Hey there! Are you curious about what a radial arm drill press is used for? Well, you’ve come to the right place! In this article, we’re going to explore the wonderful world of radial arm drill presses and discover how they can be handy tools in various situations. So buckle up and let’s dive right in!

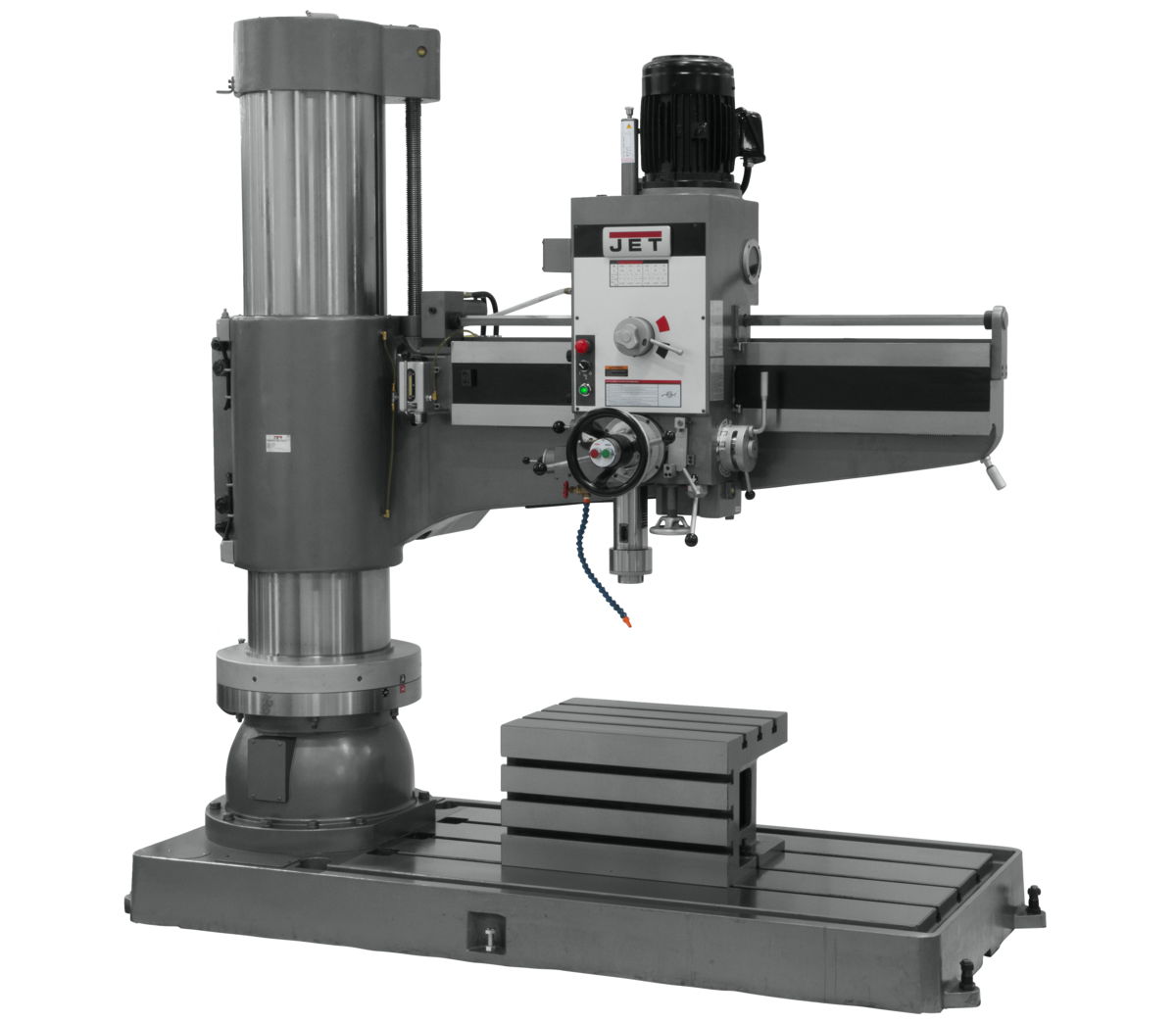

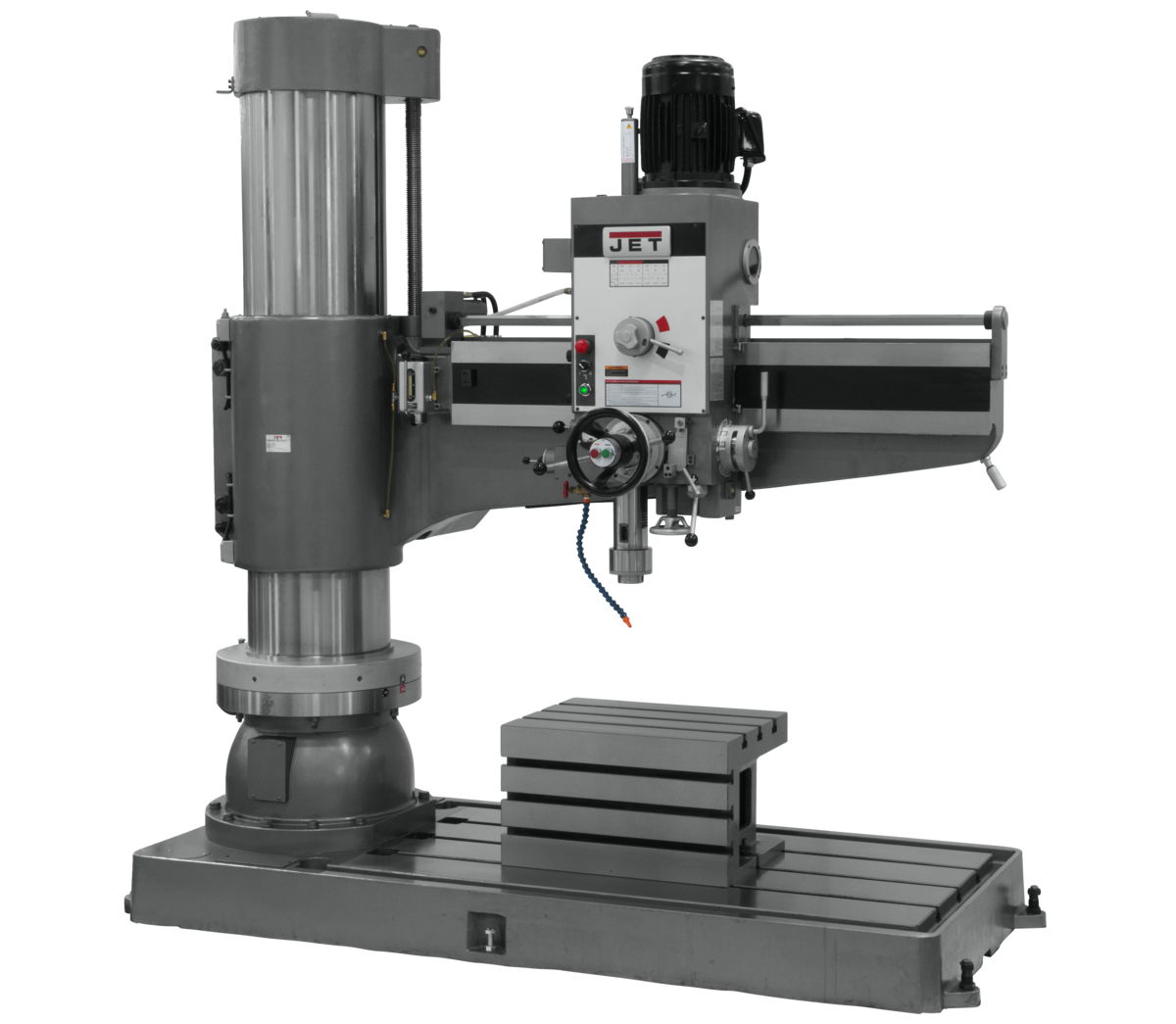

Alrighty then, let’s start with the basics. A radial arm drill press is a powerful and versatile tool that is typically used in workshops or manufacturing settings. Its main purpose is to drill precise holes in a wide range of materials such as wood, metal, and plastic.

But wait, there’s more! This amazing device offers much more than just drilling capability. With adjustable arms that can be moved up, down, and horizontally, a radial arm drill press allows you to perform a variety of operations like tapping, boring, reaming, and counterboring. It’s like having a Swiss Army knife of drilling tools!

Now that we’ve got a general idea, let’s dig a little deeper and explore the different applications of a radial arm drill press, from woodworking projects to metal fabrication and everything in between. Trust me, you’ll be amazed by its versatility and the wide range of tasks it can handle. So, let’s get into the nitty-gritty details and uncover the wonders of the radial arm drill press!

< div class="featured" >

Radial arm drill presses are versatile tools used in various industries. They feature a movable arm that can swing 360 degrees, allowing for precise hole drilling from different angles. With their adjustable height and radial movement, these machines provide flexibility in drilling operations. They are commonly used in woodworking, metalworking, and construction projects. The radial arm drill press offers the advantage of drilling holes in large workpieces or across multiple surfaces with ease and accuracy.

< /div >

What Is a Radial Arm Drill Press Used For? A Comprehensive Guide

1. Drilling Holes of Various Sizes and Depths

A radial arm drill press is a versatile machine used primarily for drilling holes in various materials. Whether you’re working with wood, metal, or even plastic, this powerful tool allows you to effortlessly create holes of different sizes and depths. With its adjustable arm and drill head, you can position the drill bit precisely where you need it, ensuring accurate and consistent results.

One of the key advantages of a radial arm drill press is its ability to drill holes at different angles. The adjustable arm allows you to tilt the drill head, making it ideal for projects that require angled holes. Whether you’re working on a piece of furniture or constructing a frame, a radial arm drill press is a valuable tool for precision drilling.

Furthermore, this machine offers a wide range of speeds, allowing you to choose the appropriate setting for your specific material and drilling requirements. Whether you’re working with soft or hard materials, you can adjust the speed to ensure optimal results without compromising the integrity of the material.

2. Boring Large Holes

In addition to drilling small to medium-sized holes, a radial arm drill press is also used for boring large holes. With its powerful motor and stable construction, this machine can handle the demands of drilling larger holes in thick materials. Whether you’re creating openings for pipes or conduits, a radial arm drill press provides the necessary power and stability to bore precise and clean holes.

When working on projects that require larger holes, it’s important to consider the diameter and depth of the hole. A radial arm drill press offers the versatility to adjust the drill bit size and control the depth of the hole with precision. This ensures that the final result matches your specifications and meets the requirements of your project.

Whether you’re a professional woodworker, metalworker, or a DIY enthusiast, having a radial arm drill press in your workshop allows you to tackle a wide range of projects, from small-scale repairs to large-scale constructions.

3. Countersinking and Counterboring

A radial arm drill press is not limited to just drilling and boring; it is also a useful tool for countersinking and counterboring. Countersinking involves creating a conical depression at the top of a drilled hole, allowing screw heads to sit flush with the material’s surface. Counterboring, on the other hand, involves drilling a larger hole partially into the material, creating a recess for the screw head to rest in below the surface.

These techniques are commonly used in woodworking to achieve a professional and polished finish. By using a radial arm drill press, you can easily perform countersinking and counterboring operations with precision and consistency. This ensures that the screws sit perfectly flush with the material, providing a seamless and aesthetically pleasing result.

Whether you’re building cabinets, shelves, or any other wooden structures that require screws to be concealed, a radial arm drill press is an indispensable tool for achieving clean and professional results.

4. Tapping Threads

In addition to drilling holes and performing various types of boring operations, a radial arm drill press can also be used for tapping threads. Tapping is the process of creating threads in a drilled hole to allow screws, bolts, or other fasteners to be securely attached.

A radial arm drill press with a tapping attachment can save you considerable time and effort compared to manual tapping with a handheld tap wrench. With its precise drilling capabilities and adjustable speeds, this machine makes it easier to tap accurate and properly aligned threads in a range of materials, from wood to metal.

Whether you’re working on a metal fabrication project or assembling a piece of furniture, a radial arm drill press with tapping capabilities can greatly enhance your efficiency and precision.

5. Slotting and Mortising

Another important use of a radial arm drill press is slotting and mortising. Slotting involves cutting long, narrow channels into a material, while mortising refers to creating square or rectangular holes to accommodate joints or hinges.

With its powerful motor and adjustable arm, a radial arm drill press provides the stability and precision required for these operations. Whether you’re building furniture, doors, or frames, you can rely on this machine to create clean and accurate slots and mortises.

By utilizing jigs and specialized tools, you can achieve consistent and repeatable results, ensuring that your joints fit together perfectly and your furniture or structures are sturdy and durable.

6. Sanding and Polishing

While not its primary function, a radial arm drill press can also be used for sanding and polishing certain materials. By attaching sanding or polishing discs to the drill chuck, you can transform the machine into a makeshift sanding or polishing station.

However, it’s important to note that this is not the most conventional or efficient method for sanding or polishing. Dedicated sanding and polishing machines offer better control, stability, and speed specifically designed for these tasks. Nevertheless, in certain situations where a radial arm drill press is the only tool available, it can serve as a makeshift alternative.

It’s worth mentioning that using a radial arm drill press for sanding or polishing may void the machine’s warranty and can be potentially dangerous if not done properly. Always exercise caution and seek alternative tools and methods when available.

7. Other Possible Uses

While the primary uses of a radial arm drill press revolve around drilling, boring, countersinking, tapping, slotting, and mortising, there are other potential applications depending on the creativity and ingenuity of the user.

For example, a radial arm drill press can be used for routing by attaching a router bit to the chuck. The adjustable arm and drill head provide the necessary maneuverability to create intricate shapes and designs in wood or other materials.

Additionally, a radial arm drill press can be adapted for use with other accessories such as wire brushes and grinding wheels, expanding its capabilities beyond drilling and related operations. These accessories can be attached to the drill chuck, allowing you to perform cleaning, deburring, and other surface preparation tasks.

Benefits of Using a Radial Arm Drill Press

A radial arm drill press offers several benefits that make it a valuable addition to any workshop or fabrication facility:

1. Versatility

With its adjustable arm, versatile drill head, and multiple speed options, a radial arm drill press can handle a wide range of drilling and boring tasks. From small holes in wood to large holes in metal, this machine has the flexibility to adapt to different materials and project requirements.

2. Precision

The stability, accuracy, and adjustable features of a radial arm drill press enable precise and consistent drilling, countersinking, boring, tapping, and other operations. This precision ensures that your holes, joints, and threads align perfectly, resulting in high-quality and professional finishes.

3. Efficiency

With its powerful motor and adjustable speeds, a radial arm drill press allows efficient and time-saving drilling and related operations. The stability of the machine also contributes to increased productivity, as it reduces the chances of errors or misalignments that may require rework.

4. Safety

Radial arm drill presses are designed with safety features such as guards and emergency stops to protect the user from potential hazards. By using this machine correctly and following proper safety protocols, you can minimize the risk of accidents and injuries.

5. Durability

Quality radial arm drill presses are built to withstand heavy-duty use and last for years. By investing in a reliable and well-built machine, you can ensure its longevity and enjoy its benefits for a long time.

Tips for Using a Radial Arm Drill Press

To maximize your productivity and ensure safe and accurate operations with a radial arm drill press, consider the following tips:

1. Read the Manual

Before operating any machinery, it’s crucial to familiarize yourself with the manufacturer’s instructions and safety guidelines. Read the manual thoroughly to understand the machine’s features, specifications, and proper use.

2. Wear Appropriate Safety Gear

Always wear safety glasses, ear protection, and other necessary personal protective equipment (PPE) when operating a radial arm drill press. Protect yourself from flying debris, loud noises, and any potential hazards associated with the specific task you’re performing.

3. Secure the Material

Ensure that the material you’re working on is securely clamped or held in place. This prevents unnecessary movement or vibrations during drilling, minimizing the risk of accidents and promoting accurate results.

4. Start with a Pilot Hole

When drilling into hard materials, it’s often beneficial to start with a pilot hole. This small, initial hole serves as a guide for the larger drill bit and helps prevent the wood or metal from splintering or the drill bit from slipping.

5. Use the Correct Drill Bit

Choose the appropriate drill bit for the material you’re drilling. Different materials require different types of drill bits, such as twist bits for wood, high-speed steel (HSS) bits for metal, and masonry bits for concrete or brick.

6. Check Speed and Feed Settings

Before starting, check the speed and feed settings of your radial arm drill press. Adjust the machine to the appropriate speed and feed rate based on the material, drill bit size, and the specific operation you’re performing. This ensures optimal results and prolongs the life of your drill bits.

7. Practice Good Maintenance

Regularly clean and inspect your radial arm drill press to ensure it remains in good working condition. Lubricate moving parts as recommended by the manufacturer and replace worn-out or damaged components promptly. Following proper maintenance practices prolongs the machine’s lifespan and ensures consistent performance.

Conclusion

A radial arm drill press is a versatile and invaluable tool in any workshop or fabrication facility. With its ability to drill holes of various sizes and depths, bore large holes, perform countersinking and counterboring, tap threads, and even tackle slotting, mortising, and other operations, this machine provides the precision, versatility, and efficiency needed to complete a wide range of projects.

By following the tips provided and practicing good maintenance, you can ensure safe and accurate operations with your radial arm drill press. Whether you’re a professional woodworker, metalworker, or a DIY enthusiast, this powerful tool will undoubtedly enhance your productivity and help you achieve professional-grade results.

Key Takeaways: What is a Radial Arm Drill Press Used For?

- A radial arm drill press is a type of drilling machine used to bore holes in various materials.

- It features a rotating arm that can be moved from side to side, allowing for flexible positioning.

- This tool is commonly used in metalworking and woodworking industries.

- It is ideal for drilling large, deep, or angled holes with precision and accuracy.

- With different drill bits and attachments, it can also perform tasks such as tapping, reaming, and countersinking.

Frequently Asked Questions

When it comes to using a radial arm drill press, there may be some questions on how it functions and what it is used for. Here are some common inquiries and their answers to help you gain a better understanding.

1. How does a radial arm drill press work?

A radial arm drill press is a versatile tool that operates by having a spindle placed on a movable radial arm. This allows the arm and the attached drill bit to move horizontally, vertically, and even at different angles. The drill press is controlled by a motor that powers the rotations and movements of the arm and drill bit. By adjusting the position and angle of the arm, you can easily drill holes into various materials, such as metal, wood, or plastic.

Overall, a radial arm drill press offers flexibility and precision in drilling, making it a valuable tool for workshops, construction sites, and DIY projects.

2. What are the main advantages of using a radial arm drill press?

A radial arm drill press offers several advantages that make it a popular choice for drilling tasks. Firstly, its radial arm allows for versatile positioning, making it suitable for drilling holes at different angles and positions. This feature is especially beneficial when you need to drill multiple holes accurately and consistently.

Secondly, a radial arm drill press provides a high level of precision. With the ability to adjust the arm and drill bit, you can achieve precise and accurate drilling depths and hole placements. This is particularly useful when working on projects that require specific measurements and hole alignments.

Lastly, a radial arm drill press offers power and speed control. With adjustable speed settings, you can adapt the drill press to the material being drilled and prevent damage or excessive force. The power of the motor allows for efficient drilling, saving you time and effort during your projects.

3. What materials can be drilled using a radial arm drill press?

A radial arm drill press is designed to drill holes in various materials, including metal, wood, plastic, and composites. Its versatility allows it to tackle a wide range of drilling tasks, making it a valuable tool in workshops and construction sites.

For drilling metal, the drill press can easily penetrate materials like steel, aluminum, and brass. The adjustable speed settings ensure that you can control the force applied to the metal, preventing any damage.

When drilling wood, the radial arm drill press provides the accuracy needed to create clean and precise holes. It is capable of drilling holes for dowels, screws, or other woodworking joints.

Additionally, the drill press can handle drilling plastic materials, such as PVC or acrylic, without causing cracks or chips. It also works well with composites, such as fiberglass or carbon fiber, commonly used in industries like aerospace or automotive manufacturing.

4. Can a radial arm drill press perform other tasks besides drilling?

While a radial arm drill press is primarily designed for drilling, it can also be used for other tasks, expanding its functionality. With the right attachments and accessories, the drill press can be transformed into a versatile tool.

For example, by attaching a sanding drum, you can use the radial arm drill press for sanding and shaping wood. This makes it convenient for woodworking projects that require precise sanding in hard-to-reach areas.

The drill press can also accommodate a wire brush or buffing wheel, allowing for effective cleaning or polishing of metal surfaces. With additional attachments, it can be converted into a mortising machine or a slot cutter, providing even more versatility.

5. What safety precautions should be taken when using a radial arm drill press?

When operating a radial arm drill press, it is important to prioritize safety. Here are some precautions to keep in mind:

Firstly, always wear safety glasses or goggles to protect your eyes from any debris or metal shavings that may be ejected during drilling. Additionally, consider wearing hearing protection as the motor can be loud, especially if drilling metal.

Ensure that the workpiece is securely clamped or held in place to prevent it from moving or spinning while drilling. This reduces the risk of accidents or injury caused by the material being drilled.

It’s also crucial to avoid loose clothing, jewelry, or long hair that could get caught in the moving parts of the drill press. Keep your work area clean and free of clutter to minimize potential hazards and distractions. Lastly, familiarize yourself with the drill press’s instructions and safety features before use.

Summary

A radial arm drill press is a cool tool that helps us make holes in things. It has a long arm that moves up and down, and a spinning drill bit. We can use it to make holes in wood, metal, and other materials. It’s important to be careful and follow safety rules when using a drill press. Remember to always wear safety goggles and keep your fingers away from the moving parts. Whether you’re building something or fixing things around the house, a radial arm drill press can be a handy tool to have.