Have you ever wondered what eccentric turning in a lathe is all about? Well, wonder no more! In this article, we’ll explore the fascinating world of eccentric turning and how it adds a twist to traditional lathe operations. So, grab your safety goggles and let’s dive in!

Picture this: you’re working on a lathe, shaping and transforming a piece of metal into a work of art. But what if I told you there’s a way to make your creations even more unique? That’s where eccentric turning comes into play. It’s like giving your lathe a secret superpower that allows you to create off-center shapes and patterns with ease.

So, how does eccentric turning work exactly? Instead of spinning your workpiece dead center on the lathe, you deliberately set it off-center. This simple adjustment unlocks a whole new realm of possibilities. As the workpiece rotates, you’ll be able to sculpt eccentric shapes that would make even the most seasoned craftsmen raise an eyebrow.

Eccentric turning adds a touch of whimsy and creativity to your lathe projects. It’s a fantastic way to break away from conventional designs and infuse your work with a dash of personality. So, if you’re ready to take your lathe skills to the next level, let’s explore the fascinating world of eccentric turning together!

What is Eccentric Turning in Lathe?

Eccentric turning is a specialized technique used in lathe machining that allows for the creation of non-circular shapes or off-center features. While traditional turning involves rotating a workpiece symmetrically around its axis, eccentric turning introduces an element of asymmetry by offsetting the center of rotation. This technique is commonly employed in various industries, including automotive, aerospace, and manufacturing, to produce components with unique profiles, such as camshafts, gears, crankshafts, and eccentric shafts.

The Process of Eccentric Turning

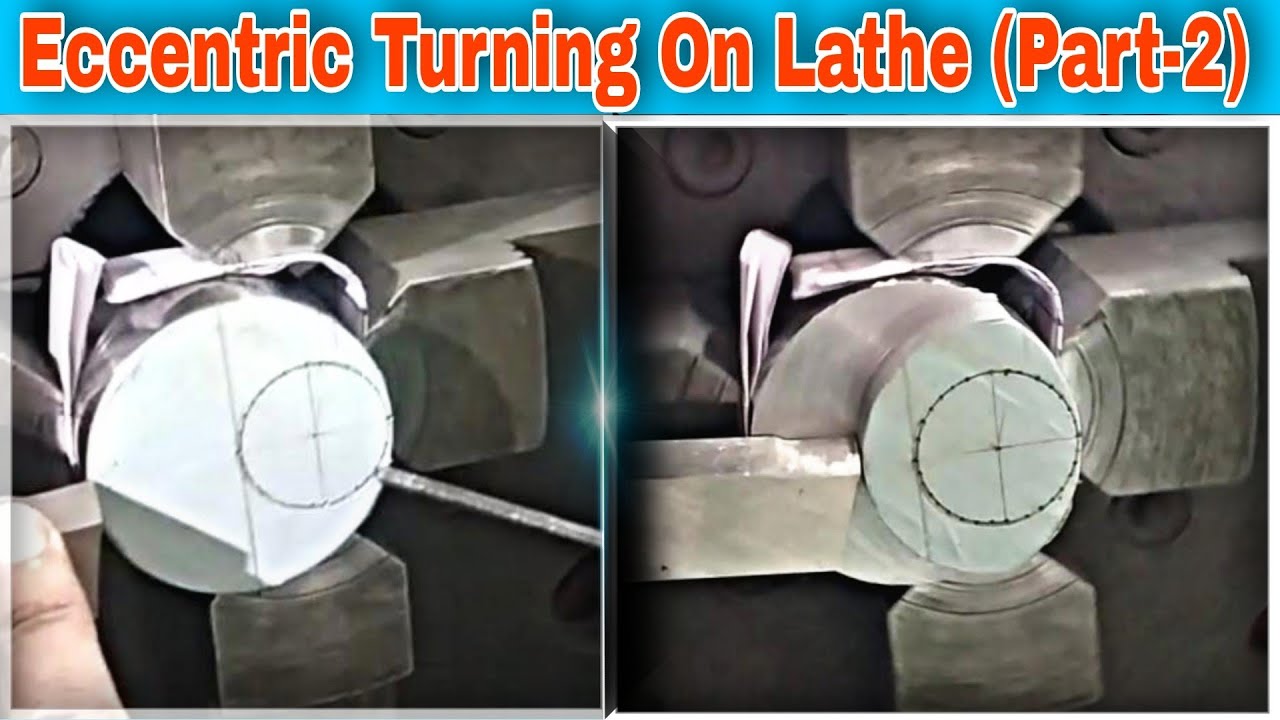

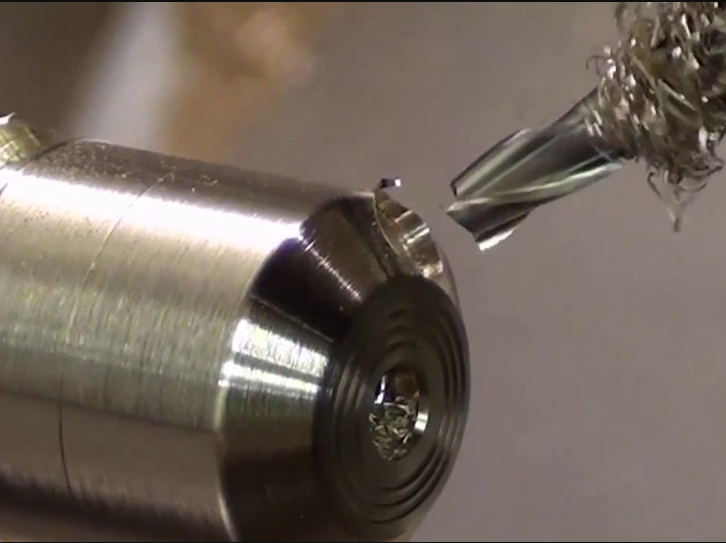

In eccentric turning, the workpiece is mounted on the lathe spindle, and the tool is positioned at a distance from the center of rotation. This offset distance determines the eccentricity or how far away the center of rotation is from the true center of the workpiece. As the lathe spindle rotates, the tool removes material from the workpiece, resulting in a non-circular shape or off-center feature.

Eccentric turning can be performed using different lathe operations, such as facing, turning, drilling, or boring. The specific technique and tooling selection depend on the desired shape and dimensions of the eccentric feature. The eccentricity can be adjusted by changing the offset distance or by using attachments like eccentric chucks or fixtures.

Throughout the eccentric turning process, the lathe operator must carefully control the tool feed rate, cutting speed, and depth of cut to ensure precision and accuracy. It requires skill and expertise to achieve the desired eccentric shape while maintaining dimensional tolerances and surface finish.

Advantages of Eccentric Turning

Eccentric turning offers several advantages that make it a valuable technique in various industries. Firstly, it enables the production of non-circular shapes and off-center features that cannot be achieved through conventional turning methods. This versatility allows for the creation of complex components used in mechanisms requiring precise motion or alignment.

Secondly, eccentric turning provides the ability to fine-tune the eccentricity to meet specific design requirements. This adjustability allows engineers to control factors such as the timing of valve operation in engine components or the force transmission in mechanical systems.

Furthermore, eccentric turning often eliminates the need for additional machining operations, such as milling or grinding, to achieve the desired eccentric features. This reduction in secondary operations saves time, cost, and material waste, making it a cost-effective solution for component manufacturing.

Considerations and Challenges in Eccentric Turning

While eccentric turning offers unique opportunities in component design and manufacturing, it also presents certain challenges that need to be addressed. One of the primary considerations is the impact on machined part geometry. The eccentric feature may introduce uneven material removal, causing variations in surface finish, concentricity, and roundness.

Another challenge is the selection of the appropriate tooling and cutting parameters. Due to the asymmetrical nature of eccentric turning, tool wear can be uneven, leading to cutting edge deterioration and decreased tool life. It is crucial to choose carbide or high-speed steel tools with suitable coatings and to regularly inspect and replace them to maintain the desired machining quality.

Lastly, the setup and alignment of the workpiece in the lathe play a crucial role in achieving accurate eccentric features. Proper fixation and alignment are necessary to ensure stability, minimize vibrations, and prevent deflection, especially when machining large or heavy components.

Key Takeaways: What is Eccentric Turning in Lathe?

- Eccentric turning is a technique used in lathe machines.

- It involves mounting the workpiece off-center, creating eccentric shapes.

- By adjusting the position of the tool, different eccentric shapes can be achieved.

- Eccentric turning is commonly used in manufacturing components such as cams and eccentric shafts.

- This technique adds versatility to lathe operations and enables the creation of unique designs.

Frequently Asked Questions

Curious about eccentric turning in lathe? We’ve got you covered! Check out these frequently asked questions to learn more.

What is eccentric turning and how is it done in a lathe?

Eccentric turning is a technique used in lathe machining to create off-center features on a workpiece. Instead of holding the workpiece center-aligned with the lathe’s spindle, it is intentionally offset. This offset results in the creation of asymmetrical shapes or features. To perform eccentric turning, the lathe operator adjusts the position of the workpiece in relation to the spindle axis by using specialized tooling like an eccentric chuck or a crankshaft. By turning the crankshaft, the operator can precisely control the degree of eccentricity and carve out unique shapes on the workpiece.

It’s important to note that the eccentric turning in lathe technique requires careful planning and accurate calculations to achieve desired results. Machinists often use a combination of mathematical calculations, trial and error, and experience to accurately determine the eccentricity needed for the desired shape.

What are some common applications of eccentric turning in lathe?

Eccentric turning in lathe is widely used in various industries for a range of applications. One common application is in the production of eccentric cams. Eccentric cams are used in mechanisms to convert rotational motion into linear motion or vice versa. Another application is in the creation of eccentric shafts, which are commonly found in engines and other rotating systems. Eccentric turning can also be used to create unique decorative designs in woodworking projects or to produce specialized components that require off-center features. Overall, this technique provides versatility in machining processes, allowing for the creation of complex shapes and components.

Additionally, eccentric turning in lathe can be advantageous in situations where a concentric turning method would be challenging or impractical. The ability to create off-center features offers flexibility in design and allows for better customization of parts to meet specific requirements.

What are the advantages of eccentric turning in lathe?

Eccentric turning in lathe offers several advantages in machining processes. Firstly, it provides the ability to create asymmetrical shapes and features that would be difficult or impossible to achieve with traditional, concentric turning methods. This opens up possibilities for unique designs and intricate components.

Secondly, eccentric turning allows machinists to fine-tune and adjust the eccentricity of the workpiece. This level of control ensures precise machining, enabling the production of parts with high accuracy and consistency.

What are some challenges faced in eccentric turning in lathe?

While eccentric turning has its advantages, it also comes with its own set of challenges. One of the main challenges is achieving and maintaining the desired eccentricity of the workpiece. Calculating and adjusting the offset requires skill and accuracy to ensure the desired shape is achieved.

Another challenge lies in the potential for increased vibration during the machining process. The off-center nature of the workpiece can introduce imbalances, leading to vibrations that may affect the quality of the machined part. Machinists must take measures to mitigate these vibrations, such as using appropriate cutting speeds, tooling, and techniques.

What safety precautions should be taken when working with eccentric turning in lathe?

When working with eccentric turning in lathe, it is crucial to prioritize safety. Machinists should ensure the workpiece is securely clamped and properly aligned to prevent accidents and injuries. It’s also essential to wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect against flying debris or sharp tools.

Furthermore, machinists should follow safe operating procedures for the lathe, including proper tool setup, regular maintenance, and keeping the work area clean and organized. Training and knowledge of lathe operation and safety guidelines are essential for anyone working with eccentric turning in lathe.

Summary

Eccentric turning in a lathe is when you make a shape that is not perfectly round. It can be used to make things like cams, which help machines move in different ways. In eccentric turning, the workpiece is set off-center, so it rotates in an uneven manner. This creates the desired shape when the cutting tool removes the excess material. Eccentric turning is a cool technique that adds variety to what can be made on a lathe!