In the world of woodworking and metalworking, there’s a tool called a drill press that you might have come across. But have you ever wondered what “drill press spindle travel” really means?

Well, my friend, the spindle travel refers to the distance that the drill bit can travel up and down. Think of it like the elevator for your drill bit—how far it can go in both directions.

You might be thinking, “Why does this matter?” Great question! The spindle travel is important because it determines the depth of the holes you can drill. So, the more travel your drill press has, the deeper the holes you can create.

Now that we’ve uncovered the mystery behind drill press spindle travel, let’s dive deeper into its significance and how it can impact your woodworking or metalworking projects. So, buckle up and get ready to explore the fascinating world of drill press spindle travel!

Understanding Drill Press Spindle Travel

Drill press spindle travel is an essential feature to consider when purchasing a drill press. It refers to the vertical distance the spindle can travel from its lowest to highest position. This measurement plays a crucial role in determining the depth at which a drill bit can penetrate a material. In this article, we will delve into the details of drill press spindle travel, its importance, and how to choose the right spindle travel for your needs.

The Importance of Drill Press Spindle Travel

Drill press spindle travel is a critical factor to consider because it determines the maximum depth to which you can drill a hole. The longer the spindle travel, the deeper the hole you can drill. This feature is especially important when working with materials such as wood, metal, or plastic that require varying depths of holes. Without sufficient spindle travel, you may be limited in the types of projects you can undertake or have to resort to using additional tools for deeper holes.

Another crucial factor to consider is the availability of adjustable depth stops on the drill press. These depth stops allow you to set specific drilling depths, ensuring consistent and accurate results. A longer spindle travel provides more flexibility in setting different drilling depths, allowing you to work with precision and achieve professional-level results. Additionally, it eliminates the need for manual measuring and marking for each hole, making your workflow more efficient.

The Relationship Between Drill Press Spindle Travel and Material Thickness

When working with different materials, it is essential to consider their thickness in relation to the spindle travel of your drill press. A general rule of thumb is that the spindle travel should exceed the thickness of the material being drilled. For example, if you are working with a 2-inch thick piece of wood, it is advisable to have a drill press with a minimum spindle travel of 2 inches.

By ensuring that your drill press has adequate spindle travel, you can avoid the frustration of incomplete holes or damaging the material. It is always better to have more spindle travel than you think you’ll need, as it provides flexibility for future projects and unexpected drilling requirements.

Choosing the Right Spindle Travel for Your Needs

When selecting a drill press, it is crucial to consider the types of projects you will be working on and the materials you will be drilling. This will help determine the appropriate spindle travel for your needs. For simple DIY projects or occasional use, a drill press with a smaller spindle travel may suffice. However, for professional woodworking, metalworking, or other intricate tasks, a drill press with a longer spindle travel is recommended. Consider the nature of your work and the maximum depth of holes you are likely to encounter.

Additionally, it is essential to ensure that the drill press you choose has other features that complement the spindle travel. These may include adjustable depth stops, variable speed control, and a sturdy construction for stability and precision. By carefully selecting a drill press that meets your specific requirements, you can enhance your drilling capabilities and achieve exceptional results.

Maximizing the Potential of Drill Press Spindle Travel

Now that you understand the importance of drill press spindle travel and how to choose the right one, let’s explore some tips for maximizing its potential:

1. Utilize adjustable depth stops:

Take advantage of the adjustable depth stops feature to set precise drilling depths without the need for manual measuring. This will ensure consistency and accuracy in your work.

2. Secure the workpiece:

It is crucial to securely clamp or secure the workpiece to the drill press table to prevent movement or shifting during drilling. This will ensure clean and accurate holes.

3. Lubricate the drill bit:

When drilling through certain materials such as metal, lubricating the drill bit with cutting oil or lubricant will prolong its life and improve drilling performance.

Frequently Asked Questions

Q: Can I use a drill press without adjustable depth stops?

A: While adjustable depth stops are a convenient feature, you can still use a drill press without them. In such cases, you will need to manually measure and mark the desired drilling depth for each hole, which may be time-consuming.

Q: Can I modify the spindle travel of a drill press?

A: The spindle travel is a fixed feature of a drill press and cannot be modified. It is determined by the design and construction of the machine. If you require a different spindle travel, you will need to purchase a drill press with the desired specifications.

Q: Should I always choose a drill press with the maximum spindle travel available?

A: It is not necessary to choose a drill press with the maximum spindle travel if you do not anticipate needing it. However, it is advisable to choose one that has a spindle travel that exceeds the maximum depth you are likely to encounter in your projects.

In summary, drill press spindle travel is a vital specification to consider when purchasing a drill press. It determines the maximum depth you can drill and plays a significant role in the accuracy and precision of your work. By understanding its importance and choosing the right spindle travel for your needs, you can enhance your drilling capabilities and achieve exceptional results.

Key Takeaways – What is Drill Press Spindle Travel?

- Drill press spindle travel refers to the distance the drill bit can be moved up and down vertically.

- It determines the maximum depth of the holes that can be drilled.

- Spindle travel is typically measured in inches or millimeters.

- A larger spindle travel allows for drilling deeper holes.

- It is important to check the spindle travel capacity before purchasing a drill press for specific drilling needs.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we answer your queries about drill press spindle travel. Read on to learn more about this important aspect of a drill press.

Q: What is spindle travel?

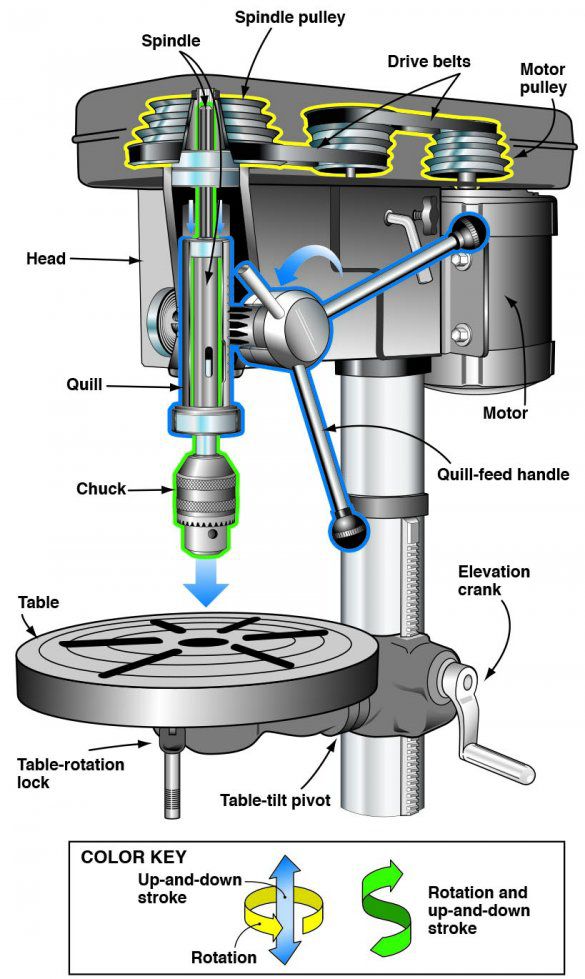

A: Spindle travel refers to the distance the spindle or chuck of a drill press can move vertically. It determines the maximum depth to which you can drill a hole. Let me break it down for you. When you lower the drill bit, the spindle moves down, and when you raise it, the spindle moves up. The distance it travels during this up-and-down motion is known as spindle travel.

If you need to drill deeper holes, you’ll require a drill press with a greater spindle travel. It’s an essential factor to consider when choosing a drill press suitable for your projects. Remember, the spindle travel is typically measured in inches and can vary from model to model.

Q: How does spindle travel affect my drilling tasks?

A: Spindle travel has a direct impact on the size and depth of the holes you can drill with a drill press. Let’s take a closer look at this. If you have a drill press with a smaller spindle travel, you’ll be limited to drilling shallower holes. On the other hand, a drill press with a larger spindle travel allows you to drill deeper holes.

When planning your drilling tasks, consider the maximum depth you’ll need to reach. Checking the spindle travel of a drill press will help you determine if it can accommodate your drilling needs. Remember, it’s always better to have a larger spindle travel than what you anticipate needing, as it gives you flexibility for future projects.

Q: Is spindle travel the same for all drill presses?

A: No, the spindle travel can vary from drill press to drill press. Different models will offer different levels of spindle travel, so it’s important to check the specifications of each drill press you are considering. Some smaller, benchtop drill presses may have a spindle travel of around 2 to 3 inches, while larger floor-standing models might have a spindle travel of 4 to 6 inches or even more.

Remember, the specific spindle travel will depend on the design and intended purpose of the drill press. So, always review the spindle travel specifications before making a purchasing decision to ensure it aligns with your drilling requirements.

Q: Can I increase the spindle travel of my drill press?

A: Unfortunately, you cannot increase the spindle travel of a drill press beyond its designed limits. The spindle travel is determined by the construction and engineering of the drill press and cannot be easily modified. If you require a larger spindle travel, you will need to invest in a drill press model that offers the desired range right from the start.

Trying to modify the spindle travel of a drill press can lead to potential safety risks and may also void any warranty or service agreements. It’s best to choose a drill press with the spindle travel you require to avoid any complications or hazards.

Q: What other factors should I consider along with spindle travel when buying a drill press?

A: While spindle travel is an important consideration, there are other factors to keep in mind when purchasing a drill press. Firstly, consider the horsepower of the drill press motor, as this determines the drilling power. Additionally, check the maximum drilling capacity, which indicates the largest hole size the drill press can handle.

Other factors include the speed settings, overall build quality, and the availability of features like adjustable depth stops. Always choose a drill press that meets your specific needs, taking into account your typical drilling tasks and future projects.

Summary

When talking about a drill press, the spindle travel is really just how deep it can drill. The spindle is the part that holds the drill bit, and the travel refers to how far it can move up and down. So, if a drill press has a spindle travel of 4 inches, that means it can drill a hole up to 4 inches deep.

Knowing the spindle travel of a drill press is important because it determines the types of projects you can do. If you need to drill deep holes, you’ll want a drill press with a larger spindle travel. But if you’re just doing simple DIY projects, a smaller spindle travel might be sufficient. So, when choosing a drill press, make sure to consider the spindle travel to ensure it meets your needs.