases and platters. This versatility makes it a valuable tool in a woodturner’s arsenal.

- Efficiency: The deep U-shaped flute of a bowl gouge allows woodturners to remove material quickly, saving time and effort. This efficiency is especially beneficial when turning large or thick-walled bowls.

- Control: The design and shape of a bowl gouge provide excellent control over the cutting action, allowing woodturners to create smooth, even curves and intricate details with precision.

- Flexibility: Bowl gouges can be sharpened and reground to suit different turning projects. Woodturners can customize the bevel angle and grind shape to achieve specific results.

- Creativity: With a bowl gouge, woodturners have the freedom to explore their creativity and experiment with different techniques and designs. The tool allows for a wide range of possibilities in shaping and decorating turned pieces.

These benefits make a bowl gouge an invaluable tool for woodturners of all skill levels and contribute to the joy and satisfaction of the craft.

Tips for Using a Bowl Gouge

While a bowl gouge is a versatile and powerful tool, using it correctly requires practice and skill. Here are some tips to ensure safe and effective use of a bowl gouge:

- Start with a sharp tool: A sharp cutting edge is essential for clean, smooth cuts. Regularly sharpen and hone the bowl gouge to maintain its effectiveness.

- Use light pressure: Let the sharpness of the tool do the work. Apply gentle pressure and let the cutting edge slice through the wood rather than forcing it.

- Support the workpiece: Secure the workpiece firmly on the lathe and use a tool rest to provide stability and control. This will help prevent catches and ensure a smooth turning process.

- Practice control and technique: Woodturning is a skill that improves with practice. Experiment with different cutting techniques and practice controlling the shape and depth of your cuts.

- Wear safety gear: Always wear safety goggles, a face shield, and ear protection when using a bowl gouge. Wood chips and debris can fly off during turning, posing a hazard.

By following these tips and continuously honing their skills, woodturners can make the most of their bowl gouge and enjoy the art of woodturning to the fullest.

Choosing the Right Bowl Gouge

The journey towards becoming a skilled woodturner begins with choosing the right bowl gouge. With so many options available on the market, it can be overwhelming to find the perfect tool. Here are some factors to consider when selecting a bowl gouge:

Material and Construction

The material and construction of a bowl gouge play a significant role in its performance and durability. Look for gouges made of high-quality tool steel, preferably M2 high-speed steel or a powdered metallurgy steel. These materials offer excellent edge retention and can withstand the rigors of woodturning. Additionally, consider the construction of the handle to ensure it provides a comfortable grip and good control over the tool.

Gouge Size and Flute Shape

The size of the bowl gouge is determined by its diameter, typically measured in inches. Larger diameter gouges are suitable for turning large bowls and heavy-duty projects, while smaller gouges are better suited for intricate detail work. Choose a size that aligns with the type of turning you intend to do most frequently.

Similarly, the shape of the flute can vary, with options such as U-shape, V-shape, and parabolic. Each flute shape offers different cutting characteristics, so consider the type of turning you plan to do when selecting the flute shape.

Grind Shape

Another important consideration is the grind shape of the bowl gouge. Common grind shapes include traditional grind, fingernail grind, and swept back grind. Each grind shape has its advantages and is suited to different types of woodturning projects. Traditional grind is more versatile, fingernail grind offers better access to tight areas, and swept back grind is suitable for scraping cuts. Choose a grind shape based on your turning preferences and the projects you plan to take on.

Brand and Reputation

When investing in a bowl gouge, it is wise to choose a reputable brand known for producing high-quality turning tools. Research different brands, read reviews, and seek recommendations from experienced woodturners to ensure you select a reliable and well-regarded product.

Price

Price is often a determining factor when purchasing tools. While it’s essential to stick to your budget, it’s also important to remember that the quality of the tool can affect your overall turning experience and the finished results. Balance your budget considerations with the need for a high-quality tool that will last and perform well.

By carefully considering these factors and conducting thorough research, you can choose a bowl gouge that suits your needs, enhances your turning experience, and allows you to create beautiful and unique woodturning projects.

Maintaining and Sharpening a Bowl Gouge

The performance of a bowl gouge is highly dependent on its sharpness and cutting edge. To maintain the tool’s effectiveness and achieve the best results, it’s essential to regularly sharpen and hone the gouge. Here are some steps to follow when sharpening a bowl gouge:

Step 1: Safety First

Before sharpening a bowl gouge, don’t forget to prioritize safety. Wear safety goggles or a face shield to protect your eyes from debris, and consider using a grinding jig or platform to keep your hands away from the spinning wheel during the sharpening process.

Step 2: Grinding

Start by grinding the bevel of the bowl gouge using a sharpening system or bench grinder. Hold the tool at the correct angle, typically 40-45 degrees, and move it across the grinding wheel in smooth, even passes. Take care not to overheat the tool, as this can damage the steel. To prevent overheating, dip the tool in cool water frequently during the grinding process.

Step 3: Honing

After grinding, hone the cutting edge of the gouge to achieve a sharp, burr-free edge. This can be done using a honing guide and sharpening stones or diamond plates. Start with a coarse grit and gradually work your way up to finer grits to achieve a polished and razor-sharp edge.

Step 4: Finishing Touches

Once the cutting edge is honed, remove any burrs or wire edges by gently rubbing the bevel on a piece of leather or a honing wheel. This will help ensure a clean and smooth cutting action when using the gouge.

Step 5: Maintenance

To keep the bowl gouge in optimal condition, it’s important to perform regular maintenance. This includes cleaning the tool after each use to remove wood chips and debris, oiling the shank to prevent rust, and inspecting the handle for any signs of wear or damage. If the handle becomes loose or damaged, consider replacing it or repairing it to maintain the tool’s functionality.

By incorporating regular sharpening and maintenance into your woodturning routine, you can ensure that your bowl gouge remains sharp, reliable, and ready for any turning project.

Using a Bowl Gouge vs. Other Woodturning Tools

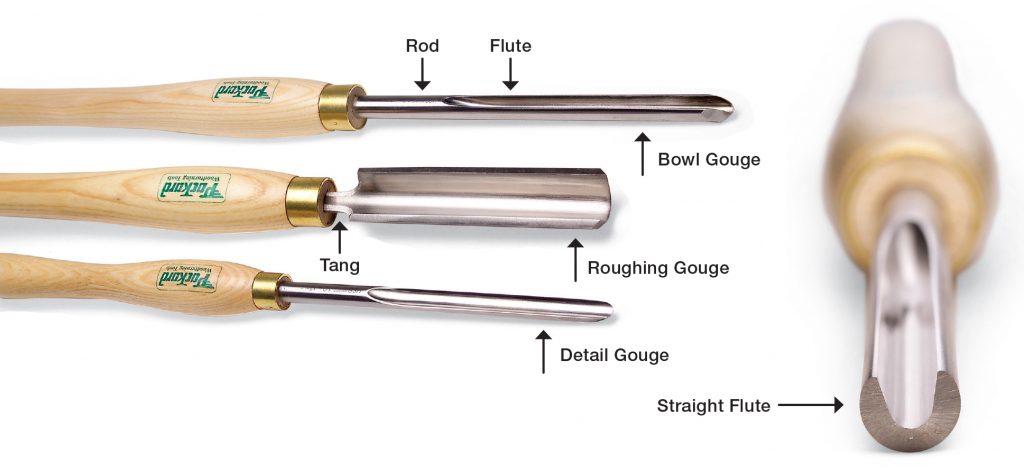

Woodturning involves a wide variety of tools, each with its own specific purpose and advantages. While a bowl gouge is a versatile and essential tool, it’s important to understand how it compares to other woodturning tools in terms of functionality and usage. Here is a comparison between a bowl gouge and other commonly used woodturning tools:

Spindle Gouge

A spindle gouge is another type of gouge chisel that is primarily used for turning spindles, such as chair legs, tool handles, and decorative components. The spindle gouge has a narrower, deeper flute compared to a bowl gouge, allowing for precise shaping and detailing. While both tools are classified as gouges, they have different grind shapes and cutting angles to accommodate their specific applications.

Parting Tool

A parting tool is a flat tool with a pointed tip that is used to separate the workpiece at the end of a turning project or to create grooves and details. It is primarily used for cutting straight lines and forming small details. A bowl gouge, on the other hand, is not designed for these types of cuts and is more suited for shaping and hollowing out bowls and other curved forms.

Bowl Scraper

A bowl scraper, as the name suggests, is a scraping tool used for smoothing and refining the surface of a turned bowl. It is typically flat or slightly curved and has a burr along the cutting edge that scrapes away wood fibers. While a bowl gouge is primarily used for rough shaping and hollowing, a bowl scraper is ideal for achieving a smooth finish on the inside and outside surfaces of a bowl.

Each of these tools has its place in woodturning and complements the others to achieve specific results. While a bowl gouge is an essential tool for turning bowls and hollow forms, it is important to have a range of other tools to tackle different turning projects and achieve a variety of shapes and details.

The Versatility of a Bowl Gouge

One of the reasons why a bowl gouge is highly regarded in the world of woodturning is its versatility. This tool can handle a wide range of projects, from turning small bowls to creating large hollow forms. Here are some examples of the versatility of a bowl gouge:

Turning Bowls and Plates

A bowl gouge is specifically designed for shaping and hollowing out bowls and plates. Its deep flute and sharp cutting edge allow woodturners to remove material efficiently and achieve the desired form. With different cutting techniques, a bowl gouge can create everything from shallow, wide-rimmed bowls to deep, narrow vessels.

Hollowing Out Vases and Urns

Beyond bowls, a bowl gouge can be used to hollow out vases, urns, and other hollow forms. By carefully controlling the cutting action and gradually removing material from the inside, woodturners can create stunning vessels with intricate shapes and delicate curves.

Shaping Spindles

While a spindle gouge is the go-to tool for turning spindles, a bowl gouge can also be used for spindle work. The versatility of the bowl gouge allows woodturners to shape spindles, such as table legs or tool handles, with precision and control. The deep flute of the gouge helps in removing material quickly and achieving smooth curves.

Creating Textured Surfaces

Woodturners can also use a bowl gouge to create textured surfaces on their turned pieces. By carefully manipulating the gouge along the surface of the wood, woodturners can create intricate patterns and textures, adding visual interest and dimension to their projects.

The versatility of a bowl gouge lies not only in its ability to handle different turning projects but also in the creative possibilities it offers to woodturners. With this tool in hand, the possibilities for shaping and decorating wooden objects are virtually endless.

Key Takeaways: What is a Bowl Gouge Woodturning?

- A bowl gouge is a specialized woodturning tool used to shape and hollow out bowls and vessels from wood.

- It features a long, slender handle and a curved, spoon-shaped blade that is designed for efficient wood removal.

- Using a bowl gouge requires proper technique, including holding the tool securely and positioning it correctly on the wood.

- It is important to maintain sharpness by sharpening the blade regularly to ensure clean and smooth cuts.

- With practice and skill, a bowl gouge can create intricate designs and beautiful pieces of wood art.

Frequently Asked Questions

When it comes to woodturning, a bowl gouge is an essential tool used to shape and hollow out the interior of a bowl. It is a versatile tool that allows woodturners to create intricate designs and smooth curves. In this article, we will provide answers to some frequently asked questions about bowl gouges in woodturning.

1. How does a bowl gouge work?

A bowl gouge is a cutting tool with a long handle and a curved, U-shaped metal tip. When using a bowl gouge, the woodturner holds the handle and applies downward pressure to engage the cutting edge with the wood. As the gouge is rotated, the curved tip slices through the wood, creating shavings and shaping the bowl. The woodturner can control the depth and shape of the cut by adjusting the angle and position of the gouge.

It is important to use proper technique and maintain sharpness for optimal performance. The woodturner should avoid applying too much pressure and let the tool do the cutting. Regular sharpening and honing of the gouge’s cutting edge will ensure clean cuts and prevent tear-outs in the wood.

2. What are the different types of bowl gouges?

There are several types of bowl gouges available, including traditional bowl gouges, bottoming bowl gouges, and fingernail bowl gouges. Traditional bowl gouges have a more rounded profile and are versatile tools for shaping bowls. Bottoming bowl gouges have a shorter flute and are designed for reaching the bottom of deep bowls. Fingernail bowl gouges have a distinctive shape resembling a fingernail and are renowned for their versatility and ability to create intricate details.

The choice of bowl gouge depends on the woodturner’s preference, the type of bowl being created, and the desired finish. Experimenting with different types of gouges can help woodturners achieve unique designs and textures in their bowls.

3. What are the main components of a bowl gouge?

A bowl gouge consists of several key components. The handle is typically made of wood or synthetic material and provides a comfortable grip for the woodturner. The shaft connects the handle to the blade and provides stability and control. The blade, also known as the flute, is the cutting part of the gouge and is made of high-speed steel or carbide. The cutting edge is ground to a specific angle for optimal cutting performance.

Some bowl gouges also have a ferrule, which is a metal collar that strengthens the connection between the handle and the shaft. The ferrule helps to prevent splitting or breaking of the handle during use. Overall, each component plays a critical role in the functionality and performance of the bowl gouge.

4. How do I choose the right bowl gouge for my project?

Choosing the right bowl gouge depends on various factors, such as the size and type of bowl being turned, the wood being used, and the desired finish. It is important to consider the shape, flute size, and grind angle of the gouge. A larger flute size provides more material removal, while a smaller flute allows for more controlled cuts and finer details. The grind angle determines the aggressiveness of the cut and the control the woodturner has over the tool.

Experimenting with different bowl gouges and seeking advice from experienced woodturners can help you find the right gouge for your specific project. It is essential to consider the characteristics of the wood, your skill level, and the desired outcome to make an informed decision.

5. How do I maintain and sharpen a bowl gouge?

Maintaining and sharpening a bowl gouge is crucial for achieving clean cuts and extending the life of the tool. Regularly inspect the gouge for any nicks, cracks, or damage. Clean the blade after each use and apply a thin coat of protective oil to prevent rusting. To sharpen the gouge, use a sharpening jig or a sharpening system to maintain the correct angle and ensure consistent sharpening.

When sharpening, focus on the cutting edge and follow the manufacturer’s recommended grind angle. Use a slow, deliberate motion and apply even pressure to achieve a sharp edge. It is important to check the sharpness frequently and make adjustments as needed to maintain optimal cutting performance. Remember, a sharp gouge not only enhances the quality of your cuts but also ensures a safe and enjoyable woodturning experience.

Summary

A bowl gouge is a special tool for carving wooden bowls and creating curves.

It has a long handle and a sharp steel blade that cuts smoothly into the wood.

Using a bowl gouge requires skill and practice, but it can help you make beautiful bowls.

Bowl gouges come in different sizes and shapes, each with its own purpose.

They can be used to rough out the shape of a bowl or refine the details.

It’s important to use proper safety precautions when using a bowl gouge to avoid accidents.

With time and patience, you can become skilled at using a bowl gouge to create wonderful wooden bowls.