What is bandsaw drift? It’s a puzzling phenomenon that can frustrate even the most experienced woodworkers. Picture this: you set your bandsaw fence at an angle, expecting a perfect straight cut, but somehow, the blade veers away from your intended line. How does this happen? Why does the blade have a mind of its own? Well, fear not, young woodworker! In this article, we’ll demystify the concept of bandsaw drift and give you the knowledge to tame this elusive beast.

So, why does bandsaw drift happen? It turns out that bandsaw blades have a tendency to follow their own path, often deviating from the desired line. The factors influencing drift are numerous and can include the blade tension, the blade’s tooth set, and even the type of wood you’re cutting. Think of it like a rebellious teenager who refuses to conform to expectations. But fret not, my curious friend, for we shall unravel the secrets of this maddening phenomenon and equip you with the tools to conquer it.

Now, you might be wondering, why should I care about bandsaw drift at all? Well, my young apprentice, understanding and addressing bandsaw drift are crucial for achieving accurate and precise cuts. Whether you’re a seasoned woodworker or just starting on your sawdust-filled journey, mastering the art of controlling drift will elevate the quality of your work and ensure beautiful, symmetrical pieces. So join me as we journey into the depths of bandsaw drift and discover the secrets to taming this wild beast. Let’s get started!

1. Adjust the blade tension

2. Check and adjust the blade tracking

3. Adjust the guides

4. Check the blade alignment

By following these steps, you can optimize your bandsaw performance and achieve precise cuts with minimal drift. Keep practicing and experimenting to find the perfect setup for your specific bandsaw.

Understanding Bandsaw Drift: What It Is and How It Affects Woodworking

When it comes to woodworking with a bandsaw, one key concept that often puzzles beginners is bandsaw drift. This phenomenon refers to the tendency of a bandsaw blade to veer off course while cutting, resulting in the cut not being parallel to the desired line of cut. Bandsaw drift can be frustrating and can significantly impact the accuracy and quality of your woodworking projects. In this article, we will delve into what bandsaw drift is, the factors that contribute to it, and how you can effectively manage and minimize this issue to achieve precise cuts with your bandsaw.

Understanding the Mechanics: How Bandsaw Drift Occurs

To comprehend bandsaw drift, it is crucial to understand the mechanics behind it. Bandsaw drift is not caused by a flaw in the tool itself but rather by a combination of factors. One key factor is the inherent tension within the bandsaw blade. This tension, along with the interaction between the teeth of the blade and the wood, can cause the blade to veer off course. Additionally, factors such as the amount of set on the teeth, the blade’s condition, and how the wood is being fed into the blade can also contribute to bandsaw drift.

When using a bandsaw, the blade should ideally track in a straight line, perpendicular to the table. However, due to the aforementioned factors, the blade may naturally “drift” towards one side or the other. This can be particularly noticeable when cutting thicker or denser woods. Understanding the underlying reasons for bandsaw drift can help you address the issue effectively and achieve accurate cuts.

The Importance of Blade Selection and Setup

One of the primary factors influencing bandsaw drift is the choice of the blade and its setup. Using the right blade and ensuring its proper installation and tension can significantly reduce or eliminate drift. When selecting a bandsaw blade, consider the width, tooth configuration, and durability of the blade. Choose a blade with the appropriate width for your intended cuts and opt for a tooth configuration that suits the material you are working with.

Once you have selected the right blade, it is important to set it up correctly. Start by installing a blade with minimal or zero drift, offering a baseline for accurate cuts. Ensure the blade is properly tensioned, following the manufacturer’s guidelines. Proper tensioning ensures the blade operates within its optimal range and minimizes the chances of drift. Taking the time to set up your bandsaw blade correctly can make a significant difference in your woodworking results.

Regular maintenance of your bandsaw blade and machine is also crucial in minimizing bandsaw drift. Keep the blade sharp, replace it when necessary, and periodically check for any issues with the tracking or alignment of the blade. Regular blade maintenance and machine upkeep will contribute to smoother, more precise cuts.

Techniques to Minimize Bandsaw Drift

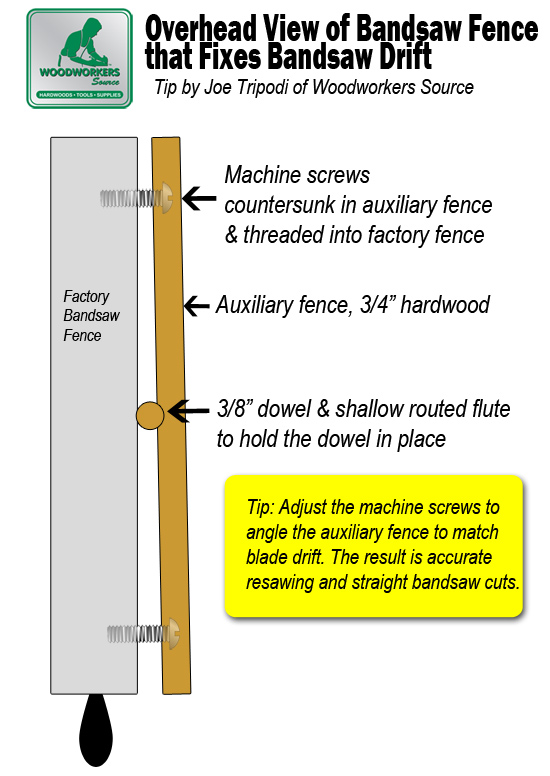

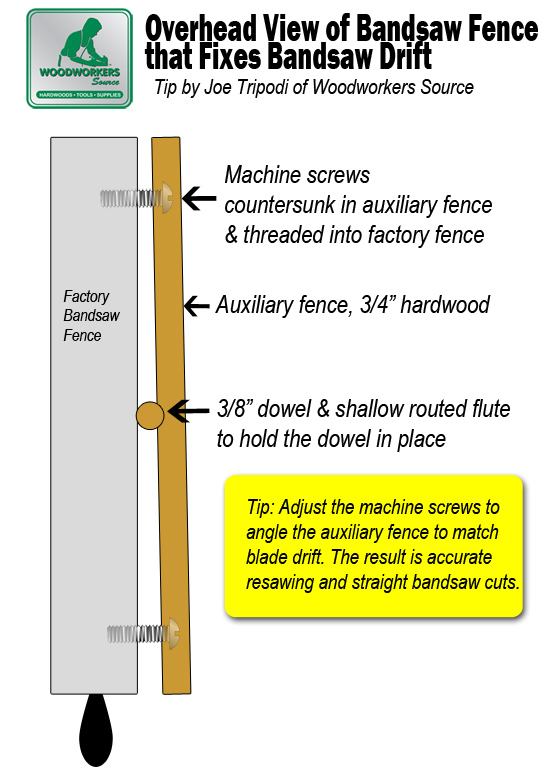

While drift may be inherent to bandsaw cutting, there are techniques you can employ to minimize its impact and achieve accurate cuts. One effective technique is using a fence or guide to control the wood’s feed direction and maintain a consistent blade-to-wood contact. A well-calibrated fence ensures that the wood is fed into the blade at a consistent angle, minimizing any tendency for the blade to drift.

Another technique is making small adjustments to the blade’s tracking. By observing the blade’s drift pattern and strategically adjusting the tracking knob, you can coax the blade to cut more accurately. Start by adjusting the tracking slightly in the opposite direction of the drift, and progressively fine-tune it until you achieve the desired straight cut.

Additionally, adjusting the speed of your bandsaw can also help minimize drift. Experiment with different speed settings and observe how the blade responds. Slower speeds can reduce the forces acting on the blade, potentially minimizing drift. However, it is important to find the right balance, as excessively low speeds can cause other issues such as burning or excessive vibration.

Understanding the Limitations and Practice for Precision

It is important to acknowledge that achieving absolute precision with a bandsaw may not always be possible due to the nature of the tool. While minimizing bandsaw drift is key, it is equally important to practice and develop your skills to compensate for any residual drift. By understanding your specific bandsaw’s characteristics and practicing with different materials, you can become adept at adjusting your technique and achieving accurate cuts.

Regular practice will help you develop a feel for your bandsaw’s tendencies and enable you to make intuitive adjustments to account for drift. Additionally, paying attention to the directional grain of the wood and adjusting your feeding technique accordingly can further enhance your ability to achieve precise cuts.

Remember, bandsaw drift is not an insurmountable obstacle. With the right blade, proper setup, and effective techniques, you can minimize its impact and achieve accurate cuts that meet your woodworking needs.

Bandsaw Drift: Overcoming Challenges for Precise Woodworking

Understanding the intricacies of bandsaw drift is crucial for achieving precise cuts in woodworking projects. However, successfully managing and minimizing this challenge goes beyond merely grasping the concept. In this section, we will explore various techniques and considerations that can help you overcome the challenges posed by bandsaw drift and enhance the accuracy of your cuts.

Choosing the Right Blade for the Job

The importance of selecting the appropriate bandsaw blade cannot be overstated. Different blades are designed for specific purposes, and using the right blade for the job can help reduce bandsaw drift. Consider the material you are working with, the desired quality of the cut, and the type of woodworking you are engaged in. Blades with a wider width and a lower TPI (teeth per inch) count are generally better suited for resawing or making straight cuts, as they provide more stability and less likelihood of drift. On the other hand, blades with a narrower width and a higher TPI count are ideal for intricate cuts and curves.

When choosing a blade, also pay attention to the set of the teeth. To minimize drift, opt for blades with minimal or zero set. These blades have the teeth aligned in a straight line and are less prone to veering off course.

Lastly, consider the blade’s condition. Blades that have become dull or damaged are more likely to cause drift. Regularly inspect your blade for signs of wear, and replace it if necessary to ensure optimal performance.

Calibrating and Adjusting Your Bandsaw

Proper calibration and adjustment of your bandsaw are essential for minimizing drift. Start by ensuring that the blade is installed correctly and tensioned according to the manufacturer’s recommendations. A blade that is too loose or too tight can contribute to drift. Use a tension gauge to achieve the optimal tension for your blade.

Next, align the bandsaw’s guide blocks or bearings to ensure the blade runs true and remains on the desired cutting line. Adjust the guide blocks so that they are as close as possible to the blade without causing friction. This will help stabilize the blade during cutting and reduce the likelihood of drift.

Another critical adjustment is the positioning of the fence or miter gauge. The fence should be squared to the table, parallel to the blade, and properly adjusted for a snug fit against the workpiece. A misaligned fence can introduce drift and compromise the accuracy of your cuts.

Using Featherboards and Accessories

When facing bandsaw drift, utilizing featherboards and other accessories can provide additional support and control during cutting. Featherboards help to apply consistent pressure against the workpiece, keeping it firmly against the fence and table. This added support helps reduce drift and ensures more accurate cuts.

You can also consider using a drift-cutting jig to overcome the challenge of bandsaw drift. This jig is specifically designed to guide the workpiece through the blade at an angle that counteracts drift. By following the jig’s predetermined path, you can achieve straight and precise cuts even with a blade that naturally drifts.

Other accessories such as stabilizers and cool blocks can help minimize friction and heat buildup, further enhancing the performance of your bandsaw and reducing the chances of drift. Experiment with different accessories to find the combination that works best for your specific bandsaw and woodworking needs.

Developing Your Technique and Building Experience

While employing the right techniques and utilizing the appropriate tools and accessories is essential, developing your own technique and gaining experience with your bandsaw are equally important. With time and practice, you will become more familiar with your bandsaw’s tendencies and be able to respond to drift intuitively.

Experiment with different speeds, feed rates, and blade tracking adjustments to find the sweet spot that minimizes drift. Keep in mind that each bandsaw is unique, and what works for one may not work for another. Anchoring your technique in your specific bandsaw’s characteristics will enable you to achieve optimal results.

Additionally, paying attention to your body positioning and posture when operating the bandsaw can have a significant impact on the accuracy of the cuts. Maintain a relaxed yet firm grip on the workpiece, evenly distributing the pressure throughout the cut. Avoid excessive pressure or any sudden movements that could induce drift.

Patience, practice, and perseverance are key when it comes to mastering the art of achieving precise cuts with a bandsaw. Embrace the learning process, and remember that even expert woodworkers occasionally encounter bandsaw drift. By constantly refining your technique and building your experience, you will steadily increase your ability to overcome this challenge and achieve exceptional woodworking results.

Bandsaw Drift: A Challenge Turned Opportunity for Precision Cuts

Bandsaw drift may initially seem like a frustrating obstacle to precision woodworking, but with the right knowledge, tools, and techniques, it can become an opportunity for mastering the art of achieving accurate cuts. By understanding the factors contributing to bandsaw drift, selecting the appropriate blade, and calibrating your bandsaw effectively, you can minimize its impact and improve the accuracy of your cuts.

Remember to utilize the various techniques discussed, such as using a fence or guide, making blade tracking adjustments, and adjusting the bandsaw speed. These strategies, combined with the use of accessories like featherboards and drift-cutting jigs, will further enhance your ability to achieve precise cuts that meet your woodworking needs.

Lastly, embrace the process of developing your technique and building experience with your bandsaw. The more you work with your bandsaw and familiarize yourself with its tendencies, the better prepared you will be to make intuitive adjustments and overcome bandsaw drift. With practice, patience, and perseverance, you can turn the challenge of bandsaw drift into an opportunity for precision and exceptional woodworking results.

Key Takeaways: What is Bandsaw Drift?

- Bandsaw drift refers to the tendency of a bandsaw blade to veer to one side while cutting.

- It is a common challenge for woodworkers and can result in uneven cuts.

- Bandsaw drift can be caused by various factors, such as blade tension, blade sharpness, and the type of wood being cut.

- Proper blade alignment and adjustments can help minimize bandsaw drift.

- Understanding and correcting bandsaw drift is essential for achieving accurate and precise cuts with a bandsaw.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we provide answers to common queries related to bandsaw drift.

1. How does bandsaw drift affect cutting accuracy?

Bandsaw drift refers to the tendency of a bandsaw blade to veer off course during a cut. This can negatively impact cutting accuracy as the blade deviates from the desired cutting line. When facing bandsaw drift, it becomes challenging to achieve precise and straight cuts.

To ensure accurate cuts, it’s crucial to understand and address bandsaw drift by adjusting the fence and blade tracking. By identifying and compensating for drift, you can achieve improved cutting accuracy in your bandsaw projects.

2. What are the causes of bandsaw drift?

Several factors can contribute to bandsaw drift. One common cause is blade tension: if the blade is not properly tensioned, it can lead to erratic behavior and drift. Another factor is blade quality; a dull or improperly installed blade can introduce drift during cutting.

Bandsaw drift can also be influenced by the type and thickness of the material being cut. Different wood species and thicknesses have varying densities and hardness, affecting the blade’s behavior. Lastly, the setup of the machine, including the blade’s tracking and alignment, can contribute to bandsaw drift.

3. How can I minimize bandsaw drift?

To minimize bandsaw drift, it’s essential to fine-tune various aspects of your bandsaw setup. Start by ensuring proper blade tension. A correctly tensioned blade minimizes vibration and improves cutting accuracy. It’s also important to select the right blade for the material you’re cutting.

Next, adjust the blade tracking and alignment to ensure it runs true on the wheels. Properly aligning the blade with the fence and miter gauge can also help reduce drift. Ensuring the blade guides are properly adjusted and lubricated is another step to minimize drift.

4. Can a bandsaw drift be eliminated entirely?

While it’s challenging to eliminate bandsaw drift entirely, you can significantly minimize its effects through proper setup and adjustment. By meticulously aligning the blade with the necessary components and adjusting the tension, you can achieve accurate cuts with minimal drift.

However, it’s important to note that certain factors like material density and blade quality can still influence drift to some extent. Patience, practice, and regular maintenance are key to achieving the best possible results with your bandsaw.

5. Are there any tips and tricks to deal with bandsaw drift?

Yes, there are several tips and tricks that can help you deal with bandsaw drift. One effective method is making light initial cuts on scrap material to identify the direction and degree of drift. You can then adjust the fence or reposition the workpiece to compensate for the drift.

Another tip is using a drift-reducing blade, specifically designed to minimize drift. These blades have a unique tooth geometry that helps maintain a straight cutting line. Additionally, taking your time and using a slow feed rate can also help reduce drift and improve cutting accuracy.

Summary

Understanding bandsaw drift can help you make more accurate cuts with your woodworking projects. Bandsaw drift refers to the tendency of the blade to veer off course, causing uneven cuts. To minimize drift, you need to adjust the angle of the fence and experiment with different blade tensions. Keep practicing and you’ll become a master of the bandsaw!

In conclusion, bandsaw drift is a common challenge faced by woodworkers. By making small adjustments and practicing, you can overcome drift and achieve more precise cuts with your bandsaw. Happy woodworking!