Have you ever wondered what an F drill bit is? Well, you’re in the right place! In this article, we’ll explore the fascinating world of F drill bits and demystify their purpose and functionality. So, grab your curiosity and let’s dive in!

Picture this: you’re working on a DIY project or helping your parents with home repairs, and suddenly, you hear the term “F drill bit.” What on earth is that? Don’t worry, it’s not some newfangled gadget from a sci-fi movie. An F drill bit is a specific type of drill bit used for various drilling tasks in woodworking and metalworking projects.

Now, don’t let the name confuse you. F drill bits have nothing to do with the letter F. It’s just a classification system used in the drill bit world to differentiate various sizes and types. So, if you’re wondering about the F drill bit’s unique qualities and how it differs from other drill bits, keep reading because we’ve got you covered!

What is an F Drill Bit?

F drill bits are a type of cutting tool used in drilling machines to create holes in various materials such as metal, wood, plastic, and more. These drill bits are part of the jobber length series, which means they have a longer flute length compared to other types of drill bits, allowing for deeper drilling. The “F” in F drill bit stands for fractional, indicating that these bits are designed to drill holes with diameters measured in fractions of an inch.

The Anatomy of an F Drill Bit

The Shank:

The shank is the part of the F drill bit that is inserted into the drill chuck. It is usually smooth and cylindrical in shape, allowing for a secure grip within the chuck. The shank size can vary depending on the specific drill and chuck size compatibility.

The Flutes:

The flutes are spiral grooves that run along the length of the drill bit. These flutes help to remove excess material and chips from the hole during the drilling process. F drill bits typically have two flutes, although variations with more flutes are also available.

The Point:

The point of an F drill bit is the sharpened tip that initiates the drilling process. It is designed to cut through the material efficiently. The point angle can vary depending on the specific application and material being drilled.

Uses of F Drill Bits

Woodworking:

F drill bits are commonly used in woodworking applications. They are ideal for drilling holes in wooden boards, plywood, and other wood materials. The sharp point and effective chip removal ability allow for precise drilling and clean holes.

Metalworking:

F drill bits are also suitable for drilling through various types of metals, including steel, aluminum, and brass. The high-speed steel construction of these bits ensures durability and heat resistance while drilling through tougher materials.

Plastic and PVC:

Due to their versatility, F drill bits can also be used to drill holes in plastic and PVC materials. The sharp point and distinct flute design prevent the material from cracking or melting during the drilling process.

Tips for Using F Drill Bits

Proper Speed and Feed Rate:

To ensure optimal drilling performance and prevent damage to the drill bit, it is essential to use the appropriate speed and feed rate. Consult the manufacturer’s recommendations or refer to drilling charts for specific guidelines.

Secure Workpiece:

Before drilling with an F drill bit, always ensure that the workpiece is securely clamped or held in place. This will prevent any unwanted movement or vibrations, resulting in a more accurate and clean hole.

Use Cutting Lubricant:

When drilling through metal or other materials, using a cutting lubricant can improve the drilling process by reducing friction and heat. Apply the lubricant to the drill bit and the area being drilled for smoother and more efficient drilling.

Frequent Chip Removal:

During drilling, it is crucial to regularly remove the chips and debris from the hole. These can accumulate and impede the drilling progress or cause the drill bit to overheat. Use compressed air or a brush to clear the chips as needed.

Dressing the Point:

Over time, the point of an F drill bit can become dull or chipped, affecting its drilling performance. To maintain optimal results, periodically dress or sharpen the point using a grinding wheel or a dedicated drill bit sharpener.

Store Properly:

To prolong the lifespan of F drill bits and prevent damage, store them in a designated case or organizer. This will protect the bits from moisture, dust, and other contaminants that can compromise their effectiveness.

In summary, F drill bits are versatile cutting tools used for drilling holes in various materials. They feature a unique design with a fractional size measurement and are commonly used in woodworking, metalworking, and plastic drilling applications. By using these drill bits correctly and following best practices, you can achieve precise and clean holes in your projects. Remember to choose the appropriate speed and feed rate, secure the workpiece, and periodically maintain the drill bits for optimal performance and longevity.

What is an F Drill Bit? – Key Takeaways

- An F drill bit is a type of twist drill bit commonly used in drilling metal and wood materials.

- The letter “F” represents the size of the drill bit, with F being smaller than G but larger than E.

- F drill bits have a diameter between 0.257 and 0.266 inches, making them suitable for various applications.

- They have a standard 118-degree point angle, which provides a balance between cutting efficiency and durability.

- F drill bits are often used in general-purpose drilling tasks and are compatible with most power drill machines.

Frequently Asked Questions

Welcome to our FAQ section on F Drill Bits, a common tool used in various industries. Below, you’ll find answers to some of the most commonly asked questions about F Drill Bits.

1. What materials can I use an F Drill Bit on?

F Drill Bits are versatile and can be used on a wide range of materials such as wood, plastic, and metal. They are particularly useful for drilling into softer materials like wood and plastic, but they can also handle tougher materials like steel. However, it’s important to note that the specific type of F Drill Bit and the drill speed can affect its performance on different materials.

For example, high-speed steel (HSS) F Drill Bits are better suited for drilling through softer materials, while cobalt or carbide-tipped F Drill Bits are more effective on harder materials like stainless steel. It’s always a good idea to refer to the manufacturer’s recommendations and guidelines to ensure you select the appropriate F Drill Bit for the material you plan to work with.

2. How do I choose the right size F Drill Bit?

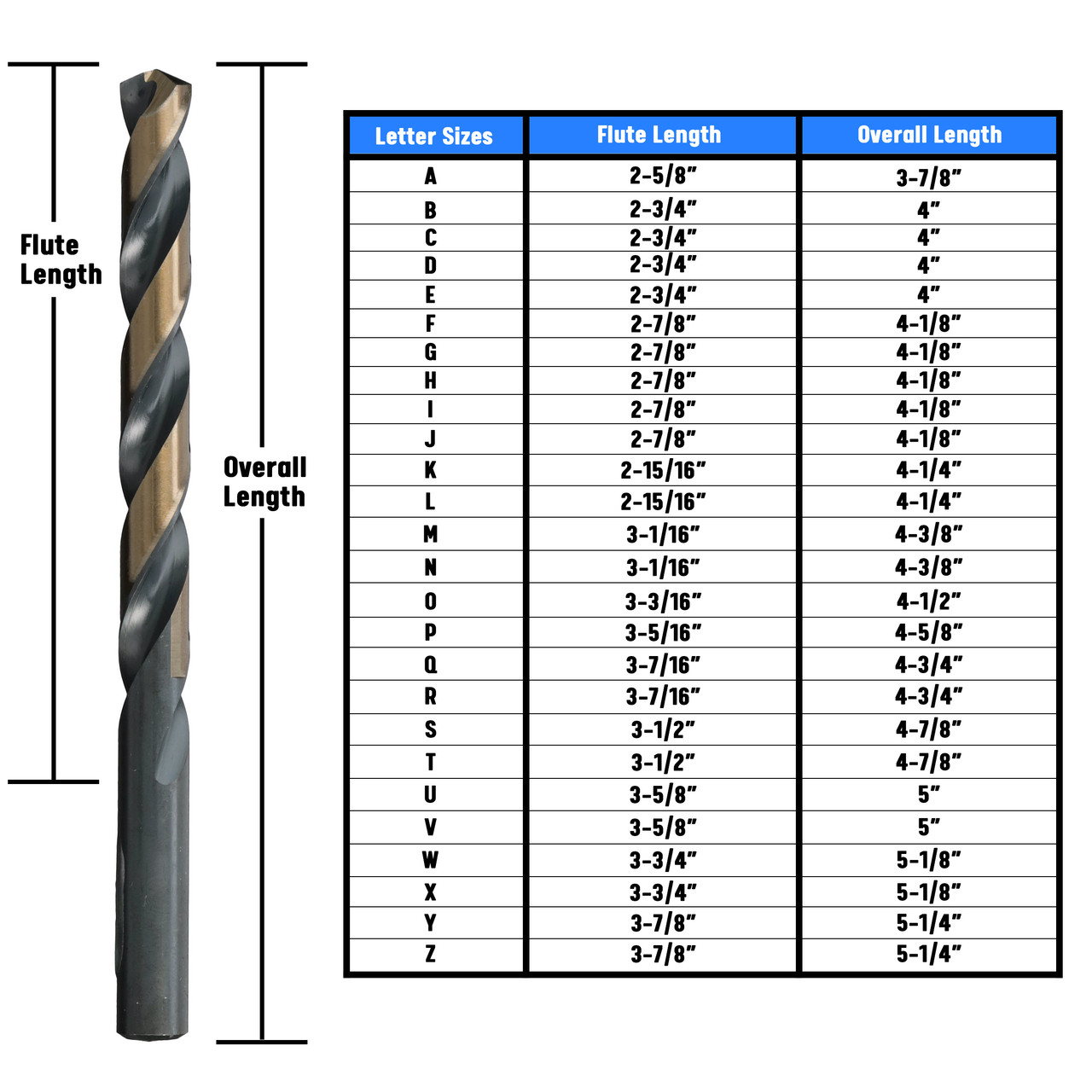

Choosing the right size F Drill Bit depends on the specific application and the hole diameter you need. F Drill Bits are available in various sizes, typically measured in fractions of an inch or in millimeters. To select the right size, consider the material you’re drilling into and the desired hole diameter.

If you’re unsure, you can start by using a drill bit size chart, which provides recommendations based on the material and hole size needed. Keep in mind that F Drill Bits are commonly available in standard sizes, but specialty or custom sizes may need to be ordered. It’s always a good idea to have a variety of drill bit sizes on hand for different projects.

3. Can I use an F Drill Bit on a handheld drill?

Yes, F Drill Bits can be used with both handheld drills and drill presses, depending on the size and type of drill bit. For smaller holes and lighter-duty applications, using an F Drill Bit with a handheld drill can be sufficient. The key is to ensure the drill has enough power and torque to effectively drive the F Drill Bit through the material.

If you’re working with a larger drill bit, drilling through tougher materials, or need more precise control, a drill press may be a better option. A drill press provides greater stability and allows for more accurate drilling. However, it’s important to always follow the manufacturer’s instructions and safety guidelines when using any power tool.

4. How do I maintain and sharpen an F Drill Bit?

To maintain and extend the life of your F Drill Bits, it’s important to keep them clean and sharp. After each use, remove any debris and clean the drill bit using a soft cloth or brush. This helps prevent buildup that can affect the drilling performance.

When it comes to sharpening F Drill Bits, it’s best to leave this task to a professional with the appropriate sharpening equipment. They have the expertise to restore the correct geometry and sharpen the cutting edges to ensure optimal performance. Attempting to sharpen them yourself without the proper knowledge and tools can result in damage to the drill bit and potentially compromise safety.

5. Are F Drill Bits compatible with all drill brands?

Yes, F Drill Bits are generally compatible with most drill brands. They have a standard shank size that fits into the chuck of the drill. However, it’s always a good idea to double-check the compatibility between the drill and the specific F Drill Bit you plan to use, especially if you have a drill with a unique chuck design.

If you’re unsure, consult the drill and F Drill Bit manufacturer’s compatibility charts or reach out to their customer support for guidance. It’s important to ensure a proper fit to prevent any issues during drilling and to optimize performance.

Summary

So, what is an F drill bit? Basically, it’s a type of drill bit that is used to create small holes in various materials. These bits have a specific size and shape, with a diameter of around 0.257 inches. F drill bits are commonly used in woodworking, metalworking, and other crafts. They are known for their versatility and ability to create precise and clean holes. Whether you’re a DIY enthusiast or a professional, understanding the different types of drill bits, including the F drill bit, is essential for successful drilling projects.