Have you ever wondered what a jig boring machine is used for? Well, you’re in luck because I’m here to spill the beans! A jig boring machine is a fascinating tool that plays a crucial role in many industries. So, hang on tight as I take you on a journey to discover the ins and outs of this incredible machine.

Now, you might be thinking, “What makes a jig boring machine so special?” Great question! These machines are designed to bore precision holes with exceptional accuracy and consistency. Imagine being able to create holes with such precision that they fit together perfectly like pieces of a puzzle. That’s what a jig boring machine is all about – accuracy to the max!

But wait, there’s more! Jig boring machines are also used for machining complex parts that require high precision. In industries like aerospace, automotive, and manufacturing, where every millimeter counts, these machines shine. From creating intricate molds to producing precise components for engines, a jig boring machine is an indispensable tool in the world of precision engineering.

So, buckle up and get ready to dive deeper into the fascinating world of jig boring machines. We’ll explore the various applications, benefits, and how these machines work their magic. Stay tuned for the ultimate guide that will satisfy your curiosity and expand your knowledge about this incredible tool!

What is a Jig Boring Machine Used For?

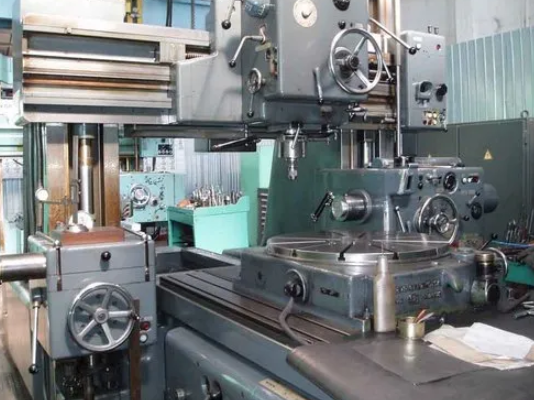

A jig boring machine is a precision tool used in machining processes to create highly accurate and intricate holes, bores, and cavities in various materials. Unlike regular drilling machines, jig boring machines offer exceptional precision and control, making them ideal for tasks that require close tolerances and intricate features. Jig boring machines are commonly used in industries such as aerospace, automotive, mold making, and tool and die manufacturing. They are a crucial tool for achieving precise and high-quality results in complex machining operations.

The Importance of Jig Boring Machines in Precision Machining

The use of jig boring machines is essential in precision machining because they enable the production of highly accurate and repeatable holes and bores. These machines provide superior rigidity and stability, ensuring minimal vibration and deflection during the machining process. Through precise adjustments and controls, operators can achieve tight tolerances and maintain consistent measurements throughout the machining operation. Jig boring machines also offer the flexibility to work with different materials, including metals, composites, and plastics, making them versatile tools in various applications.

Features and Components of Jig Boring Machines

Jig boring machines consist of several key features and components that contribute to their precision and performance. Here are some of the important aspects to note:

- Highly Accurate Guideways: Jig boring machines have robust and precise guideways that ensure smooth and accurate movement of the workpiece and the cutting tool. These guideways are meticulously designed and manufactured to minimize friction and enable precise positioning.

- Heavily Reinforced Column: The column of a jig boring machine is typically made from a sturdy material such as cast iron and is heavily reinforced to provide rigidity and stability. This construction eliminates any unwanted movement and vibrations that could negatively impact the machining process.

- Precision Spindle: Jig boring machines feature a precision spindle that holds the cutting tool and rotates at high speeds. The spindle is designed to minimize runout, ensuring that the tool remains concentric and accurate during machining operations.

- Coordinate Table: A coordinate table is an integral component of a jig boring machine. It allows for precise and controlled movements of the workpiece in multiple axes, enabling the creation of complex patterns, angles, and shapes.

- Control Systems: Modern jig boring machines are equipped with advanced control systems that provide operators with precise control over the machining process. These systems often utilize computer numerical control (CNC) technology, allowing for automated and programmable operations.

The Benefits of Using Jig Boring Machines

The use of jig boring machines provides numerous benefits in precision machining. Here are some key advantages:

- Increased Precision: Jig boring machines offer exceptional precision and accuracy, making them indispensable in tasks that require tight tolerances and intricate details. They can consistently produce holes and bores with minimal errors.

- Time and Cost Savings: By ensuring precise and accurate machining, jig boring machines reduce the need for secondary operations and rework. This saves time and minimizes material waste, resulting in cost savings for manufacturers.

- Versatility: Jig boring machines can work with a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to tackle diverse machining projects using a single machine.

- Improved Efficiency: With advanced control systems and automation capabilities, jig boring machines enable efficient and streamlined machining operations. They can execute complex patterns and shapes with high speed and accuracy.

- Quality Assurance: Jig boring machines help maintain consistent quality in machining processes. By minimizing errors and variations, these machines contribute to the production of high-quality components and products.

Applications of Jig Boring Machines

Jig boring machines find extensive use in various industries and applications. Here are some common applications where these machines excel:

- Aerospace: Jig boring machines are crucial in the aerospace industry for machining precision components such as engine parts, turbine blades, and aircraft structures.

- Automotive: In automotive manufacturing, jig boring machines play a vital role in creating intricate molds, die cavities, and engine components with high precision and repeatability.

- Mold Making: Jig boring machines are widely utilized in mold and die making industries to manufacture molds, dies, and tooling with tight tolerances and complex features.

- Tool and Die Manufacturing: Jig boring machines are essential in the production of tooling and dies used in various manufacturing processes, ensuring accuracy and precision in every detail.

Tips for Optimal Use of Jig Boring Machines

To achieve the best results with a jig boring machine, consider the following tips:

- Ensure proper maintenance of the machine, including regular cleaning, lubrication, and calibration. This helps maintain optimal performance and accuracy.

- Use high-quality cutting tools and ensure their proper alignment and balance.

- Take time to understand and utilize the control systems and programming capabilities of the machine. This allows for efficient and precise operations.

- Always work with appropriate safety measures and protective equipment to ensure the well-being of operators and minimize risks.

- Stay updated with the latest advancements and technologies in jig boring machines, as they continue to evolve and offer new capabilities.

By following these tips and leveraging the capabilities of jig boring machines, manufacturers can achieve exceptional precision and quality in their machining operations, contributing to overall success and efficiency.

Key Takeaways: What is a Jig Boring Machine Used For?

- A jig boring machine is a precision machining tool used to create highly accurate holes and shapes in metal and other materials.

- It is commonly used in industries like aerospace, automotive, and electronics for producing parts with tight tolerances.

- The machine uses a specialized tool called a boring head to enlarge, shape, or align existing holes.

- Jig boring machines are ideal for creating complex shapes with high precision and repeatability.

- They are often used for machining components like engine blocks, gearboxes, and molds.

Frequently Asked Questions

Jig boring machines are versatile tools used in the field of machining. They are primarily used for precision drilling, boring, and reaming operations on workpieces. Here are answers to some commonly asked questions about jig boring machines:

1. How does a jig boring machine work?

A jig boring machine works by using a rotating cutting tool to remove material from a workpiece. It operates on the same principles as a conventional drilling machine but with greater precision. The machine consists of a movable table on which the workpiece is clamped and a vertical column that holds the cutting tool. The cutting tool is guided by a jig, which ensures precise positioning and alignment. As the cutting tool moves vertically, it removes material, creating a hole or cavity in the workpiece. The movement of the table allows for precise positioning of the workpiece during the machining process.

The main advantage of a jig boring machine over a conventional drilling machine is its accuracy. It can achieve extremely tight tolerances, making it ideal for tasks that require high precision, such as creating holes with exact dimensions or machining complex shapes. The machine’s rigidity, stability, and adjustable speed further contribute to its accuracy and reliability.

2. What are the typical applications of jig boring machines?

Jig boring machines find application in various industries that require precise machining, such as aerospace, automotive, and medical device manufacturing. Some common applications include:

– Creating holes with tight tolerances: Jig boring machines are often used to create holes with precise dimensions. This is crucial in industries where even small deviations can affect the functionality of a component.

– Machining complex shapes: The precision and versatility of jig boring machines make them suitable for machining intricate shapes and features on workpieces.

– Reaming operations: The machine’s ability to perform reaming operations allows for the production of smooth and accurate holes with improved roundness and surface finish.

Overall, jig boring machines play a critical role in industries that demand high precision and accuracy in their machining processes.

3. What are the advantages of using a jig boring machine?

The use of jig boring machines offers several advantages in the field of machining. Some key benefits include:

– Precision: Jig boring machines are known for their exceptional precision and accuracy. They can achieve tight tolerances and produce workpieces with high-quality finishes.

– Versatility: These machines are versatile and can perform a wide range of operations, including drilling, boring, reaming, and even milling. This makes them suitable for different types of machining tasks.

– Efficiency: Jig boring machines are designed for efficiency and productivity. They allow for fast and accurate machining, which helps reduce production time and costs.

– Flexibility: These machines can handle various workpiece sizes and shapes, making them adaptable to different machining requirements.

Overall, the use of jig boring machines improves machining precision, productivity, and flexibility, making them valuable tools in the manufacturing industry.

4. Are there any limitations or drawbacks to using a jig boring machine?

While jig boring machines offer numerous advantages, they also have some limitations and drawbacks that should be considered:

– Cost: Jig boring machines can be expensive to purchase and maintain, making them less accessible for smaller businesses or hobbyists. However, their precision and versatility justify the investment for industries where high accuracy is crucial.

– Setup time: Setting up a jig boring machine can be time-consuming, especially when machining complex workpieces. Proper alignment and calibration are essential for achieving accurate results.

– Operator skill: Operating a jig boring machine requires expertise and training. It is not a machine suitable for beginners, as its precision and complexity demand skilled operators to ensure optimal performance and accurate results.

Despite these limitations, jig boring machines remain valuable assets for industries that require precise and high-quality machining.

5. How does a jig boring machine differ from other machining tools?

Jig boring machines have distinct features and capabilities that set them apart from other machining tools, such as drilling machines or milling machines. Here are a few key differences:

– Precision: Jig boring machines are designed to provide exceptional precision and accuracy, surpassing that of conventional drilling machines. They excel in creating holes and cavities with tight tolerances and an excellent surface finish.

– Guided tool movement: Unlike drilling machines, which have a fixed drill bit, jig boring machines allow for controlled movement of the cutting tool along vertical and horizontal axes. This flexibility enables precise machining of complex shapes and features.

– Customizable jigs: The use of jigs in jig boring machines allows for the customization of machining operations. Jigs are specially designed templates that guide the cutting tool’s movement, ensuring precise positioning and alignment.

These differences make jig boring machines preferred tools for industries that demand the highest levels of precision, accuracy, and surface finish in their machining processes.

Summary

So, to summarize, a jig boring machine is a special tool used in machining to create highly accurate and precise holes in workpieces. This machine uses a stationary work table and a movable spindle to drill holes with extreme accuracy. It is commonly used in industries like aerospace, automotive, and electronics to produce complex parts with tight tolerances. By using various tools and attachments, the jig boring machine can perform a wide range of operations, making it a versatile tool in manufacturing processes. Overall, the jig boring machine is an essential tool that helps to ensure the quality and precision of machined parts.