If you’ve ever wondered what a ground fault interrupter (GFI) is and why it’s important in carpentry, you’re in the right place! So what exactly is a GFI, and why should you consider using it in your carpentry projects? In this article, we’ll dive into the world of GFIs, explaining their purpose and how they can enhance safety on the job. Let’s get started!

Imagine this: you’re working on a woodworking project and accidentally nick an electrical wire. Suddenly, you’re faced with the risk of electrical shock or even an electrical fire! That’s where a ground fault interrupter (GFI) comes in. A GFI is a device designed to protect you from electrical hazards by quickly shutting off the power when it detects an imbalance in the electrical current.

Now, you might be thinking, “Why should I bother using a GFI in my carpentry projects?” Well, my friend, the answer is simple: safety! Using a GFI adds an extra layer of protection against electric shocks and potential fires caused by faulty electrical connections. It’s like having a trusty guardian angel watching over you, ensuring that you can work safely without the fear of accidents caused by electrical mishaps.

So, whether you’re a budding carpenter or an experienced woodworker, understanding what a GFI is and why it should be used in carpentry is crucial. Not only does it provide an additional level of safety, but it also gives you peace of mind as you tackle your woodworking projects. So, let’s explore this essential device together and learn how it can keep you safe on the job! Let’s dive in!

What is a Ground Fault Interrupter and Why Should it be Used in Carpentry?

Ground fault interrupters, also known as GFCIs, are electrical safety devices that protect against the risk of electric shock. These devices play a crucial role in carpentry and other construction projects where power tools are commonly used. By quickly detecting any imbalance in electrical currents, GFCIs can automatically shut off the power supply, preventing accidents and potential electrocution. In this article, we will delve into the importance of using GFCIs in carpentry and explore their many benefits.

How Does a Ground Fault Interrupter Work?

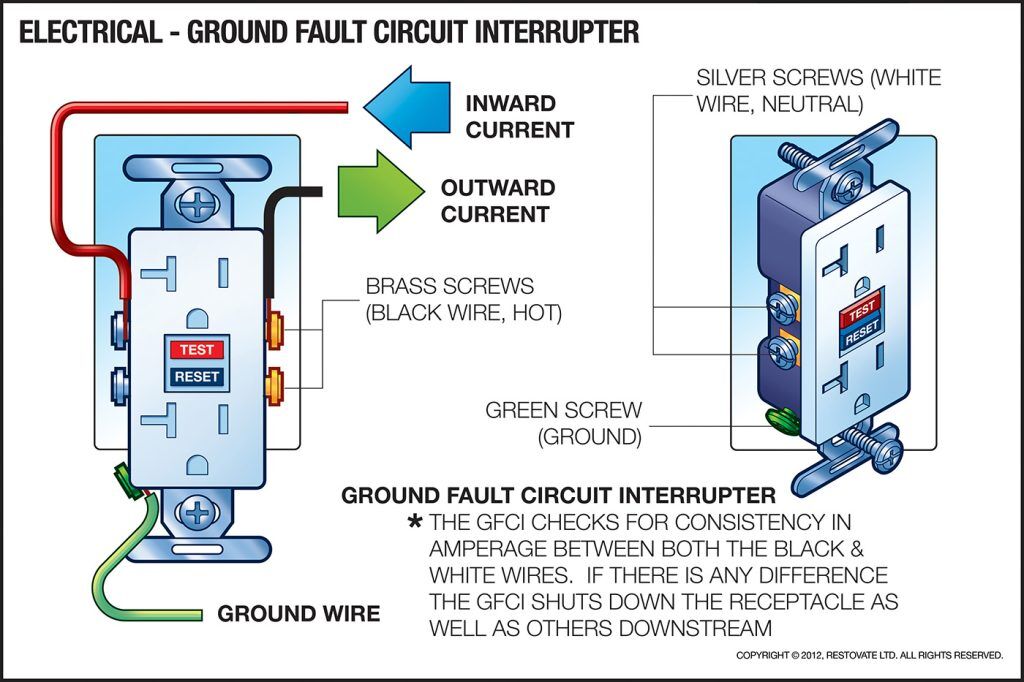

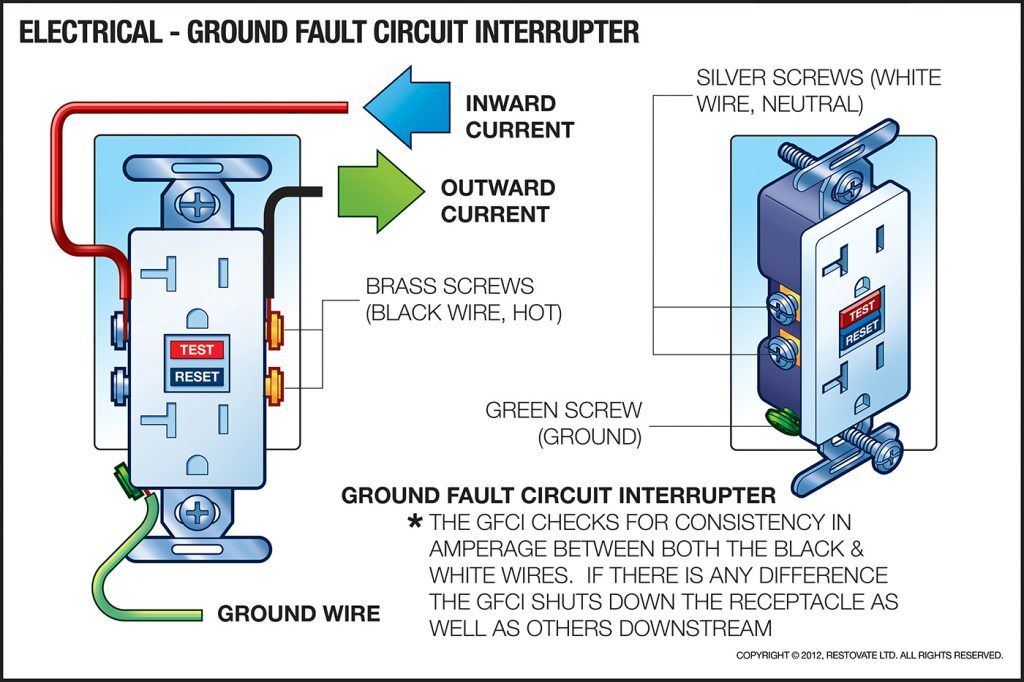

Before we discuss the significance of GFCIs in carpentry, it is important to understand how these devices work. GFCIs constantly monitor the flow of electricity through a circuit. They compare the current entering the circuit with the current leaving it. If there is a difference of as little as 4-5 milliamperes, it indicates a ground fault, such as current flowing through a person instead of continuing along the intended path. When a ground fault is detected, the GFCI will trip and cut off the power supply within a fraction of a second, preventing any potential harm.

The Importance of GFCIs in Carpentry Safety

Carpentry involves the use of various power tools, such as circular saws, routers, and drills. These tools require electrical power to function, and if not handled or used properly, they can pose significant safety hazards. Here are three key reasons why GFCIs should be used in carpentry:

- Protection Against Electrical Shock: The most important role of GFCIs is to protect against electric shock. Accidental contact with conductive materials or faulty equipment can lead to serious injury or even death. GFCIs act as a safety net, instantly cutting off the power supply when they sense a ground fault, preventing any harm to carpenters and workers.

- Prevention of Electrical Fires: Electrical fires are a major concern in carpentry and construction sites. Faulty wiring or overloaded circuits can generate heat and sparks, potentially leading to a fire outbreak. GFCIs play a crucial role in mitigating this risk by shutting off power when they detect irregularities, preventing the occurrence of electrical fires.

- Compliance with Code and Regulations: In many countries, utilizing GFCIs is mandatory by law, especially in areas where water and electricity may come into contact, such as bathrooms or outdoor workspaces. By using GFCIs, carpenters and contractors can ensure compliance with safety codes and regulations, avoiding penalties and creating a safer work environment.

Installing and Using GFCIs in Carpentry

Now that we understand the importance of using GFCIs in carpentry, let’s explore how they are installed and used:

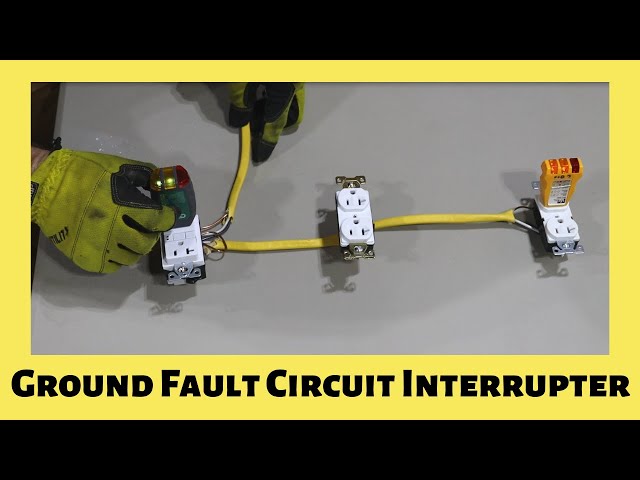

- Installation: GFCIs can be installed at the electrical panel or as individual receptacles. It is recommended to consult a professional electrician for proper installation to ensure compliance with safety standards and local regulations.

- Testing and Maintenance: Once installed, GFCIs should be tested regularly to ensure they are functioning correctly. GFCI manufacturers provide guidelines for testing, which typically involve pressing the “Test” button on the device to simulate a ground fault. If the GFCI does not trip, it may require replacement or professional inspection. Regular maintenance and inspections are essential to ensure the ongoing safety of the electrical system.

- Proper Usage: Carpenters and workers should be educated on the proper use of GFCIs. It is important to plug the power tools and equipment into GFCI-protected outlets. In outdoor or wet environments, it is crucial to use GFCI-protected outlets to minimize the risk of electrical accidents.

The Benefits of Using GFCIs in Carpentry

GFCIs offer numerous benefits when applied to carpentry projects. Here are some of the key advantages:

- Enhanced Safety: The primary benefit of using GFCIs in carpentry is increased safety. By promptly detecting ground faults and cutting off the power, GFCIs significantly reduce the risk of electric shock and electrical fires.

- Compliance with Regulations: Using GFCIs ensures compliance with electrical codes and regulations, promoting a safer work environment and preventing penalties for non-compliance.

- Protection of Equipment: GFCIs not only safeguard individuals but also protect expensive power tools and equipment from damage due to electrical faults.

- Peace of Mind: Carpenters and workers can have peace of mind knowing that their workspace is equipped with GFCIs, providing an extra layer of protection against electrical hazards.

In Summary

GFCIs play a vital role in carpentry safety by protecting against electric shock and preventing electrical fires. By closely monitoring electrical currents and immediately shutting off power in the event of a ground fault, these devices significantly reduce the risk of accidents and injuries. Carpenters and workers should prioritize the installation and proper use of GFCIs to ensure a safe and compliant work environment. Remember, safety should always be a top priority in carpentry, and GFCIs are an essential component of that commitment.

Key Takeaways

- A ground fault interrupter (GFI) is an electrical device designed to protect against electric shock.

- GFIs are important in carpentry because they can prevent accidents and potential injury from electrical mishaps.

- When using power tools in carpentry, the risk of electrical faults and ground faults increases.

- A GFI works by constantly monitoring the flow of electric current and quickly shutting off power if a ground fault is detected.

- Using a GFI in carpentry can save lives and ensure a safer working environment.

Frequently Asked Questions

If you’re a carpenter or working in the field of carpentry, understanding what a ground fault interrupter (GFI) is and why it should be used is crucial for safety. Here are some frequently asked questions about GFIs and their importance in carpentry.

1. What is a ground fault interrupter (GFI)?

A ground fault interrupter, commonly known as a GFI or GFCI (Ground Fault Circuit Interrupter), is a device designed to protect against electrical shock. It constantly monitors the electrical current flowing through an electrical circuit and shuts off or interrupts the power if it detects a ground fault or a leakage of electrical current. It is typically installed in areas where water and electricity may come into contact, such as kitchens, bathrooms, and outdoor outlets.

By quickly interrupting the circuit when a ground fault is detected, GFIs help prevent severe electrical shock and the potential for fatal accidents. They are an important safety measure in construction and carpentry, where workers are often exposed to electrical equipment and tools.

2. How does a ground fault interrupter work?

A ground fault interrupter uses a differential current transformer to monitor the flow of electricity. It compares the current entering the circuit with the current returning from the circuit. If there is an imbalance, indicating that some current is leaking to the ground, the GFI quickly shuts off the power to prevent electrocution. It can interrupt the circuit in as little as 1/40th of a second.

GFIs have a test button to ensure they are functioning correctly. This button simulates a ground fault and should cause the GFI to trip, cutting off the power. Regular testing is important to make sure GFIs are in proper working condition and providing the necessary protection.

3. Why should ground fault interrupters be used in carpentry?

Carpentry involves the use of power tools and electrical equipment, putting workers at a higher risk of electrical accidents. Ground fault interrupters are crucial in carpentry because they provide an extra layer of protection against electrical shocks. They detect even small changes in electrical current, preventing serious injuries caused by electricity passing through a person’s body.

Additionally, carpentry work often takes place in environments where water is present, such as when framing a bathroom or installing cabinets in a kitchen. Water increases the risk of electrical shocks, making the installation of GFIs even more important. By using GFIs, carpenters can work safely and minimize the risk of electrical accidents on the job site.

4. Are all electrical outlets required to have ground fault interrupters?

Not all electrical outlets are required to have ground fault interrupters. However, there are specific areas where GFIs are mandated by building codes. In general, GFIs are required in areas where there is a higher likelihood of contact between electricity and water, such as kitchens, bathrooms, outdoor outlets, garages, and crawlspaces. Additionally, any outlets within six feet of a sink or water source are typically required to have GFIs.

While not all outlets need GFIs, it is always a good practice to install them in areas where they are not mandated by code but where water and electricity may come into contact. This helps ensure the safety of individuals using electrical appliances or tools in those areas.

5. How should ground fault interrupters be tested for proper functioning?

To test a ground fault interrupter, follow these simple steps:

1. Plug a lamp or device into the GFI-protected outlet.

2. Press the “TEST” button on the GFI. The power should be cut off, and the device plugged into the outlet should turn off.

3. Press the “RESET” button on the GFI to restore power to the outlet. The device plugged into the outlet should turn back on.

If the GFI does not trip when the “TEST” button is pressed, or if it does not restore power when the “RESET” button is pressed, it may be faulty and should be replaced as soon as possible.

Summary

A ground fault interrupter is a device that helps protect you from electrical shocks. It works by detecting when an electric current is flowing in an unintended path, such as through a person. The GFI quickly shuts off the power, preventing harm.

Using a ground fault interrupter in carpentry is important because it can save lives. When working with power tools and around electricity, accidents can happen. The GFI acts as a safety net, stopping the flow of electricity if it senses a problem, reducing the risk of electrical shocks and fires. Remember, safety should always be the top priority when working with electricity!