Are you curious about what a capstan lathe is? Well, let me tell you! A capstan lathe is a fascinating machine used in manufacturing to shape and cut metal. 🛠️

Imagine being able to create precise and intricate designs on metal with just a few simple movements. That’s what a capstan lathe allows you to do! It’s like having a super-powered tool in your hands. 💪

So, how does a capstan lathe work? It spins the metal at high speeds while different tools move in and out to shape, cut, or drill holes. It’s like a symphony of movements, all perfectly coordinated to bring your metal creations to life. 🔧

Now that you have a basic understanding of what a capstan lathe is, let’s dive deeper into its components and how it revolutionized the manufacturing industry. You’re in for an exciting journey! 🚀

What Is a Capstan Lathe? A Comprehensive Guide

Welcome to this comprehensive guide on capstan lathes. In this article, we will delve into the world of capstan lathes, exploring what they are, how they work, their applications, and much more. Whether you’re new to the world of machining or an experienced engineer, this guide will provide valuable insights into the functionality and advantages of capstan lathes. So let’s get started!

Understanding the Basics

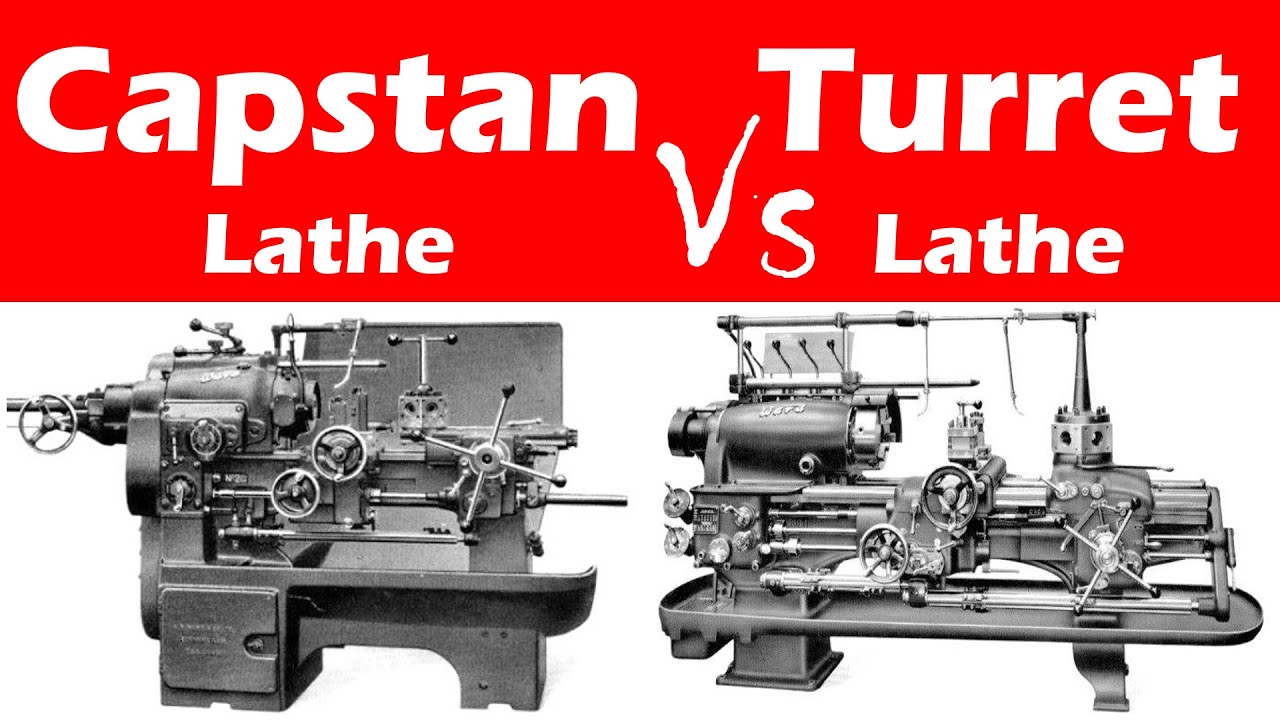

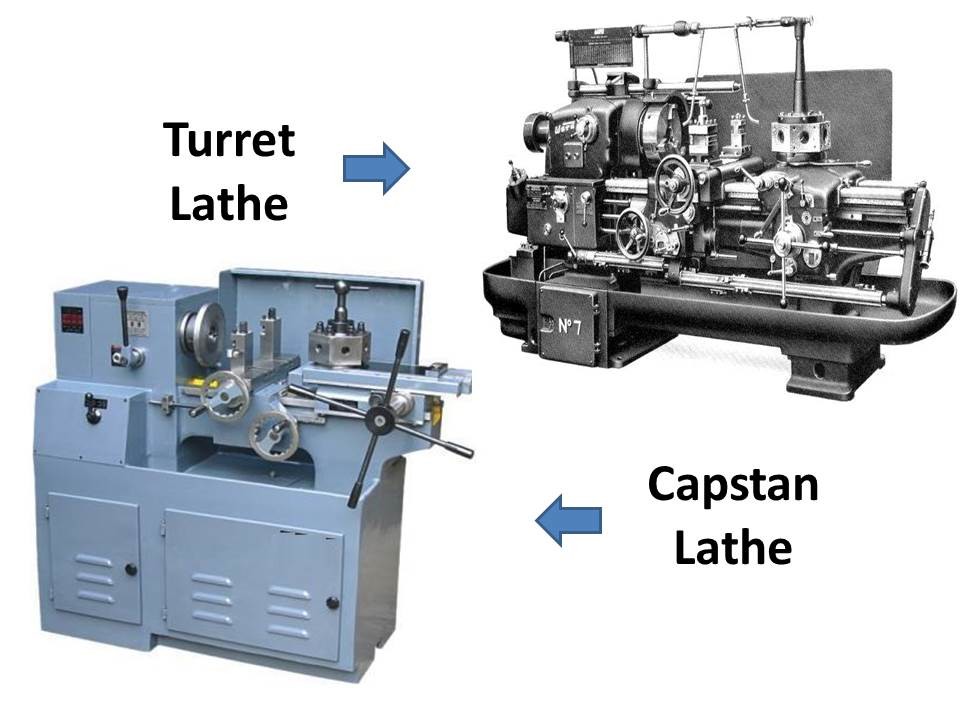

Before we dive into the details of capstan lathes, let’s start with the basics. A capstan lathe is a type of lathe machine that is specifically designed for the efficient and accurate production of small and medium-sized workpieces. So, what sets a capstan lathe apart from other lathes? Well, one key feature is the addition of a turret or capstan head.

The turret or capstan head allows for the rapid and precise indexing of tools, enabling the machine to perform a variety of operations without the need for manual intervention. This makes capstan lathes incredibly fast and efficient, making them ideal for industries where high production rates and consistent precision are crucial. Now that we’ve covered the basics, let’s explore the various components and working principles of a capstan lathe.

The Components of a Capstan Lathe

A capstan lathe consists of several key components working together to enable efficient machining. Let’s take a closer look at each of these components:

- Bed: The bed is the base of the machine that provides stability and support for the other components.

- Saddle: The saddle is mounted on the bed and holds the tool post and the cross slide.

- Turret or Capstan Head: This is the defining feature of a capstan lathe. It holds multiple tooling positions and enables quick indexing and tool changes.

- Tool Post: The tool post holds the cutting tools and allows for precise positioning and adjustment.

- Cross Slide: The cross slide moves perpendicular to the lathe’s axis, allowing for the machining of cylindrical workpieces.

- Spindle: The spindle rotates the workpiece, enabling cutting operations.

- Chuck: The chuck is a specialized device that securely holds the workpiece during machining.

By understanding the purpose and functionality of each of these components, we can begin to appreciate the capabilities of a capstan lathe.

Working Principles of a Capstan Lathe

To fully grasp how a capstan lathe operates, it’s important to understand its working principles. A capstan lathe combines the rotational motion of the spindle with the linear motion of the cutting tools to perform various machining operations.

When a workpiece is mounted in the chuck and the lathe is turned on, the spindle starts rotating. Meanwhile, the operator positions the desired cutting tool on the tool post and selects the appropriate tooling position on the turret or capstan head. With the workpiece spinning and the tool positioned, the operator engages the feed mechanism, causing the cutting tool to move towards the workpiece.

The combination of the rotating workpiece and the linear movement of the tool allows for precise cutting, shaping, and finishing of the workpiece. The turret or capstan head enables quick tool changes, making it possible to perform multiple operations without the need for manual adjustments. This efficiency is what makes capstan lathes so desirable in industries where speed and accuracy are paramount.

The Applications of Capstan Lathes

Capstan lathes find applications in a wide range of industries where the production of small to medium-sized components is required. Here are some of the key industries that benefit from the use of capstan lathes:

- Automotive: Capstan lathes play a crucial role in the production of various automotive components, such as shafts, bushings, and pulleys.

- Electronics: The precision and speed of capstan lathes make them ideal for manufacturing electronic components like connectors, pins, and sockets.

- Medical: Capstan lathes are used in the production of medical instruments, implants, and components for medical devices.

- Tool and Die Making: Capstan lathes are often employed in the production of tooling components and dies for various industries.

- General Engineering: From screws and nuts to small shafts and fittings, capstan lathes are used to produce a wide range of general engineering components.

These are just a few examples of the many industries that rely on capstan lathes for their machining needs. Now that we have explored the applications, let’s move on to the advantages of using a capstan lathe.

The Advantages of Capstan Lathes

Capstan lathes offer several advantages over other types of lathes, making them a popular choice in many industries. Here are some of the key benefits:

- High Productivity: The rapid indexing and tool changes offered by capstan lathes enables high production rates, resulting in enhanced productivity.

- Precision and Accuracy: The combination of the turret or capstan head and the linear motion of the cutting tools ensures consistent precision and accuracy in machining operations.

- Versatility: Capstan lathes can perform a wide range of operations, including turning, facing, grooving, threading, and more, making them versatile machines suitable for various applications.

- Efficiency: With the ability to perform multiple operations without manual adjustments, capstan lathes offer significant time and cost savings, increasing overall efficiency.

- Reduced Labor Intensity: Capstan lathes require less manual intervention, reducing the need for skilled operators and minimizing labor costs.

These advantages make capstan lathes highly desirable for industries that prioritize productivity, precision, and efficiency.

The Future of Capstan Lathes

The field of machining is constantly evolving, and capstan lathes continue to play a vital role in the manufacturing world. As technology advances, we can expect to see further enhancements in capstan lathe capabilities, including improved automation, integration with digital systems, and increased connectivity for data analysis and optimization.

The future of capstan lathes looks promising, with continuous developments aimed at improving speed, efficiency, and precision. As industries demand higher production rates and tighter tolerances, capstan lathes will continue to be the go-to choice for achieving these goals.

Conclusion

Capstan lathes are powerful machines that offer exceptional speed, precision, and efficiency in the machining process. With their unique turret or capstan head, these lathes can rapidly change tools and perform multiple operations without manual intervention. They find applications in various industries, from automotive to electronics and medical. By understanding the basics, components, working principles, applications, and advantages of capstan lathes, you can appreciate their role in modern manufacturing and the potential they hold for the future.

Whether you’re an engineer, a student, or someone with a general interest in machining, exploring the world of capstan lathes opens up a new realm of possibilities. So go ahead, dive deeper into this fascinating field, and discover the limitless potential of capstan lathes!

Key Takeaways: What is a Capstan Lathe?

- A capstan lathe is a type of lathe machine used for production work.

- It is designed for high-speed and high-precision machining.

- This lathe is used to manufacture small, cylindrical parts with accuracy.

- It features a turret with multiple tool stations for quick tool changes.

- Capstan lathes are commonly used in industries such as automotive and electronics.

Frequently Asked Questions

Welcome to our FAQ section on capstan lathes. If you’re curious about what a capstan lathe is and how it works, you’ve come to the right place. We’ve compiled a list of commonly asked questions to help you understand this fascinating machine. Read on to discover more!

1. How does a capstan lathe differ from a regular lathe?

A capstan lathe is a type of lathe machine that is specifically designed for high-speed and highly automated production. Unlike a regular lathe, which is primarily used for single-piece or low-volume production, a capstan lathe excels at mass production.

The main difference lies in the turret, which is a central feature of the capstan lathe. The turret houses multiple tool holders, allowing for rapid tool changes and thereby increasing productivity. This feature, along with the ability to perform multiple operations simultaneously, sets a capstan lathe apart from its regular counterpart.

2. What are the advantages of using a capstan lathe?

There are several advantages to using a capstan lathe in manufacturing processes. First and foremost, its high-speed production capabilities make it ideal for large-scale production runs. The ability to perform multiple operations simultaneously saves time and increases efficiency.

Additionally, the automation features of a capstan lathe, such as the automatic tool changing system, reduce the need for manual intervention, resulting in improved accuracy and lower labor costs. Overall, these advantages make capstan lathes a preferred choice for industries that require high-volume production with minimal downtime.

3. What are some common applications of capstan lathes?

Capstan lathes find applications in various industries that require high-volume production with precision. They are commonly used in the automotive industry for tasks like turning crankshafts, flywheels, and other engine components. They are also used in the production of small precision parts for the aerospace and electronics industries.

Furthermore, capstan lathes are utilized in the production of fasteners, such as screws and bolts, thanks to their ability to perform threading operations accurately and at a fast pace. With their versatility and high-speed capabilities, capstan lathes have become an essential tool in the manufacturing sector.

4. How does a capstan lathe improve productivity?

A capstan lathe significantly improves productivity through its various features. The turret design allows for quick tool changes, reducing downtime between operations. This means that multiple operations can be performed without the need for manual intervention or time-consuming setup changes.

Moreover, the ability to perform multiple operations simultaneously, such as drilling, boring, and tapping, greatly reduces cycle times and increases overall output. With its high-speed capabilities and efficient automation features, a capstan lathe can significantly enhance productivity in a manufacturing environment.

5. Are there any limitations or drawbacks to using a capstan lathe?

While capstan lathes are highly efficient for mass production, they do have some limitations. One limitation is their size, as they tend to be larger and more complex than regular lathes. This makes them less suitable for small workshops or spaces with limited floor space.

Another drawback is the initial investment required for purchasing and setting up a capstan lathe. As these machines are specialized and offer advanced features, they can be more expensive compared to regular lathes. However, for industries that require high-volume production, the long-term benefits often justify the investment.

Summary

A capstan lathe is a type of machine used to shape and cut materials like metal. It is operated using a system of rotating spindles and tools, making it efficient and precise. Because of its design, it is perfect for making small, intricate parts.

Capstan lathes have various features, such as the turret, which holds different tools that can be easily rotated into position for different tasks. They also have a collet that securely holds the material being worked on, ensuring accuracy. Capstan lathes are commonly used in industries like manufacturing and engineering, where precise and intricate work is required.