What is a lathe banjo? If you’re curious about this intriguing term, you’ve come to the right place. In the world of machining and woodworking, a lathe banjo plays a crucial role, and today, we’ll explore what it is and how it works. So, buckle up and get ready for an exciting journey into the world of lathes!

Now, you might be wondering, “What exactly is a lathe banjo?” Well, imagine you’re working on a lathe, shaping a piece of wood or metal. The banjo, in this context, is a versatile tool that helps support and maneuver various parts of the lathe. It acts as a sort of attachment that connects to the lathe bed and holds different components in place. Think of it as the trusty sidekick that ensures smooth and accurate turning operations.

But how does a lathe banjo work its magic? The banjo typically consists of a horizontal arm and a clamping mechanism that can be adjusted along the lathe bed. This allows you to position it wherever you need support or control. Whether it’s stabilizing a long workpiece or enabling angled cuts, the banjo steps in to make your turning projects a breeze.

So, there you have it—an introduction to the fascinating world of lathe banjos. In the paragraphs ahead, we’ll delve deeper into the different types of banjos, their functions, and the various ways they enhance your turning experience. So, keep reading to become a banjo expert and unleash your creativity on the lathe!

What is a Lathe Banjo? Exploring the Function and Benefits

When it comes to woodworking and metalworking, a lathe banjo plays a crucial role in the machining process. This versatile tool provides support and stability, allowing for precise shaping, cutting, and drilling operations. But what exactly is a lathe banjo, and how does it work? In this article, we’ll delve into the details of this essential component, discussing its functions, benefits, and usage tips.

The Anatomy of a Lathe Banjo

Before we dive into the functionality of a lathe banjo, let’s explore its structure. A typical lathe banjo consists of several components that work together to ensure smooth and accurate machining results. The primary parts include:

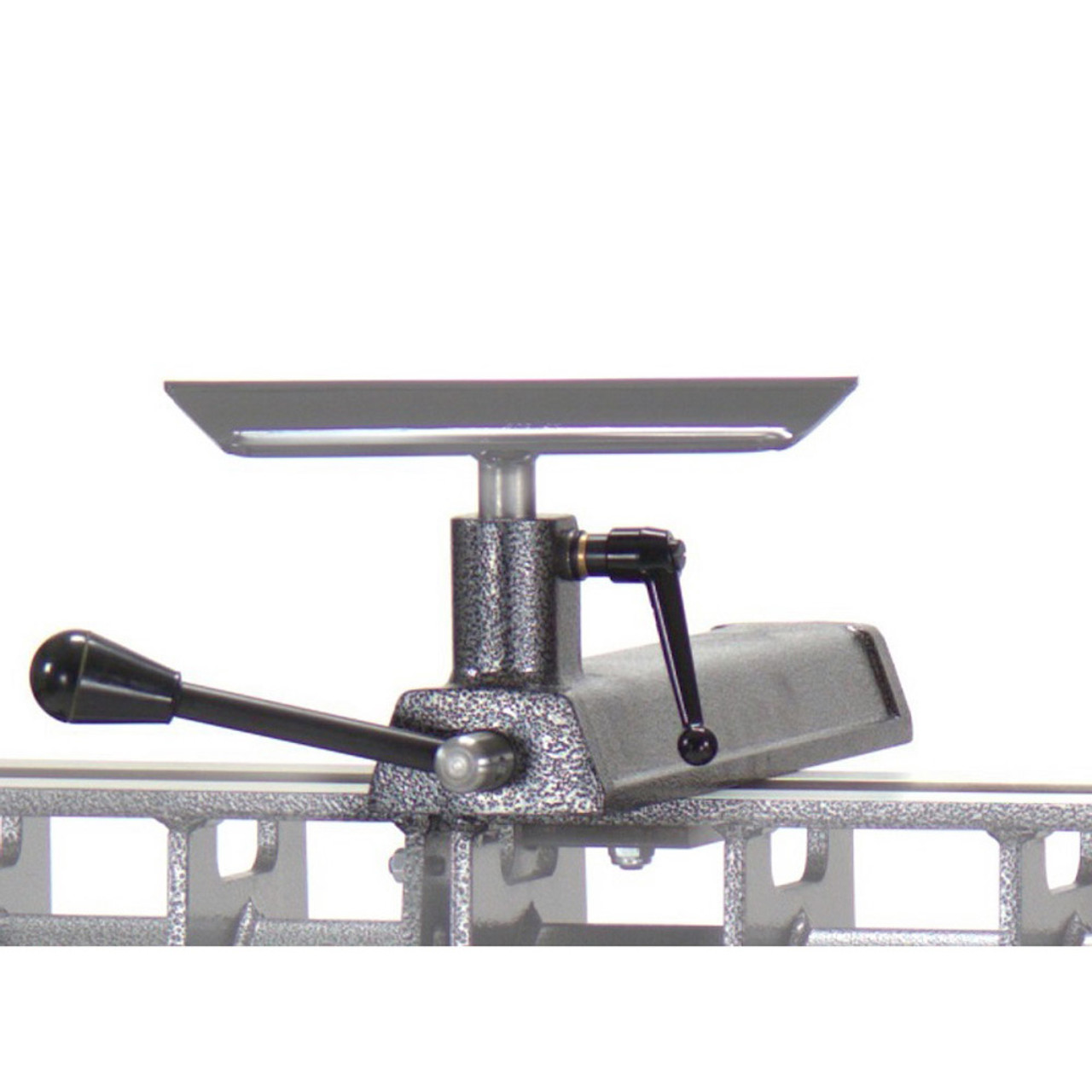

- Base Plate: The base plate serves as the foundation of the lathe banjo, providing stability and support on the lathe bed.

- Banjo Arm: The banjo arm is an adjustable metal rod that connects the base plate to the tool post. It allows for vertical positioning, ensuring precise maneuverability of cutting tools.

- Clamping Mechanism: The clamping mechanism secures the banjo arm in place, preventing any unwanted movement during machining operations.

- Tool Post: The tool post holds the cutting tool securely and enables the operator to adjust its position according to the required cutting depth and angle.

These components work together seamlessly to provide stability, support, and versatility in the lathe machining process.

The Functions of a Lathe Banjo in Machining

A lathe banjo serves several important functions in the machining process. Let’s take a closer look at each of these functions:

1. Support for Long Workpieces

One of the key functions of a lathe banjo is to provide support for long workpieces. When working with extended materials such as long rods or pipes, the banjo arm can be adjusted vertically to hold the workpiece securely in place. This prevents vibrations and bending, ensuring accurate and smooth cuts.

2. Precision Positioning of Cutting Tools

The banjo arm’s adjustability allows the operator to position the cutting tool precisely according to the desired depth and angle. By securing the tool post at the desired location, the operator can achieve consistent and accurate cuts throughout the machining process.

3. Stability and Rigidity

The base plate and clamping mechanism of a lathe banjo provide stability and rigidity to the entire setup. This helps minimize vibrations and flexing, which can lead to inaccuracies and poor surface finishes. The stability offered by the banjo ensures that each cut and shaping operation is carried out with precision.

Tips for Using a Lathe Banjo

To make the most out of your lathe banjo, here are some helpful tips to keep in mind:

1. Regular Maintenance

Ensure that your lathe banjo is clean and properly lubricated to maintain smooth movement and prevent rust or corrosion. Regularly inspect the banjo arm, clamping mechanism, and tool post for any signs of wear and tear, and address any issues immediately.

2. Proper Clamping

When securing the banjo arm using the clamping mechanism, ensure that it is tightened firmly but not overly tightened, as this can affect the flexibility of the banjo arm. Proper clamping is essential for stability during machining operations.

3. Gradual Adjustments

When adjusting the banjo arm’s vertical position or the tool post’s angle, make gradual adjustments to avoid sudden movements that can impact the precision of your cuts. Take your time and double-check the adjustments before proceeding with the machining process.

The Advancements in Lathe Banjo Technology

In recent years, there have been notable advancements in lathe banjo technology, aimed at enhancing precision and efficiency in the machining process. These advancements include:

1. Digital Positioning Systems

Some lathe banjos now come equipped with digital positioning systems that allow for precise and automated adjustments. These systems use sensors and actuators to accurately position the banjo arm and tool post, reducing the margin for human error and enhancing overall accuracy.

2. Quick-Release Mechanisms

Traditionally, adjusting the banjo arm or tool post required manual tightening and loosening of clamping mechanisms. However, modern lathe banjos now feature quick-release mechanisms that allow for swift adjustments, saving time and effort during setup and tool changes.

3. Enhanced Materials and Designs

With advancements in material science and engineering, lathe banjos are now made from high-quality alloys and feature improved designs. These advancements enhance the overall rigidity, stability, and longevity of the banjos, ensuring consistent performance over extended periods.

In conclusion, a lathe banjo is a critical component in the machining process, providing support, stability, and precision positioning for cutting tools. By understanding its functions and following usage tips, artisans and machinists can utilize this tool to achieve high-quality results in their woodworking and metalworking projects.

Key Takeaways: What is a Lathe Banjo?

- A lathe banjo is a device used in woodworking and metalworking industries.

- It is attached to a lathe machine to hold and support a workpiece during turning or shaping.

- Lathe banjos have adjustable arms that can be positioned to different angles for added flexibility.

- They help in maintaining proper alignment and stability of the workpiece, preventing vibrations and ensuring accurate results.

- Lathe banjos are essential tools for achieving precise and smooth finishes in various turning projects.

Frequently Asked Questions

Are you curious about what a lathe banjo is? Look no further! We’ve got you covered with these five Q&A pairs that will help demystify the topic.

What is the purpose of a lathe banjo?

A lathe banjo is a key tool used in metalworking and woodworking lathes. Its purpose is to support the workpiece being turned on the lathe by providing stability and control. The banjo is designed to securely hold the tool rest, which allows the operator to shape or cut the material with precision. With the help of the lathe banjo, the workpiece remains steady, reducing the risk of slip-ups or uneven cuts.

The lathe banjo acts as a support system for the tool rest, making it easier to manipulate and control during the turning process. It ensures the tool rest remains in the correct position, preventing accidental movements that could affect the quality and accuracy of the finished workpiece. In a nutshell, a lathe banjo is a crucial component in the lathe setup, providing stability and control for safe and efficient turning operations.

How does a lathe banjo work?

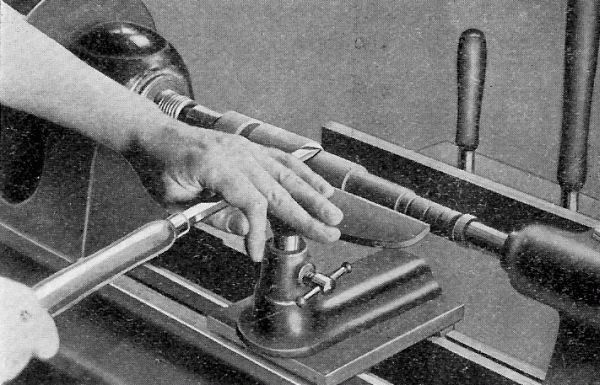

A lathe banjo typically consists of several parts, including a base, a clamp, and a tool rest. The base is attached to the lathe bed, providing stability and support. The clamp, also known as a banjo slide, holds the tool rest and can be adjusted horizontally along the base. This adjustment allows the operator to position the tool rest at different distances from the workpiece, depending on the desired cutting or shaping action.

The tool rest, which is connected to the clamp, plays a crucial role in the turning process. It acts as a platform for the cutting or shaping tool, providing a stable surface for the operator to rest the tool while working on the rotating workpiece. By adjusting the position of the tool rest using the lathe banjo, the operator can achieve precise cuts, smooth curves, and intricate patterns on the material being turned on the lathe.

Can a lathe banjo be used with different lathe sizes?

Yes, a lathe banjo can be used with different lathe sizes, but it’s essential to ensure compatibility between the banjo and the lathe. Banjos usually come in different sizes to accommodate various lathe bed widths. When purchasing a lathe banjo, it’s crucial to check the manufacturer’s specifications to determine if it will fit your specific lathe model.

Some lathe banjos have adjustable bases or clamps that can be expanded or contracted to fit different lathe sizes. These adjustable banjos offer versatility and the ability to adapt to different lathe setups. However, if a lathe banjo does not fit properly or securely on a lathe, it can compromise stability and affect the quality of the turning process. Therefore, it’s essential to ensure a proper fit between the banjo and the lathe for optimal performance.

Are there different types of lathe banjos?

Yes, there are different types of lathe banjos available to suit various turning requirements. The most common types include plain banjos, double banjos, and sliding banjos.

A plain banjo is the simplest type, featuring a fixed tool rest position that cannot be adjusted horizontally. It provides stability and support for basic turning needs. On the other hand, a double banjo has two clamps, allowing for the use of two tool rests simultaneously. This setup is beneficial when working on complex shapes or when multiple tools are required for different cutting actions.

A sliding banjo, as the name suggests, has a clamp that can be adjusted horizontally along the base. This type of banjo offers maximum flexibility, allowing for precise positioning of the tool rest at various distances from the workpiece. Sliding banjos are highly versatile and suitable for a wide range of turning tasks.

What are some tips for using a lathe banjo effectively?

To make the most out of a lathe banjo, here are a few tips:

1. Secure the banjo: Ensure the banjo is securely attached to the lathe bed to provide stability during the turning process.

2. Proper tool rest placement: Position the tool rest parallel to the lathe bed for optimal support and control.

3. Adjust the banjo position: Experiment with different banjo positions to find the most comfortable and effective working distance between the tool rest and the workpiece.

4. Use additional banjos: Consider using double banjos for complex turning needs that require multiple tool rests.

5. Maintain the banjo: Regularly clean and lubricate the banjo to keep it in good working condition.

By following these tips, you can enhance your turning experience and achieve better results with a lathe banjo.

Summary

A lathe banjo is a handy tool used with a lathe machine. It helps hold and guide the tool during cutting or shaping processes.

This tool is important for ensuring accuracy and precision in metalworking or woodworking projects. It keeps the tool steady, allowing for smooth and controlled movements. So, if you ever come across a lathe banjo, you’ll know its purpose and importance!