If you’ve ever wondered, “What is a vertical bandsaw used for?” then you’re in the right place! This handy tool is like a superhero in the world of cutting and shaping materials. A vertical bandsaw is a type of saw that has a blade running vertically, allowing you to make precise and intricate cuts with ease.

But wait, there’s more! This powerful machine is commonly used in woodworking, metalworking, and even in the creation of musical instruments. Whether you’re a DIY enthusiast or a professional craftsman, the vertical bandsaw is here to save the day, making your cutting tasks simpler and more efficient.

So, get ready to dive into the world of the vertical bandsaw and discover its wonders. From its versatile applications to the benefits it brings, we’ll explore all there is to know about this incredible tool. Let’s get started!

What is a Vertical Bandsaw Used For?

The Basics of a Vertical Bandsaw

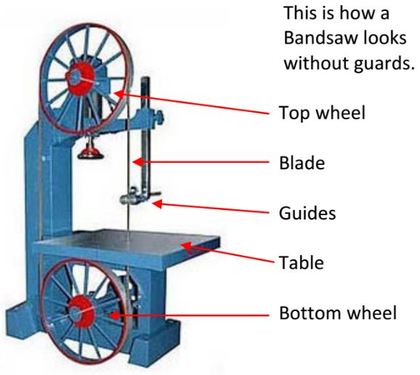

A vertical bandsaw is a versatile cutting tool that uses a continuous metal blade with teeth on one edge to make precision cuts in various materials. It is called a “vertical” bandsaw because the cutting action occurs in a vertical direction. The machine consists of a worktable and a blade that moves up and down on a pulley system, allowing it to cut through materials placed on the table.

Vertical bandsaws are commonly used in industries like woodworking, metalworking, and fabrication. They are designed to handle a wide range of materials, including wood, metal, plastic, and other composites. These machines are highly efficient and precise, making them ideal for intricate cutting tasks.

Whether you’re a professional craftsman or a DIY enthusiast, a vertical bandsaw can be a valuable addition to your workshop. Let’s explore the various applications and benefits of using a vertical bandsaw.

Applications of Vertical Bandsaws

1. Woodworking: In the woodworking industry, vertical bandsaws are used for cutting curves, resawing lumber into thinner pieces, creating intricate shapes, and making precise cuts in various types of wood. These saws are especially useful for creating furniture, sculptures, musical instruments, and other detailed woodwork.

2. Metalworking: Vertical bandsaws are commonly used in metalworking shops for cutting metal rods, bars, tubes, and other profiles. They are highly efficient when it comes to making straight, curved, or angled cuts in metal materials. These saws are essential for fabricating metal parts and components, as well as for general metal shaping and cutting tasks.

3. Plastic and Composite Materials: Vertical bandsaws are also widely used in industries that work with plastic and composite materials. The saw’s ability to make precise cuts makes it ideal for cutting plastic sheets, PVC pipes, fiberglass, and other composite materials used in construction, signage, and various manufacturing processes.

4. DIY and Home Improvement: Vertical bandsaws are not just limited to professional workshops; they can also be great tools for DIY enthusiasts and hobbyists. These saws are useful for making detailed cuts in wood, metal, and plastic materials for various home improvement projects, crafting, and model making. They offer enhanced precision and control compared to other cutting tools, making them a favorite among hobbyists.

The Benefits of Using a Vertical Bandsaw

1. Precision: Vertical bandsaws are known for their precise cutting capabilities. With the ability to make intricate cuts and angles, they offer a high level of accuracy for creating detailed workpieces.

2. Versatility: The vertical bandsaw is compatible with various materials, including wood, metal, plastic, and composites. This versatility makes it a valuable tool for professionals in different industries.

3. Efficiency: Vertical bandsaws are efficient machines that can handle a range of cutting tasks quickly. They save time and effort compared to manual cutting methods, making them essential in production and manufacturing environments.

4. Safety: These saws are designed with safety features to protect the operator from potential injuries. Blade guards, emergency stop buttons, and automatic shut-off systems ensure a safe working environment.

5. Easy to Use: Vertical bandsaws are user-friendly machines that can be operated by both professionals and beginners. With proper training and guidance, anyone can learn to safely and efficiently operate a vertical bandsaw.

Tips for Using a Vertical Bandsaw

1. Wear safety equipment, including safety glasses, protective gloves, and appropriate clothing, to protect yourself from potential hazards.

2. Choose the right blade for the material you are cutting. Different blades are designed for specific materials, ensuring optimal performance and cleaner cuts.

3. Make sure the material is securely clamped to the worktable before making any cuts. This will prevent the material from moving or vibrating while cutting.

4. Take your time and avoid rushing the cutting process. Slow and steady movements will yield better results and minimize the risk of accidents.

5. Regularly inspect the blade for wear and tear, and replace it if necessary. A dull or damaged blade can compromise the quality of your cuts and affect overall performance.

The Advantages of a Vertical Bandsaw versus a Horizontal Bandsaw

The vertical bandsaw and the horizontal bandsaw are two different types of bandsaws that vary in their cutting direction and functionality. While both are valuable tools, the vertical bandsaw offers several unique advantages:

1. Vertical bandsaws can accommodate larger workpieces due to their vertical cutting action. Their design allows for greater versatility and the ability to make cuts on larger materials.

2. Vertical bandsaws are more precise when it comes to intricate curved cuts. The vertical cutting motion offers better control and maneuverability.

3. Vertical bandsaws are often more compact and take up less space compared to horizontal bandsaws. This makes them a suitable choice for small workshops or limited workspace.

Conclusion

A vertical bandsaw is a versatile tool that finds applications in various industries, including woodworking, metalworking, and fabrication. Its ability to make precise cuts in a wide range of materials makes it a valuable asset to professionals, hobbyists, and DIY enthusiasts. From cutting curves in wood to shaping metal parts, the vertical bandsaw offers efficiency, versatility, and safety. By following safety tips and choosing the right blade for your project, you can make the most out of this powerful cutting tool.

Key Takeaways: What is a Vertical Bandsaw Used For?

- A vertical bandsaw is a machine used to cut various materials, such as wood, metal, and plastic.

- It has a vertically oriented blade, allowing for precision cuts and the ability to create intricate shapes.

- Vertical bandsaws are commonly used in woodworking, metalworking, and fabrication shops.

- They are ideal for cutting curves, bevels, and intricate designs in different materials.

- Vertical bandsaws offer the advantage of a fixed worktable, making it easier to control and guide the material being cut.

Frequently Asked Questions

Welcome to our FAQ section, where we answer your burning questions about vertical bandsaws!

1. How does a vertical bandsaw work?

A vertical bandsaw consists of a continuous, toothed metal blade that runs vertically between two wheels. The blade moves in a continuous loop and is guided by the wheels, allowing it to cut through various materials. When the machine is turned on, the blade spins, and the material to be cut is fed into it vertically. Unlike other saws, the vertical bandsaw allows for intricate and curved cuts due to the blade’s design and motion.

With its versatility, a vertical bandsaw is capable of cutting through wood, metal, plastics, and other materials, making it a must-have tool for any workshop or manufacturing setting.

2. What are the main uses of a vertical bandsaw?

A vertical bandsaw is a highly versatile tool that finds applications in various industries. It is commonly used for tasks such as cutting irregular shapes, making curved cuts, or slicing thin materials. Woodworkers often rely on vertical bandsaws for intricate cuts in furniture making or creating unique craft pieces.

In metalworking, vertical bandsaws excel in cutting various metal profiles like pipes, bars, or sheets, thanks to the blade’s downward cutting motion. It is also a popular choice for hobbyists and DIY enthusiasts who require precision cutting of different materials for their projects.

3. Can a vertical bandsaw cut through thick materials?

Yes, a vertical bandsaw is capable of cutting through materials of varying thickness. However, the cutting capacity of a vertical bandsaw depends on the specific model and its blade size. Some vertical bandsaws have a smaller throat depth, limiting the thickness of the material they can cut.

When choosing a vertical bandsaw, consider the maximum cutting capacity it offers to ensure it meets your requirements. If you anticipate cutting thicker materials frequently, opting for a bandsaw with a larger throat depth and a more powerful motor is advisable.

4. How safe is it to use a vertical bandsaw?

Using a vertical bandsaw can be safe if proper precautions are taken. It is crucial to follow recommended safety guidelines, including wearing safety glasses, using push sticks or a vice to secure the material, and keeping fingers away from the blade’s path.

Additionally, maintaining the saw properly, ensuring the blade is tensioned correctly and in good condition, and having a clean and organized work area can contribute to a safer woodworking environment. Taking precautions and being aware of the machinery’s potential risks are essential for a safe and enjoyable bandsaw experience.

5. Can a vertical bandsaw be used for resawing?

Yes, a vertical bandsaw is commonly used for resawing, which is the process of cutting a board into thinner, parallel slices. By adjusting the blade tension and employing specialized guides, a vertical bandsaw can slice through a thick piece of wood or other materials, creating multiple thinner boards.

Resawing with a vertical bandsaw allows woodworkers to maximize the use of raw materials, create veneers, or obtain thinner boards for specific projects. It can save money and provide greater flexibility in woodworking projects where thinner pieces of material are required.

Summary

A vertical bandsaw is a handy tool that helps cut different materials like wood and metal. Its main job is to make straight and curved cuts with precision. By adjusting the blade’s speed and tension, you can cut through a variety of thicknesses and shapes. It’s like having a powerful puzzle piece cutter that saves time and effort!

Using a vertical bandsaw requires careful attention to safety. Always wear protective gear and make sure to keep your hands away from the blade. With practice and proper guidance, a vertical bandsaw can become an essential tool for any DIY enthusiast or professional in need of accurate and clean cuts.