Are you curious about what a lathe dog is used for? Well, you’re in the right place! Let me break it down for you in a simple and easy-to-understand way.

So, imagine you have a lathe machine, which is a handy tool used for shaping wood, metal, or other materials. Now, a lathe dog is like a trusty sidekick for the lathe.

Think of it as a special clamp that helps hold the material firmly in place while you work your magic. It grips onto the material and ensures it doesn’t move or rotate during the turning process.

Pretty cool, right? With the help of a lathe dog, you can create all sorts of intricate designs and shapes with precision and accuracy. Stay tuned to learn more about the different types and uses of lathe dogs!

What is a Lathe Dog Used For?

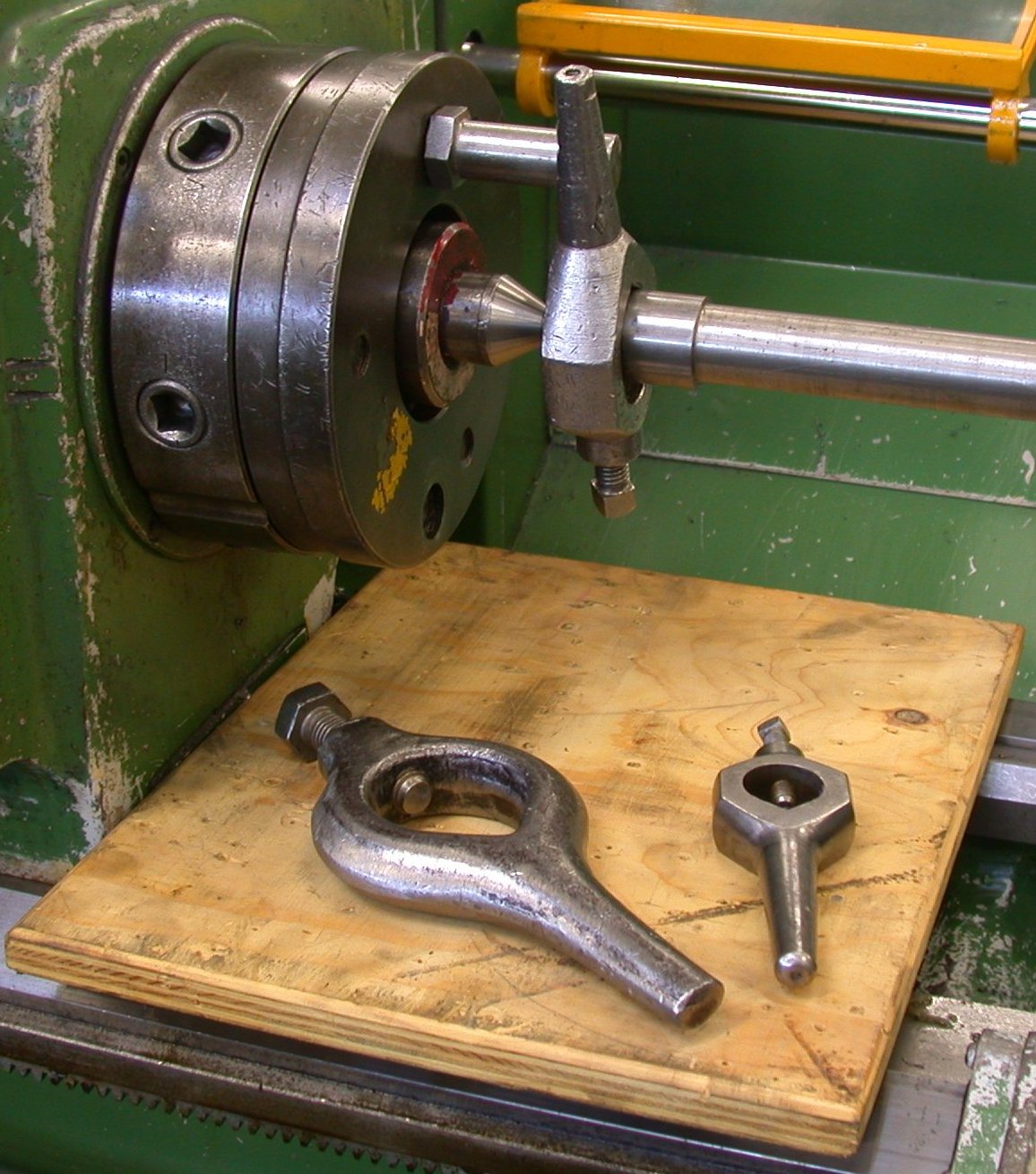

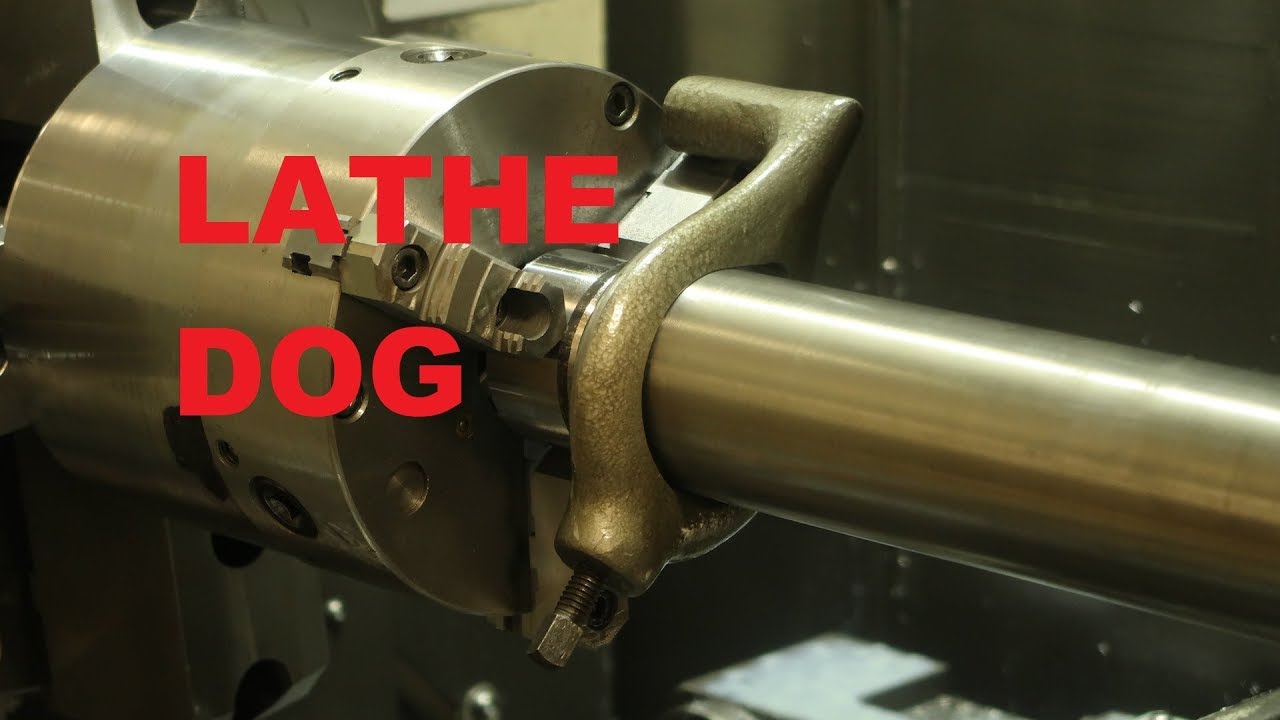

A lathe dog is a common tool used in metalworking, specifically in turning operations on a lathe. It is a device that grips the workpiece securely to ensure accuracy and stability during the machining process. The lathe dog has a claw-like shape with a curved face and teeth that engage with the workpiece, allowing it to rotate along with the spindle of the lathe.

Lathe dogs are mostly used when turning long, slender workpieces such as bars, shafts, or pipes. They provide a means to hold the workpiece firmly, preventing it from rotating or moving independently of the lathe spindle. This grip allows for precise and controlled machining, making lathe dogs an essential tool in metalworking operations.

There are several types of lathe dogs available, each designed for specific applications. Some common types include bent tail lathe dogs, straight tail lathe dogs, and faceplate lathe dogs. The choice of lathe dog depends on the shape and size of the workpiece, as well as the machining operation being performed.

1. Holding the Workpiece Securely

One of the primary purposes of a lathe dog is to hold the workpiece securely during the turning process. When turning long or slender workpieces, there is a risk of the workpiece bending or vibrating due to the cutting forces involved. By using a lathe dog, the workpiece is firmly gripped and prevented from spinning or moving independently of the lathe spindle. This ensures greater accuracy and stability during machining, resulting in better quality finished products.

Additionally, the teeth of the lathe dog bite into the workpiece, creating a strong grip that can withstand even high cutting forces without slipping. This allows for more aggressive cutting and the removal of larger amounts of material in each pass, resulting in improved productivity.

Furthermore, lathe dogs are capable of accommodating different workpiece sizes and shapes. The adjustable nature of the lathe dog allows it to adapt to the specific diameter or contour of the workpiece, providing a secure grip regardless of variations in size or shape.

2. Facilitating Turning Operations

Lathe dogs play a crucial role in facilitating various turning operations on a lathe. When a workpiece is clamped in a lathe dog, it is rotated along with the spindle, enabling the machinist to perform operations such as facing, boring, or turning down the diameter of the workpiece. The lathe dog ensures that the workpiece rotates consistently at the desired speed and in synchronization with the lathe spindle.

During the turning process, the machinist can use different cutting tools to remove material from the workpiece. With the workpiece securely clamped in the lathe dog, the machinist can focus on the cutting operation, knowing that the workpiece will rotate steadily and not be subject to unwanted movement or vibration.

The use of a lathe dog also allows for the application of consistent cutting forces on the workpiece. This is important for achieving uniform cutting depths and surface finishes across the entire length of the workpiece. Consistency in cutting forces leads to better overall machining quality and reduces the risk of surface imperfections or dimensional inconsistencies.

3. Supporting Long Workpieces

Long workpieces present unique challenges when it comes to machining on a lathe. The length of the workpiece can cause it to deflect or vibrate due to the cutting forces applied. Lathe dogs offer a solution to this problem by providing additional support to the workpiece, reducing the risk of deflection and vibration.

By clamping the workpiece at both ends with lathe dogs, a machinist can effectively support the workpiece and minimize any bending or flexing during machining. This support ensures that the workpiece remains straight and stable, leading to improved dimensional accuracy and surface finish on the final product.

Furthermore, lathe dogs can be used in conjunction with support centers or steady rests to provide even greater support for extremely long workpieces. This combination of tools allows for the machining of workpieces that would otherwise be difficult to handle and produce accurate results.

Common Applications of Lathe Dogs

Lathe dogs find widespread use in various metalworking applications where the turning of long, slender workpieces is required. Here are some common applications where lathe dogs are essential:

1. Shaft Turning

When manufacturing shafts used in various industries like automotive, aerospace, or machinery, lathe dogs are often employed to securely hold the workpiece during the turning process. Shaft turning typically involves removing material from the outer diameter of the shaft to achieve the desired size and surface finish.

2. Bar Turning

Bars, especially long bars, are commonly used as stock material in various industries. Lathe dogs are essential in bar turning operations, as they ensure the bar remains stable and centered during machining, resulting in accurate dimensions and surface finishes.

3. Pipe Threading

When threading pipes for plumbing or other applications, lathe dogs are used to grip the pipe securely while maintaining concentricity with the lathe spindle. This allows for precise and accurate threading operations, ensuring compatibility with pipe fittings and connectors.

4. Taper Turning

Taper turning involves machining workpieces with a tapered shape, such as cones or certain types of shafts. Lathe dogs are used to hold the workpiece at one end while the other end is supported by a center or a steady rest. This setup allows for the accurate machining of tapers with consistent dimensions.

5. Facing Operations

During facing operations, lathe dogs play a crucial role in holding the workpiece securely while material is removed from the face of the workpiece to achieve a smooth and flat surface. Lathe dogs provide the necessary stability to ensure accurate and consistent facing across the entire workpiece.

6. Boring Operations

Lathe dogs are used in boring operations to hold the workpiece firmly while a cutting tool removes material from the internal diameter of the workpiece. The precise grip provided by the lathe dog ensures accuracy and allows for the creation of precise internal bores or holes.

7. Woodturning

Although lathe dogs are most commonly associated with metalworking, they can also be used in woodturning applications. They provide a secure grip on wooden workpieces, enabling the machinist to shape or carve the wood with precision and control.

Advantages and Disadvantages of Lathe Dogs

Advantages:

- Securely holds workpieces during turning operations, ensuring accuracy and stability.

- Allows for controlled machining with consistent cutting forces.

- Supports long workpieces, minimizing deflection and improving dimensional accuracy.

- Enables the turning of various types of workpieces, such as shafts, bars, and pipes.

- Facilitates precise facing, boring, and taper turning operations.

- Can be used in both metalworking and woodturning applications.

Disadvantages:

- May leave marks or indentations on the workpiece.

- Requires careful alignment and adjustment for optimal grip.

- Not suitable for all workpiece shapes or sizes.

- Can limit access to certain areas of the workpiece for machining.

- Introduces the risk of workpiece damage if not used properly.

- Requires additional setup time compared to other workholding methods.

Summary

Lathe dogs are essential tools in metalworking that provide a secure grip on long, slender workpieces during turning operations. They ensure accuracy, stability, and support for the workpiece, allowing for precise and controlled machining. Lathe dogs find application in various industries and are versatile enough to be used in both metalworking and woodturning operations. While they have advantages in terms of workpiece control and improved machining quality, lathe dogs need to be used with care to avoid workpiece damage or limitations in machining access. Understanding the role and applications of lathe dogs can greatly enhance the efficiency and accuracy of metalworking processes.

Key Takeaways: What is a Lathe Dog Used For?

- A lathe dog is a device used in metalworking to hold and rotate a workpiece on a lathe machine.

- It has a pointed end that fits into the workpiece and a clamping mechanism that attaches it to the lathe’s faceplate or spindle.

- Lathe dogs are typically used when turning irregularly shaped or large workpieces that cannot be held securely by other means.

- They help maintain stability and prevent slippage, allowing for more precise and efficient machining.

- Lathe dogs come in various designs and sizes to accommodate different workpieces and machining requirements.

Frequently Asked Questions

In this section, we will explore five common questions related to lathes and the purpose of a lathe dog. Read on to learn more.

1. How does a lathe dog work?

A lathe dog is a device used in metalworking and woodworking to hold and rotate a workpiece while it is being machined on a lathe. It typically consists of two main parts: a body and a driving plate. The body is clamped onto the workpiece, allowing it to rotate, while the driving plate is connected to the lathe’s faceplate or spindle. As the lathe rotates, the driving plate engages with the lathe dog body, creating a driving force that allows the workpiece to rotate along with the lathe.

The lathe dog acts as a mechanism to transfer the rotational motion from the lathe to the workpiece, enabling various machining operations like turning, facing, or drilling. It securely holds the workpiece in place, preventing it from moving or vibrating during the machining process, ensuring accurate and precise results.

2. What are the different types of lathe dogs?

There are several types of lathe dogs available, each designed for specific applications. The most common types include the following:

– Bent-tail lathe dog: This type features a bent tail that fits around the workpiece, providing a secure hold. It is ideal for cylindrical workpieces.

– Straight-tail lathe dog: It has a straight tail that clamps onto the workpiece. This versatile type can be used for both cylindrical and irregularly shaped workpieces.

– Offset lathe dog: This type has a bent tail with an offset, allowing it to hold shorter or irregularly shaped workpieces.

– Carrier lathe dog: It is a specialized type used for thin, sheet-like workpieces. The carrier dogs have three or more pins that penetrate the workpiece, ensuring a secure hold.

Each type of lathe dog is chosen based on the shape, size, and material of the workpiece, as well as the specific machining task at hand.

3. What safety precautions should be taken when using a lathe dog?

When using a lathe dog, it is important to observe certain safety precautions to prevent accidents and injuries:

– Always ensure the lathe dog is securely attached to the workpiece to prevent it from slipping or dislodging during operation.

– Use appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself from flying debris and rotating parts.

– Keep your hands and clothing away from the rotating workpiece and the lathe dog itself.

– Avoid using damaged or worn-out lathe dogs, as they may fail to hold the workpiece securely and result in accidents.

By following these safety guidelines, you can ensure a safe and accident-free lathe dog operation.

4. Can lathe dogs be used with any lathe?

Lathe dogs can be used with most lathes that have a faceplate or spindle to which the driving plate of the lathe dog can be connected. However, it is important to ensure compatibility between the lathe dog and the lathe you are using, especially in terms of sizes and mounting methods.

Before using a lathe dog, check the specifications of your lathe to ensure it can accommodate the particular type and size of lathe dog you plan to use. This will help ensure a proper fit and prevent any operational issues or damage to the lathe or the workpiece.

5. Are lathe dogs only used in metalworking?

While lathe dogs are commonly associated with metalworking, they can also be used in woodworking and other materials. The main purpose of a lathe dog remains the same across various industries – to securely hold and rotate the workpiece during machining operations.

In woodworking, lathe dogs are used to hold and shape cylindrical or irregularly shaped wooden workpieces. They enable the woodturner to apply varying cutting tools and techniques to create decorative designs, bowls, spindles, and other turned wooden objects.

So, whether you are working with metal or wood, a lathe dog proves to be a versatile tool for rotating and machining workpieces with precision and control.

How to machine between center’s using lathe dog

Summary

A lathe dog is a handy tool used with a lathe machine to hold and rotate a workpiece. It has a curved shape that grips the workpiece tightly so it can be turned.

Lathe dogs are commonly used when working with cylindrical or irregularly shaped objects. They provide stability and prevent the workpiece from moving while it is being worked on, ensuring precise and accurate results.

In conclusion, a lathe dog is an important accessory for the lathe machine that helps in securely holding and rotating the workpiece during various machining operations.