What is a turret lathe used for? Well, let me tell you. Turret lathes are like superheroes of the machining world. They are powerful machines that can shape and transform raw materials into precision-engineered parts. But what exactly do they do?

Picture this: you have a stack of metal rods, and you need to cut, drill, and shape them into various components. A turret lathe is the go-to machine for this job. It uses a rotating turret that holds different cutting tools and allows them to be quickly switched out. This means you can perform multiple operations on a workpiece without having to manually change the tools. Pretty cool, right?

Turret lathes are commonly used in industries like automotive, aerospace, and manufacturing, where precision and efficiency are key. They can create intricate shapes, threads, and contours with utmost accuracy, ensuring that every piece fits together perfectly. So, if you ever wondered how those complex parts are made, chances are a turret lathe played a crucial role in their creation.

The Versatility and Importance of Turret Lathes

Have you ever wondered what a turret lathe is and what it is used for? Turret lathes, also known as capstan lathes, are invaluable machines in the world of manufacturing and machining. They offer precise and efficient turning operations that are essential in producing a wide range of products. In this article, we will explore the various applications of turret lathes and delve into why they are considered a fundamental tool in the manufacturing industry.

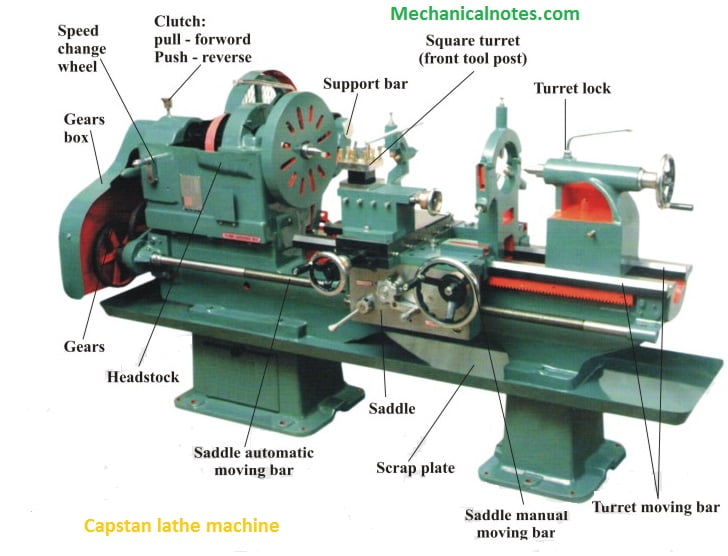

The Basics of a Turret Lathe

A turret lathe is a type of lathe machine that incorporates a turret tooling system. This system allows for quick and easy tool changes, significantly reducing the time required for machining operations. The turret is typically mounted on the lathe bed and holds a variety of cutting tools, which can be indexed into position for use. This feature eliminates the need for manual tool changes, making turret lathes highly efficient for repetitive work.

Turret lathes are known for their ability to perform both turning and milling operations. They have a horizontally mounted spindle that rotates the workpiece while the cutting tool moves along the length of the workpiece to shape it. Turret lathes can handle a wide range of materials, including metal, plastic, and wood, making them suitable for various industries.

These machines are classified based on the number of turrets they have: single-turret lathes and multi-turret lathes. Single-turret lathes have one turret with multiple stations for different tools. On the other hand, multi-turret lathes have multiple turrets, each with its own set of tools. The number of turrets determines the complexity and versatility of the machining operations that can be performed.

Applications of Turret Lathes

The versatility of turret lathes makes them indispensable in numerous industries. Here are some of the key applications of turret lathes:

- Automotive Industry: Turret lathes play a crucial role in the manufacture of automotive components such as engine parts, brake components, and transmission parts. They can efficiently machine complex shapes and contours, ensuring precise and high-quality components.

- Aerospace Industry: Turret lathes are extensively used in the production of aircraft components, such as landing gear parts, engine components, and airframe components. They enable the machining of precision parts that meet the stringent requirements of the aerospace industry.

- Medical Industry: Turret lathes are utilized in the production of medical devices and equipment, including orthopedic implants, surgical instruments, and prosthetics. The ability to create intricate and precise parts is essential for maintaining the high standards required in the medical field.

- Electronics Industry: In the electronics industry, turret lathes are employed to manufacture connectors, terminals, and other precision components that are vital for various electronic devices. The accuracy and repeatability of turret lathes ensure that the electrical connections are reliable and consistent.

These are just a few examples of the many applications of turret lathes. Their flexibility, speed, and accuracy make them an indispensable tool in the manufacturing world. The ability to perform multiple machining operations in a single setup significantly improves efficiency and reduces production time.

Advantages of Using Turret Lathes

Turret lathes offer several advantages that make them the preferred choice for many machining operations:

- Reduced setup time: The turret tooling system allows for quick and easy tool changes, minimizing setup time and increasing productivity.

- Increased precision: Turret lathes are known for their accuracy and repeatability, ensuring consistent and precise results.

- Versatility: Turret lathes can perform both turning and milling operations, eliminating the need for separate machines and reducing production costs.

- Efficiency: The ability to index multiple tools into position eliminates the need for manual tool changes, resulting in faster machining and increased efficiency.

- Cost-effectiveness: Turret lathes offer a cost-effective solution for high-volume production, as they can produce large quantities of components in a shorter time frame.

The benefits of turret lathes make them an essential tool for manufacturers who aim to optimize their production processes and achieve high-quality results.

The Future of Turret Lathes in the Manufacturing Industry

As technology advances, the role of turret lathes in the manufacturing industry continues to evolve. The integration of computer numerical control (CNC) technology has further enhanced the capabilities of turret lathes, allowing for even more precise and complex machining operations.

CNC turret lathes offer increased automation, improved programming capabilities, and greater control over the machining process. They can be programmed to perform intricate operations with minimal human intervention, resulting in higher productivity and reduced errors. With the ongoing advancements in CNC technology, turret lathes are poised to play an even more significant role in the future of manufacturing.

The Importance of Turret Lathes in Today’s Manufacturing World

In conclusion, turret lathes are versatile machines that are vital to the manufacturing industry. Whether it is producing automotive components, aerospace parts, medical devices, or electronic components, turret lathes offer precise and efficient machining capabilities. Their ability to perform multiple operations in a single setup, along with their accuracy and repeatability, make them an essential tool for manufacturers striving for quality and efficiency. With the advancements in technology, we can expect turret lathes to continue playing a crucial role in shaping the future of manufacturing.

What is a Turret Lathe Used For?

- A turret lathe is a machine used in metalworking.

- It is used to shape or cut metal objects with precision.

- It has a rotating tool turret that holds different cutting tools.

- These cutting tools can be easily changed to perform various operations.

- Turret lathes are commonly used in industries like manufacturing and engineering.

Frequently Asked Questions

Are you curious about the uses of a turret lathe? Look no further! We’ve got the answers to all your questions. Below, you’ll find information on the various applications and benefits of this versatile machine.

Q: How is a turret lathe different from a regular lathe?

A: A turret lathe is a type of lathe that features a turret, which holds multiple tools and can be rotated to quickly select and change between them. Unlike a regular lathe, where each tool must be individually changed, a turret lathe allows for faster and more efficient machining processes. This makes it ideal for high-volume production and complex operations.

A turret lathe is also capable of performing multiple operations simultaneously, such as turning, drilling, boring, and threading, which saves time and increases productivity. Additionally, with the turret’s ability to hold multiple tools, operators can easily switch between different tasks without having to stop the machine and manually change the tooling.

Q: What are the main applications of a turret lathe?

A: Turret lathes are commonly used in industries that require high precision and speed, such as aerospace, automotive, and manufacturing. They are ideal for producing parts with complex geometries, such as shafts, bushings, and connectors.

Due to their versatility, turret lathes can perform a wide range of operations, including turning, facing, drilling, boring, threading, and grooving. Their ability to handle multiple tasks in a single setup makes them highly efficient and cost-effective for large-scale production.

Q: How does a turret lathe improve efficiency in manufacturing?

A: Turret lathes offer several advantages that enhance efficiency in manufacturing. Firstly, the turret’s ability to hold multiple tools eliminates the need to manually change tools between operations, reducing downtime and increasing productivity.

Secondly, turret lathes are designed for high-speed machining, allowing for rapid production of precision parts. Their ability to perform multiple operations simultaneously further speeds up the manufacturing process. Overall, the combination of speed, versatility, and automation makes turret lathes invaluable for increasing efficiency and reducing production time in manufacturing.

Q: What are the benefits of using a turret lathe?

A: The use of a turret lathe offers numerous benefits to manufacturers. One of the main advantages is the ability to produce complex parts with high precision and accuracy. The turret’s tool rotation and indexing capabilities ensure consistent and repeatable results.

Additionally, turret lathes improve efficiency and productivity due to their quick tool change capabilities and the ability to perform multiple operations at once. This saves time, reduces labor costs, and increases output. Furthermore, the versatility of a turret lathe allows for a wide range of applications, making it a valuable asset in various industries.

Q: Can a turret lathe be automated?

A: Yes, turret lathes can be automated to further optimize production processes. Automation can include the use of robotic systems for loading and unloading parts, as well as integrating the lathe with computer numerical control (CNC) systems for precise control and monitoring of operations.

By automating a turret lathe, manufacturers can achieve even higher levels of efficiency, minimize human error, and increase the overall production capacity. Additionally, automation allows for lights-out manufacturing, where the lathe can run autonomously without constant human supervision, further maximizing productivity and cost-effectiveness.

Summary

A turret lathe is a machine that helps make round parts with precision. It has a rotating tool holder called a turret, which holds different cutting tools. This allows the lathe to cut, drill, and shape metal or other materials in different ways. Turret lathes are commonly used in manufacturing industries to create things like screws, bolts, and other cylindrical components. They are important because they can work quickly and accurately, saving time and ensuring quality in production. So, if you ever wonder how those tiny bolts and screws are made, now you know! It’s all thanks to the handy turret lathe.