Are you curious about what is a good rpm for a table saw? Well, you’ve come to the right place! Whether you’re a budding woodworker or a seasoned DIY enthusiast, understanding the ideal speed for your table saw is crucial for achieving precise and efficient cuts. In this article, we’ll dive into the world of table saw rpms and help you determine the best range for your woodworking needs.

Now, let’s talk about the importance of rpm. RPM stands for “revolutions per minute,” and it refers to the number of times the saw blade rotates in a minute. The speed at which the blade spins directly impacts the quality, accuracy, and safety of your cuts. Too high of an rpm can cause excessive friction, leading to burn marks on your wood, while too low of an rpm may result in a sluggish cut. So, finding the sweet spot is key!

So, what is a good rpm for a table saw? While the ideal speed varies depending on the type and size of the blade, a general rule of thumb is to aim for an rpm between 3,000 and 4,000. However, always refer to the manufacturer’s guidelines and recommendations for your specific table saw and blade. By understanding the optimal rpm range, you can ensure smooth cuts, minimize tear-out, and prolong the lifespan of your equipment. So, let’s get spinning!

When it comes to determining the ideal RPM for a table saw, there are a few factors to consider. Generally, a good RPM for a table saw falls between 3,000 and 4,000 revolutions per minute. This range provides a balance between cutting efficiency and safety. Higher RPMs can result in smoother cuts, while lower RPMs are safer for larger workpieces. However, always refer to the manufacturer’s guidelines for your specific table saw model to ensure optimal performance.

What is a Good RPM for a Table Saw?

Table saws are versatile and powerful tools that are widely used in woodworking and construction. Their effectiveness depends on various factors, including the speed of the blade. The rotation per minute (RPM) of a table saw blade determines its cutting speed and performance. But what is a good RPM for a table saw? In this article, we will explore the ideal RPM range for different table saws and discuss the factors that can influence this setting.

Factors to Consider when Choosing RPM for a Table Saw

When determining the RPM for a table saw, several factors come into play. While there isn’t a one-size-fits-all answer, understanding these factors can help you make an informed decision:

The Blade Size

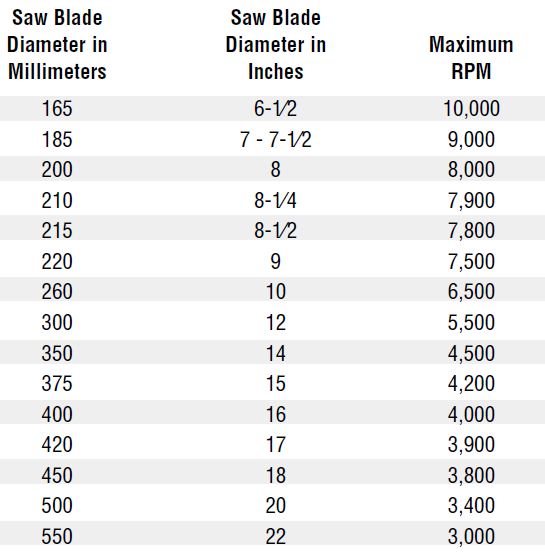

Table saw blades come in various sizes, ranging from 6 inches to 12 inches. Larger blades generally require slower RPM to achieve optimal cutting performance. This is because larger blades have a larger circumference, resulting in higher linear blade speed even at slower RPM. On the other hand, smaller blades require higher RPM to generate enough cutting power due to their smaller circumference. As a general rule, a 10-inch blade used in most table saws should run at around 3,450 RPM for optimal performance.

The Material Being Cut

The type and thickness of the material being cut also play a significant role in determining the ideal RPM for a table saw. Cutting denser or thicker materials, such as hardwood or plywood, may require a slower blade speed to ensure clean and smooth cuts. Conversely, softer or thinner materials, like softwood or thin veneer, may benefit from a higher RPM to prevent burning or chipping. It’s essential to adjust the RPM according to the material to achieve the best results.

The Type of Cut

The type of cut you are making, such as crosscuts or rip cuts, can influence the RPM setting. Crosscuts, which involve cutting across the grain, generally benefit from higher RPM to prevent tear-out and achieve cleaner and smoother edges. Rip cuts, on the other hand, require slower RPM to maximize cutting power and minimize kickback. It’s important to consider the type of cut you are making and adjust the RPM accordingly to ensure safety and precision.

The Blade Quality and Sharpness

The quality and sharpness of the blade can greatly affect the RPM setting. Dull or low-quality blades may require higher RPM to compensate for their reduced cutting efficiency. Investing in high-quality blades and ensuring they are sharp can help achieve better results even at lower RPM settings. Regularly maintaining and sharpening your blades is crucial for optimal performance.

The Table Saw Motor

The motor of the table saw is designed to handle specific RPM ranges. It is important to consult the manufacturer’s guidelines to determine the recommended RPM for your specific table saw model. Exceeding the recommended RPM range can strain the motor and lead to premature wear, decreased performance, and even potential safety hazards.

The Nature of the Task

Lastly, the nature of the task at hand should be considered when determining the ideal RPM for a table saw. For intricate cuts that require precision, a slower RPM might be more suitable. However, for tasks that require fast and efficient cutting, a higher RPM may be necessary. It’s crucial to assess the requirements of each task and adjust the RPM accordingly to achieve the desired results.

Benefits of Maintaining the Right RPM for a Table Saw

Maintaining the right RPM for a table saw offers several benefits:

Enhanced Cutting Performance

By setting the RPM in the appropriate range for the type of cut and material, you can ensure enhanced cutting performance. This leads to cleaner, smoother, and more precise cuts, minimizing the need for additional finishing work.

Improved Blade Lifespan

Running the table saw at the right RPM can significantly extend the lifespan of the blade. When the blade runs at the correct speed, it experiences less strain, reducing the likelihood of overheating, warping, or premature dullness. This results in cost savings, as you won’t need to replace the blade as frequently.

Enhanced Safety

Setting the RPM correctly is vital for ensuring safety while using a table saw. Running the blade too fast or too slow can result in kickback, poor cutting quality, and even accidents. By understanding the appropriate RPM for your table saw and adjusting it accordingly, you can work more safely and reduce the risk of injury.

In conclusion, the ideal RPM for a table saw depends on various factors such as blade size, the material being cut, the type of cut, blade quality and sharpness, the table saw motor, and the nature of the task. By considering all these factors and adjusting the RPM accordingly, you can achieve optimal cutting performance, increase the lifespan of your blade, and work more safely. Remember to consult the manufacturer’s guidelines and regularly maintain your table saw to ensure it performs at its best.

Key Takeaways – What is a Good RPM for a Table Saw?

- A good RPM (revolutions per minute) for a table saw typically ranges between 3,000 and 4,000 RPM.

- RPM determines the speed at which the saw blade rotates and affects the cutting performance of the table saw.

- Higher RPM generally allows for faster cuts, but it may require more caution and expertise to control the saw.

- Lower RPM can provide more control and safety, especially for beginners or delicate materials.

- Selecting the right RPM depends on the type of material being cut and the desired precision and speed.

Frequently Asked Questions

Curious about the ideal rpm for your table saw? We have answers to frequently asked questions!

1. How do I determine the right rpm for my table saw?

The right rpm, or revolutions per minute, for your table saw depends on the type of material you are cutting. Generally, a good range is between 3,000 and 4,000 rpm. However, harder materials like oak may require a slower speed, while softer materials like pine may benefit from a faster speed. It’s important to consider the size and condition of your saw blade as well, as these factors can affect the rpm.

Keep in mind that your saw’s manual will often provide recommendations for the appropriate rpm for different materials. Consulting the manual is always a good starting point to ensure safe and efficient cutting.

2. What are the consequences of using a too high or too low rpm?

Using a higher rpm than recommended for a specific material can result in a rough or burnt cut. The excessive speed can cause the wood to heat up, which may lead to scorch marks, chipping, or tear-outs. On the other hand, using a lower rpm than necessary can lead to a slower, less efficient cut. The blade may struggle to smoothly cut through the material, resulting in jagged edges or even stalling the saw.

It’s important to find the balance between the material you’re cutting and the appropriate rpm to ensure clean, precise, and safe cuts.

3. Can I adjust the rpm on my table saw?

The rpm on most table saws is set by the manufacturer and cannot be adjusted. However, some high-end table saw models offer variable speed control, allowing you to adjust the rpm to suit different materials. If your table saw has this feature, consult the manual or follow the manufacturer’s instructions to adjust the rpm accordingly.

If your table saw does not have adjustable rpm, it’s important to choose the right blade and consider the material you’re cutting to ensure you’re operating at an appropriate speed.

4. What other factors should I consider besides rpm when cutting on a table saw?

While rpm is an important factor, other aspects should also be considered. The quality and sharpness of the blade play a crucial role in achieving clean cuts. Dull or low-quality blades can lead to splintering and rough cuts, regardless of the rpm. Additionally, the setup of your table saw, including the alignment, motor power, and fence positioning, can affect the overall performance and quality of your cuts.

Regular maintenance, proper blade selection, and ensuring the overall accuracy of your table saw setup are essential for achieving optimal results, along with selecting the appropriate rpm for your specific cutting needs.

5. Are there any safety precautions to follow when using a table saw?

Yes, safety should always be a priority when operating any power tool, including a table saw. Some essential safety precautions include wearing appropriate safety gear, such as safety glasses and ear protection. It’s crucial to use proper cutting techniques, keeping your hands and fingers away from the cutting area.

Make sure the table saw is securely positioned and the blade is properly aligned and tightened. Always follow the manufacturer’s instructions and guidelines provided in the manual. If you’re new to using a table saw, consider seeking guidance from experienced woodworkers or taking a woodworking class to learn proper usage and safety techniques.

Summary

So, remember, the RPM of a table saw is important for safety and precision. Higher RPM means faster cutting, but lower RPM is better for cutting denser materials. Finding the right RPM depends on what you’re cutting and your own experience. Keep practicing and stay safe!