Are you curious about what a semi chisel chain is? Well, you’ve come to the right place! Let me break it down for you in a way that’s easy to understand.

Imagine you have a chainsaw—a powerful tool that cuts through wood with ease. Now, picture the chain that wraps around the blade of the chainsaw. That’s the key component we’re talking about here—the chain.

A semi chisel chain is a specific type of chainsaw chain that has unique features. It’s designed to strike a balance between cutting efficiency and durability. This means it can handle a variety of cutting tasks, from light to heavy-duty, without wearing out too quickly. Cool, right?

Now that you have a basic idea of what a semi chisel chain is, let’s dive deeper into its characteristics and advantages. Ready to learn more? Let’s get started!

What is a Semi Chisel Chain? Explained in Detail

When it comes to chainsaws, a key component that plays a crucial role in the cutting process is the chainsaw chain. Different chainsaw chains are designed for specific purposes and cutting applications. One such type is the semi chisel chain, which offers a balance between cutting performance and durability. In this article, we will delve into the details of what exactly a semi chisel chain is, how it works, its advantages, and some tips for using it effectively.

1. Understanding the Semi Chisel Chain

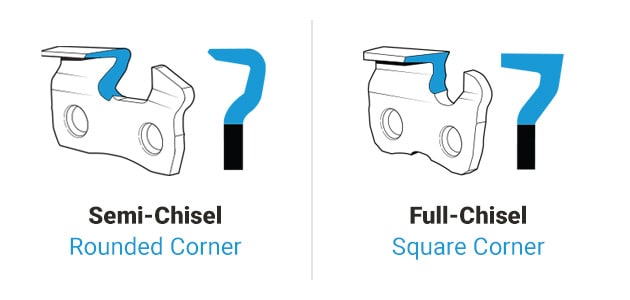

The semi chisel chain is a type of chainsaw chain that features a hybrid design, combining the features of both a full chisel chain and a low-profile chain. It is characterized by its alternating rounded-corner, square-corner cutter teeth, giving it the name “semi chisel.” These teeth are located on every second drive link, allowing for efficient cutting performance while also maintaining durability.

The semi chisel chain is known for its versatility, making it suitable for a wide range of cutting applications. It is commonly used by homeowners, farmers, and professional loggers for tasks such as limbing, pruning, and felling small to medium-sized trees. The design of the semi chisel chain also facilitates smooth cutting through both soft and hardwood materials.

This type of chain is available in various pitch and gauge sizes, which should be selected based on the specific chainsaw model and the intended cutting requirements. Choosing the right size ensures optimal performance and prevents premature wear and tear of the chain.

2. Benefits of Using a Semi Chisel Chain

There are several advantages to using a semi chisel chain over other types of chainsaw chains:

Durable and Long-Lasting:

One of the main benefits of a semi chisel chain is its durability. The rounded-corner teeth reduce the risk of chipping and breaking, allowing the chain to withstand tougher cutting conditions. This type of chain also retains its sharpness for a longer period, reducing the need for frequent sharpening or replacement.

Less Kickback:

Safety is a top priority when working with chainsaws, and the semi chisel chain offers a reduced risk of kickback compared to a full chisel chain. The rounded-corner teeth are less prone to “grabbing” the wood, minimizing the chances of the saw being forcefully pushed back towards the operator.

Efficient Cutting Performance:

The combination of square-corner and rounded-corner teeth on a semi chisel chain allows for efficient cutting performance. The square corners provide aggressive cutting action, while the rounded corners help to maintain the chain’s stability and reduce vibration, resulting in smoother and faster cuts.

Versatile:

A semi chisel chain is suitable for a wide range of cutting tasks, making it a versatile choice for both professional and occasional users. Whether you’re working on softwoods or hardwoods, the semi chisel chain can handle the job effectively.

3. Tips for Using a Semi Chisel Chain

To ensure optimal performance and longevity of a semi chisel chain, consider the following tips:

Maintain Proper Chain Tension:

Regularly check the tension of the chain to ensure it is properly aligned with the guide bar. A loose chain can lead to poor cutting performance and increase the risk of accidents.

Keep the Chain Sharp:

A sharp chain is essential for effective cutting. Regularly sharpen the chain using a suitable file or chain sharpener to maintain its cutting efficiency.

Proper Lubrication:

Ensure that the chain is adequately lubricated to reduce friction and heat buildup. Utilize a high-quality chainsaw bar oil to keep the chain running smoothly.

Practice Safe Operation:

Always follow proper safety precautions when operating a chainsaw. Wear appropriate protective gear, maintain a stable stance, and be aware of your surroundings.

Semi Chisel Chain: Versatility and Performance Combined

The semi chisel chain offers the best of both worlds in terms of cutting performance and durability. Its hybrid design allows for efficient cutting through different types of wood while also providing enhanced durability and reduced kickback. By following the tips mentioned above, you can maximize the performance and lifespan of your semi chisel chain for successful cutting operations. Remember to choose the correct pitch and gauge for your chainsaw model and cutting requirements, and always prioritize safety during operation. With the right maintenance and proper usage, the semi chisel chain can be an invaluable tool in your chainsaw arsenal.

The Anatomy of a Semi Chisel Chain

Before we jump into the benefits and applications of a semi chisel chain, it’s important to understand its anatomy. A semi chisel chain is composed of various components that work together to facilitate efficient and clean cutting. Let’s explore the different parts that make up this versatile chainsaw chain.

1. Drive Links

The drive links are the sections of the chain that fit into the guide bar’s groove and engage with the chainsaw’s drive sprocket. These links provide the power to rotate the chain, enabling it to cut through wood effectively.

On a semi chisel chain, the drive links alternate with the cutter teeth. This spacing allows for balance between cutting power and stability.

2. Cutter Teeth

The cutter teeth are the sharp components of the chain that make contact with the wood being cut. In a semi chisel chain, the cutter teeth are designed with a combination of square corners and rounded corners.

The square corners provide aggressive cutting action, making it easier to penetrate the wood. The rounded corners, on the other hand, help to reduce vibration, increase stability, and minimize the chances of the chain getting stuck or snagging in the wood.

3. Depth Gauges

The depth gauges, also known as the rakers, are the small projections located in front of each cutter tooth. Their purpose is to determine the depth of the cut made by the tooth.

The depth gauges need to be properly filed to ensure the correct depth of the cut. If the depth gauges are too high, it will result in a more aggressive cutting action, while if they are too low, the chain may not cut effectively or even dive into the wood, increasing the risk of kickback.

4. Tie Straps

The tie straps are the components that connect the cutter teeth to the drive links, holding the chain together. They play a crucial role in maintaining the integrity and strength of the chain, ensuring it stays securely and tightly wrapped around the guide bar.

5. Lubrication Holes

Most chainsaw chains, including semi chisel chains, have lubrication holes or slots located on the drive links. These holes allow oil to be distributed to the chain and guide bar during operation, reducing friction and preventing overheating.

Proper lubrication is essential for the longevity and performance of the chain, as it helps to minimize wear and tear and improve cutting efficiency.

Common Applications of Semi Chisel Chains

Now that you have a good understanding of what a semi chisel chain is and its anatomy, let’s explore some common applications where this type of chainsaw chain excels:

1. Limbing and Pruning

The semi chisel chain’s versatility makes it an excellent choice for limb removal and pruning tasks. Its ability to cut through both softwoods and hardwoods with efficiency and precision allows for smooth and controlled cuts, making limb removal and pruning a breeze.

2. Small to Medium-sized Tree Felling

For those working on small to medium-sized tree felling projects, a semi chisel chain can be the ideal option. It offers a balance between cutting performance and durability, allowing for efficient cutting through both thick and thin wood.

The reduced risk of kickback and the ability to handle various cutting conditions make the semi chisel chain a reliable choice for tree felling.

3. DIY Woodworking

If you’re engaged in DIY woodworking projects, a semi chisel chain can be a valuable tool. Its versatility enables clean and precise cuts on different types of wood, making it suitable for tasks such as crafting furniture, making sculptures, or building structures.

Whether you’re working with softwoods like pine or hardwoods like oak, a semi chisel chain will help you achieve accurate and professional-looking results.

Key Takeaways: What is a Semi Chisel Chain?

- A semi chisel chain is a type of chainsaw chain commonly used for cutting wood.

- It has teeth that are curved, with rounded edges, providing a good balance between cutting speed and durability.

- Compared to a full chisel chain, a semi chisel chain is less prone to dulling and can withstand harsh conditions better.

- It is versatile and suitable for various cutting tasks, including pruning, felling trees, and cutting firewood.

- A semi chisel chain provides good cutting performance in different wood types, such as both softwood and hardwood.

Frequently Asked Questions

A semi chisel chain is an important component of a chainsaw. It has a unique design that offers a balance between performance and durability. If you’re curious about semi chisel chains and how they work, check out these common questions and answers:

Q1: How does a semi chisel chain differ from other chainsaw chains?

A semi chisel chain has rounded cutting teeth that are more durable compared to a full chisel chain. The rounded design allows for better performance in demanding cutting conditions such as dirty or frozen wood. However, it sacrifices a bit of cutting speed compared to a full chisel chain.

Unlike a full chisel chain, a semi chisel chain is less prone to kickback. This makes it a safer option for novice chainsaw users or when working in challenging environments. Overall, a semi chisel chain offers a good compromise between cutting speed, durability, and safety.

Q2: When should I use a semi chisel chain?

A semi chisel chain is suitable for a variety of cutting tasks. It is ideal for general-purpose cutting, such as trimming trees, cutting firewood, or pruning branches. Additionally, the design of a semi chisel chain allows it to handle dirty or frozen wood more effectively than a full chisel chain.

If you are uncertain about the type of chain to use, a semi chisel chain is a safe choice that can handle most cutting tasks. However, for specialized jobs that require maximum cutting speed, a full chisel chain may be more appropriate.

Q3: How do I maintain a semi chisel chain?

To keep a semi chisel chain in good working condition, regular maintenance is necessary. After each use, clean the chain with a brush or compressed air to remove debris. It’s important to inspect and replace any damaged or worn-out cutting teeth.

Additionally, ensure the chain tension is properly adjusted according to the manufacturer’s instructions. Lubricate the chain with bar and chain oil to reduce friction and prevent overheating. Proper maintenance will help extend the lifespan of your semi chisel chain and improve cutting performance.

Q4: Can I sharpen a semi chisel chain myself?

Yes, you can sharpen a semi chisel chain yourself if you have the right tools and knowledge. It’s recommended to use a round file and a filing guide designed specifically for semi chisel chains. Follow the manufacturer’s instructions for the correct angle and technique.

If you’re unsure about sharpening the chain yourself, it’s best to seek assistance from a professional or take it to a chainsaw service center. Proper sharpening is crucial to maintain the cutting performance and safety of a semi chisel chain.

Q5: Can I use a semi chisel chain on any chainsaw?

In most cases, a semi chisel chain is compatible with a wide range of chainsaw models. However, it’s important to ensure that the chain is the correct pitch, gauge, and length for the specific chainsaw you are using.

Refer to the chainsaw manufacturer’s guidelines or consult the user manual to determine the suitable chain specifications. Using a properly fitted semi chisel chain will ensure optimal performance and reduce the risk of accidents.

Summary

So, what is a semi chisel chain? It’s a type of chainsaw chain with rounded teeth that stay sharp for longer, making it great for tough jobs. They’re not as aggressive as full chisel chains, but they’re more durable and easier to maintain. Semi chisel chains are commonly used by homeowners and professionals for general cutting tasks and are a good option for cutting dirty or frozen wood. Remember to choose the right chain for your chainsaw to ensure optimal performance and safety. Happy cutting!