Have you ever wondered what a negative rake lathe tool is? Well, you’re in the right place! In this article, we’ll uncover the ins and outs of this specialized tool that plays a crucial role in machining. So, if you’re curious and ready to dive into the world of lathes and cutting tools, let’s get started!

When it comes to lathe tools, the term “negative rake” might sound a bit perplexing. But fear not! The idea behind a negative rake lathe tool is surprisingly simple. In essence, it refers to the angle at which the cutting edge of the tool is positioned in relation to the workpiece.

Now, you might be wondering, why is this angle important? Well, the negative rake angle offers distinct advantages, such as increased tool strength and improved chip control. So, whether you’re a hobbyist or a seasoned machinist, understanding the concept of a negative rake lathe tool can greatly enhance your turning experience.

So, get ready to grasp the fundamentals, as we explore the world of negative rake lathe tools together. From its benefits to its applications, we’ll cover it all in an easy-to-understand manner. So, without further ado, let’s unravel the mysteries of this fascinating tool!

Understanding Negative Rake Lathe Tools: A Guide to Enhanced Cutting Efficiency

When it comes to lathe tools, one term that often comes up is “negative rake.” But what exactly does this term mean and how does it impact the performance of a lathe tool? In this comprehensive guide, we will delve into the world of negative rake lathe tools and explore their benefits, uses, and practical tips for maximizing their efficiency. Whether you are a seasoned machinist or just starting out, this article will provide you with all the information you need to understand and utilize negative rake lathe tools effectively.

The Basics of Negative Rake Lathe Tools

Before we dive into the intricacies of negative rake lathe tools, let’s start with the basics. An essential component of a lathe machine, lathe tools are used for cutting and shaping various materials such as wood, metal, and plastic. The design of a lathe tool, including its rake angle, significantly affects its cutting performance.

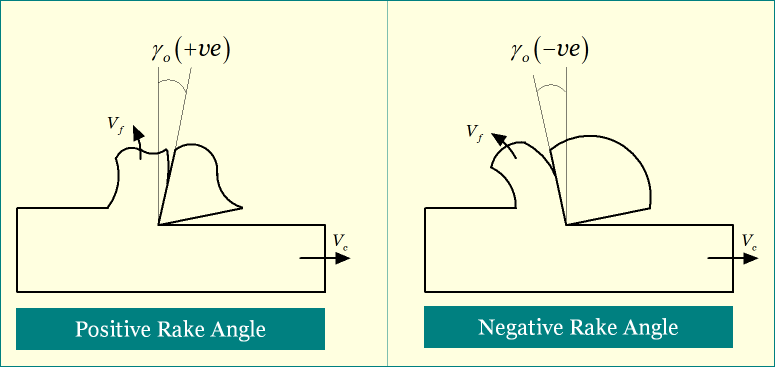

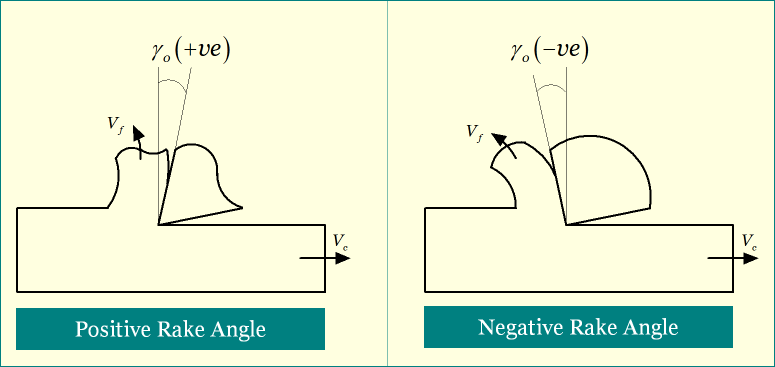

In the case of negative rake lathe tools, the rake angle is set to be less than zero degrees, meaning that the cutting edge slopes backward away from the workpiece. This deviation from a traditional positive rake angle has several implications in terms of cutting performance and tool life. Let’s explore some of the key benefits and considerations associated with negative rake lathe tools.

The Advantages of Negative Rake Lathe Tools

1. Increased Cutting Stability: One of the primary benefits of negative rake lathe tools is their enhanced cutting stability. The backward slope of the cutting edge allows for a larger contact area between the tool and the workpiece, resulting in reduced vibration and chatter during the cutting process. This stability is particularly advantageous when working with challenging materials or performing heavy-duty cutting operations.

2. Longer Tool Life: Negative rake lathe tools tend to exhibit superior tool life compared to their positive rake counterparts. The reduced friction and heat generated during cutting contribute to less tool wear and prolonged tool life. This translates to cost savings as the tools require less frequent replacement, leading to increased productivity and efficiency in machining operations.

3. Improved Surface Finish: Another notable advantage of negative rake lathe tools is their ability to produce a superior surface finish on the workpiece. The controlled cutting action reduces the formation of unwanted chip patterns and allows for smoother, cleaner cuts. This is especially important in applications where aesthetics or precision are critical factors.

Choosing the Right Negative Rake Lathe Tool

When selecting a negative rake lathe tool, it’s crucial to consider factors such as the material being machined, the desired cutting speed, and the specific application requirements. Here are a few tips to help you choose the right tool:

- Consider the workpiece material: Different materials may require different tool materials and coatings. Research the compatibility of the tool with the material you will be working with to ensure optimal performance.

- Take into account the cutting speed: Negative rake lathe tools can handle higher cutting speeds compared to positive rake tools. Adjust the cutting speed based on the material, tool characteristics, and desired machining outcome.

- Refer to manufacturer recommendations: Manufacturers often provide guidelines on their tools’ capabilities, recommended applications, and maintenance procedures. Follow these recommendations to maximize the tool’s performance and lifespan.

Negative Rake vs. Positive Rake: Understanding the Difference

While negative rake lathe tools have their advantages, it’s important to note that they are not universally superior to positive rake tools. Positive rake tools are still widely used and have their own set of benefits. Here’s a comparison between the two:

| Negative Rake Lathe Tools | Positive Rake Lathe Tools | |

|---|---|---|

| Advantages | Increased cutting stability, longer tool life, improved surface finish | Lower cutting forces, faster material removal rates |

| Materials | Recommended for challenging materials | Suitable for general-purpose machining |

| Applications | Heavy-duty cutting, high precision machining, low-speed operations | General machining, high-speed operations |

Proper Maintenance and Tips for Negative Rake Lathe Tools

To ensure optimal performance and longevity of your negative rake lathe tools, it is crucial to follow proper maintenance practices. Here are some tips:

- Regularly inspect the cutting edge for wear, damage, or excessive chipping. Replace the tool if necessary to avoid compromising the quality of the cuts.

- Keep the cutting edge clean and free from debris during machining operations. Use appropriate cutting fluids or lubricants to minimize friction and heat buildup.

- Store the tools in a cool, dry place to prevent rust or corrosion. If using a toolbox, ensure that the tools are properly secured to prevent them from coming into contact with each other.

Key Considerations for Negative Rake Lathe Tools in Different Industries

Now that we have explored the advantages and characteristics of negative rake lathe tools, let’s take a closer look at how they are used in different industries:

Automotive Industry

In the automotive industry, negative rake lathe tools are commonly used for precision turning operations on engine components such as crankshafts, pistons, and connecting rods. The enhanced stability and control provided by these tools allow for high-precision machining and improved surface finishes.

Aerospace Industry

In the aerospace industry, where precision and safety are critical, negative rake lathe tools find applications in machining complex parts made from materials such as titanium and stainless steel. These tools enable efficient material removal while maintaining the required precision and integrity of the components.

Woodworking Industry

Negative rake lathe tools are also widely used in the woodworking industry for turning wooden pieces with intricate designs. The stability and improved surface finish provided by these tools make them ideal for creating smooth, precise cuts and achieving desired woodwork aesthetics.

In conclusion, negative rake lathe tools offer numerous advantages in terms of cutting stability, tool life, and surface finish. By understanding their characteristics and following proper maintenance practices, machinists can harness the full potential of these tools in various industries. Whether you are a professional machinist or an avid hobbyist, incorporating negative rake lathe tools in your repertoire can elevate your machining capabilities and yield superior results.

Key Takeaways: What is a Negative Rake Lathe Tool?

A negative rake lathe tool is a cutting tool used in a lathe machine that has its cutting edge angled slightly backwards. It helps in reducing cutting forces and improving tool life.

Benefits of using a negative rake lathe tool:

- Produces smoother surface finishes

- Reduces chatter and vibrations

- Increases tool stability

- Offers better chip control

- Improves productivity and machining accuracy

Frequently Asked Questions

In the world of machining, negative rake lathe tools are an essential tool for precise and efficient turning operations. Here are some common questions related to them:

1. How does a negative rake lathe tool differ from a regular lathe tool?

While a regular lathe tool has a positive rake angle (angled towards the direction of the cut), a negative rake lathe tool is angled away from the direction of the cut. This subtle difference affects the cutting process and performance of the tool.

A negative rake angle provides several advantages: it increases tool life, reduces cutting forces, and enhances stability. These tools excel in difficult-to-machine materials like stainless steel and cast iron, where high force and heat are generated during the cutting process.

2. What are the benefits of using a negative rake lathe tool?

Using a negative rake lathe tool offers several benefits. First, it improves tool life by reducing wear on the cutting edge. By reducing the force required to remove material, it also minimizes the risk of tool failure.

Additionally, negative rake lathe tools produce an excellent surface finish, meaning smoother and more precise workpieces. Their enhanced stability allows for higher cutting speeds, resulting in faster machining times. Overall, these tools are a reliable choice for achieving high-quality turning operations.

3. Are there any drawbacks or limitations to using negative rake lathe tools?

While negative rake lathe tools have numerous advantages, they also have some limitations to consider. One notable drawback is that they require higher cutting forces compared to tools with a positive rake angle. Consequently, a machine with sufficient power and rigidity is necessary.

They may also be more challenging to sharpen due to the angled cutting edge. As a result, special care and precision are necessary for maintaining and regrinding these tools. However, with the right techniques and equipment, these potential limitations can be effectively managed.

4. When should I choose a negative rake lathe tool over a positive rake tool?

Choosing between a negative rake lathe tool and a positive rake tool depends on various factors. If you primarily work with difficult-to-machine materials such as stainless steel, cast iron, or exotic alloys, a negative rake lathe tool is the better choice.

However, if you predominantly work with softer materials like aluminum or brass, a positive rake tool may be more suitable. It’s important to consider the specific characteristics of the material, the desired surface finish, and the machining conditions when making this decision.

5. How can I optimize the performance of a negative rake lathe tool?

To optimize the performance of a negative rake lathe tool, proper tool selection and setup are crucial. Ensure the tool geometry, including the rake angle, clearance angle, and cutting edge geometry, are appropriate for the material and machining operation.

Additionally, maintaining good cutting fluid application, adequate machine rigidity, and using proper cutting parameters will help maximize the tool’s performance. Regular inspection, maintenance, and regrinding of the tool are also essential for consistent results and extended tool life.

![]()

Summary

So, what is a negative rake lathe tool? It’s a special kind of tool that helps us make things on a lathe. It has a cutting edge that faces downward instead of upward like most tools. This makes it stronger and better at removing material. Negative rake tools are great for tough materials like steel. They also reduce vibrations and make for a smoother, safer cutting experience. So if you ever get a chance to use a negative rake lathe tool, give it a try and see how it can make your lathe work easier and more efficient!