What is carriage in a lathe machine? If you’ve ever wondered about the different parts of a lathe machine and how they work together, then you’re in the right place. In this article, we’ll explore the concept of carriage in a lathe machine, which plays a crucial role in the machining process. So, let’s dive in and discover what exactly the carriage is and how it contributes to the functionality of a lathe machine!

To understand the carriage, let’s imagine a lathe machine as a dynamic workshop assistant. The carriage is like the helpful arm of the lathe that holds and moves the cutting tool. Without the carriage, a lathe machine wouldn’t be able to perform its tasks effectively. It’s responsible for moving the cutting tool horizontally and longitudinally, allowing for precise machining operations.

In simpler terms, the carriage is like the skilled worker who positions the tool and controls its movement, making accurate cuts and shaping objects. Whether it’s turning, facing, boring, or threading, the carriage ensures that the tool performs its job with precision. So, let’s explore the inner workings of the carriage and understand its importance in the fascinating world of lathe machines!

In a lathe machine, the carriage is a crucial component that holds and moves the cutting tool across the workpiece. It consists of a saddle, cross-slide, and apron, allowing for precise and controlled movement. The saddle provides longitudinal movement, while the cross-slide enables transverse movement. The apron houses the gears, feed mechanisms, and other components necessary for the carriage’s operation. The carriage plays a vital role in shaping and machining the workpiece with accuracy and efficiency.

Understanding the Carriage in Lathe Machines

Lathe machines are essential tools in mechanical engineering and woodworking. They are used to shape, cut, and drill materials with precision. One of the key components of a lathe machine is the carriage. The carriage plays a crucial role in the movement and control of the cutting tool, enabling the operator to create various shapes and sizes. In this article, we will explore the concept of the carriage in lathe machines, its components, functions, and how it contributes to the overall operation of the machine.

The Carriage: An Overview

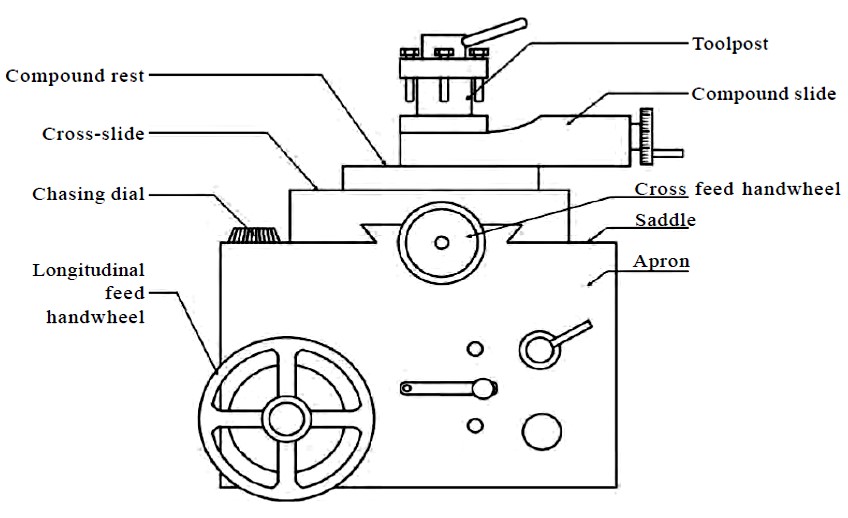

The carriage is the part of the lathe machine that holds and moves the cutting tool. It is located on the bed, which is the main horizontal component of the lathe. The carriage consists of several important components, including the saddle, cross-slide, compound rest, tool post, and apron. These components work together to facilitate the movement and positioning of the cutting tool, allowing the operator to perform various machining operations.

The saddle is an integral part of the carriage and is responsible for providing linear movement along the bed. It is mounted on the bed and can move along its length. The cross-slide is positioned on top of the saddle and enables movement perpendicular to the bed, allowing for precise cutting and shaping. The compound rest provides an additional level of control, allowing for angular adjustments of the cutting tool. The tool post, located on the compound rest or cross-slide, securely holds the cutting tool in place. Finally, the apron contains mechanisms for controlling the feed, direction, and speed of the carriage.

The carriage is an essential component that enables the operator to manipulate the cutting tool with precision, allowing for a wide range of machining operations. By controlling the movements of the carriage, the operator can achieve desired shapes, dimensions, and surface finishes on the workpiece.

Functions of the Carriage

The carriage performs several important functions in the operation of a lathe machine. These functions include:

- Movement Control: The carriage facilitates the movement of the cutting tool along the bed, allowing for precise positioning and cutting. The operator can control the movement of the carriage manually or through automated mechanisms, such as power feeds.

- Tool Positioning: The carriage components, such as the cross-slide, compound rest, and tool post, enable the operator to position and secure the cutting tool in the desired orientation for the machining operation.

- Feed Control: The apron of the carriage contains mechanisms for controlling the speed and direction of the carriage movement. This allows for accurate and consistent feed rates, essential for achieving desired results.

- Thread Cutting: The carriage is also responsible for thread cutting. By utilizing specific mechanisms, the carriage enables the operator to cut threads of different types and pitches.

- Support and Stability: The carriage, along with the saddle and cross-slide, provides support and stability to the cutting tool. This ensures that the tool remains in the proper position during the machining process, minimizing inaccuracies and vibrations.

By performing these functions, the carriage plays a crucial role in the overall effectiveness and accuracy of the lathe machine.

Components of the Carriage

The carriage of a lathe machine is composed of various components that work together to achieve precise movement and control of the cutting tool. These components include:

Saddle:

The saddle is a critical component of the carriage. It is mounted on the bed and can move along its length, providing linear movement of the cutting tool along the workpiece. The saddle is typically equipped with a handwheel or lever for manual control, allowing the operator to adjust the position of the carriage.

Cross-Slide:

The cross-slide is positioned on top of the saddle and enables movement perpendicular to the bed. It is responsible for fine-tuning the lateral position of the cutting tool, allowing for precise cutting and shaping. The cross-slide is equipped with handwheels or micrometer dials for accurate adjustments.

Compound Rest:

The compound rest is mounted on top of the cross-slide and provides angular adjustment of the cutting tool. It allows the operator to tilt the tool to a specific angle, enabling the creation of bevels, tapers, and other angled cuts.

Tool Post:

The tool post is an integral part of the carriage and securely holds the cutting tool in place. It allows for easy and quick tool changes, ensuring efficiency and versatility during machining operations. There are various types of tool posts available, including quick-change tool posts that enable rapid tool changes without the need for readjustments.

Apron:

The apron is located at the front of the carriage and contains mechanisms for controlling the feed, direction, and speed of the carriage. It houses components such as gears, clutches, and levers, which allow the operator to adjust the feed rate, engage or disengage the carriage movement, and reverse the carriage direction.

These components work together seamlessly within the carriage, enabling precise control and movement of the cutting tool, making the carriage a vital part of the lathe machine.

#MORE H2 TOPIC:

Advantages of a Well-Maintained Carriage

Keeping the carriage of a lathe machine well-maintained is crucial for achieving optimal performance and prolonging the machine’s lifespan. A well-maintained carriage offers several advantages, which we will explore in this section.

Common Issues with Carriages and How to Troubleshoot Them

Despite regular maintenance, carriages in lathe machines can sometimes develop issues that affect their performance. In this section, we will look at some common issues that can arise with carriages and discuss troubleshooting steps to resolve them.

Tips for Proper Carriage Maintenance

Maintaining the carriage of a lathe machine is essential for ensuring its smooth operation and longevity. In this section, we will provide some useful tips for proper carriage maintenance to keep your lathe machine in top condition.

Key Takeaways: What is Carriage in Lathe Machine?

- The carriage is an essential component in a lathe machine.

- It is a movable part that holds the cutting tool and moves along the bed of the lathe.

- The carriage is responsible for controlling the tool’s position and movement during the machining process.

- It allows for precise and accurate shaping of the workpiece.

- The carriage can be manually operated or powered by the machine’s motor.

Frequently Asked Questions

In a lathe machine, the carriage is an essential component that plays a crucial role in the machining process. The carriage is responsible for providing support to the cutting tool and controlling its movement along the length of the workpiece. It consists of several parts and mechanisms that work together to achieve precision and accuracy in turning operations.

Q: How does the carriage work in a lathe machine?

The carriage in a lathe machine moves along the lathe bed, facilitating the movement of the cutting tool towards or away from the workpiece. It is equipped with a tool post that holds the cutting tool securely in place. The carriage can be manually operated or powered by a motor, allowing for automatic movement. By adjusting various controls, such as the cross-slide and longitudinal feed, the operator can control the depth of cut and the direction of the tool movement. Overall, the carriage provides the necessary support and control for precise machining operations in a lathe machine.

Q: What are the different parts of the carriage in a lathe machine?

The carriage in a lathe machine consists of several components that work together to facilitate machining operations. These include:

1. Saddle: The saddle is the main component of the carriage that moves along the lathe bed.

2. Apron: The apron houses various mechanisms, such as the feed rod, half-nut lever, and gears, which control the movement of the carriage.

3. Cross-slide: The cross-slide is responsible for moving the cutting tool perpendicular to the axis of rotation, allowing for facing and tapering operations.

4. Tool post: The tool post holds the cutting tool securely in place, ensuring stability during machining.

5. Compound rest: The compound rest allows for angular tool movements, enabling the execution of operations like chamfering and thread cutting.

Q: What is the purpose of the half-nut mechanism in the carriage?

The half-nut mechanism in the carriage is crucial for engaging and disengaging the lead screw. When engaged, the half-nut mechanism locks onto the lead screw, allowing for automatic longitudinal movement of the carriage. This mechanism provides a smooth and accurate feed while cutting threads on the workpiece. By disengaging the half-nut, the carriage can be manually moved along the lathe bed to the desired position. The half-nut mechanism ensures precision and repeatability in thread cutting, making it an essential part of the carriage in a lathe machine.

Q: Can the carriage movement be automated in a lathe machine?

Yes, the carriage movement in a lathe machine can be automated by integrating a motorized feed mechanism. By connecting the motor to the carriage, the movement can be controlled and automated. This not only reduces manual effort but also ensures consistent and precise machining operations. The automated feed mechanism allows for the execution of complex profiles and accurate machining, enhancing productivity and efficiency. However, manual control of the carriage movement is also possible, giving operators the flexibility to choose between manual and automated operations based on their requirements.

Q: How does the carriage contribute to the accuracy of turning operations?

The carriage in a lathe machine plays a vital role in achieving accuracy in turning operations. It provides support to the cutting tool, keeping it stable and reducing vibrations during machining. The cross-slide movement allows for precise control of the tool’s position, ensuring accurate depth of cut and surface finish. The compound rest enables angular adjustments, allowing for the creation of intricate profiles. Additionally, the half-nut mechanism ensures consistent and accurate thread cutting. Together, these features and functionalities of the carriage contribute to the overall precision, quality, and accuracy of turning operations on a lathe machine.

how lathe carriage feed mechanism animation

Summary

The carriage in a lathe machine is the part that holds and moves the cutting tool. It moves along the bed and helps in shaping the workpiece. There are different types of carriages, such as the apron carriage and the compound carriage, each serving its own purpose. The carriage is an important component in a lathe machine and plays a key role in the machining process.

In conclusion, the carriage in a lathe machine is responsible for holding and moving the cutting tool. It helps in shaping the workpiece and there are different types of carriages for various functions. Understanding the role of the carriage is essential for using a lathe machine effectively.