What is an engine lathe? If you’ve ever wondered how things like screws, bolts, and other cylindrical objects are made, an engine lathe is an important tool in that process. It’s like a superstar in the world of machining! So, let’s dive in and explore the fascinating world of engine lathes together!

Engine lathes are powerful machines that can shape metal into various cylindrical shapes with exceptional precision. They are like the magician’s wand for skilled machinists, allowing them to turn raw materials into finely crafted components. With its spinning action and cutting tools, an engine lathe can carefully remove layers of material, transforming a rough piece into a perfectly smooth and symmetrical work of art in no time!

Imagine being able to create your own unique designs and shapes with incredible accuracy. Engine lathes enable machinists to unleash their creativity and bring their ideas to life. Whether it’s creating intricate patterns, threading screws, or making cylindrical objects of different sizes, an engine lathe is a versatile tool that can handle a wide range of tasks.

So, if you’re curious about how things are made or interested in the world of machining, understanding what an engine lathe can do is like opening the door to a whole new world of possibilities. With this powerful tool in the hands of skilled machinists, there’s no limit to what can be created!

Exploring the Versatility of an Engine Lathe

An engine lathe is a versatile tool that is widely used in machining and manufacturing processes. Whether you are a hobbyist or a professional, understanding what an engine lathe is and how it works can greatly benefit your work. In this article, we will dive into the details of an engine lathe, exploring its functionality, applications, and advantages. Let’s embark on this journey to discover the wonders of the engine lathe.

What is an Engine Lathe?

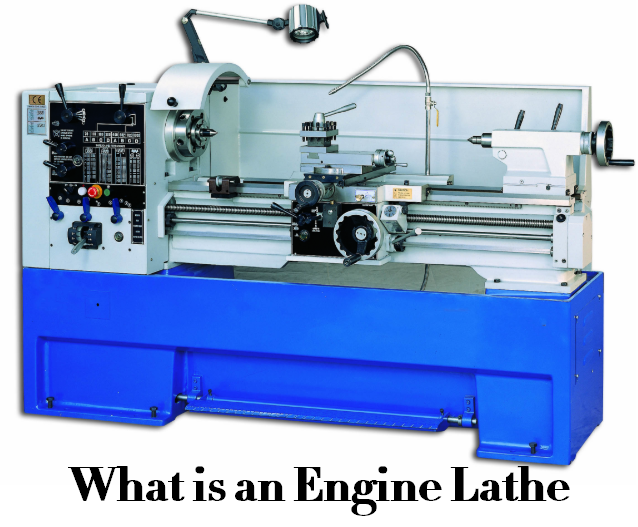

An engine lathe is a type of lathe machine that is used to shape and cut metal materials. It has been around for centuries and has evolved with modern technology. The main function of an engine lathe is to rotate a workpiece while cutting, shaping, or drilling it with various cutting tools. It is a fundamental tool in workshops, manufacturing facilities, and even educational institutions.

Engine lathes come in different sizes, ranging from small benchtop models to large industrial-grade machines. They consist of various components, including a bed, headstock, tailstock, carriage, and toolpost. The key feature of an engine lathe is its ability to perform precise and intricate operations on the workpiece, such as turning, facing, threading, and tapering.

With the advancement of technology, modern engine lathes often incorporate computer numerical control (CNC) systems, enhancing their precision, automation, and versatility. CNC engine lathes allow for programmable operations, reducing human error and increasing productivity.

The Functionality and Versatility of an Engine Lathe

Engine lathes offer a wide range of functionalities, making them an indispensable tool in various industries. Here are some of the key functions and applications of an engine lathe:

- Turning: The primary function of an engine lathe is to perform turning operations. This involves rotating the workpiece and using cutting tools to remove material and create cylindrical shapes. Engine lathes can turn both external and internal surfaces, allowing for the production of precise and symmetrical parts.

- Facing: An engine lathe can be used to create flat surfaces on the workpiece, a process known as facing. By using the cross-slide and the toolpost, the lathe operator can move the cutting tool across the workpiece, resulting in a smooth and even surface.

- Threading: With the help of specialized threading tools, an engine lathe can cut threads on the workpiece, allowing for the creation of screw threads. This is particularly useful in applications where threaded parts are required, such as in the production of nuts, bolts, and fasteners.

- Tapering: Engine lathes are also capable of creating tapered surfaces. By adjusting the position of the toolpost, the lathe operator can create gradual or steep tapers, depending on the desired specifications.

- Drilling: Although drilling is typically associated with drilling machines, engine lathes can also perform drilling operations. With the addition of a drill chuck or drill bit holder, the lathe can bore holes in the workpiece.

The versatility of an engine lathe is further enhanced by the wide range of cutting tools and attachments that can be used. From turning tools, parting tools, and threading tools to special-purpose attachments like steady rests and follower rests, an engine lathe can handle various machining tasks with precision and efficiency.

Advantages of Using an Engine Lathe

There are several advantages to using an engine lathe in machining and manufacturing processes:

- Flexibility: Engine lathes offer a high degree of flexibility, allowing for the production of a wide range of parts and components. With the ability to handle different sizes of workpieces and perform various operations, an engine lathe eliminates the need for multiple machines, saving both space and cost.

- Accuracy: Engine lathes provide great precision and accuracy in machining operations. The operator has full control over the speed, feed rate, and depth of cut, ensuring that the desired dimensions and specifications are met.

- Customization: An engine lathe allows for customization and the creation of unique parts. Whether it’s creating complex shapes or adding intricate details, an engine lathe provides the flexibility to bring imagination to reality.

- Cost-effective: Despite being a versatile and powerful tool, engine lathes are relatively affordable compared to other machining equipment. They are cost-effective solutions for small businesses, educational institutions, and hobbyists.

- Learning tool: Engine lathes are widely used in machining education and training programs. They provide a hands-on experience and allow learners to understand the principles of metalworking and machining processes.

In conclusion, an engine lathe is a vital tool in the world of machining and manufacturing. Its versatility, functionality, and precision make it an indispensable asset in various industries. Whether you’re a professional machinist or an aspiring hobbyist, an engine lathe can elevate your craft and bring your creations to life.

Key Takeaways: What is an Engine Lathe?

- An engine lathe is a machine used to shape and cut metal.

- It is commonly used in manufacturing and machining industries.

- The lathe rotates the workpiece while a cutting tool shapes it.

- Engine lathes can create various shapes and cuts, such as cylindrical, conical, and threading.

- They are versatile machines that can be programmed for precision and efficiency.

Frequently Asked Questions

Curious to know more about engine lathes? Check out these common questions and answers

How does an engine lathe work?

An engine lathe is a machine tool used for shaping and machining cylindrical objects like metal and wood. It operates by holding the workpiece securely in place and rotating it against a cutting tool. The cutting tool removes material from the workpiece, enabling the desired shape or design to be achieved. This process, known as turning, is the primary function of an engine lathe.

The machine’s spindle, driven by a motor, rotates the workpiece at varying speeds, while the cutting tool, mounted on a tool post, moves along the workpiece, cutting away material as required. The operator of the engine lathe uses various controls and adjustments to ensure precise measurements and smooth operation, resulting in accurate turned parts.

What are the main components of an engine lathe?

An engine lathe consists of several key components. The bed, which is a heavy, rigid structure, provides a stable platform for the other parts. It supports the headstock, tailstock, carriage, and tool post. The headstock contains the main spindle and motor, which rotates the workpiece. The tailstock is positioned opposite the headstock and supports the other end of the workpiece. It can be adjusted to secure longer workpieces.

The carriage is a movable component that holds the cutting tool and moves it along the workpiece. It is equipped with controls for moving the tool horizontally and vertically. The tool post, mounted on the carriage, holds the cutting tool securely in place. Other components include the feed rod for controlling the tool’s movement and the chuck or faceplate for securing the workpiece to the spindle. Safety features such as emergency stop buttons and guards are also present.

What are the advantages of using an engine lathe?

Using an engine lathe offers several advantages. Firstly, it allows for precise machining of cylindrical objects with high accuracy. The operator can control factors such as the feed rate, depth of cut, and spindle speed, resulting in accurately shaped and dimensioned parts. Engine lathes are also versatile machines that can handle different materials and produce a variety of shapes and designs.

Additionally, an engine lathe is relatively easy to operate and can be used by both skilled machinists and beginners. With the right training, operators can quickly become proficient in using an engine lathe. Another advantage is the longevity and durability of these machines. Engine lathes are built to withstand heavy usage and can last for many years with proper maintenance.

What are the common applications of an engine lathe?

Engine lathes are widely used in various industries for a range of applications. One common use is in metalworking, where engine lathes are used to shape and turn metal parts and components. They are also used in woodworking to create cylindrical shapes in wooden workpieces. Engine lathes are crucial in the production of shafts, rods, and other cylindrical parts used in machinery and vehicles.

Furthermore, engine lathes are utilized in the repair and maintenance of existing parts. They can be used to restore worn-out components to their original dimensions, extending their lifespan. Engine lathes also play a role in creating prototypes and developing new designs. Overall, their versatility makes them essential tools in various manufacturing and repair processes.

Can an engine lathe be automated?

Yes, an engine lathe can be automated to enhance productivity and streamline operations. Automation can be achieved through the addition of various accessories and components. For example, a computer numerical control (CNC) system can be integrated into an engine lathe to automate the machining process. This allows for precise and repeatable movements of the cutting tool, resulting in increased efficiency and accuracy.

In addition to CNC systems, other automation options include automatic tool changers, parts catchers, and robotic loading systems. These enhancements can reduce manual labor, improve cycle times, and increase overall productivity. Furthermore, automated engine lathes often come with advanced features such as programmable controls, tool monitoring systems, and self-diagnostic capabilities, making them even more efficient and user-friendly.

Summary

An engine lathe is a special machine used to shape and cut metal. It has a spinning motor that rotates the workpiece and different tools to shape it. Lathes are really useful for making precision parts and they come in all sizes, from big ones used in factories to smaller ones you might have at home. Remember, lathes are important tools in manufacturing and can help bring our ideas to life!