If you’re diving into the world of woodworking and need a versatile tool, you’ve probably asked yourself, “What is a good general purpose bandsaw blade?” Well, my friend, you’ve come to the right place!

Whether you’re a woodworking enthusiast or a professional carpenter, finding the right bandsaw blade can make all the difference in your projects.

Today, we’re going to explore the realm of bandsaw blades, uncovering the secrets to selecting the perfect one for your needs. So, grab your safety goggles and let’s dive in!

What is a Good General Purpose Bandsaw Blade?

A bandsaw is a versatile tool used in woodworking and metalworking industries. It consists of a continuous blade with teeth that rotate around two or more wheels, allowing for precise cutting. One of the key components of a bandsaw is the blade itself. Choosing the right bandsaw blade can greatly impact the quality and efficiency of your cuts. In this article, we will explore what makes a good general purpose bandsaw blade and how to select the right one for your needs.

1) Types of Bandsaw Blades

When it comes to general purpose bandsaw blades, there are two main types: carbon steel blades and bi-metal blades. Carbon steel blades are made from a high carbon content steel, which makes them durable and capable of maintaining their sharpness for a longer time. Bi-metal blades, on the other hand, consist of two different metals fused together – usually high-speed steel teeth and a flexible spring steel backing. These blades offer a combination of durability and flexibility, making them suitable for a wide range of cutting tasks.

Both carbon steel and bi-metal blades have their advantages and choosing between them depends on the specific needs of your project. Carbon steel blades are more affordable and are ideal for cutting soft materials like wood, while bi-metal blades are more expensive but can handle tough materials such as metal and hardwood.

2) Blade Width and TPI (Teeth per Inch)

The width of the bandsaw blade and its TPI (Teeth per Inch) are crucial factors to consider when selecting a general purpose blade. Blade width determines the cutting capacity of the bandsaw, meaning how thick of a material it can handle. Narrow blades are suitable for intricate cuts, while wider blades are better for resawing and cutting thicker materials. Typically, a blade width of 1/8 inch to 1 inch is suitable for general purpose use.

TPI refers to the number of teeth on the blade per inch. Blades with a higher TPI provide a smoother finish and are better for precision cuts. However, they have a slower cutting speed. Blades with a lower TPI have a faster cutting speed but a rougher finish. For general purpose cutting, a blade with 6 to 10 TPI is recommended as it offers a good balance between cutting speed and finish quality.

3) Blade Tooth Style

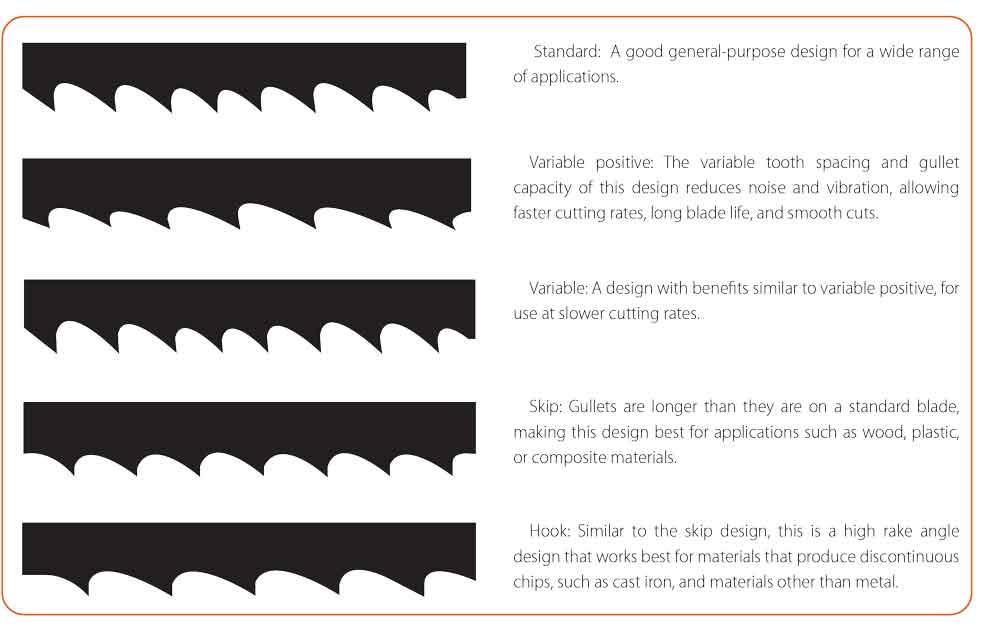

Blade tooth style also plays a significant role in the performance of a general purpose bandsaw blade. There are different tooth styles available, such as hook tooth, skip tooth, and regular tooth, each designed for specific cutting tasks.

Hook tooth blades have deep gullets and large gullet openings, making them ideal for fast cuts in soft materials. Skip tooth blades have widely spaced teeth, which prevent clogging when cutting thick materials. Regular tooth blades have evenly spaced teeth and are versatile for a variety of cutting tasks. For general purpose use, a regular tooth blade is a reliable choice as it can handle most materials efficiently.

4) Blade Thickness and Durability

The thickness of the bandsaw blade affects its durability and stability during cutting. Thicker blades have more torsional rigidity, reducing the chances of blade deflection and ensuring accurate cuts. However, thicker blades also require more power to drive, so it’s essential to consider the capabilities of your bandsaw when selecting the thickness.

In terms of durability, the material used in the blade plays a crucial role. Whether it’s carbon steel or bi-metal, a good general purpose bandsaw blade should be made from high-quality materials that can withstand wear and tear. Look for blades that are heat-treated and have hardened teeth for extended longevity.

5) Blade Tracking and Tensioning

Proper blade tracking and tensioning are essential for optimal performance and safety. The blade should run smoothly on the bandsaw wheels without any wobbling or drifting. It’s crucial to adjust the blade tension according to the manufacturer’s guidelines to prevent blade damage and enhance cutting accuracy. Regular maintenance, such as cleaning and lubricating the bandsaw, will also contribute to the longevity and performance of the blade.

6) Choosing the Right Blade for the Job

When selecting a general purpose bandsaw blade, it’s important to consider the specific requirements of your project. If you primarily work with wood, a carbon steel blade would be a cost-effective choice. For cutting metal or hardwood, a bi-metal blade would offer superior performance and durability. Assess the thickness of the materials you’ll be cutting and choose the appropriate blade width and TPI. Consider the tooth style that best suits your cutting needs, and make sure to maintain proper blade tracking and tensioning for optimal results.

7) Getting the Most out of Your Bandsaw Blade

To ensure the longevity and performance of your general purpose bandsaw blade, follow these tips:

- Always use the appropriate blade for the task at hand.

- Keep the blade clean and free from debris.

- Monitor the blade for signs of wear and replace it when necessary.

- Properly tension the blade according to the manufacturer’s guidelines.

- Regularly inspect and maintain your bandsaw to prevent any issues that may affect the blade’s performance.

Benefits of Using a Good General Purpose Bandsaw Blade

Using a good general purpose bandsaw blade offers several benefits:

- Versatility: A general purpose blade can handle a wide range of cutting tasks, reducing the need for multiple specialized blades.

- Efficiency: A high-quality blade improves cutting speed and accuracy, allowing you to complete projects more quickly and with better results.

- Durability: A well-made blade lasts longer, reducing the frequency and cost of blade replacements.

- Quality of Cuts: A good general purpose blade ensures clean, precise cuts, resulting in professional-looking finished products.

- Cost-effectiveness: Investing in a reliable general purpose blade can save money in the long run by eliminating the need for multiple blades and reducing material waste.

Conclusion

A good general purpose bandsaw blade is essential for achieving accurate and efficient cuts in a variety of materials. Consider factors such as blade type, width, TPI, tooth style, thickness, and durability when choosing the right blade for your needs. Proper blade tracking and tensioning, along with regular maintenance, will help maximize the performance and lifespan of the blade. Enjoy the versatility and benefits that a good general purpose bandsaw blade brings to your woodworking or metalworking projects.

Key Takeaways: What is a Good General Purpose Bandsaw Blade?

- A good general purpose bandsaw blade is versatile and can cut through various materials.

- It should have a balanced mix of tooth count and tooth type for cutting different materials.

- The blade’s thickness and width should match the bandsaw’s capacity and the desired cutting accuracy.

- The material of the blade, such as carbon steel or bi-metal, determines its durability and cutting performance.

- Choosing the appropriate blade length based on the bandsaw’s wheel diameter and the desired cutting applications is crucial.

Frequently Asked Questions

Welcome to our FAQ page on general-purpose bandsaw blades! If you’re looking for the right blade for your bandsaw, you’ve come to the right place. Below, we have answered some common questions to help you choose the perfect blade for your needs.

1. What are the key features to look for in a good general-purpose bandsaw blade?

When it comes to choosing a good general-purpose bandsaw blade, there are a few important features to consider. First, pay attention to the width and thickness of the blade. The width should match the specifications of your bandsaw, and the thickness should be suitable for the type of cuts you plan to make. Additionally, look for a blade with the right number of teeth per inch (TPI) for your cutting needs. Higher TPI is ideal for smoother cuts, while lower TPI is better for faster, rougher cuts.

Another key feature to consider is the material of the blade. High-quality blades are often made from carbon steel or bi-metal, both of which offer durability and cutting performance. Finally, be sure to check the blade’s compatibility with your bandsaw model to ensure a proper fit.

2. How do I determine the right blade width for my bandsaw?

Choosing the right blade width for your bandsaw is essential for achieving accurate cuts. To determine the appropriate width, start by consulting your bandsaw’s manual or manufacturer’s guidelines. Typically, the width should match the maximum blade width recommended for your specific bandsaw model.

Keep in mind that wider blades are generally more rigid and provide stability during cutting, making them suitable for resawing or cutting thicker materials. However, for intricate curves and tight radius cuts, a narrower blade would be more appropriate. Consider the types of cuts you’ll be making most frequently and choose the blade width accordingly.

3. What type of teeth configuration should I choose for a general-purpose bandsaw blade?

When selecting a general-purpose bandsaw blade, the tooth configuration plays a crucial role in determining the cutting performance. For general-purpose cutting applications, a blade with a regular tooth or hook tooth configuration is often recommended.

Regular tooth blades have evenly spaced teeth designed for smoother cuts, while hook tooth blades have larger gullets that clear out material more quickly, making them ideal for faster, rougher cuts. Ultimately, the tooth configuration depends on the type of materials you’ll be cutting and the desired finish.

4. Are there any special considerations for cutting different materials with a general-purpose bandsaw blade?

Yes, when using a general-purpose bandsaw blade to cut different materials, there are a few considerations to keep in mind. First, it’s important to adjust the blade speed and tension according to the material being cut. Softer materials may require a lower blade speed, while harder materials might require a higher speed.

Additionally, choosing the right blade TPI can enhance cutting performance. For example, when cutting thick hardwood, using a blade with a lower TPI can prevent clogging and ensure a smoother cutting experience. Experimenting with different blade configurations and settings will help you find the best results for each material you work with.

5. How often should I replace my general-purpose bandsaw blade?

The frequency of blade replacement depends on various factors such as usage, material type, and overall blade condition. As a general guideline, you should inspect your bandsaw blade regularly for signs of wear, damage, or dullness. If you notice tooth wear, cracks, or loss of flexibility, it’s time to replace the blade.

It’s also important to keep the blade properly maintained by cleaning it after each use, checking for proper tension, and storing it correctly. Regular maintenance can prolong the lifespan of your blade, reducing the need for frequent replacements. However, always trust your judgment and replace the blade whenever it no longer performs optimally.

Summary

Choosing the right bandsaw blade is important for a good cutting experience.

You need to consider factors like tooth pitch, blade width, and material thickness.

A general-purpose blade with a medium tooth pitch and narrow width is versatile for various tasks.

If you’re cutting thick materials, go for a wider blade with fewer teeth.

It’s also crucial to maintain the blade properly by cleaning it regularly and checking for damages.

With the right blade and proper maintenance, you can achieve accurate and smooth cuts with your bandsaw.

Remember, practice makes perfect, so keep experimenting and adjusting for better results.