Have you ever wondered what a gap bed lathe is? Well, get ready to dive into the world of machining as we explore this fascinating piece of equipment! A gap bed lathe is a specialized machine used in metalworking to shape and cut various materials.

So, what makes a gap bed lathe special? It’s all in the name! This type of lathe has a gap in its bed, which allows for larger diameter materials to be turned. This feature is especially useful when working on projects that require turning long or bulky workpieces.

But that’s not all! Gap bed lathes are versatile machines that can be used for a wide range of applications, from producing intricate parts for aerospace engineering to creating beautiful woodturning projects. So, whether you’re a budding engineer or a DIY enthusiast, understanding the world of gap bed lathes is a must!

What is a Gap Bed Lathe? A Comprehensive Guide to Understanding the Basics

A gap bed lathe is a versatile and essential tool in the machining industry. It is a type of lathe machine that features a removable section in the bed, allowing for the machining of long or oversized workpieces. This unique design feature sets the gap bed lathe apart from other conventional lathes and makes it an indispensable tool for various applications.

With its ability to accommodate larger workpieces, the gap bed lathe offers a wide range of benefits. It allows for the turning of cylindrical parts with larger diameters, such as pipes, shafts, or rods, without the need for additional tools or equipment. This makes it a cost-effective solution for many manufacturing processes. Additionally, the gap bed lathe can also handle irregularly shaped workpieces, giving machinists greater flexibility in their projects.

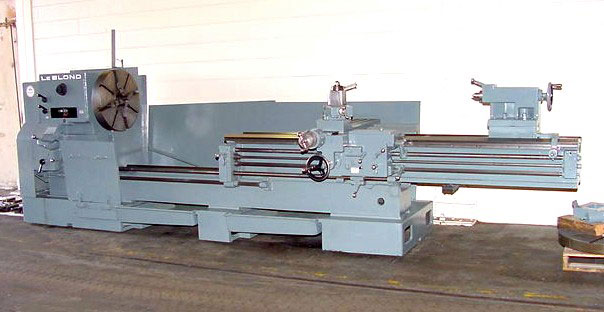

The Construction and Components of a Gap Bed Lathe

A gap bed lathe primarily consists of three main components: the bed, the headstock, and the tailstock. The bed is a robust and sturdy base that supports the entire machine. It is usually made of cast iron or steel to ensure stability and minimize vibrations during operations. The bed also features a removable section, known as the gap, which allows for the machining of longer workpieces.

The headstock is located at one end of the bed and houses the main spindle. It is responsible for providing the rotational power necessary for the machining process. The main spindle is connected to the motor and can be adjusted to control the speed and direction of rotation. The headstock also includes various mechanisms for holding and securing the workpiece, such as chucks, collets, or faceplates.

The tailstock is situated at the opposite end of the bed and serves as a support for long workpieces. It consists of a movable spindle, which can be adjusted to align with the main spindle to hold the workpiece securely. The tailstock spindle can be locked in place using a clamp or a lever, ensuring stability during the machining process. Overall, the construction and components of a gap bed lathe are designed to provide optimal performance and accuracy.

The Versatility and Applications of Gap Bed Lathes

Gap bed lathes are highly versatile machines that can be utilized in various industries and applications. Their capacity to accommodate larger workpieces makes them suitable for machining projects that involve the production of long or oversized parts. For example, gap bed lathes are commonly used in the automotive industry for turning crankshafts, axles, and drive shafts. They are also prevalent in the aerospace industry for manufacturing components like landing gear struts and turbine shafts.

Moreover, the unique design of the gap bed lathe allows for the machining of complex shapes and features. This makes it an excellent choice for creating prototypes, custom parts, or one-of-a-kind components. Additionally, gap bed lathes can be used for threading, taper turning, facing, and other machining operations that require precision and accuracy.

The versatility of gap bed lathes extends beyond metalworking applications. With the right tools and accessories, they can also be used for woodworking, creating intricate designs on wooden pieces, or even for working with materials like plastics or composites. This versatility and adaptability make gap bed lathes invaluable tools for both large-scale manufacturing operations and smaller-scale workshops.

Factors to Consider When Choosing a Gap Bed Lathe

When selecting a gap bed lathe for your machining needs, there are several factors to consider. Firstly, the size and capacity of the lathe should match your workpiece requirements. Consider the maximum swing diameter and the length of the gap bed to ensure that it can accommodate your desired projects.

Additionally, pay attention to the spindle speed range and the available tailstock options. Different projects require different speed settings, and having a wide range of options will allow for greater control and versatility. Similarly, having various tailstock accessories, such as steady rests or follow rests, can further expand the capabilities of the lathe.

Another aspect to consider is the level of automation and technology offered by the lathe. Some gap bed lathes come equipped with advanced features like CNC controls, automatic tool changers, or digital readouts. These features can significantly enhance machining efficiency and precision, but they may also come at a higher cost. Evaluate your specific needs and budget to determine the right balance between manual and automated functionalities.

In conclusion, a gap bed lathe is a versatile and valuable tool in the machining industry. Its ability to accommodate larger workpieces and handle complex shapes makes it an essential machine for various applications. When selecting a gap bed lathe, consider factors such as size, capacity, spindle speed range, tailstock options, and level of automation. By making an informed decision, you can ensure that your gap bed lathe meets your machining requirements and helps you achieve precise and efficient results.

Key Takeaways: What is a Gap Bed Lathe?

- A gap bed lathe is a type of lathe machine used in metalworking.

- It has a removable section in the bed, known as the gap, which allows larger and longer workpieces to be turned.

- This lathe is useful for machining cylindrical or conical shapes.

- It is commonly used in manufacturing industries for various applications.

- By utilizing the gap, the working capacity of the lathe can be significantly increased.

Frequently Asked Questions

In the world of machining, a gap bed lathe is a popular tool for shaping metal. It offers versatility and flexibility, making it a valuable asset in various industries. Here are some commonly asked questions about gap bed lathes:

1. How does a gap bed lathe differ from a regular lathe?

A gap bed lathe differs from a regular lathe in its bed design. While a regular lathe has a solid, continuous bed, a gap bed lathe has a removable section in the bed. This gap allows you to swing larger diameter workpieces over the bed without the need for disassembling or repositioning. It provides the flexibility to handle larger and longer workpieces.

Additionally, the gap bed lathe provides a wider working area when the gap section is removed. This allows for increased machining possibilities and expanded applications, making it an ideal choice for projects that require extra space or involve large-scale workpieces.

2. What are the advantages of using a gap bed lathe?

One of the main advantages of using a gap bed lathe is its ability to accommodate larger diameters and longer workpieces. The gap created in the bed allows for the machining of materials with a larger diameter that would exceed the capacity of a regular lathe.

The increased swing diameter and wider working area of a gap bed lathe provide versatility for turning projects of various sizes and shapes. It allows for the machining of large shafts, pipes, and other cylindrical components. Furthermore, the gap bed lathe offers flexibility in terms of chuck and tooling options, enabling machinists to work on a wide range of materials and achieve precise results.

3. What industries commonly use gap bed lathes?

Gap bed lathes find application in numerous industries, including aerospace, automotive, oil and gas, and heavy machinery manufacturing. These industries often require machining of larger components with complex shapes, where a regular lathe might not be suitable due to size limitations.

In the aerospace industry, for example, gap bed lathes are used to fabricate large aircraft parts like landing gear components, engine shafts, and turbine disks. In the automotive industry, they are used for machining crankshafts, connecting rods, and other engine components. Gap bed lathes are also commonly used in the production of oil and gas equipment, such as drill collars and pump shafts, due to their ability to handle large-scale machining.

4. What considerations should be made when choosing a gap bed lathe?

When selecting a gap bed lathe, several factors should be taken into account. Firstly, consider the size and weight of the workpieces you typically work with and ensure that the lathe’s swing diameter and capacity can accommodate them.

It’s also important to consider the power and speed requirements for your machining projects. Make sure the lathe has a motor with sufficient horsepower, along with a speed range that allows for desired cutting speeds and feeds.

Other considerations include the availability of optional features such as digital readouts, tool holders, and coolant systems, as well as the reputation and reliability of the lathe manufacturer. Price and budget constraints should also be factored in, along with any specific requirements unique to your industry or machining needs.

5. Are there any safety precautions to keep in mind when using a gap bed lathe?

As with any machine tool, safety is of utmost importance when operating a gap bed lathe. Always ensure that you are familiar with the lathe’s operating manual and follow proper safety procedures.

Some general safety precautions include wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. Keep the work area clean and free from clutter, and always secure the workpiece securely in the chuck or on the workholding device.

Additionally, it’s important to be aware of rotating parts and moving components when operating the lathe. Maintain a safe distance from the rotating workpiece and use caution when adjusting tooling or making any adjustments to the machine. Regular maintenance and inspection of the lathe are also crucial for safe and reliable operation.

Millport 1540 Gap Bed Lathe with Lots of Tooling

Summary

A gap bed lathe is a machine that helps you shape and cut metal pieces. It has a big space in the middle, called a gap, which allows you to work on long items. You can change the speed and direction of the lathe to make different cuts. It’s a handy tool for making things like table legs or engine parts.

You have to be careful and follow safety rules when using a gap bed lathe. Don’t wear loose clothes or jewelry that can get caught in the machine. Make sure the piece you’re working on is securely held in place. Always ask for help from an adult or someone who knows how to use it if you’re not sure. With practice and caution, the gap bed lathe can be a useful tool for crafting and creating.