Are you curious about what a drill press machine is? Well, you’re in the right place! In this article, we’ll explore the ins and outs of this handy tool that’s a must-have for any DIY enthusiast or aspiring woodworker. So, let’s dive in and discover everything you need to know about drill press machines!

Now, you might be wondering, “What exactly is a drill press machine?” Well, think of it as a supercharged version of your typical handheld drill. It’s a stationary power tool that is designed to drill precise and accurate holes in various materials. With its adjustable table, powerful motor, and different speed settings, the drill press machine offers improved control and precision for your drilling projects.

Whether you’re building a birdhouse or working on a woodworking masterpiece, a drill press machine will be your trusty companion. It not only makes drilling holes easier and more accurate but also allows you to explore different depths and angles. So, get ready to take your DIY projects to a whole new level with the help of a fantastic tool – the drill press machine!

A drill press machine is a versatile tool used for drilling precise holes in various materials. It provides accuracy, control, and power that handheld drills can’t match. With a sturdy base, an adjustable table, and a rotating drill head, a drill press machine allows you to perform drilling tasks with ease. Whether you’re a professional woodworker or a DIY enthusiast, a drill press machine is an essential tool to have in your workshop.

Exploring the Drill Press Machine: A Comprehensive Guide

Drilling holes is a common task in various industries, from woodworking to metalworking. To streamline this process, craftsmen and professionals turn to a versatile tool known as the drill press machine. In this guide, we will delve into the details of what a drill press machine is, how it functions, and its various applications. Whether you’re a hobbyist or a professional, this article will provide you with valuable insights into the world of drill press machines.

What is a Drill Press Machine?

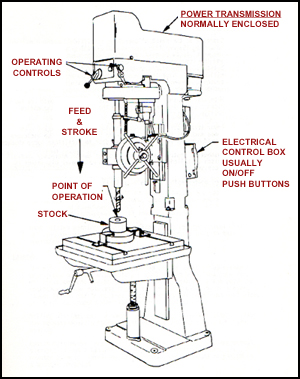

A drill press machine is a stationary tool that is designed to accurately and efficiently drill holes into various materials. It consists of a base, a column, a table, a spindle, and a motor. The motor powers the spindle, which holds the drill bit and rotates it at high speeds. The drill press machine offers precise control over drilling depth and speed, making it ideal for tasks that require accuracy, such as creating dowel joints or drilling holes for cabinet hardware.

The drill press machine is commonly used in woodworking, metalworking, and construction industries. Its sturdy construction and stability allow for consistent and precise drilling, even on hard materials. Additionally, the ability to set the drilling depth and control the speed makes it a valuable tool for creating countersinks, chamfers, and other specialized drilling operations.

While the traditional hand drill requires manual effort and lacks consistency, a drill press machine eliminates these limitations. With its adjustable table and depth stop, it allows users to repeat drilling operations with accuracy, ensuring uniformity in hole placement. The drill press machine also offers increased safety, as it allows users to secure the material and operate the machine with both hands, reducing the risk of accidents.

The Components of a Drill Press Machine

To better understand the functionality of a drill press machine, it is important to familiarize yourself with its key components. Here are the main parts of a drill press machine:

1. Base: The base provides stability and support to the machine, preventing it from tipping over during operation.

2. Column: The column is a vertical cylindrical structure that connects the base to the head of the machine. It provides rigidity and supports the other components.

3. Table: The table is a flat surface located beneath the spindle. It can be tilted and adjusted in height to accommodate different workpieces.

4. Spindle: The spindle is a rotating shaft that holds the drill bit. It is driven by a motor and can be adjusted for different speeds.

5. Motor: The motor powers the spindle, providing the rotational force required for drilling. It is usually located on top of the drill press machine.

6. Depth Stop: The depth stop allows users to set the desired drilling depth, ensuring consistent results across multiple holes.

7. Chuck: The chuck is a mechanism that holds the drill bit securely in place while allowing for easy installation and removal.

Understanding these components will help you make informed decisions when choosing a drill press machine that suits your needs. Each component plays a crucial role in the overall performance and functionality of the machine.

Applications of a Drill Press Machine

The versatility of a drill press machine makes it an indispensable tool in various industries and applications. Here are some common uses of a drill press machine:

1. Woodworking: From making dowel joints to creating intricate designs, a drill press machine is widely used in woodworking projects. Its precision and stability allow for accurate drilling of holes in wood, enhancing the quality and efficiency of woodworking tasks.

2. Metalworking: When it comes to drilling holes in metal, a drill press machine offers superior control and accuracy compared to handheld drills. It is commonly used in metal fabrication, automotive repair, and other metalworking applications.

3. Construction: In construction projects, a drill press machine is utilized for tasks such as installing electrical outlets, drilling holes for plumbing, and creating precise anchor points. Its ability to handle various materials and provide consistent results makes it a valuable tool on the construction site.

4. Jewelry Making: Drill press machines find application in the intricate art of jewelry making, allowing craftsmen to create precise holes in metals and gemstones. The ability to control the speed and drilling depth is essential for drilling delicate materials without causing damage.

5. PCB Drilling: Printed Circuit Board (PCB) manufacturing requires precise and controlled drilling of holes. A drill press machine with adjustable speed and accurate depth control ensures clean and accurate holes in the PCB, enabling the seamless assembly of electronic components.

Whether you’re a DIY enthusiast or a professional in need of a reliable drilling tool, a drill press machine offers a range of applications and benefits. Its versatility, accuracy, and safety features make it an essential tool in various industries, enhancing productivity and ensuring high-quality results.

The Benefits of a Drill Press Machine

Key Takeaways: What is a Drill Press Machine?

A drill press machine is a powerful tool used to accurately and safely drill holes into various materials.

It consists of a motor, a spindle, and a drill bit to provide controlled precision and depth.

Drill press machines are commonly used in woodworking, metalworking, and construction projects.

They offer greater stability compared to handheld drills, reducing the risk of accidents and ensuring precise results.

Drill press machines are versatile and can be adjusted to different speeds and angles for various drilling tasks.

Frequently Asked Questions

Welcome to our FAQ section on drill press machines! Here, we’ve compiled some common questions to help you understand this essential tool better. Read on to find answers to your queries about drill press machines.

1. How does a drill press machine work?

A drill press machine is a tool used to create holes in various materials. It consists of a motor that powers a rotating drill bit. When the machine is turned on, the motor drives the drill bit downwards, which then penetrates the material. The drill press machine offers precision and control, ensuring accurate hole drilling with consistent depth and angle.

The machine’s components include a spindle, which holds the drill bit, and a worktable or base that secures the material being drilled. Users can adjust the speed of the drill press machine based on their requirements, and the drill bit can be changed to suit different hole sizes and materials.

2. What are the advantages of using a drill press machine?

Using a drill press machine offers several benefits. Firstly, it provides greater precision and accuracy compared to handheld drills, as the machine’s design allows for consistent alignment and controlled drilling depth. This is particularly useful when working on projects that require precise measurements.

Secondly, a drill press machine allows for improved safety. The machine’s stationary design, combined with its adjustable depth stop, reduces the risk of accidents and ensures a secure drilling operation. Additionally, many drill press machines feature built-in protective features, such as safety guards and emergency stop buttons.

3. Can a drill press machine be used for materials other than wood?

Yes, a drill press machine can be used on various materials besides wood. While wood is a common material worked on with a drill press machine, the tool is also suitable for drilling holes in metal, plastic, and other materials. However, when drilling different materials, it’s important to use the appropriate drill bits specifically designed for the material being drilled. This ensures optimal results and prevents damage to both the drill bit and the workpiece.

Drill press machines equipped with variable speed settings are particularly useful in accommodating different materials. They allow users to adjust the rotation speed of the drill bit, ensuring efficient drilling while minimizing the risk of overheating or damaging the material being worked on.

4. What safety precautions should I follow when using a drill press machine?

When using a drill press machine, it’s crucial to prioritize safety. Always start by wearing appropriate personal protective equipment, such as safety glasses and, if necessary, a face shield or gloves. Additionally, ensure that the machine is well-maintained, with all parts in good working condition.

During operation, make sure the workpiece is securely clamped to the worktable and held in place with a vise or other suitable methods. This prevents movement or slippage while drilling. Keep your hands away from the rotating drill bit and avoid wearing loose clothing or jewelry that may get caught in the machine. Lastly, always read and familiarize yourself with the manufacturer’s instructions and follow any recommended safety guidelines.

5. Can a drill press machine be used for other tasks apart from drilling holes?

Yes, a drill press machine can be used for tasks other than drilling holes. With the appropriate attachments, the versatile tool can perform various operations such as sanding, buffing, and mortising. These attachments expand the functionality and value of the drill press, making it a multi-purpose tool in the workshop.

When using attachments, it’s crucial to ensure they are compatible with your drill press machine and follow the manufacturer’s instructions for proper installation and usage. Some attachments may require adjusting the machine’s speed settings or using different accessories for optimal performance.

Summary

A drill press machine is a tool that helps you make holes in things. It has a motor that spins a drill bit, so you don’t have to do all the work yourself. It’s like having a super-powered hand that can make holes easily.

One important thing to remember is to always be safe when using a drill press. Make sure to wear safety goggles and keep your hands away from the moving parts. Also, don’t forget to choose the right drill bit for the material you are drilling into. With these tips in mind, you’ll be a drilling pro in no time!