Do you know what a jig boring machine is? If not, don’t worry! I’m here to explain it to you in a fun and easy way. So, let’s dive in and discover the fascinating world of jig boring machines!

Imagine you have a project that requires precise and accurate holes to be drilled. That’s where a jig boring machine comes in handy. It’s like a super-powered drill that can create incredibly precise holes with tight tolerances. Whether it’s for metalworking, woodworking, or even 3D printing, this machine is a master of precision.

Jig boring machines work by using a special device called a jig. The jig holds the workpiece securely and guides the cutting tool to create holes with exceptional accuracy. These machines also allow for adjustments in various directions, making it easy to achieve the exact hole size and position required. So, if you need perfection in your drilling projects, jig boring machines are the way to go!

What is a Jig Boring Machine? A Comprehensive Guide

In the world of machining, precision and accuracy are of utmost importance. One of the machines used to achieve this level of precision is the jig boring machine. This article will delve into the details of what a jig boring machine is, how it works, its benefits, and its applications in various industries.

1. Understanding the Jig Boring Machine

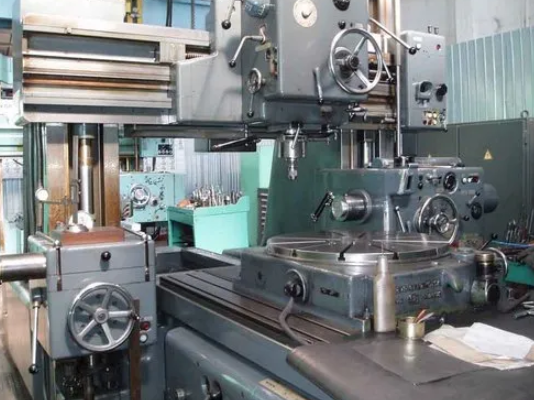

The jig boring machine is a specialized machine tool used to create highly accurate and precise holes in workpieces. It is similar to a vertical milling machine but is designed specifically for boring tasks. The machine incorporates a unique feature known as a jig, which provides a guide for the boring tool, ensuring precise positioning and alignment.

The construction of a jig boring machine typically consists of a heavy base, column, and spindle. The spindle can move vertically along the column, while the workpiece is securely held on the machine’s table. The spindle rotation allows for drilling, reaming, and fine finishing operations.

Jig boring machines employ a highly precise measuring system, such as micrometers or digital readouts, to ensure accuracy to within microns. This level of precision makes them suitable for applications where tight tolerances are required, such as in the aerospace, automotive, and electronics industries.

2. How Does a Jig Boring Machine Work?

The operation of a jig boring machine entails several key steps. First, the workpiece is clamped onto the machine’s table, ensuring it is securely held in place. The jig, which acts as a guide, is then attached to the machine’s spindle.

Next, the spindle is carefully positioned over the desired drilling location on the workpiece. This is achieved by moving the spindle vertically along the column. Once in position, the machine operator can activate the spindle rotation to start the drilling process.

During the drilling process, the jig keeps the boring tool aligned and steady, ensuring that the hole is drilled precisely according to the desired specifications. The operator can monitor the progress and make any necessary adjustments using the machine’s measuring system.

Jig boring machines often have the capability to perform additional operations, such as reaming and fine finishing. These processes further enhance the precision and quality of the hole.

3. Benefits of Using a Jig Boring Machine

Jig boring machines offer numerous advantages over other machining methods, making them an invaluable tool in precision engineering. Some key benefits include:

1. Accuracy: Jig boring machines are known for their exceptional accuracy, typically achieving tolerances within microns. This level of precision is crucial in industries where small deviations can result in significant functional issues or product failures.

2. Versatility: These machines are versatile and can be used for a wide range of applications, including drilling, boring, reaming, fine finishing, and more. The ability to perform multiple operations in a single setup saves time and increases efficiency.

3. Surface Finish: Jig boring machines produce superior surface finishes due to their ability to control tool movements and eliminate vibrations. This makes them ideal for industries where smooth and high-quality surface finishes are essential, such as in the production of optical lenses or precision molds.

4. Repeatable Results: The use of jigs ensures repeatable results, allowing for the production of multiple identical workpieces with consistent dimensions. This is particularly important in industries with high-volume production requirements.

5. Cost-Effective: Despite their precision and capabilities, jig boring machines can be cost-effective in the long run. The reliability and accuracy of these machines reduce waste, rework, and the need for manual labor, ultimately leading to increased productivity and cost savings.

The Versatility of Jig Boring Machines

1. Jig Boring vs. Conventional Boring: Understanding the Difference

2. Applications of Jig Boring Machines in the Aerospace Industry

3. Key Considerations When Choosing a Jig Boring Machine

4. The Role of Jig Boring Machines in the Automotive Industry

5. Enhancing Accuracy with Jig Boring Machine Attachments

6. Common Mistakes to Avoid When Using Jig Boring Machines

7. Exploring Jig Boring Machine Innovations

The Future of Jig Boring Machines: Advancements and Trends

1. Industry 4.0 and the Integration of Jig Boring Machines

2. The Impact of Artificial Intelligence on Jig Boring Machine Performance

3. Emerging Technologies in Jig Boring Machine Design

Conclusion

Jig boring machines play a crucial role in achieving high precision and accuracy in various industries. With their ability to produce repeatable results and superior surface finishes, they are indispensable tools for industries that require tight tolerances and reliable performance. Although jig boring machines have been around for decades, advancements in technology and the integration with industry trends, such as Industry 4.0 and artificial intelligence, continue to shape the future of these machines. As industries evolve, the versatility and capabilities of jig boring machines will ensure their continued relevance in the world of precision engineering.

Key Takeaways: What is a Jig Boring Machine?

- A jig boring machine is a type of machine tool used to accurately enlarge existing holes or create new holes with high precision.

- It uses a specialized cutting tool called a jig borer to remove material and shape the hole.

- Jig boring machines are commonly used in industries such as aerospace, automotive, and tool and die making.

- These machines are known for their ability to achieve tight tolerances and ensure precise hole positions.

- With their versatility and accuracy, jig boring machines play a crucial role in manufacturing processes that require precision machining.

Frequently Asked Questions

A jig boring machine is a specialized machine tool used to accurately enlarge or create holes in a workpiece. It is commonly used in industries like aerospace, automotive, and manufacturing. Here are some frequently asked questions about jig boring machines:

1. How does a jig boring machine work?

A jig boring machine works by clamping a workpiece securely on a table and using a rotating cutting tool to drill, bore, or enlarge holes with precision. The machine ensures accuracy by utilizing a jig or a fixed guide that guides the cutting tool’s movement. This guide enables the machine operator to achieve tight tolerances, resulting in accurate and consistent hole dimensions.

The cutting tool, which is typically a boring bar or a precision drill, is mounted on a spindle that rotates at high speeds. It is controlled by various means, including manually-operated machines or CNC (Computer Numerical Control) systems. The operator adjusts the machine to the desired feed rate, spindle speed, and depth of cut to achieve the required hole specifications.

2. What are the advantages of using a jig boring machine?

Using a jig boring machine offers several advantages in precision hole machining. Firstly, it allows for extremely accurate hole positions and sizes, ensuring tight tolerances are met. This precision is crucial in industries where optimal fits and alignments are necessary, such as precision engineering or tool and die making.

Secondly, a jig boring machine provides excellent surface finish on the machined holes. The machine’s rigidity and stability, combined with precise cutting tools, produce smooth and consistent surfaces, even at tight hole tolerances. This makes it ideal for applications that demand high-quality finishes, like in mold making or aerospace component manufacturing.

3. Can a jig boring machine be used for other machining operations?

Yes, in addition to hole drilling and boring, a jig boring machine can be used for other machining operations. The machine’s precision and stability make it suitable for tasks such as milling, reaming, and tapping. By changing the cutting tool, the machine can perform various operations, expanding its versatility and usefulness in the workshop.

However, it is important to note that while a jig boring machine can handle multiple tasks, it is specifically designed for accurate hole machining. Other dedicated machines like milling machines or lathes may be more efficient for certain operations, depending on the requirements of the specific task.

4. Is operating a jig boring machine difficult?

Operating a jig boring machine effectively requires proper training and experience. While modern machines may incorporate user-friendly features like CNC control systems, understanding the machine’s principles and fundamental operating procedures is essential.

Machinists need to be knowledgeable about things like tool selection, machine setup, and measurement techniques. They also must have a good understanding of cutting parameters and how they impact the machining process. Training programs, vocational courses, or apprenticeships are ways to gain the necessary skills and knowledge to operate a jig boring machine safely and efficiently.

5. Are there different sizes and types of jig boring machines?

Yes, jig boring machines come in various sizes and types, catering to different machining needs. The machine’s size is typically determined by the maximum workpiece dimensions it can accommodate. Larger machines are capable of handling bigger workpieces and drilling larger holes.

As for types, there are vertical jig boring machines and horizontal jig boring machines. Vertical machines are more common and are used for most applications. Horizontal machines, on the other hand, are typically used for larger and heavier workpieces that require special setup arrangements. The choice between vertical and horizontal machines depends on the specific machining requirements and the nature of the workpieces to be machined.

Summary

A jig boring machine is a fancy tool that helps make super precise holes. It has a special table that moves around to make the holes just right. The machine is used by experts in industries like aerospace and automotive to create parts with extreme accuracy. It’s like a superhero of drilling!

Jig boring machines are special because they can make holes within thousandths of an inch. They have a spindle that rotates and a special measuring system for precise control. The machine helps make things like engines and airplane parts, ensuring they fit perfectly together. So, next time you see a super precise part, remember it might have been made by a jig boring machine!