If you’ve ever wondered, “What is a noggin in carpentry?” you’re in the right place! Let’s dive into the world of carpentry and explore the fascinating role that noggins play in the construction industry.

In simple terms, a noggin is essentially a horizontal piece of timber that is used to strengthen and support the structure of a building. Think of it as a secret superhero hidden within the walls of a house, providing extra stability and preventing those pesky creaks and squeaks.

Noggins are like the glue that holds everything together, ensuring that walls, floors, and roofs stay sturdy and secure. So, whether you’re a budding DIY enthusiast or just curious about the inner workings of carpentry, let’s unravel the mystery of noggins and discover their importance in the world of construction.

What is a Noggin in Carpentry?

In the world of carpentry, there are many terms and techniques that may seem unfamiliar to those who aren’t familiar with the trade. One such term is “noggin.” While it may sound strange, a noggin is actually a critical component in the construction and stability of certain structures. In this article, we will explore what a noggin is in carpentry, its purpose, and how it is used. So, let’s dive in and uncover the world of noggins!

Understanding the Basics: What is a Noggin?

At its core, a noggin in carpentry refers to a horizontal piece of timber or metal that is used to provide additional support and stability between vertical elements of a structure, such as studs or joists. Noggins are typically installed at regular intervals and are often found in walls, floors, and roofs. They act as the connective tissue, strengthening the overall framework and preventing the structure from flexing or warping.

In terms of appearance, noggins are usually shorter in length compared to the vertical elements they connect. They are often cut to fit snugly between the vertical members, ensuring a tight and secure connection. Noggins can be made from various materials, including timber, metal, or even engineered products like plywood or oriented strand board (OSB).

The Role and Benefits of Noggins in Carpentry

Now that we know what a noggin is, let’s explore why they are such a crucial part of carpentry. Noggins serve several important functions, including:

- Enhancing Structural Integrity: Noggins play a key role in providing additional strength and stability to the overall structure. By connecting the vertical elements, they help distribute loads and minimize any potential shifting or movement.

- Preventing Warping and Flexing: With their tight connections, noggins help prevent excessive flexing or warping of the vertical elements, ensuring a more rigid and durable structure. They help maintain the integrity of walls, floors, and roofs, even under heavy loads or external forces.

- Improving Soundproofing and Fire Resistance: Noggins can contribute to the soundproofing and fire resistance properties of a building. By filling the gaps between vertical members, they reduce the transmission of sound waves and slow down the spread of fire.

Installation and Tips for Working with Noggins

Now that we understand the importance of noggins, let’s briefly touch on their installation and offer a few tips for working with them:

- Plan Ahead: Before installing noggins, it’s crucial to carefully plan their placement and quantity. Consult building regulations and structural engineers if necessary to ensure proper spacing and alignment.

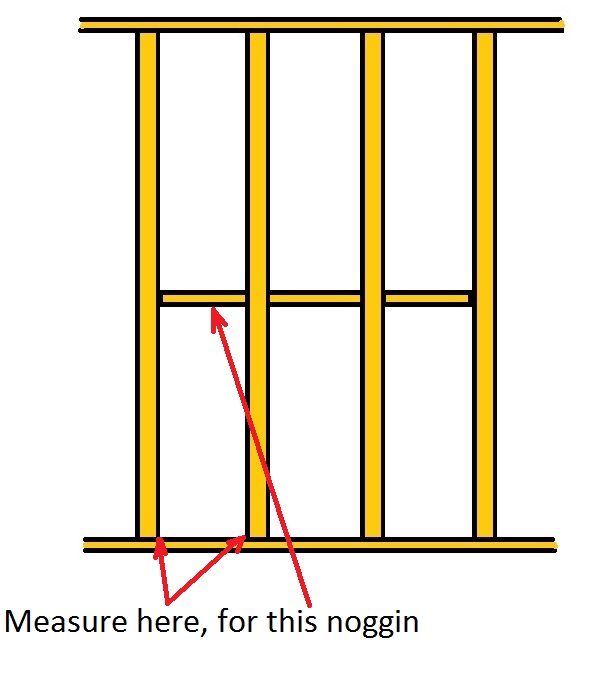

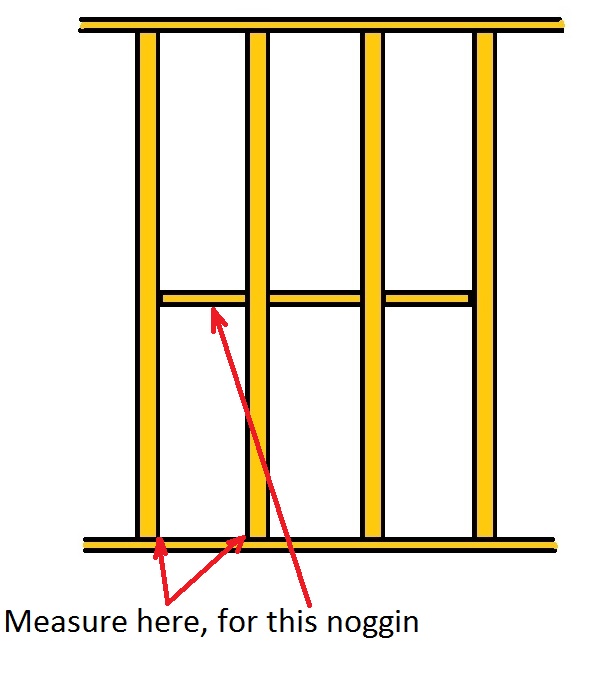

- Measure and Cut Precisely: Noggins should be accurately measured and cut to fit snugly between the vertical members. Take care to account for any necessary adjustments due to variations in timber dimensions or other factors.

- Secure Properly: Ensure that the noggins are securely fastened to the vertical elements using appropriate fixings, such as nails, screws, or brackets. This will ensure the overall strength and stability of the structure.

- Consider Material and Fire Safety: When choosing the material for noggins, consider factors such as fire resistance and moisture resistance. Depending on the intended use and building regulations, specific materials may be required.

Different Types of Noggins

When it comes to noggins in carpentry, there isn’t just one type that fits all situations. Depending on the specific application and structural requirements, different types of noggins may be used. Let’s explore a few common types:

1. Timber Noggins

Timber noggins are the most common type and are typically made from solid pieces of timber. They offer good structural integrity and can easily be cut to size and shaped according to specific requirements. Timber noggins are often used in residential and commercial construction due to their affordability and versatility.

Pros of Timber Noggins:

- Readily available and cost-effective.

- Can be easily cut, shaped, and installed.

- Durable and provide good structural support.

Cons of Timber Noggins:

- May be susceptible to moisture damage if not properly treated.

- Can shrink or expand with changes in humidity levels.

- Not suitable for applications requiring high fire resistance.

2. Metal Noggins

Metal noggins, often made from steel or aluminum, offer exceptional strength and durability. They are commonly used in commercial and industrial construction projects where strength and precision are paramount. Metal noggins are resistant to moisture, insects, and fire, making them a popular choice for challenging environments.

Pros of Metal Noggins:

- High strength-to-weight ratio.

- Excellent durability and resistance to moisture and fire.

- Can be easily fabricated and customized.

Cons of Metal Noggins:

- More expensive compared to timber noggins.

- Require specialized tools and expertise for installation.

- May conduct heat and cold, requiring additional insulation in certain applications.

Common Uses of Noggins in Carpentry

Noggins can be found in various areas of carpentry and construction. Here are some common applications:

1. Wall Framing

Noggins are frequently used in wall framing to provide lateral stability, prevent twisting or racking, and enhance the overall rigidity of the structure. They are installed horizontally between the wall studs, typically at intervals of 400 to 600 millimeters.

2. Floor Structures

In floor construction, noggins are employed to distribute loads evenly across floor joists and reduce any flexing or movement. They help create a solid and uniform platform for flooring materials. Noggins are often installed parallel to the joists, enhancing the overall strength and stability of the floor structure.

3. Roof Construction

Noggins play a vital role in roof construction by providing additional support for roof rafters or trusses. They help distribute the weight of the roof evenly and prevent any flexing or sagging. Noggins are typically installed horizontally between the rafters, reinforcing the overall structure and ensuring its long-term durability.

These are just a few examples of the many ways noggins are used in carpentry and construction. Their versatility and importance in providing stability and strength cannot be overstated.

Tips for Working with Noggins

Working with noggins requires precision, careful planning, and attention to detail. Here are a few additional tips to keep in mind:

1. Follow Building Regulations

When installing noggins, it is essential to adhere to the relevant building regulations and guidelines in your area. These regulations specify the minimum requirements for structural stability, fire resistance, and other safety considerations.

2. Seek Professional Advice if Needed

If you are unsure about any aspect of working with noggins, do not hesitate to consult with a professional carpenter or structural engineer. They can provide valuable insight and ensure that your construction meets the necessary standards.

3. Use the Right Tools and Equipment

Invest in high-quality tools and equipment specifically designed for the installation of noggins. This will ensure accurate cutting, precise measurements, and secure fastening.

By following these tips and taking the necessary precautions, you can work with noggins effectively and ensure a safe and durable construction.

In conclusion, noggins are an essential component in carpentry that provides strength, stability, and durability to structures. Whether it’s in wall framing, floor structures, or roof construction, noggins play a vital role in maintaining the overall integrity of buildings. By understanding their purpose, installation techniques, and different types available, carpenters can make informed decisions and ensure the success of their construction projects.

Key Takeaways: What is a Noggin in Carpentry?

- A noggin in carpentry is a short piece of timber used to provide support and strengthen structures.

- It is commonly used to fill in gaps between studs or joists in walls and floors.

- Noggins help to prevent sagging and add stability to the overall structure.

- They are typically cut to fit snugly between the existing framework and secured with nails or screws.

- Noggins are an essential component in carpentry, ensuring the durability and strength of the construction.

Frequently Asked Questions

In the world of carpentry, a noggin refers to a specific element used in construction. It plays a vital role in providing additional support, stability, and reinforcement to structures. Here are some common questions people have about noggins in carpentry:

1. How is a noggin used in carpentry?

A noggin is a short length of timber, usually around 3-4 inches wide, used to connect and strengthen two adjacent joists or studs. It is placed horizontally between two structural elements, serving as a brace or crosspiece. By adding noggins, carpenters ensure the stability and rigidity of the structure, preventing any potential movement or weakening of the framework.

Noggins are commonly employed in floor and wall framing to provide additional support and distribute loads evenly. They help prevent twisting or warping, minimizing the risk of the structure sagging or failing. Noggins are also integral in preventing the spread of fires within buildings by acting as fire-stops, hindering flames and smoke from passing through the cavities between walls.

2. What materials are used for making noggins?

Traditionally, noggins were made from timber due to its strength and durability. Common types of timber used for noggins include pine, spruce, or other hardwoods. These materials offer excellent load-bearing capabilities while being readily available and cost-effective.

However, in modern construction, alternative materials such as metal noggins or engineered wood products like plywood or oriented strand board (OSB) are also used. Metal noggins, typically made of steel, provide robust support and can be a good option in areas where moisture or termite infestation is a concern. Engineered wood noggins offer high strength, stability, and resistance to warping, making them suitable for various construction applications.

3. Do noggins have any specific measurements or placement requirements?

The measurements and placement of noggins in carpentry depend on the specific structural requirements and building codes. Generally, noggins are cut to fit snugly between the adjacent joists or studs. They are typically spaced at regular intervals, with the distance between each noggin determined by factors such as the load-bearing capacity needed and the span of the structure.

For example, in floor framing, noggins are often installed at approximately 400-600mm (16-24 inches) intervals, depending on the floor’s design and load requirements. It’s essential to consult local building codes or rely on a structural engineer’s recommendations to ensure proper placement and sizing of noggins for optimal structural integrity.

4. Are noggins only used in vertical structures like walls?

No, noggins are used in both vertical and horizontal structures. In vertical structures, such as walls, noggins are inserted between studs to provide stability, reduce flexing, and increase load-bearing capacity. They also help to secure wall panels and prevent warping or cracking.

In horizontal structures like floor framing, noggins are placed between joists to prevent them from twisting, sagging, or bouncing under the weight of the floor itself or any loads applied to it. Noggins enhance the overall strength of the floor and increase its resistance to deformation.

5. Can noggins be used for decorative purposes as well?

Absolutely! While noggins primarily serve structural functions, they can also be incorporated into carpentry projects for decorative purposes. By selecting visually appealing timber or utilizing decorative metal brackets or connectors, noggins can add a touch of aesthetic charm to certain architectural designs.

For example, exposed noggins in a loft or timber-framed building can create a rustic and visually striking feature. The unique patterns or designs created by arranging noggins in a specific way can enhance the overall character and appeal of a space. So, noggins can be both functional and aesthetically pleasing in carpentry projects.

FITTING TIMBER NOGGINS – TIP TOP TOP TIP

Summary

In carpentry, a noggin is a small piece of wood used to strengthen structures. It is placed between floor joists to prevent them from twisting or bending. Noggins also help distribute the load evenly, making the structure more stable and durable.

While noggins are not always necessary, they can greatly enhance the strength of a construction. Carpenters carefully measure and install noggins to ensure the safety and stability of the building. So, next time you see a small piece of wood holding things together, you’ll know it’s a noggin!