Are you curious about what a lathe dog is? Well, let’s dive in and uncover this intriguing tool! 🛠️

Now, you may be wondering, “What is a lathe dog?” 🤔 Simply put, a lathe dog is a clever contraption used in metalworking. It’s designed to hold a workpiece securely in place while it rotates on a lathe machine. You can think of it as a helpful companion for your lathe adventures!

With a lathe dog, you can effortlessly shape and contour your workpiece, creating intricate designs and smooth finishes. So, whether you’re crafting a metal bowl or fashioning a spindle for a staircase, a trusty lathe dog is there to lend a helping paw. So, let’s roll up our sleeves and discover more about this remarkable tool!

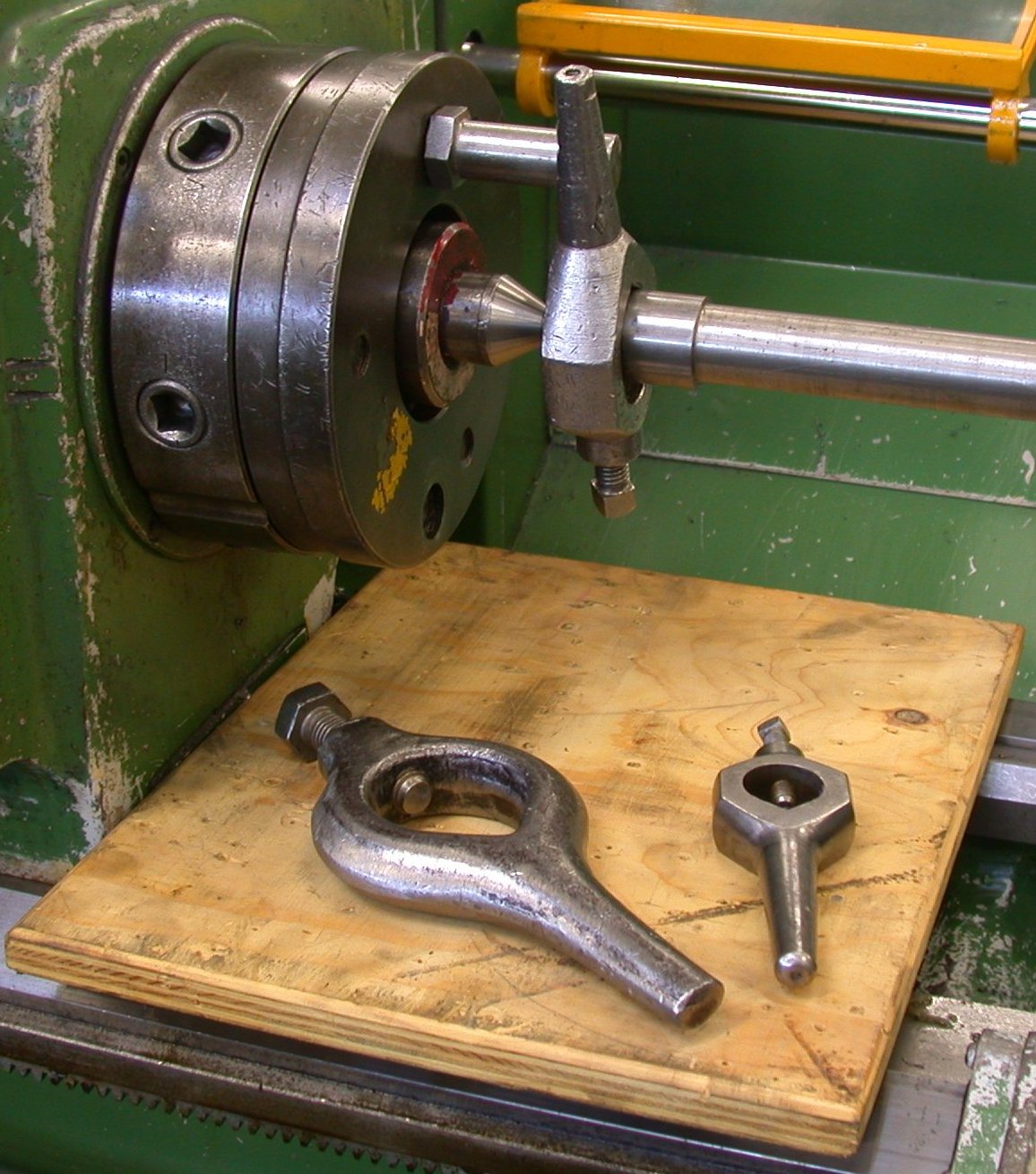

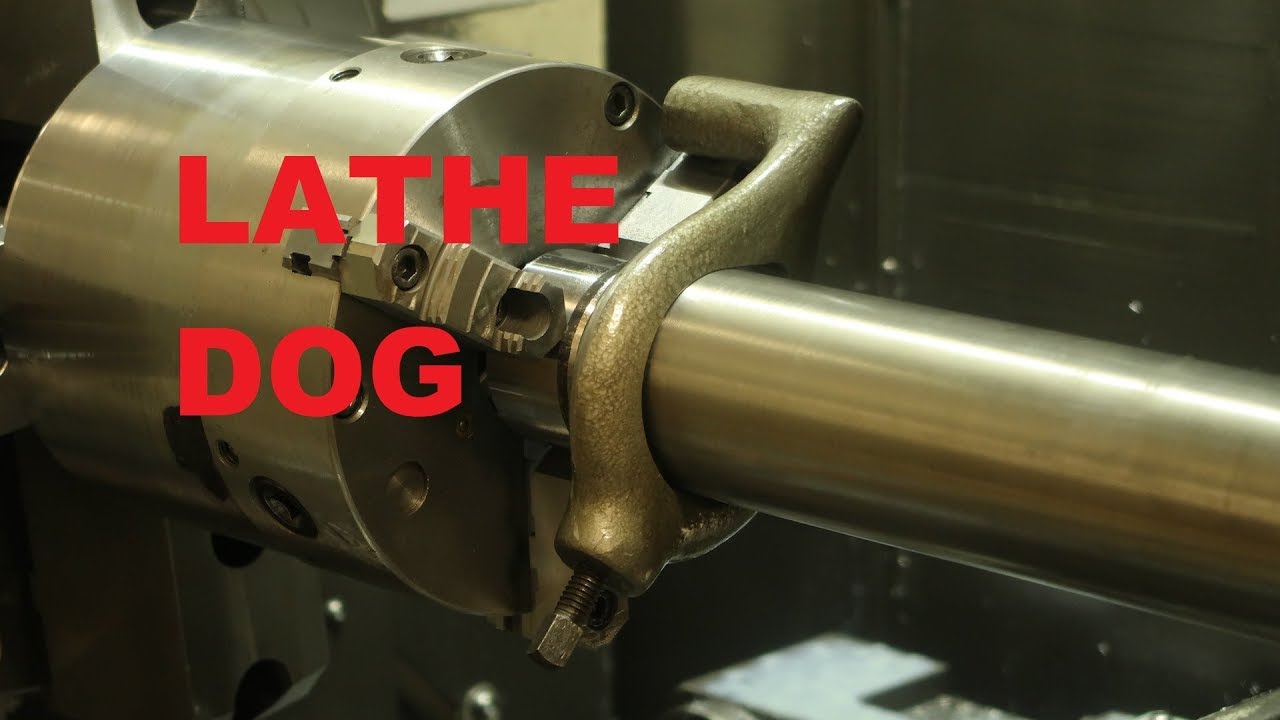

A lathe dog is a device used in woodworking and metalworking to hold and rotate a workpiece on a lathe. It consists of two parts: the body, which attaches to the lathe’s faceplate, and the bent tail, which clamps onto the workpiece. This allows the workpiece to be securely held and rotated while being operated on. Lathe dogs come in various sizes and designs to accommodate different workpieces and lathe setups.

The Basics of a Lathe Dog: Exploring a Fundamental Tool in Metalworking

Welcome to the world of metalworking! Whether you’re a seasoned machinist or just starting out, understanding the essential tools of the trade is crucial. One such tool is the lathe dog. In this article, we’ll delve into the intricacies of a lathe dog, its purpose, and how it is used in the world of metalworking. So, let’s get started and unravel the mysteries of this fundamental tool!

Types of Lathe Dogs: A Closer Look at the Varieties

When it comes to lathe dogs, there is a wide variety to choose from. The specific type of lathe dog you select will depend on the shape and size of the workpiece you are working with. Let’s take a closer look at some of the different types of lathe dogs:

1. Standard Lathe Dog

The standard lathe dog is the most commonly used type. It consists of a bent bar with a pointed end that is inserted into the workpiece. The other end of the bar has a socket or a hole to attach it to the lathe spindle. This type of lathe dog is versatile and can be used for a wide range of workpiece shapes and sizes.

One key feature of the standard lathe dog is its ability to grip the workpiece firmly without causing damage. The pointed end is inserted into a hole or a slot in the workpiece, ensuring a secure hold while the lathe rotates.

2. Bent-Tail Lathe Dog

The bent-tail lathe dog, as the name suggests, has a bent tail instead of a pointed end. This design allows for a more secure grip on irregularly shaped workpieces. The bent tail can be inserted into a groove or a notch on the workpiece, ensuring a stable hold throughout the machining process.

One important consideration when using a bent-tail lathe dog is to ensure that the tail is securely seated in the groove or notch. This will prevent any movement or slipping of the workpiece during machining, ensuring accurate and precise results.

Benefits of Using a Lathe Dog

Now that we understand the different types of lathe dogs, let’s explore the benefits of using this essential tool in metalworking:

1. Secure Workpiece Holding

One of the primary advantages of using a lathe dog is its ability to securely hold a workpiece during machining. The pointed or bent tail design allows for a firm grip, ensuring that the workpiece remains steady and stable while the lathe rotates. This secure holding is crucial for achieving precise and accurate results.

Additionally, the ability to hold irregularly shaped or asymmetrical workpieces is a significant advantage of using a lathe dog. The various types of lathe dogs available provide flexibility in gripping different workpiece shapes and sizes, making them indispensable tools in metalworking.

2. Facilitates Machining Operations

Another benefit of using a lathe dog is its ability to facilitate various machining operations. By securely holding the workpiece, a lathe dog allows the machinist to perform operations such as turning, facing, tapering, and threading with ease.

With the help of a lathe dog, the machinist can apply the necessary force and cutting tools to shape the workpiece according to the desired specifications. This versatility makes lathe dogs indispensable tools in the metalworking industry.

3. Cost-Effective Solution

In addition to their functional benefits, lathe dogs are also cost-effective tools. They are relatively affordable and readily available in the market. Investing in a few different types of lathe dogs can provide the machinist with a range of options for gripping and machining various workpiece shapes and sizes.

Compared to more complex and specialized workholding solutions, lathe dogs offer a practical and economical solution for securing workpieces during machining operations.

Tips for Using a Lathe Dog Effectively

Now that we have explored the benefits of using a lathe dog, let’s discuss some tips for using this tool effectively:

1. Select the Right Type

Before using a lathe dog, carefully consider the shape and size of the workpiece. Select the appropriate type of lathe dog that will provide a secure and stable grip on the workpiece. This will ensure optimal results and prevent any slippage during machining.

2. Properly Position the Lathe Dog

When attaching the lathe dog to the lathe spindle, it is essential to position it correctly. Make sure that the pointed or bent tail is securely inserted into the designated hole, groove, or notch on the workpiece. This will ensure a solid grip and prevent any movement during machining.

3. Regularly Check the Grip

During machining, it is essential to periodically check the grip of the lathe dog on the workpiece. Any loosening or slipping can result in inaccurate machining and compromised results. If necessary, readjust the lathe dog to ensure a tight and secure hold throughout the process.

Conclusion

The lathe dog is an indispensable tool in the world of metalworking. Its ability to securely hold workpieces, facilitate various machining operations, and provide a cost-effective solution makes it a must-have for machinists. By understanding the different types of lathe dogs and following tips for effective usage, you can harness the full potential of this essential tool. Happy metalworking!

Key Takeaways: What is a Lathe Dog?

- A lathe dog is a specialized tool used in metalworking on a lathe machine.

- It is shaped like a clamp and is used to hold and rotate the workpiece on the lathe.

- Lathe dogs have pointed teeth that grip onto the workpiece securely.

- They are used when turning long, slender workpieces that need additional support.

- Lathe dogs are commonly used in woodturning and metalturning projects.

Frequently Asked Questions

Here are some common questions related to lathe dogs:

1. How does a lathe dog work and what is its purpose?

A lathe dog is a device used in machining to hold a workpiece securely on a lathe. It consists of two main components – a body and two arms. The body is designed to fit onto the lathe’s spindle, while the arms have angled teeth that grip the workpiece. When the lathe spindle rotates, the lathe dog engages with the workpiece and prevents it from rotating. The primary purpose of a lathe dog is to enable the machining of parts that would otherwise be difficult to hold or work on.

By clamping onto the workpiece with its teeth, the lathe dog allows the machinist to perform operations such as turning, facing, or boring. This ensures precise and accurate machining while preventing the workpiece from moving or slipping. Lathe dogs are particularly useful when working on long, slender workpieces that may flex under the forces of machining. They provide additional support and stability, resulting in better-quality finished parts.

2. What are the different types of lathe dogs available?

There are several types of lathe dogs available, each designed for specific applications. Some common types include:

– Bent tail dogs: These lathe dogs have a curved tail, allowing them to be easily positioned on the lathe’s spindle.

– Straight tail dogs: These dogs have a straight tail and are typically used for heavier workpieces.

– Double claw dogs: These dogs have two sets of teeth, providing enhanced grip and stability.

– Spring dogs: These dogs have a spring mechanism that automatically adjusts to the workpiece diameter.

– Dog plates: These are specialized lathe dogs used for holding irregularly shaped workpieces.

Choosing the right type of lathe dog depends on factors such as the size and shape of the workpiece, the machining operation being performed, and the desired level of stability and grip.

3. How do you use a lathe dog on a lathe machine?

To use a lathe dog on a lathe machine, follow these steps:

1. Select the appropriate lathe dog based on the workpiece and machining operation.

2. Mount the lathe dog onto the lathe’s spindle, ensuring a secure fit.

3. Position the workpiece between the lathe dog’s arms, aligning it with the teeth.

4. Tighten the arms of the lathe dog to securely grip the workpiece.

5. Start the lathe machine and perform the desired machining operation, taking care to use appropriate cutting tools and feeds.

6. After finishing the machining, release the grip of the lathe dog and remove the workpiece.

It’s essential to ensure that the lathe dog is securely tightened and aligned before starting the lathe machine to prevent any accidents or damage to the workpiece.

4. Can a lathe dog be used with any lathe machine?

Lathe dogs can be used with most lathe machines, but compatibility may vary based on the size and design of the lathe’s spindle. It’s important to check the lathe dog’s specifications and compare them with the lathe machine’s spindle specifications to ensure a proper fit.

Additionally, the lathe dog should be suitable for the size and weight of the workpiece. Heavy workpieces may require stronger lathe dogs with better gripping capabilities. It’s always recommended to consult the lathe machine’s manual or seek guidance from an experienced machinist to select the appropriate lathe dog for a specific lathe machine.

5. Are there any safety precautions to consider when using a lathe dog?

When using a lathe dog, it’s important to take certain safety precautions:

– Always ensure the lathe dog is correctly mounted and tightened onto the lathe’s spindle before starting the machine.

– Verify that the workpiece is securely gripped by the lathe dog and properly aligned.

– Use appropriate cutting tools, feeds, and speeds to prevent accidents or damage to the lathe dog or workpiece.

– Avoid placing hands or fingers near the lathe dog’s arms while the lathe machine is in operation.

– Regularly inspect the lathe dog for any signs of wear or damage, and replace it if necessary.

By following these safety precautions and exercising caution, users can minimize the risk of accidents and ensure safe and efficient machining operations with a lathe dog.

Summary

A lathe dog is a tool used in a lathe machine to hold and rotate a workpiece. It has two parts – the body and the bent tail. The body is clamped to the lathe’s spindle, while the bent tail holds onto the workpiece. Lathe dogs come in different sizes and shapes to fit various materials and applications. They are important for turning and shaping objects on a lathe.

Overall, a lathe dog is a handy tool for machinists to secure and rotate workpieces accurately on a lathe machine. It helps ensure precise cutting, shaping, and turning operations. By understanding what a lathe dog is and how it works, you can appreciate its role in the world of machining.